Everything posted by GreenZZZ

-

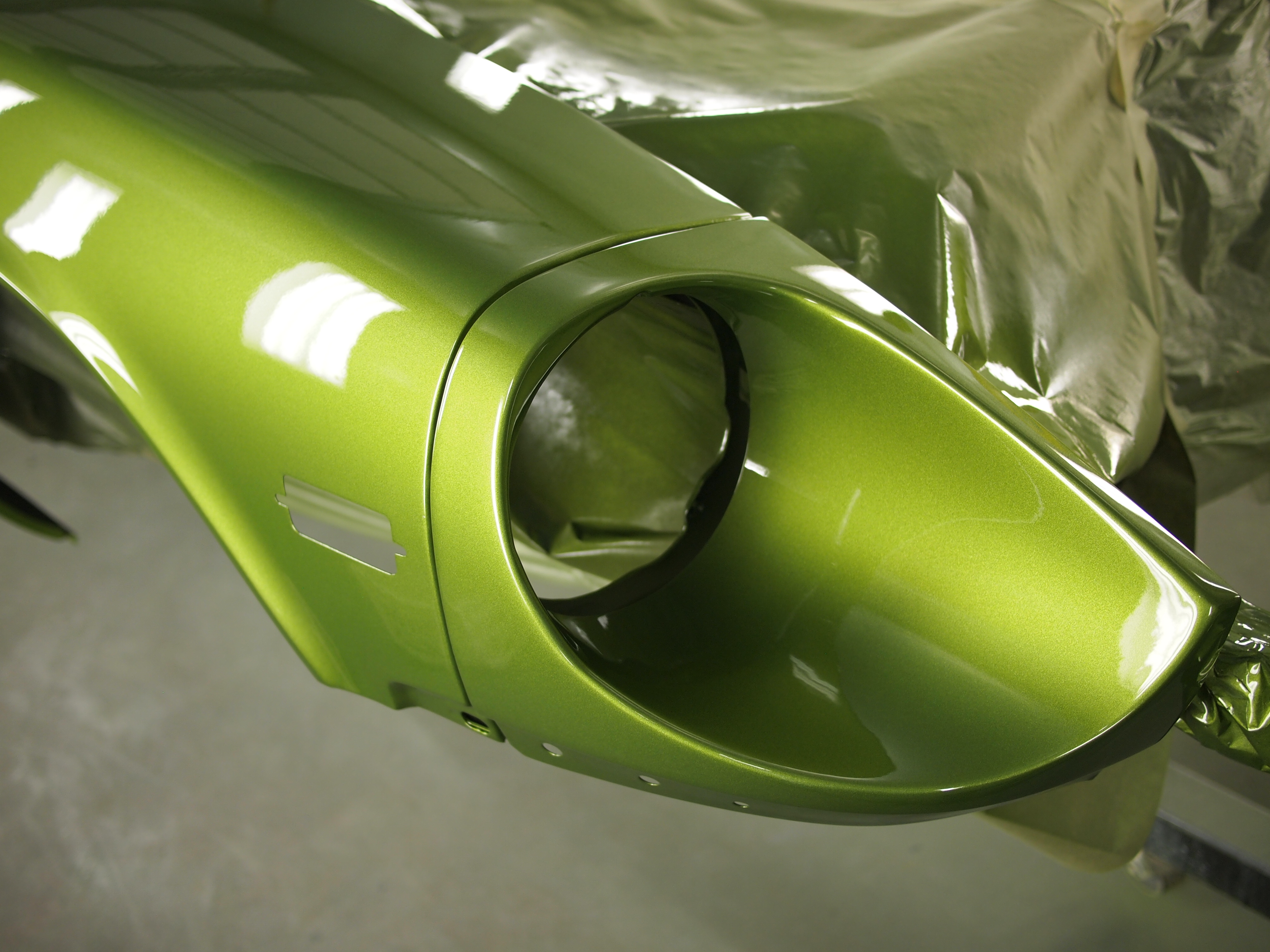

Off4Paint

Hauling off rolling chassis to Z-Clinic for total body overhaul. Interesting snap. Car looks like a tethered crazed animal trying to jump out at you from the live oak trees.

-

Off4Paint

-

Off4Paint

-

Off4Paint

Hauling off rolling chassis to Z-Clinic for total body overhaul. Something creapy about this shot... Looks like the left front tire is floating. Rear suspension all painted, bushed, struts, springs, axle bearings...

-

stub axle removal +

And the most difficult award goes to.... Outer lower control arm bushings!!!

-

stub axle removal +

Make sure you grind off the peened portion of the nut on the stub axle very carefully with a dremel. Otherwise you end up with hosed axle. The torque on the nut is pretty intense. Lots of different methods... This one is good. http://www.atlanticz.ca/zclub/techtips/rearwheelbearings/index.html If the big-o-air-tool doesn't work, what I do is install the strut in a wheel with a tire on it. Two people. One with a 4 foot bar sitting with feet on the wheel pull hard on the bar and the other guy standing on the wheel whacking on with a 2 or 5 pound hammer. It's pretty amazing when two people pulling on a 4 foot bar doesn't remove a bolt! If you don't "de-peen" the nut, you end up with an f'd up stub axle like what I found in my car... Notice the dremmeled nut in the bottom right and bad threads in the axle on the left. http://www.classiczcars.com/photopost/showphoto.php?photo=32730&ppuser=14083

-

R-T diff mount Group Buy

I'm doing that then. Figure the solid diff mounts used in racing show you can go to zero movement so I figure what you did is the proverbial "Goldilocks Zone".

-

DHM Car Show and Swap Meet

Great idea. I'll probably do black instead of silver, but killing the rust rot is key.

-

engine dies when i pull out dipstick

I was hoping this thread was sick off color joke... Instead I found a legitimate technical discussion. Prurient dipstick references obviously does not belong on this thread. Go here instead... http://www.google.com/search?hl=en&source=hp&q=dipstick+joke&btnG=Google+Search

-

R-T diff mount Group Buy

Good stuff. Next thing to try is an extra quarter or 3/8 inch on the bumpstop over the diff. You would obviously need a jack to press up on the bumpstop to get the diff mounted into place. Might be a nice track mod. Probably wouldn't be noticeable cruising around. Figure we all have an extra bump since they come in pairs...

-

Stub axle dilemma

- Stub axle dilemma

- Stub axle dilemma

Decided to go with aftermarket stub axle bearings... They appear to be commonly used throwout bearings. The Nissan stock bearings shot up in price pretty badly recently and Motorsport followed (something like $60.00 for the outer bearing alone). BlackDragon sells the inner/outer and seal for $50.00 per side. This is what is in the kit. Any good/bad/ugly on the aftermarket stub axle bearings? Beck/Arnley makes pretty good stuff from my experience. Don't know RHP... http://www.classiczcars.com/photopost/showphoto.php?photo=32788&ppuser=14083- Clock repair for Z's

Ron has website hosting issues going on. He is over at ZCLOCK4U@aol.com temporarily.- Stock mustache bar bushing flare

Got my front and rear control arm bushings installed (stock). Decided on stock mustache bar bushings. They are longer than I expected, but I figure after you press them in you have to flare the end somehow. Check the photo. Is this the right part ('72Z with an R200 swap). If its right, how do you press them in? http://www.classiczcars.com/photopost/showphoto.php?photo=32789- Stock Mustache Bar Bushing

- Whats your Z plan for 2010?

http://www.classiczcars.com/photopost/showphoto.php?photo=32786 Suspension painted!!!- Stub Axle Bearings

Black Dragon stub axle bearings. Quite reasonable considering the price increase on the Nissan parts. Wanted to document the manufacturers part numbers before I threw away the boxes...- IMG_1935

- Suspension POR

Suspension sand blasted, prepped and POR'd. Control arms rebushed stock. mustache bar not bushed yet, gas tank straps not in photo. 2 4oz cans of POR- Suspension POR

Suspension sand blasted, prepped and POR'd. Control arms rebushed stock. mustache bar not bushed yet, gas tank straps not in photo. 2 4oz cans of POR- 260Z Roof Skin Graft (Thanks Arne)

- Whats your Z plan for 2010?

Got my 240Z stripped to the carcass. Body work, paint, rebuilt motor, POR'd suspension, some aluminum buffing. Looks like I need a new axle :surprised: BTW - Motorsport is out of weatherstrip kits until July. Hopefully no delays past that. Hope to have the car mostly assembled by then.- Stub axle dilemma

Thanks Nigil. Z barn has strut tubes for $75. That sounds cheap to me. I'll call and see if it includes the axle. With new lug nuts I'll end up with 2 backing plates that way. I think it was torqued correctly and then loosened. I had a Z shop put in axle bearings around '90 or '91 as I didn't have the accumulations of tool like I have now. I bought the car in late 80's and have been working on it since something like '82. I'm sure the Z mechanic put ~190 ft lbs on it as its been running fine for 18 years. I'm assuming the nut back off to 40 as it didn't have peening or lock-tight on the nut. It probably backed off at the track when I blew the motor up!! Will never know who shaved the axle... Happy New Year!- Stub axle dilemma

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.