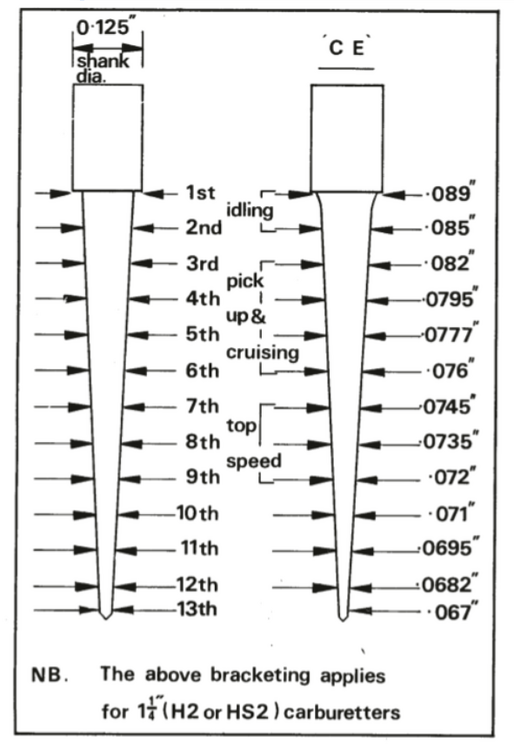

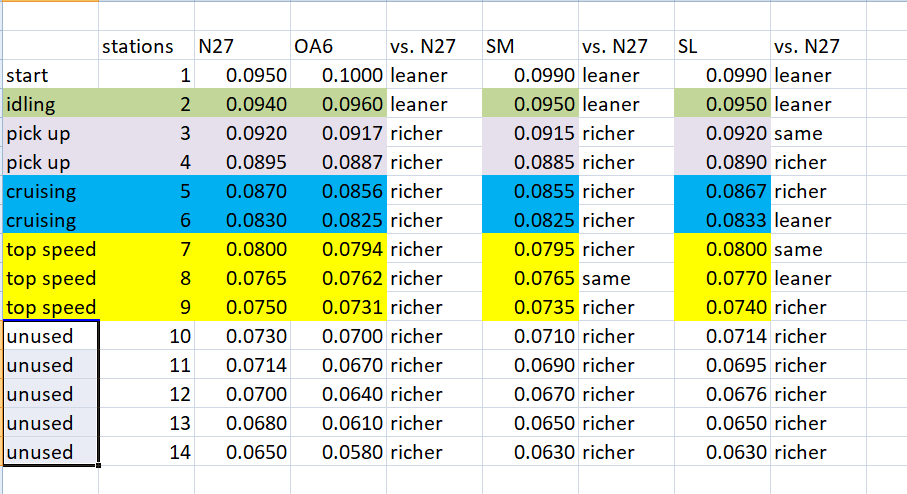

You are probably right, Charles. I'll tell you what I find myself thinking about though. The open height of the pistons in the domes at cruise, for example, is likely very close if not identically the same with needles that are not radically different from each other (and with all other factors (oil, springs, nozzle heights, etc. the same). If cruise is stations 3, 4, 5, and 6, and I am getting an AFR of 16.0 at "cruise", then wouldn't I be able to run a calculation to determine what percentage increase in fuel flow I would need to achieve an AFR of 14.7 instead, for example? And, subsequently, could I not calculate the change needed to the annulus area, and thus back into the width of the needle that I would need at "cruise"? If the issue is which of the four stations is "cruise"... then that might be determinable, perhaps by recording operation of the pistons in a video (with markings or indicators for readability). Also, the needles do continuously taper. So, if I am seeing a consistently lean AFR through the entire range of "pickup" and "cruising" (e.g. 16 AFR for tip in, pick up and cruise) then I may need the same percentage of fuel increase across all those stations. Yah - nice video! I do plan on at least using the AFR info as guidance as to which general portion of the needle needs to change. I have spent some time reviewing specs for needles. Here is a small selection of the few I have found to not be obviously bad choices: From here, I plan to set the mixture screws at 2.2 turns out (per the factory manual spec). Then I will make some recordings with the LM-2 wideband. My RPM signal is not being capture accurately at the moment, so I will have to address that first. I think fixing that will assist with some of the repeatability that will be needed for testing. When I do that, AFRs will change from what I have seen thus far, as right now, the mixture screws are about 2.7 turns out. While I am seeing around 11 at idle, and 16s pretty much everywhere else (other than throttle lift off, which will cause AFR to hit 19-20), I may find that idle moves to 14 instead, and everything else jumps past 18. Who knows. But, I will attempt to get some AFRs with 2.2 out on the mixture screws and use those as my N27 "reference" AFRs. Once I have these, I will review the above needles again, comparing with the N27, and consider the change in "general direction" that will be necessary at each station. Regarding sucking the bowls down, I believe I would observe lean mixtures getting leaner as RPM's increase. In other words, during heavy throttle applications (I haven't gone full yet, but I have gone close) as the revs build, I would expect AFRs to go leaner. I don't have the data to show that is not happening (yet), but I will when I get the RPM signal working properly. From my driving experiences thus far, accelerating near full throttle through several gears in succession, can be repeated, with no notable increase in AFR at any point in time during the series of "pulls". Simply put, the AFRs are lean, but very consistently so. I will do a little run tomorrow, weather permitting, and see what pulling the choke lever up does to the AFR. I have done that a couple of times when the engine is a touch cold and the slight hesitation (from being lean) goes away.

Subscriber

Subscriber 1Points1,282Posts

1Points1,282Posts