All Activity

- Past hour

-

Front Brakes dragging

- Front Brakes dragging

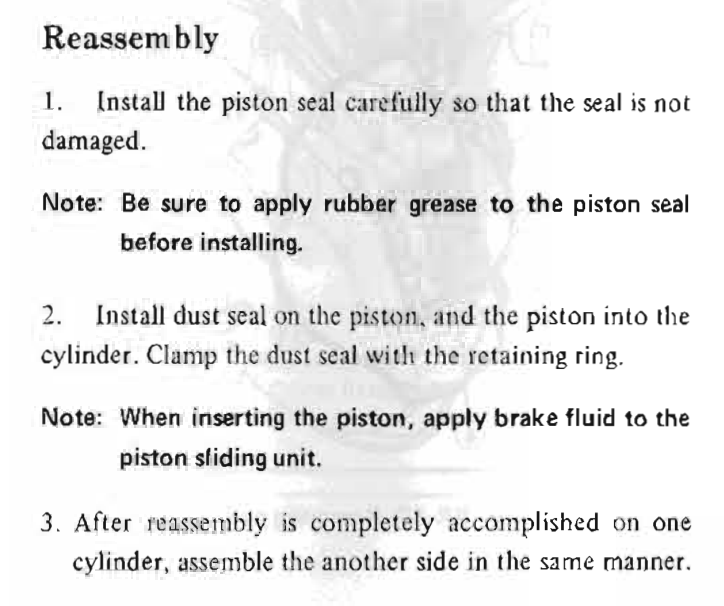

If you have a caliper on the bench you might as well pop the piston out. Don't scratch the cylinder with the metal dust seal retaining ring. Images won't load but the Brake chapter describes it. Uploading Attachment... Uploading Attachment...- Front Brakes dragging

Not sure what you mean by two pieces. But if it's sitting on the bench then, obviously, there's an open port to atmosphere. No way to hold pressure. The piston should be easily moved by hand if the caliper is new or newly rebuilt and has had fluid in it. Or maybe not, re above. Where did you get the calipers? Might have a bad rebuild. Tight seals.- 1971 HLS30-14938 "Lily" build

Cody's in Florida so I think he's safe. I just don't want to ship it back and then realize it's mine. But I don't recall any part like that- Front Brakes dragging

Most calipers I've worked couldn't be collapsed by hand and my hands are pretty strong. Have the calipers been rebuilt?- Front Brakes dragging

There is still fluid in that assembly. Did you blow everything out with compressed air?- Today

- Front Brakes dragging

Did you open the bleeder??- Front Brakes dragging

Haha, rabbit hole for sure. Sitting on the bench, with the caliper taken apart in 2 pieces, the brake pads "piston" ought to be able to compress without having to open the bleeder, correct? The fluid should go back the way it came from. Anyway, how hard should it be to move the piston? Can you compress it by hand or do you need a C clamp like I did?- 1971 HLS30-14938 "Lily" build

Might want to ask Cody if he had a few parts he wanted to slide in on the Old man!😂😂- Front Brakes dragging

Brake line is quite different than the bleed system. IMO go back and do it by having that bleeder open. You might be going down a rabbit hole here.- 1971 HLS30-14938 "Lily" build

I can't recall anything like that on my ride, so no idea.- Front Brakes dragging

Opening the bleeder when the brakes are stuck will tell you if the problem is pressure in the caliper or something else. If there's pressure in the caliper you can work your way back to the the MC fitting by fitting. Or work your way down, from the MC. First you need to know if it's hydraulic pressure or just mechanical sticking.- Front Brakes dragging

Probably worthwhile to read the Brake Chapter. It's not long. Well-illustrated.- Front Brakes dragging

But, don't overlook the brake pressure warning switch. Or the NP valve. Can't remember the car. (https://www.classiczcars.com/settings/signature/) It can get gummed up also. Uploading Attachment... Uploading Attachment...- Front Brakes dragging

No, I don't think so. But the line was disconnected. It has new rubber hoses, so don't think that's it. The hole in the master cylinder, that creates the pressure when you hit the brakes, is this also the return hole for the fluid?- Front Brakes dragging

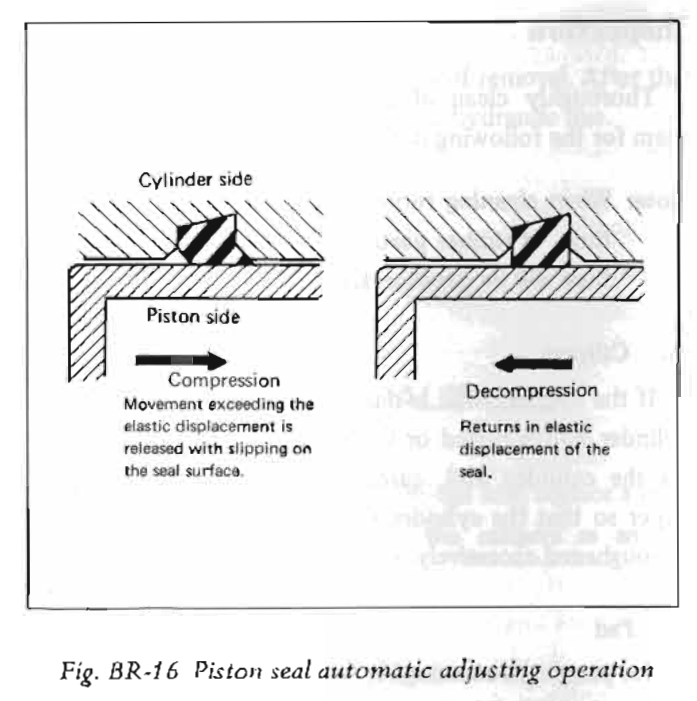

The Nissan calipers use the rubber seal to retract the pistons. One common cause of sticking caliper pistons is collapsed rubber hoses. The MC can generate high pressure to push through the collapse but the rubber seal cannot to allow the pressure to release. It becomes like a check valve. On some cars the cause is a metal clamp on the hose that rustjacks and pinches the hose. But just degrading internal material can cause it also. I ould guess that a kink in the hose could cause it also.- Front Brakes dragging

Was the bleeder open when you tried to push the piston in?- Front Brakes dragging

I appreciate all the info. I removed one of the calipers and to compress the pistons, I needed to use a C clamp. Is this normal? Seems like they're awful hard to move. It takes alot of pressure to get them to move one way or the other. So when a guy applies the brakes, then releases the brakes, there's no spring to make the pads retract, they just kinda ride along the rotor. This drag is causing things to heat up and expand, making it tight. Some Fords have springs in the calipers to make them retract. I applied the brakes while the front end was lifted up, it wasn't heated up. After releasing the pedal, there was a more noticeable drag on the rotors. I pulled the master cylinder away from the master-vac, and there was no change. I don't think that's the issue.- 1971 HLS30-14938 "Lily" build

I have no clue what those are. Also, looks like you have 5 of them, which is an odd number.- 1971 HLS30-14938 "Lily" build

Jim do you recognize that last part in my chrome post? @motorman7 ??- 1971 HLS30-14938 "Lily" build

Good to know!- Front Brakes dragging

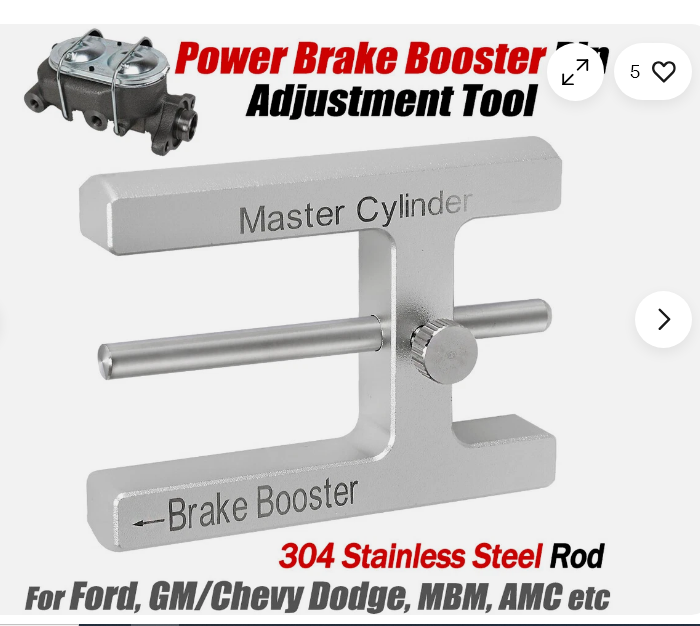

If you can do this when the brakes are stuck it will tell you if the rod from the booster to the MC is too long, causing the return port in the MC to be blocked. You'll have to do it while things are still warm though. Patcon is implying that the air expands as it gets warm creating pressure in the system. They make a tool for setting the booster rod length. It's a fairly common problem, especially with rebuilt boosters. If you stare at the parts long enough you can figure out other ways to get it right.mogolv joined the communityYarb started following Front Brakes dragging- Front Brakes dragging

I believe that’s what he was referring to.- 1971 HLS30-14938 "Lily" build

I never had any pushback and I have friends getting work done there now.- 1973 Rebuild

I was able to get these out with a small hook. I think the corrosion was holding them in. Once I got it open I found out I have the wrong rebuild kit. I have 46020-C6126, which is for the Tokico . This is a Nabco, which uses totally different residual valves. I think the kit part number is 46011-P6525. - Front Brakes dragging

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.