-

Early/late thermostat housings

-

Early/late thermostat housings

Cool. Seen that hole before on some housings, but never noticed it was threaded. Only ever seen the spark plug holder bracket go under the rear therm housing bolt. Let me see if I have one

-

Axle Stands

https://technotoytuning.com/garage/parts/techno-toy-tuning-hub-stands?srsltid=AfmBOopa6jRW6cUSQ9PXFDILN9oYNqUzVHqm3tx5nVKNJKdkWBs52W8E

-

Oil Won't Prime

Happened to me too, engine shop didn’t put it back, “someone” forget to check if its there….. Wasn’t….. There is a back one as well…. Just have to ask, you’re spinning the priming rod CCW right?

-

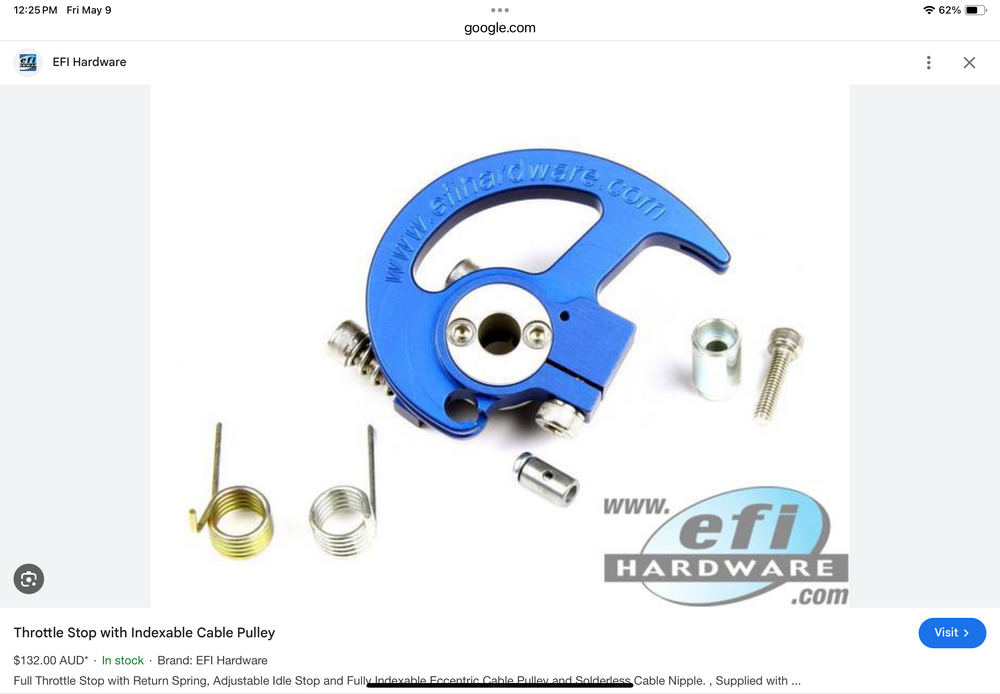

Jenvey ITB Cable Throttle Wheel?

-

Rear Inner Wheel Bearing Loose In Hub - What can I do?

Great! I’ll send you a PM here and we can exchange better contact info.

-

Rear Inner Wheel Bearing Loose In Hub - What can I do?

I can help with a hub I think, will look tomorrow for sure. What part of western canada zRot? @ZROT

-

Paint protection film

After replacing the insanely expensive cracked windshield in our 2025 Mazda CX-70 next week, I’m going straight to a shop to get Tera Shield installed on it. ZRAuto. Claims its three layers, clear for ever, blah blah blah. No idea about price yet. If it saves me one windshield it will pay for itself. That’s the brand the place I’m going to uses. I’ve looked online, and found a couple of retailers selling DIY kits in the $200 USD price range. Might try the DIY stuff on the Datsun just to say I did it.

-

240Z front bumper differences

73 bumpers still have a pair of studs, they are just farther apart to fit the much heavier bracket design. The location of the bumperettes changed as well. The 74 early 260 skinny bumpers changed again as it was mounted to hydraulics and it had a single mount stud as I remember. This bumper seems to have that. Another indicator is the little weld in studs (M6) alone the top inside face that mounted that rubber spacer strip that filled the gap from bumper to body with the farther out 73 and 74 bumpers.

-

Rear tie down hooks for originality: Yes or no?

Exactly one chain. Printed out a side view and laid out the chain around the outline. Took a couple of zooms in and out to get the scale down to exactly one chain. Added a couple of embellishments. Gotta do a 510 next. Can do another Z if you want!

-

Rear tie down hooks for originality: Yes or no?

The memory is swirling with details of tow hooks, but I would like to point out that from the point of view of originality, the presence of tow hooks is optional. First remember they are tie down hooks, not tow hooks. They secured the car to the boat they came over on. Memory of past discussions suggests there was a Nissan order to dealers that they be removed before selling. Correct me if that’s wrong. Seems from the many Z’s I’ve seen, most still had “some” so I suspect many dealers didn’t bother. So it would appear to be “Correct” to have them or not on a restoration. If you could somehow know if they were there or not on delivery day for your particular car, then you would know to either include them or not to make it “right”. Then the issue of what particular style was installed at each of the four spots comes up, but I think that was covered in some other thread. I made a coat hook rack for the back of my shop door out of some of the ones I have laying around. Probably sacrilege to some. Too bad.

-

Tacoma blast cabinet

Wow, that Tacomacompany stuff is top notch. I’ve made all kinds of mods to my Harbour freight/Princess Auto cabinet over the years, and it woks pretty well, but I see the advantages to almost all of their products. Will be upgrading the feed and vacuum controls for sure. The one huge thing I recommend is to make the top glass area into your access door rather than the big door on the right. My compressor is right there, never able to get bigger parts in there anyway And use plexi sheets instead of glass. I buy a 4x8 and chop it up into 16x24 pieces to fit my frame. Disposable and cheep. I use cheap LED strip light strips ringing the entire inside top of the cabinet for lighting. They are surviving just fine. What really amazes me is the amount of sand that makes out of my supposedly sealed seams….

-

zKars started following Little Shop trick to share. Installing Sun Visors and interior mirror

-

Little Shop trick to share. Installing Sun Visors and interior mirror

Some of you have dealt with this little annoyance, and I have found a perfect solution. When doing a full restoration, or at least the full interior, you often have to replace the head liner and the A pillar vinyl, as well as the vinyl trim that goes across the top of the windshield where the sun visors and rear view mirror mount. While I won’t discuss the pain of installing these items, what I have found is even more of a pain, is finding the nine M5 threaded holes to put the visor and mirror mount back in. All that fresh painfully installed lovely vinyl, and 9 secret little holes you have to find to poke holes through. Get out the pokey thingy of your choice and start poking until you find them. If you put some kind of thin foam behind the vinyl like you’re supposed to, those damn holes are just a nightmare to sleuth out. Not any more! I put some nice long M5 grub screws in the nine threaded holes, THEN do the upholstery. Then finding the tips of them sticking out is easy! Make little “X” slits to expose them, grab your M3 hex key, back them out and screw in the visor and mirror mounts. Five minutes each! Easy peasy.

-

240Z fuel pumps - How many different OEMs?

-

Ignition not cranking the engine (only click is heard at starter)

Being lazy and not having read the entire thread, I have a suggestion that perhaps has not been tried yet. Replace the spade connector on the end of the BY wire at the starter. It may “look” just fine, you may have even cleaned and tightened the metal contact. I had one where there was only one strand of wire still crimped under the terminal tangs and that strand (like the rest) were filthy and corroded. No way to get enough current flowing to engage the starter solenoid. Snip, strip, scrape any corrostion off of the bare wire, crimp a new 1/4 FM terminal, stuff it on the starter terminal.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber