Everything posted by Dave WM

-

280z with 5 speed ZX conversion 1st impressions

I was able to take my 75 280z out for a test run with the 81 ZX 5speed today. Wow is all I can say, what a difference. I have the 3.54 diff and find it a very nice match up with the tall 5th (.75). I was concerned that the taller 1st may be a problem but it was a non issue, can barely tell the difference when starting off. From there its only better. The gears seem better suited in all traffic conditions, and when I was on the open road I put into 5th and was going 75mph at about 2600 rpm, 80 was about 3000. Prior to this 80 was 4000 (60 was 3000, 70 @3500). The car seemed much quieter and perfectly happy with the load (credit the torque of the L-28). Needless to say I am thrilled with this modification, I generally like to keep things completely stock, but this is just so much better I feel its worth it.

-

FS5W71B 280zx transmisson rebuild

Whoo Hoo, it works great! I just decided to go ahead and install the rebuilt trans and see how it sounds, no different from the 4speed now, so what ever the problem was the rebuild/gear seems to have fixed it. I made sure all the gear were working and shifting well, did not get a chance to really open it up but I did get in into 5th and all gears were noise free. I figured more testing would take as much time as just installing it and hearing what it sounded like. While I was in there I replaced the throw out bearing (used the press to install in a spare hub). could not see any oil leakage from behind the cover plate (no dripping but as long as I was in there figured it would be worth peeking in to see how the main and side seals looked). Tomorrow I will get it out on the highway to really wring it out. I did take a quick check of the speedo, all seems good there, I knew the right pinion was installed (black for a 3.54) but I just wanted to make sure the cable itself was properly seated. The only test I can do now is to see if any gears pop out with more spirted driving than my brief test was able to accomplish.

-

First drive in the z in 25 years.....impressions.

think you just need to chase them all down, gaskets/grommets if its that bad I would think it should be obvious when you start pulling panels off and examine. I have always wanted to do the box fan taped into the window pulling air out of the car then get a smoke and walk around to see if you can find where the leak is.

-

First drive in the z in 25 years.....impressions.

you get used to it. if you have a delicate nose I suppose you could try smoking them out with some kind of smoke generator, look for leaks, like around the tank hoses that share the inside of the car and go thru grommets to the outside world.

-

Underside protection

I agree with the don't drive it on salted roads. gets a beater for that, keep the Z in a garage. the corrosion protection on cars of that era was non existent.

-

Transmission internals question

nice work on those drawings.

-

Transmission internals question

if you do a full rebuild, and have the tools (v blocks and dial gauge) get a reading on the run out of the output shaft, I am curious since that something I really wish I had done when I had it all apart.

-

Transmission internals question

depends, if the bearings look ok (no broken cages or obvious damage), you may just want to switch out the counter shaft bearings and the tail shaft bearing, easy to do with minimal breakdown. I the cages look good and the baulk rings seem to be grabbing and have the in spec gaps. I did not even use the rebuild baulk rings and the adapter plate bearing were nearly as good as the new ones. there is a lot you can do without pulling the shafts out.

-

Transmission internals question

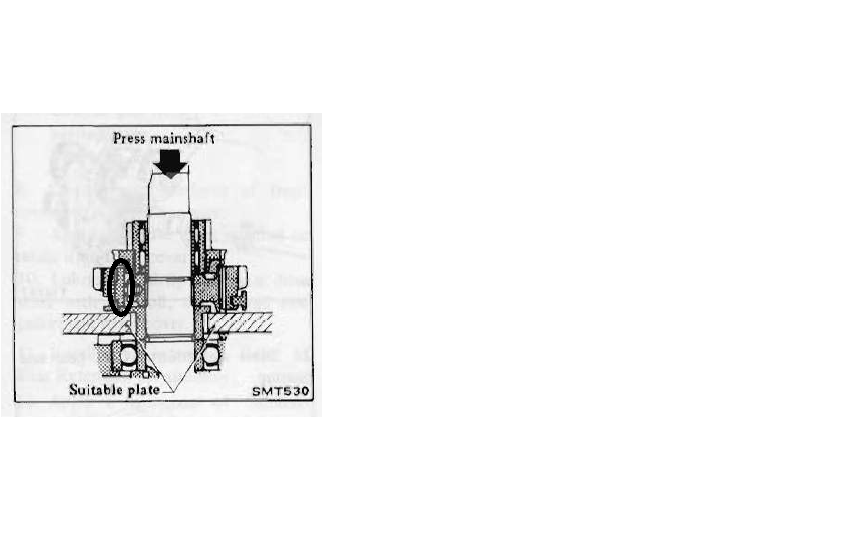

Its really not that hard to take apart, do like I did and watch that village land video a few dozen times. You only have to take the back part off, so you can stop watching when he gets that far. just don't let those springs jump out on you when you pull the sleeve off. The only misleading thing on that video is the ease he has of pulling the hub, that inner race of the 5th gear needle bearing is pressed on pretty hard. He shows it just coming off, yea right. Also don't loose the various balls used in the fork detents as well as the speedo worm gear and the 5th gear thrust washer.

-

Transmission internals question

Dang, that is one scary situation to be in as in nightmare scenario , never a win for the car in a car vs train.

-

Transmission internals question

That pretty much clarifies the correct way to install, both EuroDat and I came up with the same conclusion on the correct install. So now its going to be up to Redfogo to decide (as ZH already mentioned) if he wants to fix his or just run with it the way its been installed before (and presumably working albeit prob with some occasional issues with getting out of reverse). I am pretty sure reversing the inserts will require the level of effort I previously described, but cant say that for sure since I never attempted a limited tear down just for that purpose.

-

Transmission internals question

forgot looks like all the shift forks would need to come out, which gets you into the detents springs and balls. best to watch all mine (I skipped the 1st one) or the village land guy to get an idea of what you are going to need to do. Not an easy fix due to how much have to come off, tedious.

-

Transmission internals question

- Transmission internals question

- Transmission internals question

think would have to remove the entire sychro assembly, It pretty difficult to assemble the springs and inserts with it on the table, trying to do it with the hub still attached to the output shaft could be a bit too much. So removing the hub... the way I did it was to pull the speedo gear and output shaft rear bearing. just some snap ring pliers and a bearing puller from harbor freight. Next up is a monster box wrench on the left hand thread main nut, clock wise to loosen on this one, with that out of the way, you get to a thrust washer then 5th gear comes off easy along with the baulk ring. Then the shift fork (drive out the roll pin) and coupler should be able to come off the back of the hub, don't loose the insert springs as the inserts will want to jump out as soon as the coupler sleeve clears them. I cant remember if the counter shaft 5th gear has to come off, prob does to clear the hub. now comes the fun part, the hub and inner race of needle bearing for 5th, IF you can fabricate a puller that can reach the end of the shaft and get it behind the hub then you are good to go. On mine I use the bearing puller from harbor freight but in order to use this I had to get the idler shaft and gear out of the way, this means removing the bearing plate with its 6 torx screws that trap the idler shaft. once that is out of the way the bearing puller and lots of extentions later I got the hub off. its some where in my rebuild video, part 2 or 3 I think. The hub and the inner race are a tight fit, maybe just the inner race (5th) but regardless need the puller to get it off. If you have a really long 2 jaw puller you maybe able to skip the removal of the bearing plate and idler shaft. with the hub off you can rebuild the sychro as a unit. I used a series of washers and the main nut to press it all back on. hard to explain in a step by step fashion, its not hard but it is tedious and you must use the correct tools (no cave man stuff here) the 3" 4" bearing puller from harbor freight was enough for me, a long gear puller would have saved me some step, but I was tearing it down all the way so no need to save steps. you have to not lose some little steel ball and a steel peg (speedo gear and 5th thrust washer). If it was mine I would do it. Yes it prob works but I bet it gets hung up now and then as evidenced by those deep gouges in the pad on the shift inserts. if you have done it before, 1 hour, if 1st time more like 3 hours as you struggle to figure which tool to use.- Transmission internals question

That would be great I know Red would like some verification, I noted errors in the exploded pics as well. on some of the manuals it was the other way on the exploded. one had both ways on the same pic. I am surprised that the manual did not deal with this better.- Transmission internals question

here are some pic I took at the time, just found them. note the spring hole is just forward a bit of the center cut line on the hub. in the second pic you can see how the spring will be located directly under the pad on the insert. You can assemble either way, but IIRC it was popping up oddly when the coupling sleeve was pushed forward when configured as in the 1st pic. I am trying to recall this, I cant remember if I posted about it in the orig rebuild thread. It was just one of those things that I had to deal with since when removing the sychro, the coupling sleeve popped off and the insert went flying. I had not intended to take it apart. On the other sychros I was more careful to remove as a complete unit.- Transmission internals question

very easy to just rev the direction of the insert, I know since when mine came apart I had to do research (the cross sectional drawing) to figure out the correct way to install. Pretty sure I tried it with them in the wrong way just to see what would happen, but I cant recall exactly the details (I vaguely recall it did not seem right). It was just a quick check and make sure it was right back when I 1st took it apart. the other real test was to look a were the spring is, it should be located under the pad of the insert, his is not, its in front of the pad on the insert. when the collar goes forward, the pad is exposed and the insert lifts up in the back, loosing indexing.- Transmission internals question

that's the other side of the gutter. His may work, but I suspect it will not work as well as it should. The main thing I see is the damage to that insert, Seems the only way to account for that is improper assembly, looks like a lot more than just reg wear and tear.- Transmission internals question

took a measurement before removing bell housing, attached pic and mech drawing of how I see it should go. this shows how much of the pad on the top of the insert shows when in the rev position with bell housing on and how much of the hub is exposed. approx. 1/2 inch of the hub is shown while in rev, note how close the coupling sleeve is to the bearing plate as well. You can see that only a fraction of the pad is exposed, so there would be no way the coupling sleeve teeth could get behind it in normal use. OP should get a measurement of the hub at the 1/2" mark as well and see if the pad is still under the coupling sleeve. I have added the cross sectional again for comparison of orientation of the insert. I did see several exploded drawings in my research, some had it as the OP, some had them both ways (one insert with the long side pointing back one with it going forward), and I found on a C version which uses the same type of sycro the longs side of the insert all facing the back. For that reason I trust the cross section drawing. there is no damage to the shift insert like shown by the OP.- Transmission internals question

I have to put mine back together, when I do I will mount the adapter plate and try moving it (nothing to stop the shift rod) and see if I can overshoot on the coupling sleeve.- Transmission internals question

Eurodat, you don't think that insert is in backwards? I assumed the damage was done in reg use where the top of the insert was routinely popping up (in the rev installation of the insert I don't think it would be possible for that to happen), and the damage done by attempts to get out of reverse jamming the coupling sleeve into the exposed top while the baulkring was not indexed. after repeated attempts rotation of the output shaft would eventually allow the cut out on the baulk ring to get back and then the insert would find its way back in.- 1972 240z datsun rolling shell was rust free (Just a little Crispy)

burned off all the rust.- Facebook vs Forums

I assume to use face book you need to create an account, for me not gonna happen. so you need a fancy phone for that? I am clueless on that stuff, prob why I like the tech of a 40+ year old car. "Get off my lawn!!!!!"- Jai's Status

- Transmission internals question

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Account

Navigation

Search

Configure browser push notifications

Chrome (Android)

- Tap the lock icon next to the address bar.

- Tap Permissions → Notifications.

- Adjust your preference.

Chrome (Desktop)

- Click the padlock icon in the address bar.

- Select Site settings.

- Find Notifications and adjust your preference.

Safari (iOS 16.4+)

- Ensure the site is installed via Add to Home Screen.

- Open Settings App → Notifications.

- Find your app name and adjust your preference.

Safari (macOS)

- Go to Safari → Preferences.

- Click the Websites tab.

- Select Notifications in the sidebar.

- Find this website and adjust your preference.

Edge (Android)

- Tap the lock icon next to the address bar.

- Tap Permissions.

- Find Notifications and adjust your preference.

Edge (Desktop)

- Click the padlock icon in the address bar.

- Click Permissions for this site.

- Find Notifications and adjust your preference.

Firefox (Android)

- Go to Settings → Site permissions.

- Tap Notifications.

- Find this site in the list and adjust your preference.

Firefox (Desktop)

- Open Firefox Settings.

- Search for Notifications.

- Find this site in the list and adjust your preference.