Everything posted by Dave WM

-

fuel injection pressure wierdness...

and about 30 min later I am at 20 psi... Oh and btw, the engine noise is really not like what is sounds like in the video. Sounded like hell on the video but in person it is much quieter. Also the fan slows down after a few seconds.

-

fuel injection pressure wierdness...

posting up a new video shortly showing cold start/fuel pressure/thermotime etc...

-

fuel injection pressure wierdness...

well if you ever need to replace that thermotime, get the hotter one. I think the L jettronic was used on the old super beetle VW, and IIRC that is the one I used (it came standard with the hotter temp). But like you said its really just an annoyance.

-

fuel injection pressure wierdness...

sounds like the same story here. cold never really an issue (assuming cold enough for the cold start to fire, which in florida is not often, even changed it for a hotter one just so it would fire at 85f). The leak down is a real mystery, did the same thing, clamping various parts. I am starting to think it maybe just the fuel lines themselves may account for some of the different times. If you think about it, assume the lines were all metal, ANY loss of fuel would result in a dramatic loss of pressure in a static (pump off) situation (in fact it would prob be zero the instant the pump was off). Just guessing of course. Maybe a comparison to a modern car will show the same inconsistency, seems like yours and mine a perhaps a lot of other Z's sure have the same issue, so maybe its not really an issue at all.

-

another broken bolt 280z

I will have to look into that. I had stick welder 30yrs ago, never used it.

-

fuel injection pressure wierdness...

Yes have the fram G-3 prefilter, the fuel pump is a new OE Nissan. Of course it started right up this morning, and the pressure is holding, not indefinitely but much better that when it would drop in seconds. I think I need to drive the car more and work on it less....

- Found this under the dash

-

fuel injection pressure wierdness...

EuroDat, your guide is pretty much everything I did but for the flow rate Now that it is holding pressure again I will see if the problem comes back. I had the same issue when I 1st got the car, problematic starting. It resolved on its own back then as well. Maybe there was a bit of junk in the new lines I installed. I know while I had it on the test stand there was NO leakage from the injectors (they were mounted to the rail and the entire setup was pressurized. I don't recall any leakage at that time from the FPR vacuum line so its prob ok.

-

fuel injection pressure wierdness...

5 speed is my next big project. Need to get a new clutch Excedy seems to be talked about a lot.

-

fuel injection pressure wierdness...

yea, this was def a case of shoulda left it be. Good news is the pressure as not moved in over an hour. when I 1st had the problem it would bleed down is seconds.

-

fuel injection pressure wierdness...

280z 1975 I pulled the FI's and cleaned by running cleaner thru them while cycling. Put it all back together, at 1st no issue, then hard starting, have to throttle it to get it going. Once started no issue. Spark, check while cranking, all good. started disconnected ign to start fuel pressure, slow to come up then bleeds off fast. Has a new OE pump. get out some clamps, clamp the return line, no effect same thing slow to pressure then drops off fast when start returned to run (will not hold pressure) One more time this time get assistant to turn key to start while I prep to clamp the fuel in line (and the return line is still clamped). while showing the asst how to turn to start for 1 second, I notice the pressure gauge does NOT drop even with out the second clamp. hmmm so I go and disconnect the return line clamp, still no drop sitting at about 36 psi. Attach the starter solenoid wire, cranks right up. Turn it off, pressure holding at 30 psi. so for some reason I was losing pressure and for the life of me cant figure it out, seems intermittent. I am seriously considering getting some rebuilt FI's. Oh I clamped off the cold start supply 1st no effect. Note all this began AFTER I pulled the injectors for cleaning (I really just wanted to base line the spray patterns).

-

another broken bolt 280z

Well the upside to the story is the car started and runs fine after I messed with it, so no harm at least (no noticeable change either way). The main issue I had was with that very short piece of hard to get fuel line that was starting to show a gas leak, no engine fires please. I did use FI rated line (had to go to 4 auto parts stores, all they had was reg fuel line before I found it at oreily's), all looks good. I am going to take a break on the nut for now. I do want to get a mig welder, but need to do some research. I want a decent one, ok to spend some $$$ I just don't want to by twice. I know good tools make the job easier. I guess my next post will be about good welders.... I have always wanted to learn how to weld.

-

another broken bolt 280z

I was replacing the remaining old FI hose (short pieces around the regulator) and while I was doing that I wanted to check the spray pattern on the FI's what a pita to get it all off, but the worst part was a snapped the bolt on the front of the head that is used to attach the metal hard lines for the FI rail. The one on the side is ok (shares the lift plate). The one that broke only has one function, and frankly I don't think it would be a problem if I did not use it. But... I was wanting to get a welder (wire feed type) and I have seen it used to weld on a nut to the broken bit. There is some of the bolt still sticking out but no way is it coming out, the vice grips are just chewing it up so I stopped while there was still some left. Now the question, will the alum heads be at risk from the welding heat? my plan was to use a washer 1st over the broken bit, then a nut that fits over it, weld from the center of the nut. I have never used a welder like this, did use an stick welder back in HS but that was 40 yrs ago.. I would of course practice on some scrap bolts etc.. to get my technique down. Other dangers would be electronics (I presume disconnect battery completely and unplug the ECU maybe even the ign module), not sure how the current in the weld process may effect those. fire from fuel. Will make sure the reinstalled rail is leak free tomorrow morn, too late to crank it up now to check my work. Its all back together, while I had it apart I pressurized the fuel rail with some FI cleaner using a pressure bottle at about 35 psi. turn on one injector at a time with a low volt AC supply (60hrz) The spay pattern was consistent for all the injectors, Not very much of a pattern I expected more of an aerosol effect the spray was maybe 1" wide at about 4" out. I ran several a couple oz of the cleaner thru each injector. but since I lack a frame of ref, not sure if they are good. but they are consistent. Back to the bolt, am I ok with using the mig welder? Just don't want to crack the alum head.

-

rear main sealant

I picked up the seals and gasket from local Nissan today. Geez the RMS is big, 100mm. Seem like it has little dots of red grease already on the inside of the seal. So I assume with the OE real no need to prelube with lithium as per the FSM? I cant find a driving tool that is 100mm, I like to use the correct tools. Any ideas where to find such a tool. Most of the stuff I see for sale is 81mm.

-

5sp Trans Chatter

I use the GL-4 stuff (as per the FSM). Perhaps the mobil oil GL-5 is ok with the brass in the trans, but the reason I used the GL-4 rated MT-90 was for the brass. I would look into this, found it in the mobil-1 oil info sheet. Could be a problem as I recall reading that sulfur additives where the issue for the brass. "sulfur-phosphorous additive system" From more reading it seems that modern GL-5 oils are prob fine. I suspect this has been hashed out a zillion times. a google search will get you a lot of opinions. I also suspect the oil is not the issue, but always good to make sure you have the correct type and amounts of fluids in the car.

-

rear main sealant

will do ZH. If that is the case I understand there are two options: Displace seal slightly so lip rides on undamaged part of crankshaft (fabricate a spacer wire to hold off lip just a bit, sounds dicey, or perhaps a fixture that would allow for incomplete but accurate driving in of the seal to displace outward slightly with out a wire to act as a spacer). Not sure about either of these approaches as the need for the seal to be driven in square could be comprised. Use a crankcase sleeve. Lets just hope it does not come to that.

-

rear main sealant

hope to get to it in the next month. Been waiting for cooler weather. the attached video above really showed me just how badly the seal can leak.

-

rear main sealant

if the source of the leak is more likely to be the rear main than say the pan/side seals, then it would make since to alter my order. I will do the trans swap and replace the rear main. Only if the leak persists will I then do the pan/side seals. This order makes since as I KNOW I have to pull the trans for the swap, good time to do the rear, while the pan gasket/side seal is optional.

-

rear main sealant

Note for some reason he does not use the lithium grease but rather just reg motor oil. I would follow the FSM and use the lithium grease. the video is good as a reference for what it will look like once I get in. the FSM has illustrations I prefer seeing actual pictures or in this case video. I also edited my orig post to make it easier to see the specific area I am trying to get the sealer for, added the pic instead of the link.

-

rear main sealant

Zed Head, I have a leak, seems like it could be pan gasket, but not sure. Its the pass side, rear of the pan, does not look to be from the weep hole of the bell housing but not sure about that. I have ordered the rear main seal, the side seals, and a pan gasket (all OE Nissan). should be here in about a week. Since I plan to pull the trans anyway to swap in the 5 speed, I was thinking the seal maybe the source of the leak. Much of my research has folks saying replace anyway if I am already pulling the trans. So the rear main for sure. I was thinking as long as I am pulling the pan to see if the gasket is the issue I may as well replace the side seals. So I do plan to do all but maybe not a the same time. I was thinking of the pan and side seals 1st just to see if that stops the leak. When I pull the trans it would be a good time to inspect the clutch/flywheel/rear main, I assume I will be able to look at it and determine if the seal is leaking but as mention before even if not I suppose it makes since to replace it, unless it looks brand new. I figure I will know better once its apart. the plan is to replace the clutch and get the flywheel machined or replace with new. found these videos that were helpful. clutch rear main

-

rear main sealant

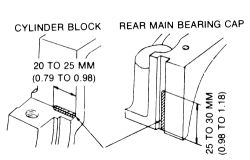

https://www.permatex.com/products/gasketing/anaerobic-gasket-makers-flange-sealants/permatex-anaerobic-flange-sealant/ for this the two places one on the block where the rear main bolts and some on what looks like the inside groove of the bearing cap where the rubber side seals go. Not it give very specific coverage areas, but the illustration leave a bit unclear on the bearing cap, I ASSUME its just applied to one side of the groove. I search and search and searched, seems so many conflicting info, thought I would bring it up again.

-

high idle 79 zx

easy stuff 1st check throttle plate not hanging up then the AAR valve Not sure about 79, but if they have it the BCDD check the BCDD. down load a factor service manual and study the fuel injection system.

-

280z 75 dovetails

I got the billet ones today installed, look great, work great.

-

the next project on my 75 280z

tried snugging up pan bolts, no help. will check the rack bushing, using the described method.

-

the next project on my 75 280z

the to do list, no particular order outer rear hatch weather seal find source of oil loss pan gasket rear main side seals I see no blue smoke or other evidence of internal leakage (no oil in rad, no water in engine)that being said I go thru about 1/2 quart in 400 miles. I have oil seepage at the rear of the engine around the pan and down the trans cover, Not a lot, so not sure if this accounts for the loss 5 speed from a 81 ZX TC bushings (not in great shape) front sway bar (also not that great) rack bushings (not sure about the condition) ball joints dust boots or new, prob 555's would like to clean and check the old if ok just boots check of drive shaft u joints, no sounds but scary to think of what could go wrong Clutch including pressure plate (same time as 5 sp swap) AC work (install NOS cond/compressor, drier of course) dye carpets (look good but for fading) passenger side seat bottom foam and covering, got new stuff may as well use it. rear wheel bearings check out and replace if needed. half shaft rebuild (no idea if needed). rad to shop for rod out, not sure about this. I like the idea of the OE style vs alum. pull ign module check heat sink grease and any small eletro caps if present IIRC there was one. install billet dove tails on door latch (on the way) head light relay, just a precaution. I don't intend to run high output lights just don't want to stress out the switch. Mustache bushing stoppers (have some nos, the old ones look beat up). fix the broken exhaust manifold bolt on rear of engine. replace cracked FI plug boots and any other rubber electrical connector boots. remove and have the FI's pro cleaned. that's all that I can think of off the top of my head. Nothing critical as the car drives great, just thinking of the maintenance (car had no repair history papers). the slight oil loss bothers me the most I have to remember to check it frequently while making long trips, and even though there is some seepage is just does not seem to be enough to account for the loss. My long range plan is to buy a hoist and engine stand and pull the engine. Detail up the bay and address any engine related issues. my pressure test is about 150-155 across all cylinders, I put in a few drops of oil and it jumped to about 175. I read that a 15% increase is about normal when doing this so I assume the rings are not too bad. the car has indicated about 89k which I think is correct for the amount of wear on the pedals (vs 189k), but that is just my guess. My last trip I got about 25 mpg mostly about 70mph no AC , the plugs look good so I think the FI's are prob ok but still would like to clean just so I can add to the maint history. what I have done Alt (external 60amp) hoses (all but heater inside cabin) vacuum lines (all) fuel lines (all but FI's and pressure reg short ones) filters (air/oils) tank pro cleaned fuel pump OE Nissan G-3 prefilter (no sock on tank pickup) brake booster front wheel bearing service (good just clean and lube) water pump replaced all the worm drive hose clamps used on FI system with correct style Plugs (after faulty ECU fouled the ones installed badly) thermotime (new higher temp 85f) temp sensor water temp sending unit water temp switch for egr PCV valve (Nissan oe) flame arrestor in valve cover vent battery cables with molded fittings valve lash adj OE radio and speaker install windshield leak fixed (sealer on gasket) windshield washer pump new OE style and hoses. Driver side seat bottom foam and cover I am sure there are other things but that's about it for now.