Everything posted by Matthew Abate

-

Designing A/C System Using Other Cars Parts?

Exactly. The only reason I’m not 100% sure I’m going to do that is that I don’t know where I will put the servo. Otherwise it’s pretty simple.

-

Black out areas

-

Designing A/C System Using Other Cars Parts?

Thanks for the compliments! That’s interesting about the constant idle system. I’m assuming that plugs into an ECU? I’m running Mikunis and a ZX distributor so don’t have a computer to control. I’m thinking of rigging up an adjustable servo actuator triggered by the compressor that would interfere with the throttle lever to raise the idle when the AC is on, but I haven’t thought it through yet. I’ve integrated all of my AC wiring into my engine harness, which I am rebuilding now. Here’s the thread:

-

Designing A/C System Using Other Cars Parts?

@gotham22 posted photos of some places where things for the AC go through the firewall on my build thread if that helps. https://www.classiczcars.com/forums/topic/51541-1973-rebuild/?do=findComment&comment=645520&_rid=30168 You should only need one wire, though, that goes from the AC thermostat switch to the pressure switch and then to the compressor.

-

Black out areas

Awesome! Thanks. I can probably do it tonight then.

-

Black out areas

@jfa.series1 Any specific paint recommendations? I have single-stage paint in all of those areas so I am hoping I can use something in a rattle can and be done with it.

-

1973 Rebuild

It’s far more complicated than “copper is better than aluminum.” Yes, a chunk of copper transfers heat better than a chunk of aluminum. However, if you look at computer heat sync design, you’ll see that they frequently use a copper base to pull heat out of the devices, but then have aluminum vanes to radiate the heat because of aluminum’s ability to transfer heat to the air. I don’t know the science in this, but I have read in a handful of places that copper is better at absorbing heat and aluminum is better at expelling heat. That might be suspect, but it might be true. Also, copper radiators are tin soldered and aluminum radiators are brazed/welded with aluminum. Tin soldering inhibits the heat transfer between the copper pieces, reducing the overall efficiency of the radiator as a whole. Welding doesn’t introduce this problem, so that brings the net effect closer together. Additionally, aluminum is stronger, which allows manufacturers to use different designs and to have denser tubing throughout the core, not to mention parallel flow vs serpentine, etc. A copper radiator made the same way would weigh 100 pounds. Add into that the quality of the manufacturing and you are 100% precluded from saying a copper/brass radiator is always better than an aluminum one. I already know that (on a test bench) a Koyo cross flow is more efficient than a copper 3-row, and that is because of the design. But that doesn’t mean the Koyo is the better option. The fact that it can’t take a shroud negates some of that better design and manufacturing. But people still rave over their Koyos, which is why I am looking for real world experience with Champion vs Koyo. So if we could get back on topic and look at the performance of specific radiator models against each other I would appreciate it.

-

1973 Rebuild

https://www.hotrodhotline.com/md/html/aluminum_vs_copper.php

-

1973 Rebuild

Okay, I know versions of this question have been danced around for a while but I’m having a hard time finding real information on it so I’ll risk the ire and ask it anyway: Has anyone compared the cross-flow radiators (Koyorad or MSA) to the 3-row radiators at Z Car Depot and MSA with a shroud? I’ve been going back and forth on this for a while and have seen speculation but I don’t think anyone has gone directly from one to the other and captured the results. Most of what I’ve found on this site and Hybridz is discussing going to one of those options from the factory radiator. Right now I can get a Koyorad cross flow with the correct cap for $427.74 (plus tax and shipping). I can get the 3-row from MSA $362.67 (plus tax and shipping). I think Champion makes these. They also have the 2-row high flow, but I’ve never seen anyone talk about those. That would cost $352.57 (plus tax and shipping). I think this is also from Champion. The Koyorad is cool and I’ve seen a ton of anecdotes about it cooking really well. Everyone who posts about theirs seems to love them. I’ve seen a ton of horror stories about the Champions leaking after a year or two. Based on that I was about to pull the trigger on the Koyo, but I really don’t like that it can’t take a shroud. I also don’t love how far down the bottom of the radiator comes and that they don’t have a drain plug. I won’t complicate things by mixing the options at Z Car Depot into this, because I think those are mostly the same as the ones at MSA (except maybe the “Ultimate” one, but I’m not spending $669 on this). If anyone has done actual comparisons between these, either by swapping from one to the other, by installing them on multiple cars, or through some other means of getting info about their performances, please chime in. Oh, and then there’s always the CSF brass/copper option… 🤪

-

1973 240z Custom Wiring From Scratch

Finally. The engine harness took me forever for a number of reason, but the main one being my earlier indecision on electric fans. I spent a ton of time trying to figure out where to put the relays (and the AC drier) in the car and how to protect them from the elements, only to realize that I am better off sticking with the mechanical fan for my purposes. Hear me out… 1. From what I’ve been able to find on the internet, the mechanical fan draws somewhere around 3,400 CFM at cruising RPM when below speeds that the fan clutch disengages and lets it freewheel. The best drawing electric setup I could find was two 12” High Output Spal fans that, together, would get me 3,740 CFM at optimal conditions. That’s great but they pulled 100 amps EACH when they start and 40 amps each when they run. The next best (strongest) option without the electrical consumption issue produced 3280 CFM. When I make changes I’m looking for better than stock. 2. If the mechanical fan really only saps 3-5 horsepower, then the simplicity, lower cost, and reduced wiring is more desirable than that gain. Yes I have a 100 amp alternator, but I don’t want to tax it more that I need to. 3. I am not a fan of the radiator shroud options for electrics. Anything that isn’t just a flat sheet reduces the clearance between the fan and the engine because the fans are all surface mounted. The mechanical fan protrudes into the old school shroud, and I can get a fiberglass replica at MSA. I did find an OEM metal one but it has been cut in two places and I think the guy wants too much for it. However, the reason I kept going back and forth was I do like that electric fans can pass more air over the radiator at a stand still than the mechanical one because they are governed by the engine temperature rather than the engine speed. I figure that I can always put a 1630 CFM pusher fan on the AC condenser if I start having issues later, or I can always change this later if I have issues. The engine harness is together, I have the connectors on the interior side, and now I can go on to adjusting the positions of zip ties that set up the the harness branches, which I hope to have done by a week from now. @billgtp, thanks for the photos! That was super helpful

-

1973 240z Custom Wiring From Scratch

Okay, I have a real dumb question, but seeing as my car was not put together when I bought it and I can’t find photos of this, I feel like I can ask anyway… How are the wires connecting the engine harness to the headlights routed? I don’t see any holes forward of the radiator support that go to the area behind the headlight bucket. The only thing I can figure is they go under the frame and then back up u set the fender, but this seem awe fully exposed to the elements. If someone could take some photos of the correct routing I would appreciate it.

-

Possible to Swap 280ZX condenser into 280z?

I have to double check the measurements, but I think the vintage air 12x24 would be a better fit for a 240z. 13” seems to be the max height and nostalgic doesn’t have one wide enough but also that short. https://www.vintageair.com/custom/product-pop.php?pn=037033

-

Possible to Swap 280ZX condenser into 280z?

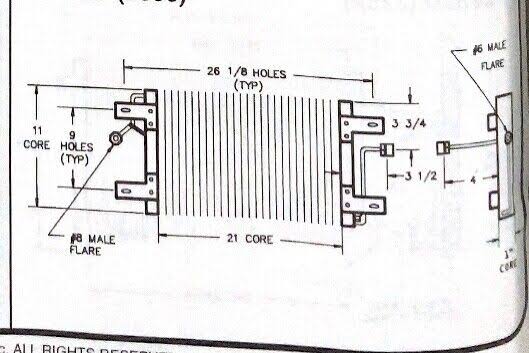

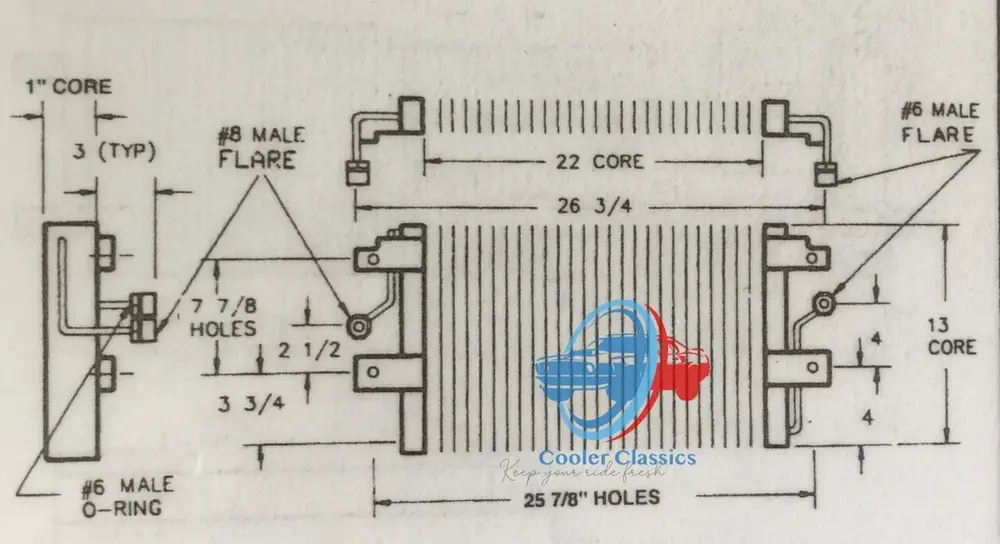

@Muzez, did you ever do this? Sorry to revive a dead thread, but I think the original question is an important one. I haven’t seen anyone confirm that a S130 A/C condenser fits into an S30 of any year. I’d like to know if one would fit in a 1973 240z. I’ve found the dimensions in inches for the 1979-81 280zx version: If these or the 260/280 versions fit I may get one of these: https://www.originalair.com/81-83-datsunnissan-280zx-parallel-flow-condenser-high-performance-parallel-flow Update: I found the dimensions for the 260z 2x2 and 280z 2x2 Condensers. I am speculating that the 260z had the same geometry as the 240z for this. 260z: 280z:

-

1973 240z Custom Wiring From Scratch

I was wondering if I had the light wires backwards.

-

1973 240z Custom Wiring From Scratch

-

1973 240z Custom Wiring From Scratch

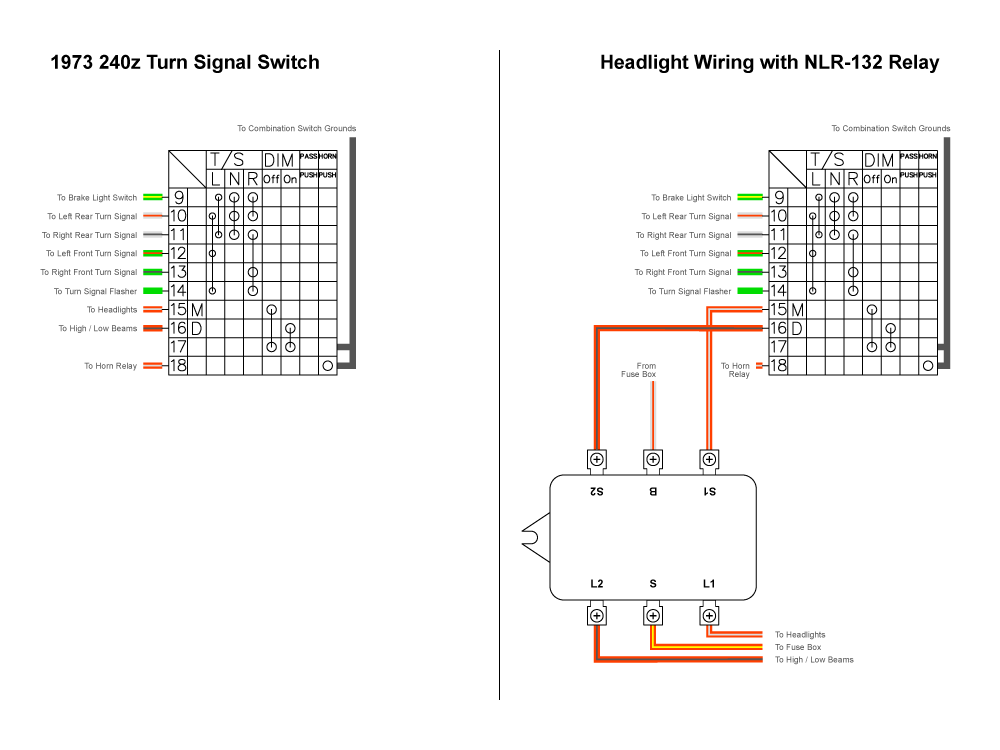

Made some good progress on the engine harness today. Im hoping I’ll get that done this weekend. Deleting the circuits for the voltage regulator and the throttle opener and all of the related bits freed up a fair number of terminals in the colored connectors. I contemplated consolidating them but decided against it. Better to stick with the factory positions for each wire, even though I made my own diagram and labeled everything. I also decided to hard wire the fuel pump A and B harnesses into the engine and dash harnesses rather than have so many connectors. With the increased wire gauge, AC, and extra relays under the dash I need all the space I can get. No pictures today. It just looks like piles of wire right now. Oh, by the way, @SteveJ, does that relay you posted need anything special due to the negative switching on the headlights? I read somewhere that it has a common ground on the signal circuits, which makes me think it would have to be wired differently than it may be design to be wired.

-

1973 240z Custom Wiring From Scratch

I’ve seen relays like this in some build threads for various domestic cars I’ve seen around. Could be a good way to go. At the moment I am considering putting my relays in the space where my radio used to be. I was planning to have a box there for my phone but I might be able to do both. Edit: It seems that there are many manufacturers of the NLR-132, but I think the original (and probably best quality) was made by New Era for the JDM. I see a few floating around obscure corners of the internet but nothing easy to acquire without an importer in Japan.

-

1973 240z Custom Wiring From Scratch

I have been struggling to design a relay box that could fit where I want it to go and contain everything I want in it, but this morning I had an epiphany. If I can get the relays I am adding for the lights under the dashboard I don’t have to worry about it. So here’s my question: Has anyone figured out how to squeeze four more relays under the dash without them being seen? Keep in mind I have an air conditioning evaporator under there already so I think most of the space that would be there normally is already gone. I’m wondering if it’s possible to rebuild the relay board on a sheet of ABS to fit in the original location but fit 4 more relays. I’m going to look into that. If that’s not going to work I need to find a new spot in the engine bay which I don’t like.

-

1973 240z Custom Wiring From Scratch

Very cool! Where I’ve netted out on this is as follows: I am going to punt on the decision to go electric or not until I am closer to starting the car. In the mean time I will build the provisions for an electric fan into my engine harness and if I don’t use it I’ll tuck it away.

-

1973 240z Custom Wiring From Scratch

Update: I made a major decision to scrap the electric fans. After much digging around I had three major issues that were not insurmountable but we’re hanging me up and not really worth the effort. 1. I could not find a relay module that could handle 40 amps and had a provision for 6 relays (headlights, parking lights, and fans). I found some from MSD that can hold 1, 2, or 4, and I could gang them up, but it was getting sloppy. On top of that the extra wiring was not appealing. 2. Making sure that I was pulling at least as much air as the mechanical fan was also starting to become a mess of options and getting a fan shroud that works with the various radiators I am considering, fits fans that pull enough air (>2,800 CFM total) was not impossible but was giving me a headache. 3. Buying everything necessary to do an electric fan setup is more expensive that replacing my mechanical fan (or refurbishing my old one) and having been out of work for seven months now, I can justify that. So, I am probably going to get a new fan and clutch, buy a fiberglass fan shroud from MSA, and call it a day. Now back to our regularly scheduled programming.

-

1973 240z Custom Wiring From Scratch

Looks like the electric fans MSA and Z Car Depot are selling are pulling between 10 and 25 amps. I’m going to look further but I’m speculating that 12 AWG would be sufficient if those numbers are accurate. However, if I need to go above 30 amps, the tech rep at Eaton recommended this stand alone relay/fuse power relay module they make. https://www.eaton.com/us/en-us/catalog/emobility/series-37700-pfm-prm.html

-

1973 240z Custom Wiring From Scratch

Good point. The search continues.

-

1973 240z Custom Wiring From Scratch

I haven’t decided if I’m going to get the LED headlights yet. I may go with H4s and driving lights, so I want to be able to handle that. This is mostly because I don’t want to cut the headlight cups behind the bulbs to fit the LED cooler. I am doing an electric fan so I’m going to need those 40 amps. That’s how I got on this train of thought. But I did find some 40 and 50 amp micro relays today. I’m going to see if Bosch makes any and then see what the reviews look like.

-

1973 240z Custom Wiring From Scratch

I have hit a snag. I was going to get a busman relay box with fuses to go where the voltage regulator was, but I’m realizing that between the electric fans, the headlights, and the parking lights, I would have six relays, which is going to get pretty big. The little busman box I was looking at only has room for five micro relays, but the relays in the upgrade harness are 40 amps for the headlights and I’m not seeing any micro relays that go that high. So now I am rethinking this whole strategy. I could keep the relays for the headlights and parking lights on the upgrade harnesses, but I am not sure where I will secure them and they wouldn’t be covered. I could get a bigger relay box, but I don’t know where to mount it. I suppose I could forego the fuse in the box and use a box just for relays and have inline fuses as they are in the upgrade harnesses now. What do you guys think? @SteveJ, I’m interested in your opinion on the best brands for relays as well.

-

1973 240z Custom Wiring From Scratch

Rad! Thank you. I had no idea what they were called.