Everything posted by inline6

-

Parts for Sale: 16 X 7 zero offset Panasport Wheels (two) - great condition

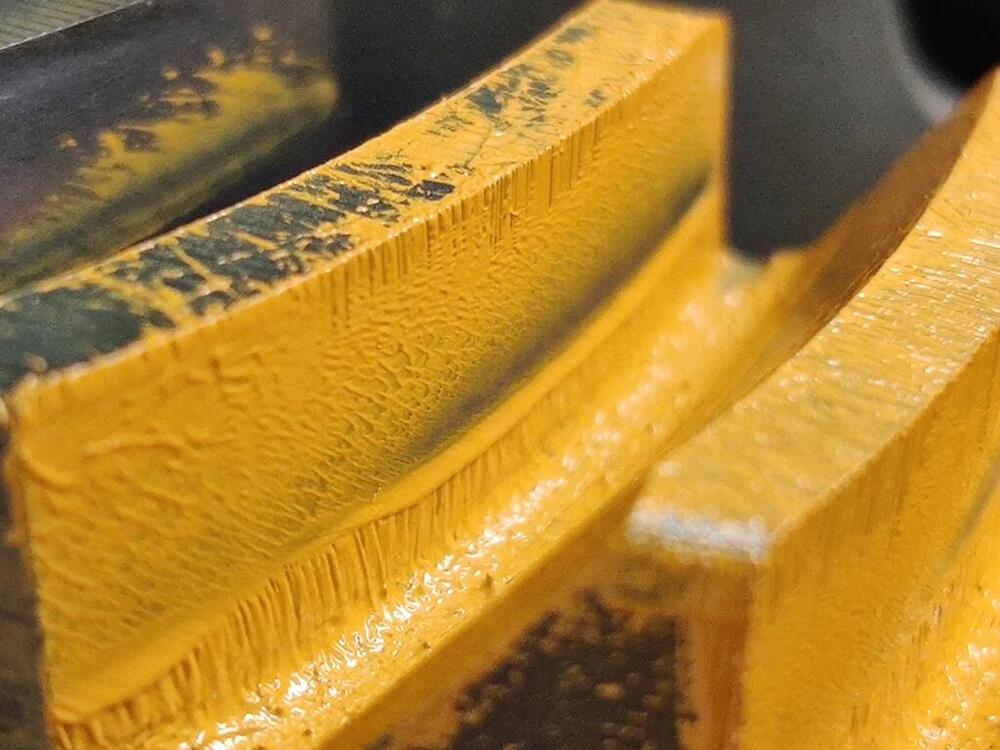

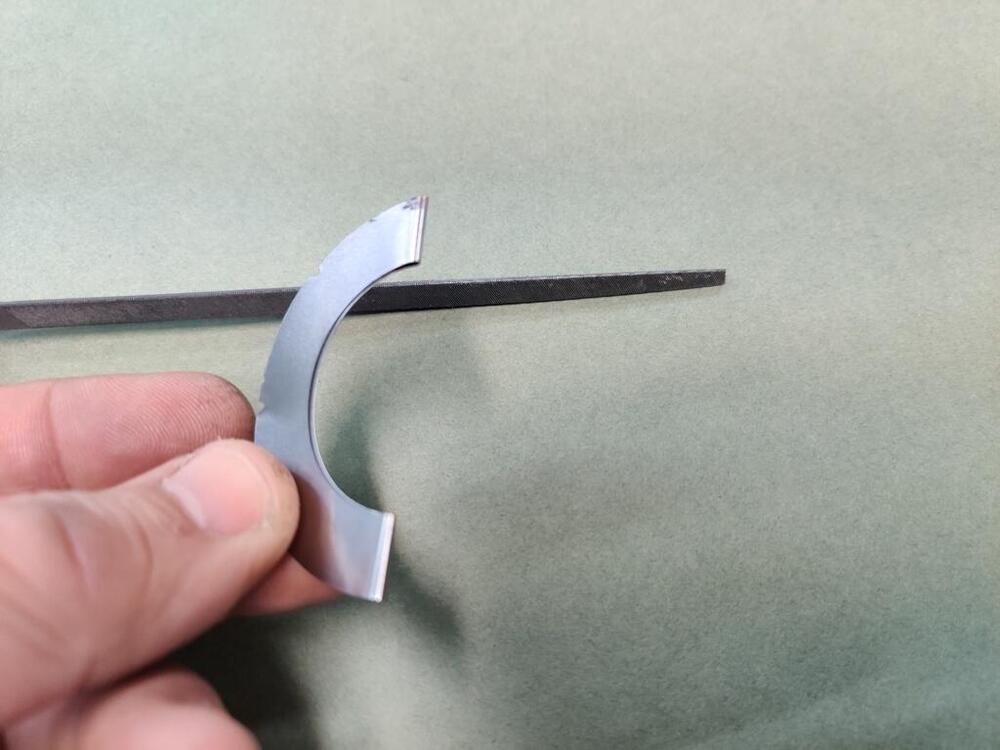

View Advert 16 X 7 zero offset Panasport Wheels (two) - great condition I have two of these for sale along with two new old stock center caps. The wheels are in great condition. One of them has a light scrape on the outer edge, which I dressed lightly with a file (pictures of before and after included here). It is about 1/2" or so long. A couple of paint chips here and there. They still have the stickers on them from new. The wheels are boxed up and ready to ship. Price is $450 plus the cost of ground shipping to you. Advertiser inline6 Date 02/08/2024 Price $450 Category Parts for Sale

-

1971 HLS30-14938 "Lily" build

Hmmm. I wonder if it is a permissions thing. I will have a look to see if I can resolve. Evidently, there are no permissions levels that are suitable to allow others to expand the sections. So, I have opened them all up.

-

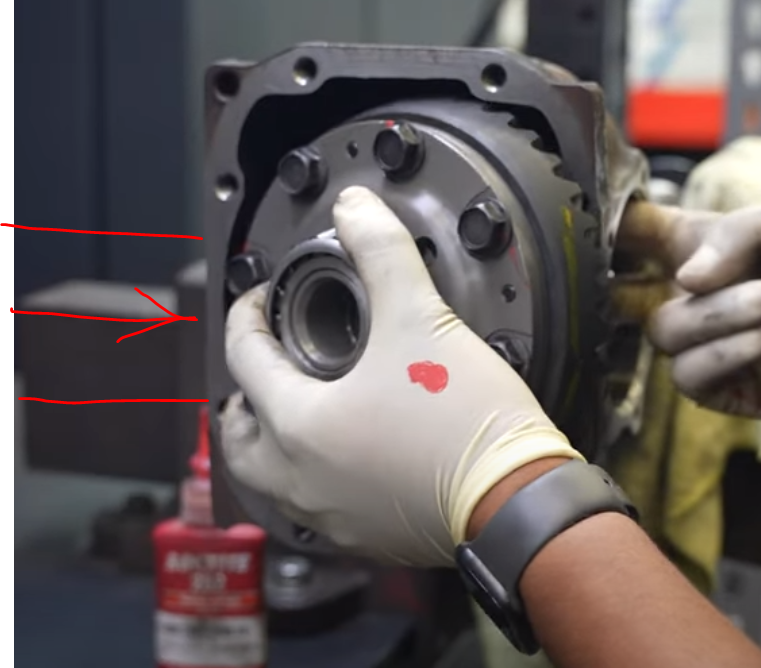

Quaife LSD Installation in R180 - With Questions About Installation Also

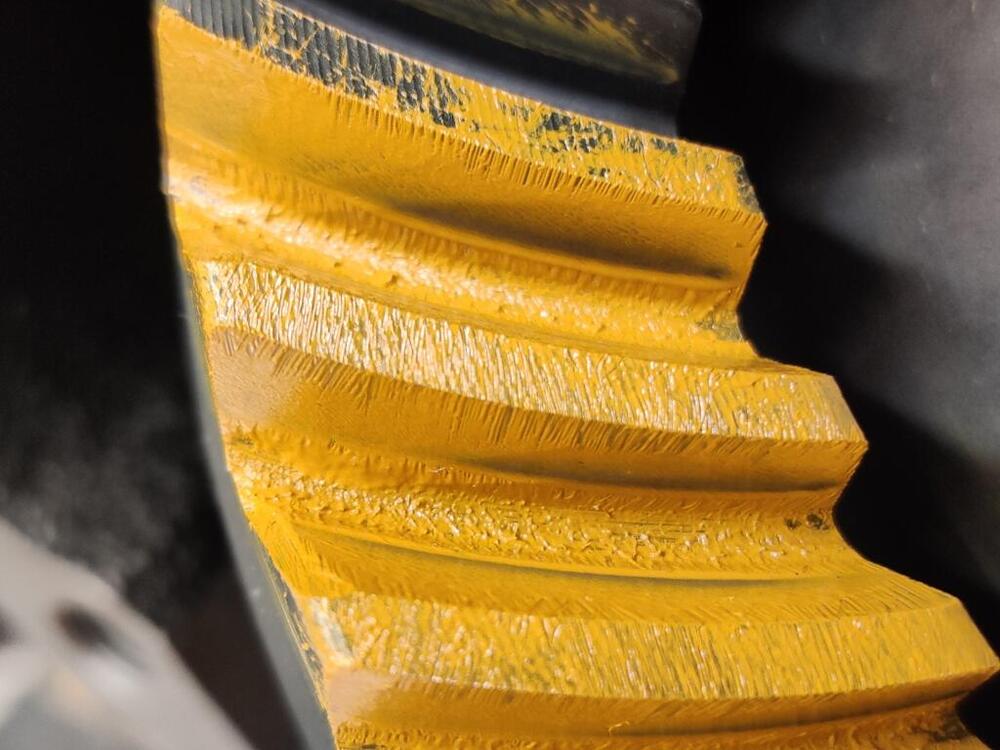

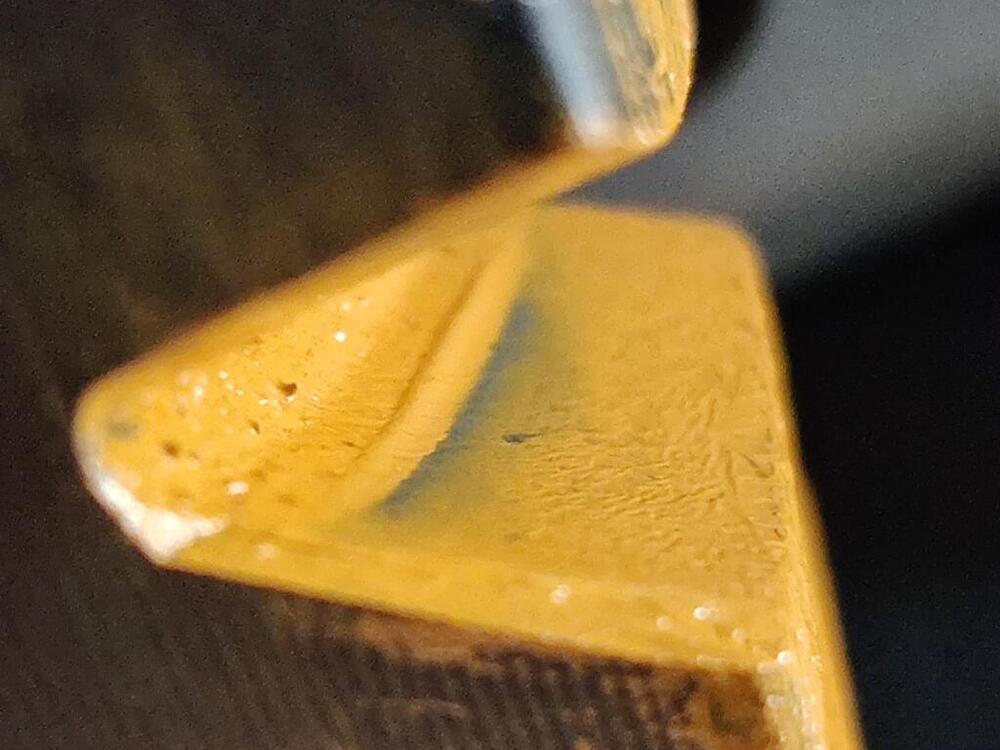

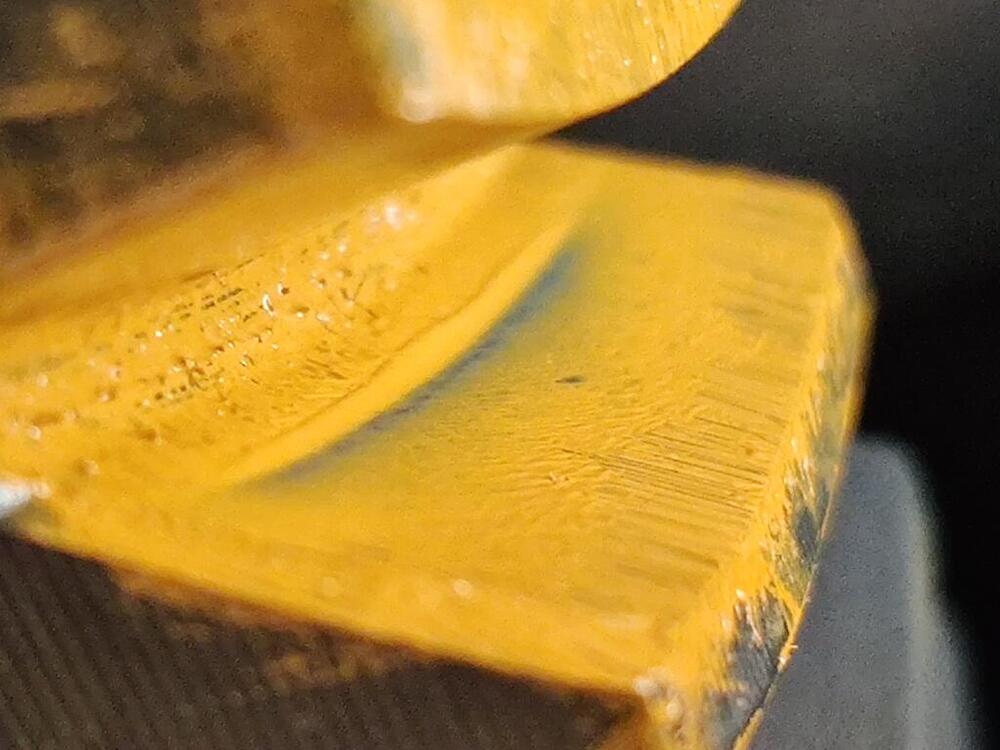

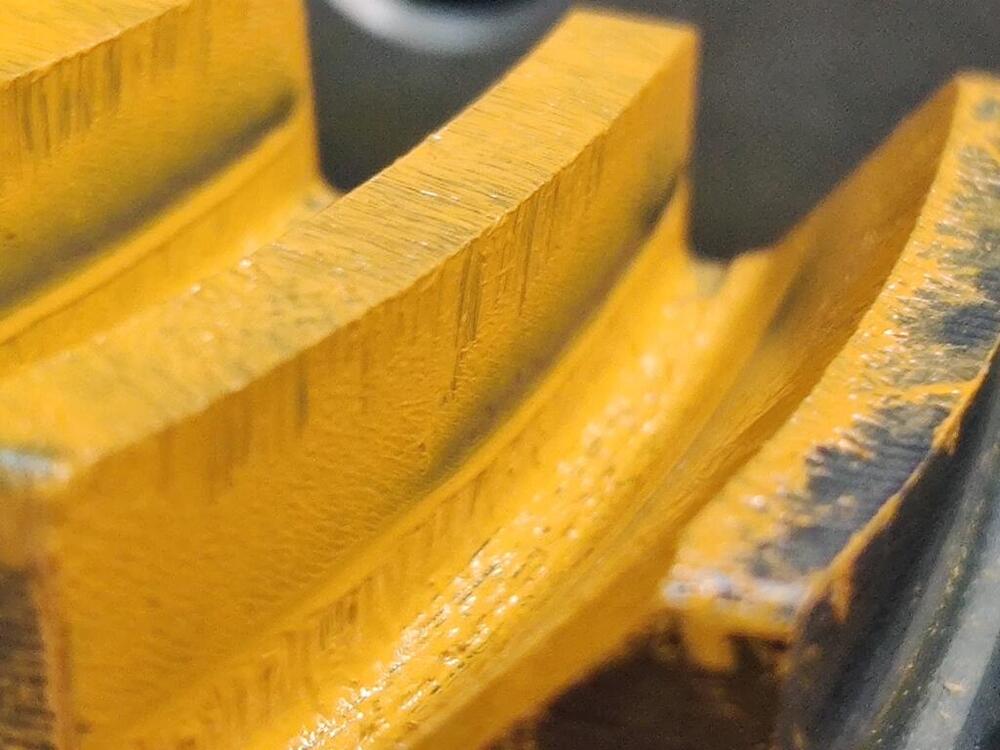

The contact patterns are looking very close to optimal to me. I think I need to experiment with something between .015" and .020" of extra shim thickness to see if I can move the patterns on the drive and coast side to be closer to the same contact area on the tooth. Right now the coast side is a bit more towards the heel and the drive side is a bit too close to the toe. I hope pressing the bearings on and removing them from the pinion gear this many times is not causing any issues.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Another round. This time, I only shuffled some side flange shims. I removed the .3 mm from the left side and replaced it with a .2 mm. Then, I swapped out the .4 mm on the right side for a .5 mm. So, the right side has 2 .5 mm instead of a .4 and .5 mm. So, with the OEM shim, + .020" of extra shims and the side flange shims as just described, the back lash was a touch over .006". I put the marking compound on thin again with brush strokes the same as before: One pic showing wipe patterns on both sides of the ring gear teeth: And the rest - note that beyond the obvious displacement of the paint that reveals the tooth surface, the brush strokes are "erased" further out, indicating possible tooth to tooth contact there (or super close proximity) as well.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

That is the one I got.

-

Restoration of BringaTrailer 240z - HLS30-35883

@dutchzcarguy - I measured 3.4 ohms of resistance. Yay! Tonight I put my focus on testing fit of the front bumper. I made note of asymmetric fit a long time ago and though I worked on it some to address that at the time, I want to resolve the issue completely before sending it off for re-chroming. While it looks pretty close, the bumper curve matches the curvature of the body on the the right side well and on the left side not as well. Those two picture show the difference pretty well. The curvature of the bumper on the left side of the bumper is less than the curvature of the body, causing the bumper end to stick out a bit. I double checked the left vs. right center alignment of the bumper. It is within an 1/8th of an inch of being centered. I checked the bumper mounting brackets for symmetry and that is good. So, I will see if I can work the left bumper end a bit to tighten the curve. I think it likely that the upper and lower surfaces on that end just need to spread a touch further apart. Doing that should tighten the arc. I also have been working on the original rear bumper. Pictures don't really capture what the issue is. This car was tapped in the rear, and the center bumper bar was "re-shaped" a bit during that impact. In this picture, a new old stock bumper is on the left and the original bumper on the right. If you look closely, you will see some of the rear "face" of the original bumper (on the right), especially in the center of the bumper bar. It also has less curvature over its length when comparing to the NOS bumper. When it was hit from behind the center of the bar was twisted... downward. I have been working it to restore its original shape using the NOS bumper as a guide. Generally, this involves using my hydraulic press and some pieces of scrap metal which I use to clamp the bumper in place. Then I beat on it with a hammer to attempt to reverse the "twist" it has. I also use the scrap metal as spacers, and use the press to push on certain areas to work curvature back into it. When looking at the picture above, I will be happy when I can get that rear face to not be visible at this same viewing angle. The curvature also needs to be restored to mirror the NOS bumper section on the left. Both the original bumpers are quite rust free, so I feel they are worth the time and effort to straighten. I also want to get the shape right before sending them to the plater. Then, they can focus on banging out the little dents, and grinding and straightening to remove the surface imperfections. I will be sending the original rear and the NOS rear bumper pieces, and two front bumpers, as well plus one set of over riders for the front and one for the rear.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Perhaps. You can try taking close up pictures and using zoom to see if that helps.

-

Restoration of BringaTrailer 240z - HLS30-35883

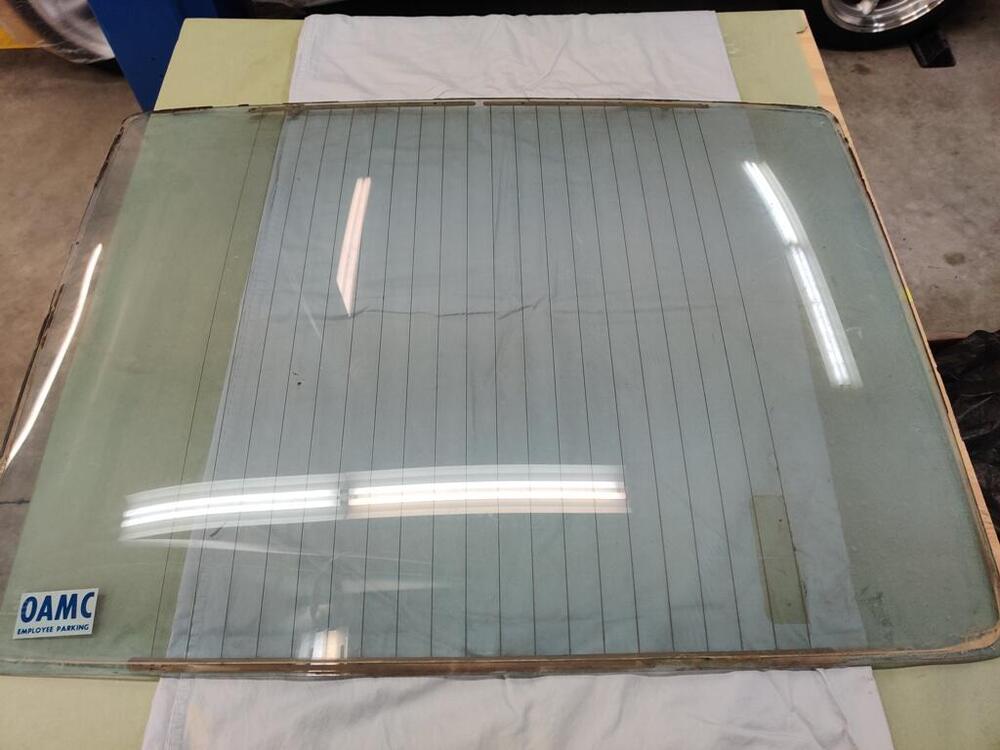

Hmmm. I will give it a shot. It looks to me like 2 to 3 of the lines off to one side of the grid have small gaps, but the rest looks good. Having a working rear defrost isn't a necessity where I live, but it would be nice. The other glass has more damage: more scratches and some kind of metal looking rub mark on it that won't come off.

-

Restoration of BringaTrailer 240z - HLS30-35883

I forgot to mention that I spray Windex on the body of the car before putting the quarter windows in place. It lubricates the area so the rubber doesn't fight your attempts to compress it as much.

-

Restoration of BringaTrailer 240z - HLS30-35883

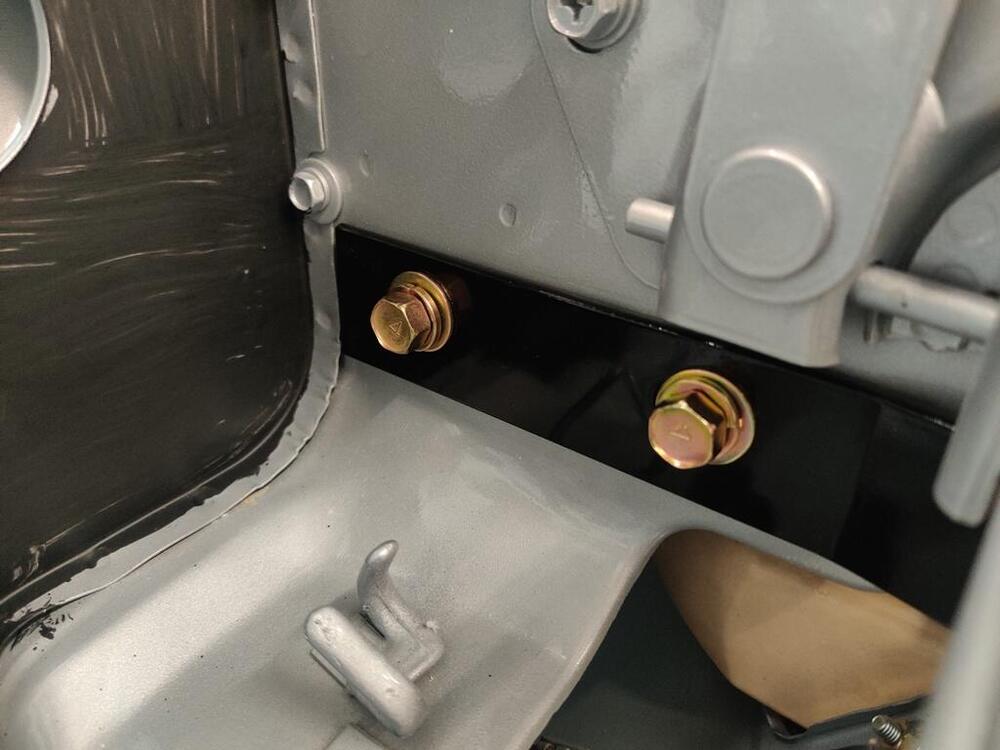

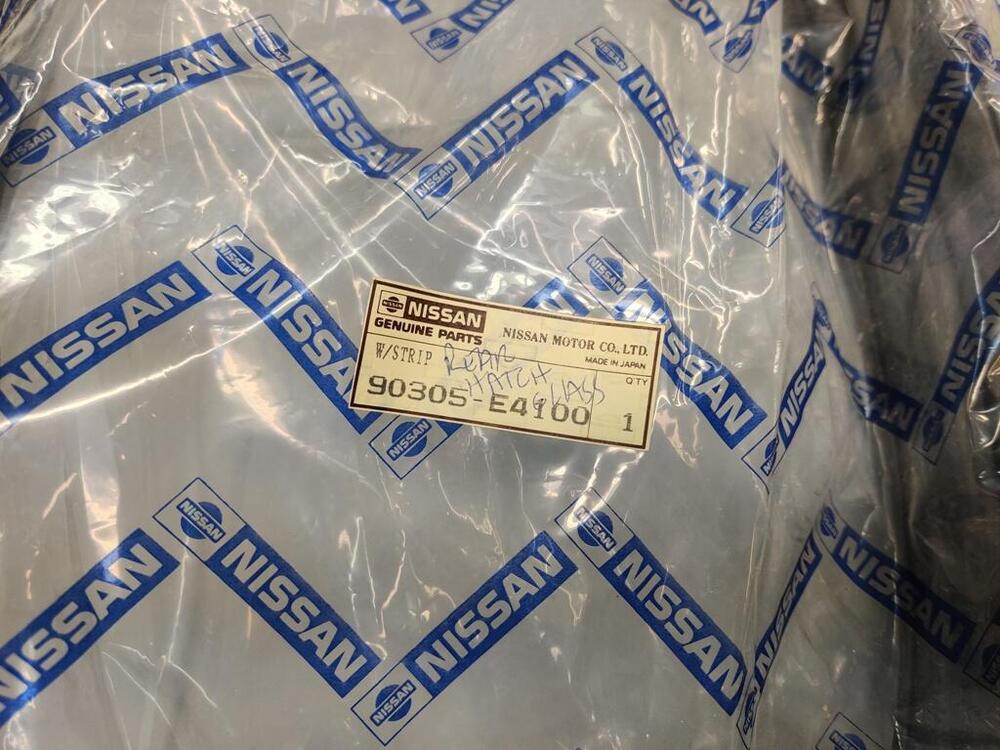

I was able to install the quarter windows this past weekend. I don't have quite enough door gap yet on the left side (last pic). I will let the weather strip that goes between the quarter window and the body compress a bit over a few days, and then attempt again to push it back a bit more away from the door frame. These windows can be difficult to install. I find the best way to do it is to angle the back part of the window out from the fully seated position, and secure the window with the two front screws first. Angling the back of the window out allows a bit more rearward movement. Once the two front screws are in, tighten them to snug while pushing the window back as far as it will go. You may have to push back pretty hard just to get the front bolts to align and thread. After snugging the fronts, push the back of the window inwards and thread the back two bolts in. Then snug those. If still too close to the door, wait a day or two and then loosen the screws, push the quarter window back further and retighten the screws. After I put these in, I shifted over to the rear hatch glass. I actually started cleaning up the wrong one at first. It was a spare that came with the car when I bought it. But, the etching showed July of 71, so I switched to the correct one, which shows May of 1971 (dot above P in TEMPERLITE (month) and S in ASAHI - year. A couple of tips for cleaning windows... Using a window scraper and fresh razor blades is very helpful to get the glass clean of dirt and grime. It will not scratch the glass not matter how aggressive you are with it. I find a razor blade is very effective for removing "rain spots" or other stuck on "hazing" from dried water. You may have to go over it many times, but it is pretty amazing how effective it is. For final cleaning of "hard water deposits" #0000 steel wool is the ticket. Again, the steel wool will not scratch the glass, and it is necessary to remove the final remains of hard water spots. Also, when you are trying to get the inside of the hatch glass that clean, you can't use a razor blade and scraper unless you want to gamble with damaging the defroster lines. Again, using the steel wool, you can go directly over the filaments. It does a great job of getting stuck on crude that cleaning does not remove. Finally, I wrestled with installing the rear hatch weather strip. I did not expect it to be so difficult, but after about an hour I was able to get it on, but was a bit worn out from the effort. 😁 I also made some notable progress with the issues I have been having with the differential. I am looking forward to getting that done, so I can install it and all the things that are being held up by it.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

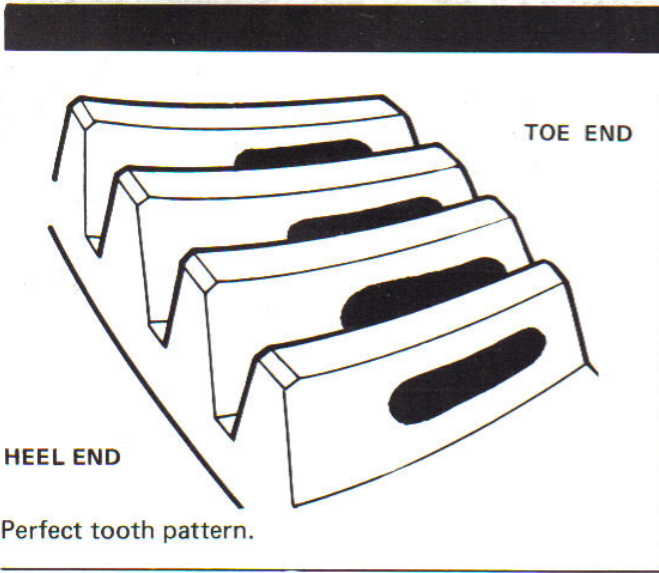

On Sunday, I took the diff back apart and reassembled it with .020" of additional shims instead of going back to the .015". The reason for the change? I just figured I'd learn more if I tried something I had not before. First, one pic showing the wipe pattern on both drive and coast sides at the same time with the .030" of shims: Note the wipe patterns are offset. You see it is to the left on the coast side and to the right on the drive side. Ideally, the contact would be in the same area on both sides of the teeth. Now a pic after switching to .020" of extra shims: Ha HA! This is better. With .020" of extra shims, and the .3 mm shim on the left and .4 mm and .5 mm shims on the right, I measured .009" of backlash. When I tried to switch the .3mm shim to the right with the other two, I noticed that everything was bound up as I was tightening the side flange bolts. I was careful to not tight them all the way as it was clear that I had zero backlash. So... I think I am very close to the correct pinion shim size now, but I am thinking I may need to alter the side flange shims a bit to get the backlash within factory spec. Time to order some more side shims to experiment with. More pics of contact pattern with .020" of extras shims - I have been putting the paint on thinner so it is easier to see the pattern:

-

Quaife LSD Installation in R180 - With Questions About Installation Also

I will never know for sure. However, I got the timing chain off by one tooth (it has a Kameari chain tensioner set up) and the valves contacted the tops of the pistons for a few minutes upon start up while it was like that. I corrected it, and went to Road Atlanta for a track day a week or so later. During the fourth and last session, I had a rod bearing, and then rod let go at over 100 on the main straight. That block had holes on both sides when I pulled it out. According to another Z racer, turns 6 and 7 do a number on cars that run there. He has an Accusump in his Z (and an 8 qt Nissan Competition oil pan like I was running) and he said he sees the Accusump "working" on that part of the circuit, meaning oil pressure is dropping under the high G load.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Dropping the clutch for launching will have to be handled by my other Z - when I am in that mood 😉. I have a replacement engine for that one sitting on a stand and a few other upgrades planned before I can fire that beast up again. It will be worked on this year for sure. This is the old engine, which I broke at Road Atlanta back in August of 2015: This is the new one: This new engine is very similar to the one I destroyed. Changes include an 89 mm bore, (is now a 3.0 liter vs. 2.93 before), same cam and valve train except intake valves are titanium this time and were stainless steel before. And this time the crankshaft not lightened and knife-edged, but it is still offset ground and combined with eagle rods to get to the 3.0 liters. This new engine will utilize a dry sump oiling system. But, I digress...

-

Quaife LSD Installation in R180 - With Questions About Installation Also

I worked on the differential again today. I was surprised that upon taking the carrier out for about the 15th time, it "fell into" a different spot, I was able to remove it from the case with "more than enough" clearance where I had ground the case on the left side. I feel like an idiot - I didn't have to grind as much of the case as I did. Anyway, I'm not going to think about it anymore. I'm not going to be abusing this car, so hopefully I won't have a problem with the case where I ground it. If I do have a problem later, at least I will have the experience behind me of how to assemble one of these properly. I put another .015" of shims onto the pinion gear, added to the original .126" shim and the .015" of shims I had already. With .030" of additional shims, I assembled everything again. I put the side flange shims into their original positions. I measured back lash at just under .009". Disappointing. It will need to come back apart and more shimming experimentation performed. ☹️ I went ahead with checking the wipe pattern. This time, I made the brush strokes perpendicular to the gear teeth, so it would be easier to see where the gears contact each other. Drive side and coast side, respectively: Drive side: Coast side: I learned today that when meshing the gears together to check the wipe pattern in the paint, there needs to be a light load of resistance. In other words, when turning the pinion gear to drive the ring gear in the direction to move the car forward, dragging on the gear with one hand loads the ring gear teeth against the pinion gear teeth to show the pattern better. If you don't load the ring gear, the gears "float" a bit more and leave a less visible impression in the paint. Same is true for rotating backwards. Apply some drag with one hand to load the ring gear against the pinion to make the pattern more visible on the coast side. I think I see what has happened here since last time. This time, the contact area on the coast side has moved more toward the heel end (outer edge) of the ring gear. And, it looks to me like the contact area on the drive side has moved a touch more toward the toe end of the gear. If the pinion is either too "short" (needs to be moved toward the ring gear) or too "tall" (needs to be moved away from the ring gear), the wipe pattern will not be in the same area of the ring gear teeth on both the drive side and the coast side. If the pinion is too "short", the contact area will be more on the heel of the drive side, and more on the toe of the coast side. If the pinion is too "tall", the contact area will be more on the toe of the drive side, and more on the heel of the coast side. So... I think I have too much pinion shim now. Looking again at the pics from last time (.015" additional shim, and all three side flange retainers on the right side, which resulted in a backlash of .005"): I think the contact area is more centered on the coast side (first two of the three pics above). And I think the contact area is a touch more toward the center of the drive side as well. I think what I will do from here is go back to the previous set up. Regarding the contact area appearing lower toward the base of the tooth, I think that putting a load on the ring gear may help to show more clearly that the contact is actually more centered than it looks in those pics from last time. The second pic above gives me hope. We'll see. Also important to note is that there is some additional flexibility with the pinion shims. Right now, I have a .3 mm on the left and a .4 mm and .5 mm on the right. They are sold in the following mm sizes: .2, .25, .3, .4 .5. As long as the combination I use adds up to 1.2, I will keep the pre-load where it needs to be. So, these are equivalent options, but move the ring gear toward the pinion differing amounts: .2 and .5 + .5 .25 and .25 + .2 + .5 The learning continues.

-

KAAZ R180 LSD fit problem

Ummmm... well, I found out today that I didn't need to grind that much. Yeah, I didn't realize until today that I ground more off than I needed to. As I was taking the carrier out today, it "fell into" a different location, and I was able to "make the turn" as you say. I feel like an idiot now. Hopefully, I haven't ground too much as to weaken the case and cause an issue. The key is to butt the ring gear up against the right vertical wall of the back of the case, and then rotate the carrier as you push it in.

-

Courtesy Nissan Parts Online - New Address

Not a problem. We do have a lot of work to do. FYI- the Nissan folks are subsidizing a promotion for the entire month of Feb: "From 2/1/2024 through 2/29/2024, we’re offering Nissan owners 15% off select genuine Nissan parts and accessories* & free shipping on orders over $75 with the code FREESHIP.** "

- Jute patterns tunnel & floor mat

-

Welding advise needed!

The tab thickness is .7 mm or .028"? What is the thickness of the panel? You are getting nearly zero penetration into the panel to which you are attaching the tabs? What is your wire speed? Is the panel prepped to bare metal where you are attempting to attach the tabs? Are you starting in the center of the hole, on the panel, or at the edge of the hole in the tab? Do the former, not the latter. Trigger, and then stay in the center of the hole in the tab - on the panel only, as if just trying to put a blob of weld on the panel portion. As that builds, you can move out out of the center of the hole and "pick up" the edge of the tab. When you do, the tab metal will melt (quickly) and pull the "blob" you started in the middle of the hole - the molten metal of what you started on the panel and the molten metal of the tab will join. Following this technique will maximize time on the thicker panel portion, and should help with penetration on that panel. Another idea: How big is the diameter of the hole in the tabs? If I still couldn't get good penetration to the panel with the above technique, I'd consider making the hole in the tab larger and repeating the technique above. Looking at your pic, the holes can be enlarged without making the edges too thin. You need to get the panel hot enough first, then slide to the tab which will melt much quicker by comparison. A larger hole in the tab will allow you to buy time "pre-heating" the panel, which equates to better penetration.

-

Courtesy Nissan Parts Online - New Address

LOL. Yeah. We have an endless amount of work to do, but we try.

-

KAAZ R180 LSD fit problem

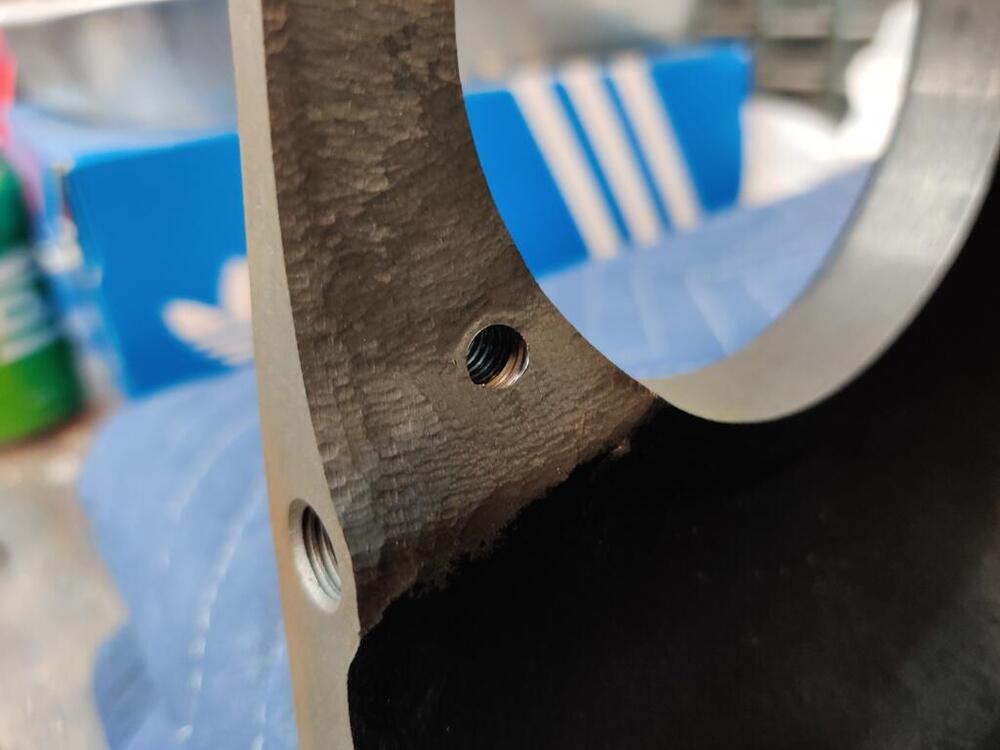

Hi Jeff, Just glancing at the pictures you provided, it looks to me like this area on the Subaru case is much thinner than on your case: I had to grind extensively to get the Quaife unit to fit. On the right side, I ground a little bit, and then made deep depressions to allow a couple the bolts to fit in "wells": On the left side, I ground more extensively, so much so, that I broke thought to the side retainer bolt holes. I spent hours with a die grinder. I would test fit, and knock lsd into the case lightly to make marks... which I then ground away. Again and again I repeated that process until the carrier went in. I also had to remove one of the ring gear bolts in order to get the carrier to slip in. After I determine the final shim size, I will assemble it one last time. During that final assembly, after the carrier slips into the case, I will need to torque that one last ring gear bolt through the side hole. Then I will be able to install the side retainers and finish assembly. The KAAZ unit may need similar approach.

-

Courtesy Nissan Parts Online - New Address

Just on the down low... I work for SimplePart - the company that provides the ecommerce platform that Courtesy is now using. 😉

-

Quaife LSD Installation in R180 - With Questions About Installation Also

I have two brand new R160 shims (I think) that are useless to me. I could hit one of those with the file also to see how it compares... or send you one of them to see what hardness it is? They are 3.5 ish mm thick. G

-

Restoration of BringaTrailer 240z - HLS30-35883

VIN HLS30-60325 is much later than my car, so no chance on the driver window. But if you see any other candidates, don't hesitate to let me know!

-

Restoration of BringaTrailer 240z - HLS30-35883

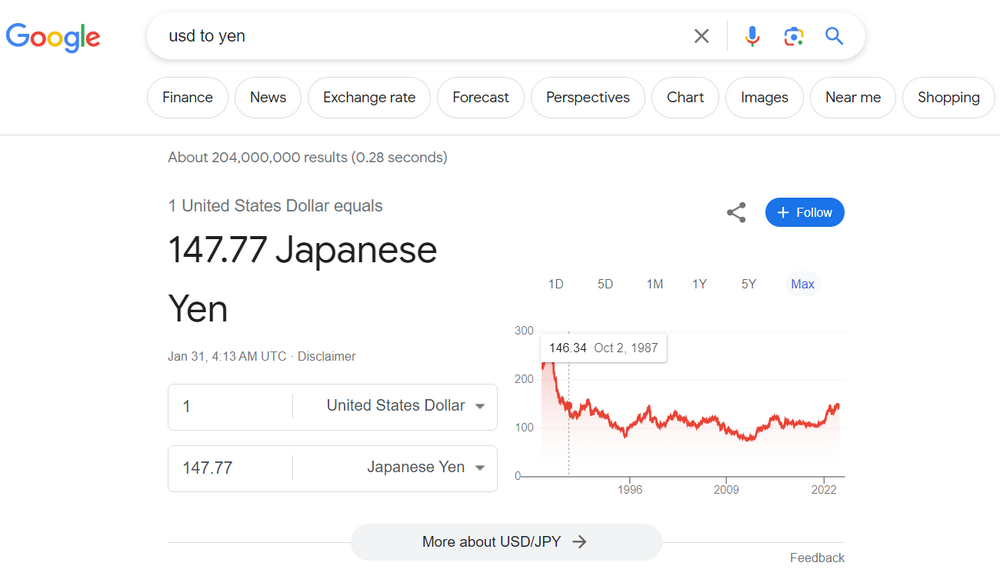

Today, I received some items I won from auctions in Japan. I use a third party, Jauce.com, to assist with the logistics. They handle receiving items... holding them until all are ready to export, and then packaging and sending them to me. There are many fees. There are bank fees when depositing funds. There are auction fees when you win. There are tax fees. There is shipping from the seller to the Jauce warehouse. There is the cost of shipping to the US. With all the fees and shipping, it can be difficult to determine whether what you paid was a good price. I thought it would be interesting to share a bit about my experience with purchasing and importing these items. The steering wheel is a "Nissan competition replica" - this one is wood vs. others available which are vinyl. I also got several genuine Nissan parts including a front set of front bumper rubber strips (the horizontal ones), a set of matching rear bumper strips, an ignition switch, a couple of window cranks, a horn pad for the steering wheel, and a clutch slave cylinder reservoir. Apparently someone made a batch of these replica steering wheels a while back, and you can still find them available in a few places. Generally speaking, without the horn button, you're looking at a minimum of $389 here in the US. Pair of genuine Nissan front bumper rubber strips are discontinued and no longer available - $200.84 with free shipping from eBay Pair of genuine Nissan rear rubber strips (the horizontal ones) $145 and $17 shipping from eBay and $66.51 plus shipping each from NissanPartsDeal.com Original Kanto Seiki ignition switch is available on eBay for $398 plus $19 shipping Set of two genuine Nissan window cranks $46.85 ($93.70 for two) currently, though they go on sale for about 15% off from time to time) plus shipping from NissanPartsDeal.com A genuine Nissan horn pad for a stock steering wheel - $310 on eBay and $269 plus shipping from NissanPartsDeal.com (but not currently available) A genuine Nissan clutch slave cylinder reservoir (old type) which is discontinued and no longer available Adding in all the fees and allocating the final shipping to the US. proportionately per item with the final auction price with fees included, here is what I actually paid: Replica steering wheel - $320.69 Pair of genuine Nissan front bumper rubber strips (NLA) - $96.46 Pair of genuine Nissan rear rubber strips - $109.77 Original Kanto Seiki ignition switch - $145.93 Set of two genuine Nissan window cranks - $63.16 A genuine Nissan horn pad for a stock steering wheel - $193.49 A genuine Nissan clutch slave cylinder reservoir - $21.30 A dollar buys a lot of yen these days, historically speaking, as can be seen from the graph below. The exchange rate is pretty much what it was back in about 1987. Something to consider!

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Welp... 😑 I thought maybe I was close to done with the shim issue until tonight. First came some shim testing. Folding one in half... and no spring back whatsoever. Then, I took a small triangular file and made a few strokes with meaning behind them. Even stacked twice as thick .010", four or five strokes was cutting through the shim pretty easily. Subjective... but not great signs based on the guidance. Then, I put the paint on the ring gear to check the wipe pattern. As a reminder, all three side shims are on the right, and backlash is .005". Start: Coast side - contact is at the lower portion of the gear tooth. A closer view and from a different angle of the same: And here is the drive side. Compare with the illustration from the Nissan differential manual: I am beginning to think that moving the pinion shaft toward the ring gear is not equal to moving the ring gear towards the pinion shaft --- as it relates to contact pattern. There is also as possible issue with cleaning the ring gear with WD40 - the paint may not be acting the same way as it was before with the perfectly oil free ring gear. I think my next step will be to remove the pinion gear yet again and take my best guess at additional shim thickness necessary to allow me to get about .004"/.005" backlash with the one left and two right side retainers in their original positions. Also, I am not comfortable with the hardness of these latest shims based on my observations today.

Subscriber

Subscriber