Everything posted by Zed Head

-

The Edited Banner

The big EDITED banner at the bottom of an edited post bothers me so much that I now leave all of my small mistakes in the post. Is this wrong? Can't even edit within seconds, without the banner.

-

My New Z

I would also read, a lot, before buying anything. There are many threads on this forum about seal kits that don't work right. Most of us, that are now happy with out seals, are using Kia Sportage seals, either from a wrecking yard or through the internet or Kia dealer. You can waste a lot of money if you don't research what you're buying first. Also, in that vein, there will probably be a time when your engine doesn't run quite right. You'll be tempted to make a quick diagnosis and buy more replacement parts, like fuel pumps, AFM's, ignition modules, EFI relays, etc. Don't do that without testing first. One purchase you could make today, that will pay off in the long run, is a decent multimeter. In a few months you'll be an expert in primitive EFI systems.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Thanks. It's the detergents that would be the issue, I suppose. Sludge. Browsing through all of the various oil container labels, and ad copy, and internet information, it's surprising that none of the companies can paint a clear picture of what someone with an old, pre-catalytic converter car can use to keep their old car engine in safe condition. Seems like there's an opportunity here. Not to mention all of the old cars with catalytic converters, What are they supposed to do? Valvoline seems to get closest with their VR-1 but even they can't simply address the basics of everyday use. Still called a racing oil, with just an insinuation that it's appropriate for daily usage. Pennzoil doesn't even have a link to their racing oil on the Pennzoil web site. http://www.valvoline.com/pdf/vr1_racing.pdf Somebody needs to just produce an "old car oil" and supply information about how they address the cam wear issue. With zero hype. That would be awesome.

-

My New Z

Nice. I kind of wish mine was the dark green, although my stealth brown probably saves me some traffic stops. The intake snorkel in the engine bay is stock. It's a dry spot. The air is moving and getting replaced in there anyway, so still "cold". If you park it outside, beware of leaking seals. They're probably dried and shrunk by now and various areas will drip and fill up with water without your knowledge. Spare tire well, under the seats, down by the ECU and fuse box, down the back of the firewall. Don't jump the car on a dead battery, then use the alt. to charge the battery. it's a good way to overload the alternator and damage it. If the engine was started last year, You probably don't need to do much to the engine before restarting. But the fuel tank could need some work. The hydraulics, noth brake and clutch, might be on the edge due to moisture buildup. don't be surprised if they work for a while, then fail. The heater hoses are probably on the edge too. Same thing. Drive it for a little while before modding. You'll probably change your mind about some of the things you're planning to change. It can take some time to work all of the little bugs out.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

"Bar car"? Pickup car? That's a lot of oil. Just stopped by the auto parts stores, OReilly and Baxter are side by side, to check out oils. Three big names in diesel oils, Motorcraft, Delo, and Rotella, all had notes on the bottle about how they were formulated for with low ash for the latest emissions devices, one even said catalysts. Could be that ZDDP is leaving the diesel oils too. May not be the cheap option anymore. Baxters had the whole selection of racing oils, except for Brad Penn and Pennzoil. The VR-1 was $6.29 per quart, the others ranged up to $12. Redline's synthetic oil said right on the label - not for break-in, only after 3000 miles. Kind of implying that you need that ZDDP in there for a few thousand miles, at least. So maybe the whole deal is to get any roughness at all smoothed away before the ZDDP isn't necessary. Which would make sense since roughness would have extreme pressure and ZDDP is also defined as an extreme pressure additive. Although I think it was originally added for oxidative stability. If I remember right.

- Rocker Revival

- Rocker Revival

-

Rocker Revival

A note from the past, and a thought: the first Nissan rocker arms for this application were chrome plated. Very, very smooth, I assume. So, surface roughness of any kind may not be desirable. The roughness for cylinders is more to get the two surfaces, cylinder and ring, matched for sealing purposes, not long-term wear. I think. And since you have fresh metal now, assuming that the ZDDP basics are correct, you should treat that new rocker pad surface with ZDDP-containing break-in oil or break-in paste. To rebuild that critical "anti-wear" layer. The ZDDP action is at the molecular level, much, much finer than any roughness level you could decide to shoot for. I'd go for a super smooth surface with ZDDP-containing paste and oil for break-in. Of reputable brand. Based on the stuff I just packed n to my brain over the last few days.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Apparently the phosphorous ash coats the catalyst particles, rendering them ineffective. It doesn't pack the pores, just makes the catalyst inert. Doesn't take much, but it probably does take a while. That's the reason they removed the ZDDP from the oil in the first place. As I understand things.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Aren't the racing oils designed for low miles? How often do the Porsche guys change their oil? Pretty cheap at Amazon though, with free shipping. http://www.amazon.com/Pennzoil-3623-12PK-Performance-25W-50-Racing/dp/B00B2IO58W

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

A note, or warning, for anyone reading through this who has a later year, or CA, car - these ZDDP containing oils will probably degrade your catalytic converter. You can't use them. So the focus for those people would be on the best wear resistance, without ZDDP. So far, the things that stand out to me, from what I've read, are that zinc,or ZDDP, level alone will not predict wear protection (it's the complete oil and additive package). ZDDP is most important during break-in, like within the first few seconds of contact and pressure and the first hour or two of wear-in. Once the galling starts, it just keeps going. ZDDP is more important for engines that have high pressure areas, like flat tappet cams with high performance cams and springs. Cam and rocker materials probably play a factor too, they need to work together. And it's a complicated subject that's hard to understand, even for the professional engineer. Some of the most interesting work out there is by engineers who were trying to do a study on another issue, but their mule engines kept wiping cam lobes. I've collected several papers and may add them later. They're long and boring though. Also, the most reliable recommendations, after break-in anyway, will probably be from people who run (ran) fleets of cars, like taxi companies. High mileage, abusive conditions, and the bad oils are probably weeded out pretty quickly. But it would have to be from before the shift to roller-rockers. I'm still looking for that kind of information. In today's world, the marketing guys just have too much influence, I can't believe anybody's ad copy.

-

Clutch Slave Cylinder Stainless Steel Hose Doesnt Fit

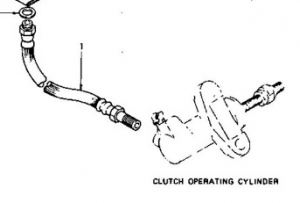

Might be the hose length. ? The slave cylinders are the same up to 83. Notice it's a different cylinder, looks like a rebuilt OEM, or new OEM. Not the aluminum body aftermarket unit. http://www.thezstore.com/page/TZS/PROD/classic22b01e/21-2102

-

Cam Wear?

Reading all of the articles on the internet from people selling zinc additives does not lead to understanding. You've fallen for the hype. Sorry, many people do. Edit - we should stop dumping in grannyknot's thread. Please start a new one if you want to collect all of the internet articles promoting ZDDP, and racing oils using Pennsylvania crude. Please don't fill up my other thread either. Nothing wrong with a good discussion, but each one has a place.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Last comment, the idea that has to make everyone wonder - if ZDDP is necessary to keep old engines alive, then we should be seeing failures on a regular basis of camshafts and rockers in old high mileage cars with stock camshafts, since the ZDDP is gone and most peole (I think) use plain old oil n their cars.. But we don't. They're just not failing. Which is strong evidence that ZDDP is not necessary, once the engine is broken in, or if a stock Nissan factory camshaft is used. So back to the original request, if anyone makes it this far - what oil are you using, how many miles on the engine, have you broken in a new cam or is this an old stocker, etc.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Anyway, I'm just hoping to identify a procedure and a set of materials that will give a good break-in of a new cam, but avoid the unecessary spending on magic oils that aren't needed. Plus the fact that not all zinc additives are alike. Could be that plain old cheap Rotella 10W-30W is the break-in oil to use for break-in nad maybe for the life of th engine. But, real numbers are needed, from people who have actually driven and maintained the cars.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Thanks for getting back Dr. I think that there might too much "lore" in this area to get a good focus on a few combinations of parts and lubes that have high odds of working. Too many sales pitches, too many magic elixirs, too much confusion (intentional and unintentional). But it's worth a shot. Any time there's market for a new product, and the science ro technology inthe area is hard to understand, various companies will come up with a solution and market it as long as thy can sell product. Gasoline atomizers for fuel efficiency, octane boosters, hydrogen generators, fancy spark plugs, etc. In this case, one problem is "zinc". Zinc is just one element in the chemical compound used to provide lubrication during the initial wear-in of the metals. There's more than just zinc metal there. ZDDP stands for zinc diealkyldithiophosphate ( I Googled it!). Thio means "sulfur". So the nasty yellow metal killer is in ZDDP. Besides that, who really knows what zinc is? (I do, but I took a class or two). http://www.valvoline.com/faqs/motor-oil/racing-oil/ (More than just zinc). Notice that Valvoline implies that zinc is not needed for an old engine,but is happy to supply a product if you want it. Actually question #4 in the link - " What is the controversy surrounding the amount of zinc in motor oil? Many hands-on car enthusiasts and engine experts believe the lower levels of zinc in SM motor oil is causing excessive wear in older style push-rod and flat-tappet engines. This is despite the fact that all new motor oil classifications are intended to be backward compatible. This has resulted in the widely accepted belief that modern motor oil is not adequate to protect older engines. What solutions does Valvoline offer to the zinc issue? Valvoline offers two solutions to the zinc issue: Valvoline VR1 Racing Oil: Contains 75% higher zinc than SM motor oil with a balanced additive package designed to work in both racing and street-legal applications. This product will protect older style push-rod and flat tappet engines. Valvoline provides this product in both multi and mono viscosity grades: 20w50, straight 50, 10w30, straight 30, straight 40, and straight 60. Longer-Lasting Zinc/Phosphorus: Valvoline uses an advanced zinc/phosphorus additive that keeps higher levels of phosphorus in the motor oil where it protects the engine instead of poisoning the catalytic converter. Valvoline is the only brand offering this unique additive across its entire line of passenger car motor oils including SynPower -- the only synthetic oil that offers this additive.

-

Cam Wear?

You're just not seeing the point. The "Critical Break-In Process" that the cam guys talk about is not the same as what's needed for use after break-in. I'm not re-inventing anything, I'm questioning unsupported dogma. As far as proven facts, I'd have to see some facts. Not just talk about some other "expert's" opinion. What a lot of other guys, or other engine builders or other people in general do, is just other stuff..

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Here's some ad copy from Comp Cams just to illustrate. Everything in the ad implies that you only need it for break-in. "The critical break-in process". http://www.compperformancegroupstores.com/store/merchant.mvc?Store_Code=CC&Screen=PROD&Product_Code=159 It is kind of amusing though that the break-in additive is an "extreme pressure additive". Like the stuff they put in GL-5 oils. One of the other lubricant issues that has some "can't hurt" concepts behind it.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

How did you break in the engine rebuild and was this a new cam, reground cam, or used stock cam? How many miles before damage and what kind of damage? "Appears" is the operative word. I'm trying to find out what's really needed. No offense. It's in the details somewhere. I saw the guys on Fast 'n' Loud destroy a cam in a rebuilt engine, supposedly because they used cheap oil and a zinc additive. It was a push rod engine. They got it rebuilt and used the "special break-in oil with zinc already in it" (Brad Penn?, couldn't tell) and went on their merry way. The car probably has 10 miles on it by now, and who knows, may have destroyed its cam again. Anyway, I see three regular oils with no major issues, two "can't hurts", a break-in plus a few oil changes, and a destroyed cam shaft (reason unclear), so far. Not judging or drawing a conclusion just collecting stories.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Do they recommend it forever or for break-in and you just kept using it? Just to be clear. I get the "extra insurance" or "can't go wrong" inclination, I'm just really curious about the true need. In your case, you have a performance cam, maybe ground from Isky chosen material, not a regrind from Nissan metal? Does the Isky cam use stock springs or their own? Trying to get the details. Thanks for adding.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

I'm on about mile # 30,000 of my old 1978 stock 280Z engine and have never used a zinc additive or special oil on this engine. Just common oils, like Quaker State and Pennzoil 10-40W. I think that my engine has about 150,000 miles on it. No problems or signs of excessive wear. If you have the time, please post some details on how many miles are on your engine, how many miles you've driven it since oils changed, and if you've had any cam shaft wear. Just trying to collect more real data on the zinc issue. Maybe I should be running Rotella.

-

Cam Wear?

Impressions are, by their nature, not incorrect. They are the result of what the person has experienced. Anyway, I've seen all of the writing on why people with old cars need to buy expensive oil. My point is that many, many, many of us don't use zinc additives on our old cars, and our cams and rockers are fine after many,. many, many miles. And, in addition, I've seen many accounts of people who used zinc additives during break-in, on essentially stock systems and still wiped their cams and rockers. When you collect all of the real world accounts, not just the theory, and do the math, reality doesn't match the theory. A poll would be interesting, to see how many people are running common oil on the their stock engines, and for how many miles. Compared to a poll of how many people have wiped a new cam lobe and/or rocker pad, while using zinc additives. If you wanted precise numbers.

-

Clutch Slave Cylinder Stainless Steel Hose Doesnt Fit

Pummeling this horse in to glue - here's a shot of the Beck Arnley hose. I noticed in the MSA link that that's an Earl's hose. They have a good rep, but times may have changed.

-

Clutch Slave Cylinder Stainless Steel Hose Doesnt Fit

IF I was in a hurry or didn't want to bother with MSA, I'd cut and grind the end, then clean it up and use a new crush washer. But I have a grinder, and a vise and a few other tools. When I was looking for a replacement clutch hose like that but rubber, just an inexpensive one, and wasn't in a hurry, I found that essentially all of the rubber hoses at all of the auto parts stores and all over the internet, are the same hose and come from one place. So I bought one locally and it was not great quality and took a few tries with a new washer and probably overtorqueing to get it to seal. It's one of those odd low-volume parts. And, if you look in the manual, and various sources, the factory didn't seem to use a crush washer. So you may have a hose for the factory style cylinder that won't fit well on aftermarket slaves.

-

Cam Wear?

My impression has been the zinc additives are necessary for break-in, to build up a smooth case-hardened wear surface, but the cams and rocker arms do fine with today's common no-zinc oils after a proper break-in. I've been using common oil for ~30,000 miles on my current high mileage stock engine, from a 78 280Z, and did the same with my old 76 engine for about 25,000 miles. I did use 5 quarts of Rotella once on the 76 engine because it was on sale. Most of the cam problems happen with new or reground cams, shortly after break-in. Often, it's with the zinc-additives. There seems to be a general problem with the way cams and rockers are ground today. Makes you think that there's a bad specification out there that everybody is using, or the factory cams have a subtle profile to them that is important for long life. Like the fact that lash is typically higher one side of a lobe than the other. Maybe the grinders, cam or rockers, are grinding to a shape that applies to much pressure on a certain spot.