Everything posted by Zed Head

-

Z's on BAT and other places collection

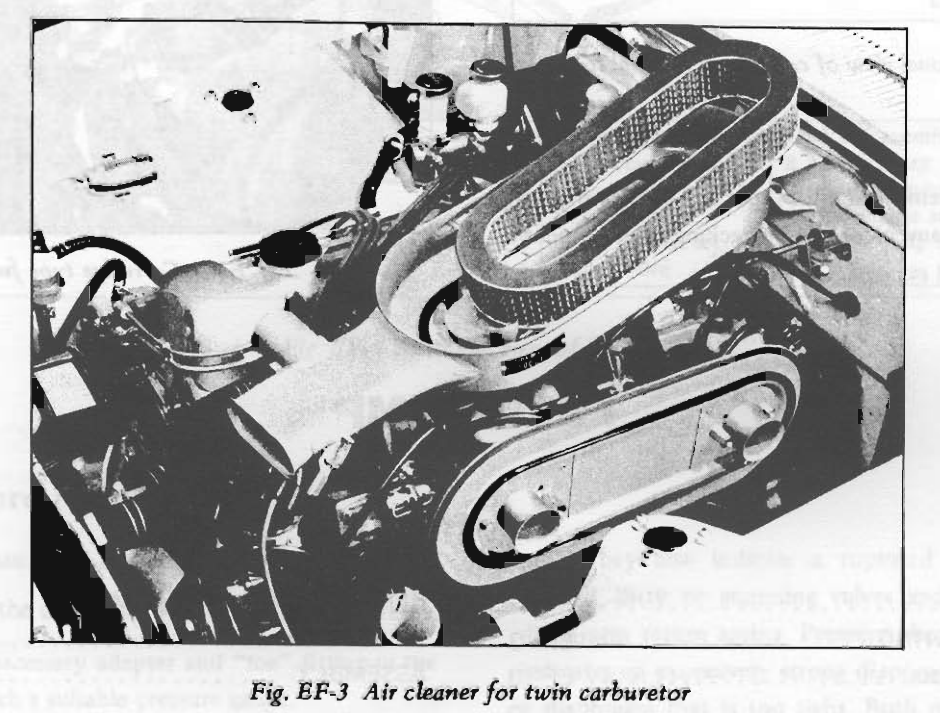

Pretty cool. Odd that there's no fan shroud. Maybe because it doesn't get that hot in the U.K.? I've heard/read about the carb'ed European 260Z's, still around after EFI was introduced in the States. Never seen one.

-

Front Brakes dragging

- Front Brakes dragging

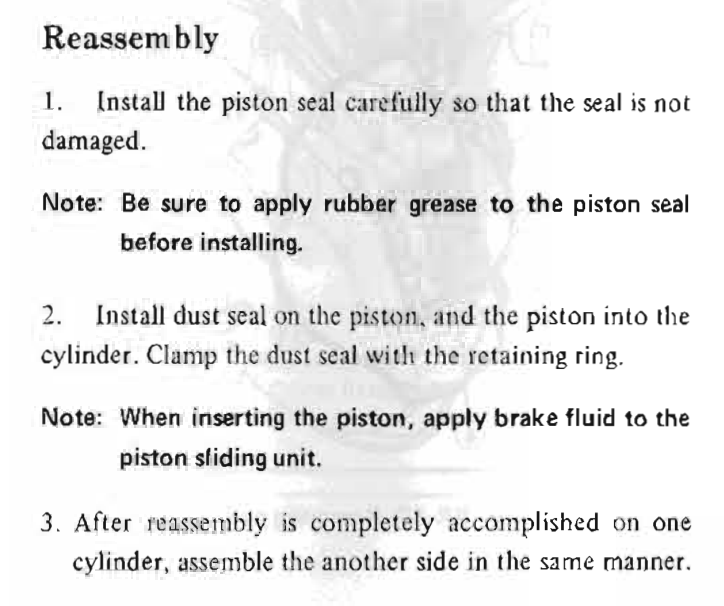

If you have a caliper on the bench you might as well pop the piston out. Don't scratch the cylinder with the metal dust seal retaining ring. Images won't load but the Brake chapter describes it. Uploading Attachment... Uploading Attachment...- Front Brakes dragging

Not sure what you mean by two pieces. But if it's sitting on the bench then, obviously, there's an open port to atmosphere. No way to hold pressure. The piston should be easily moved by hand if the caliper is new or newly rebuilt and has had fluid in it. Or maybe not, re above. Where did you get the calipers? Might have a bad rebuild. Tight seals.- Front Brakes dragging

Opening the bleeder when the brakes are stuck will tell you if the problem is pressure in the caliper or something else. If there's pressure in the caliper you can work your way back to the the MC fitting by fitting. Or work your way down, from the MC. First you need to know if it's hydraulic pressure or just mechanical sticking.- Front Brakes dragging

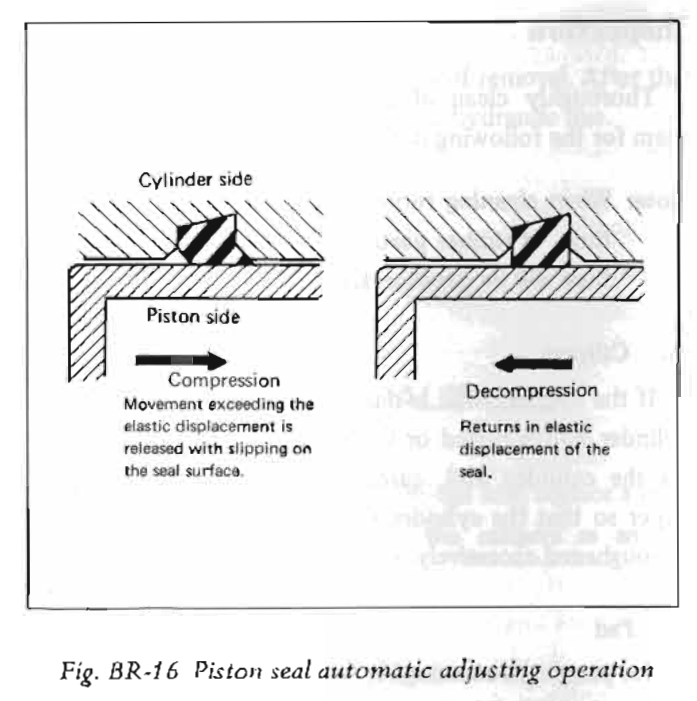

Probably worthwhile to read the Brake Chapter. It's not long. Well-illustrated.- Front Brakes dragging

But, don't overlook the brake pressure warning switch. Or the NP valve. Can't remember the car. (https://www.classiczcars.com/settings/signature/) It can get gummed up also. Uploading Attachment... Uploading Attachment...- Front Brakes dragging

The Nissan calipers use the rubber seal to retract the pistons. One common cause of sticking caliper pistons is collapsed rubber hoses. The MC can generate high pressure to push through the collapse but the rubber seal cannot to allow the pressure to release. It becomes like a check valve. On some cars the cause is a metal clamp on the hose that rustjacks and pinches the hose. But just degrading internal material can cause it also. I ould guess that a kink in the hose could cause it also.- Front Brakes dragging

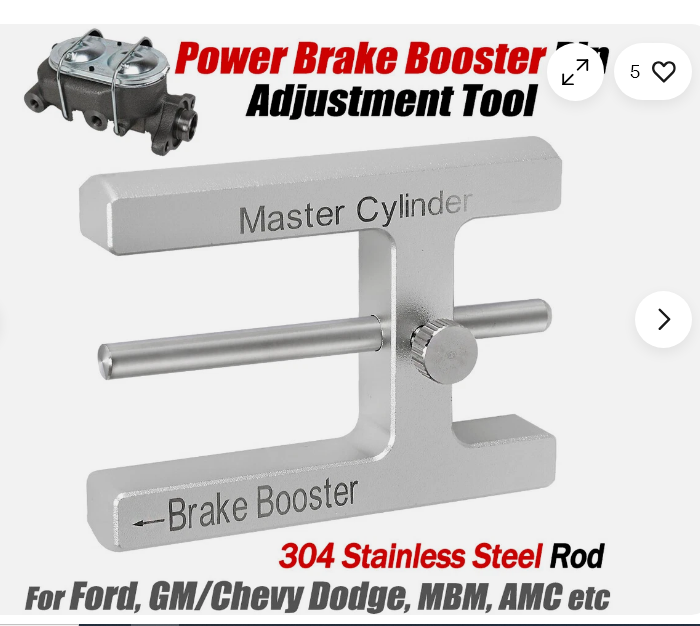

If you can do this when the brakes are stuck it will tell you if the rod from the booster to the MC is too long, causing the return port in the MC to be blocked. You'll have to do it while things are still warm though. Patcon is implying that the air expands as it gets warm creating pressure in the system. They make a tool for setting the booster rod length. It's a fairly common problem, especially with rebuilt boosters. If you stare at the parts long enough you can figure out other ways to get it right.- Series I is more hesitant to Start

I had a 1978 igntion switch with that problem. I was able to fix it by restaking the copper contact with a chisel. You'll need to remove the switch and disassemble it. Or, it could be that the mechanical portion is worn and not turning the electrical contact far enough. I fixed that on my 76 by putting some extra twist in the rod between the mechanical and electrical parts. Once you get the switch out and examine it you can test either possibility with a meter. Stole this from ZCarDepot to show the staked contacts. https://zcardepot.com/products/ignition-starter-switch-240z-260z-280z-510 And here's the back side where the rod inserts.- Series I is more hesitant to Start

It might help to add some detail about what this means. Are you saying that the starter does not spin the engine? It's just click, click, click, then spinning happens? Also, watch your gauges and the ammeter. If they all go dead, then come back to life that's a sign of a bad battery cable connection. The heat from the starter motor draw causes the bad connection to expand and open. Then it cools and closes. The small spade connection at the starter solenoid can be loose also. Same effect. I almost replaced a starter once, but instead just repinched that connector. It was loose.- Z's on BAT and other places collection

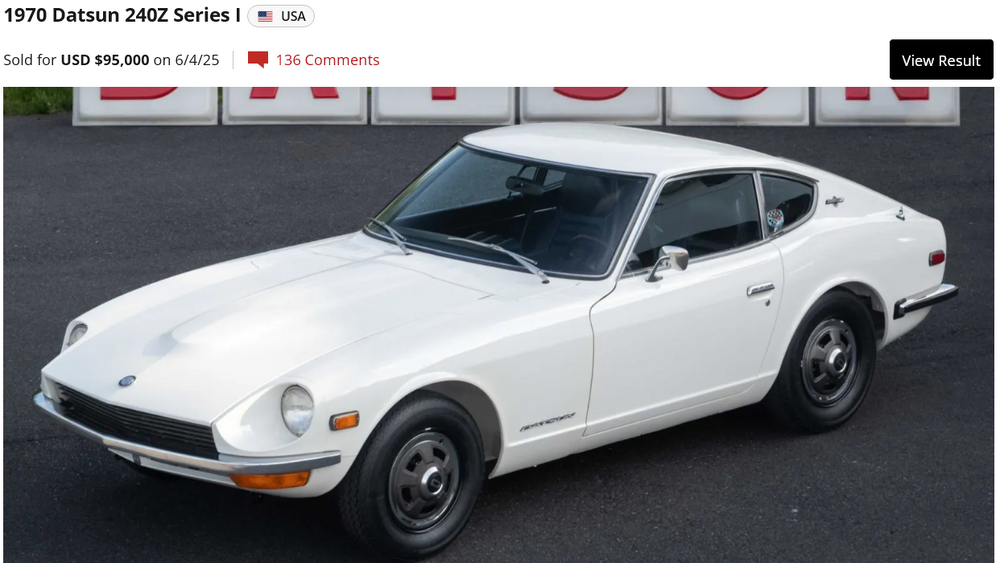

The seller said he could see holes for an AC system. So he assumed that it had had AC. Who knows. It almost broke 100. 95. The winner didn't play the small bid game, every bid was a big jump. https://bringatrailer.com/listing/1970-datsun-240z-133/- Z's on BAT and other places collection

Somebody bumped the bid on the white 1970. By an odd amount. The guy buys a lot of car so there could be an interesting battle on tomorrow. Does anyone know if a 1970 240Z could have a three groove damper pulley? It has an L28 crankshaft so the damper has been off. The sellers on BaT are interesting because they often don't really know the details but don't want to say "I don't know".- Z's on BAT and other places collection

Does anybody want to guess on the final bid then? Will it break 100?- Z's on BAT and other places collection

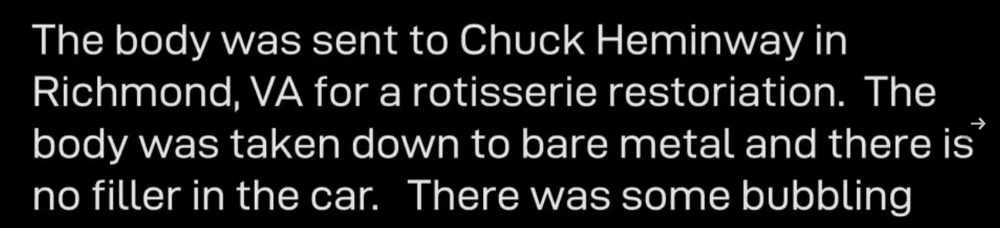

I have to guess then that this auction is for a select crowd that already knows that. I looked through all of the paperwork and the description and don't see Chuck's Frame Shop mentioned anywhere. Seems like it would be worth advertising. There is a Chuck mentioned, findable if a person looks closely, in one of the images. I guess that people in the resto world would know about him. It's a fascinating world. I don't live in it but it's fun to watch.- Z's on BAT and other places collection

Are the seller and the restorer the same person? Chuck is Garage44?- Z's on BAT and other places collection

Does this really mean that $71,970 was over Reserve? There's still four days left. Probably get no more bids. Posting for entertainment now. These high dollar auctions are usually interesting.- Z's on BAT and other places collection

That big bid to $71,970, from a previous bid of $28,500, is still interesting. Like somebody that owns some already wants to be sure the "value" stays high. My cynical view. I don't think that seller understood the point of the question, of unfiltered air in to the newly rebuilt engine. Actually there isn't much discussion about the engine. Normally a Datsun Spirit engine would be a big deal. But it only cost about 8% of the bid value, so far.- Z's on BAT and other places collection

And, is anyone going to get in to the Comments over there and ask about the open port? Who wants to be the bad guy? 😈- Z's on BAT and other places collection

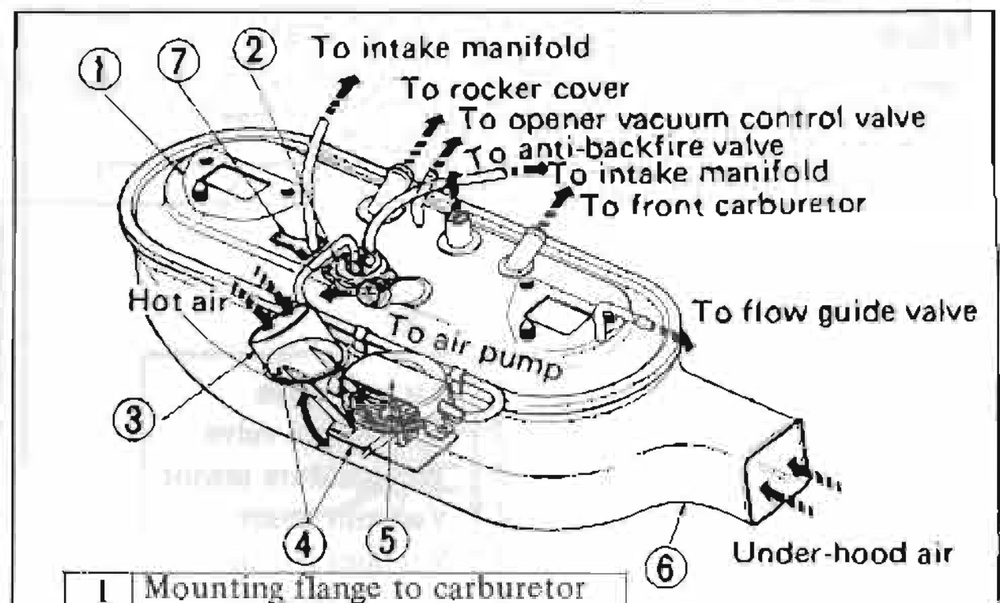

Funny, I wanted to be sure I knew what that port/nipple is called and/or what it's for so I looked through the FSM's and it doesn't show up until 1973. Is that the right air filter housing for a 1970? 1972 1973- Z's on BAT and other places collection

This one? The bids seem surprisingly high for so early in the auction. Somebody went directly to a very large number. And the engine is not original, it's been bumped up to L28 size apparently. Although I had always though that the L24 blocks would not take L28 bore size. And it has an E88 head. Looks like one of those interesting auctions. https://bringatrailer.com/listing/1970-datsun-240z-133/#comments-anchor- 1980 Datsun 280 zx

What are Euro-Top pistons? What did the chambers measure out at? Just curious about compression ratio. You should add a driving video. Good luck.- Need full shock absober kit for my 1972 datsun 240z

Mismatched and high miles. Yikes. Why were they removed? What's on the car now?- Problems with 240z doors from Resurrected Classics.

So you probably have over 100 potentially disappointed customers out there. Good luck with that. The fact that they were purchased does not mean that they are of good quality. It means that people expected good quality, like these two disappointed individuals did. Besides the possible disagreement on quality, the problem here seems to be the lack of communication. Anyway, these things are not uncommon. At least you have a dialog going now. Good luck.- Problems with 240z doors from Resurrected Classics.

It's been documented, with measurements. - Front Brakes dragging

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.