Everything posted by Zed Head

-

Electrical Fuel Pump Pressure Problems

You only need 30 gph. Excess volume will cause excess current draw. You'll be upgrading your alternator next. Good luck.

-

Electrical Fuel Pump Pressure Problems

He also sells the Airtex pump. https://zcardepot.com/catalog/product/view/id/176/s/electric-fuel-pump-fuel-injection-280z-280zx-75-83.html/

-

Electrical Fuel Pump Pressure Problems

Is it new? Pumps do go bad if they get crud in them, or rust up. I had a wrecking yard pump that seemed fine in the first few minutes but would slowly lose power and pressure as it ran. Even with the fuel cooling it the motor got hot and crapped out. It's still unclear how, exactly, you're testing the pump. Would love to see just a pump, some hose, an FPR, and a pair of pliers for pinching the return line. With a gauge reading of course. You're probably going to find that it was something simple once it's done. Carry on.

-

Electrical Fuel Pump Pressure Problems

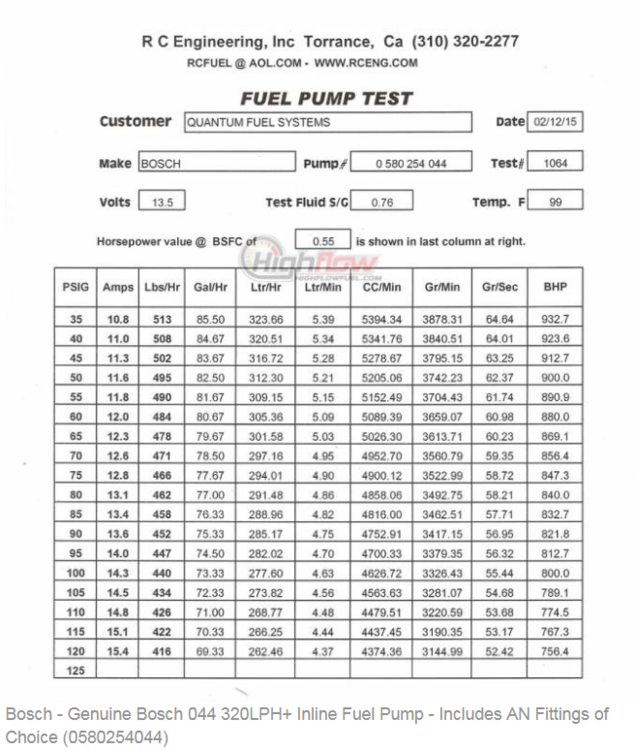

Seems much more than adequate. I don't know why they don't just put the specs out there somewhere. That pump is a replacement for Ford F350's with 445 CI diesel engines. Which means high volume of a more viscous fuel. The general spec for a stock L6 is about 30 gph at 36 psi. Higher volume means bigger draw on the electrical system. You don't want that on these cars, the electrical is on the weak side already. The Airtex E8312 is a common replacement. I have one, it's worked great for years and many miles. https://www.amazon.com/Airtex-E8312-Electric-Fuel-Pump/dp/B000DT7Y7K/ref=sr_1_1?ie=UTF8&qid=1540865716&sr=8-1&keywords=airtex+e8312 Here's the data for the 69136 - https://www.summitracing.com/parts/bch-69136/applications

-

5 speed clutch question

Motorsport is good if you have the money and want someone else to do it for you. Or you can do the math and save a few dollars, plus learn "why" for the future, and be able to double-check Motorsports work. The bearings are all the same and are easily replaced in the sleeve. Here's that thread, with more links.

-

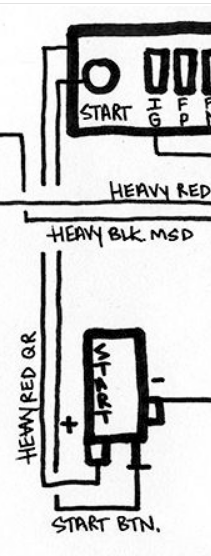

Very Cool Ignition Upgrade

I see three "starts" here. Is the box on the bottom actually the startER? You don't have a the positive cable connected there, so it's not clear. Wouldn't be a surprise if your Start button cut power to the other switches. That's how the factories do it. Max power to the coil and starter.

-

Very Cool Ignition Upgrade

Exactly. If you're not losing voltage at Start then you need to look at why the 123 wouldn't be making and breaking the coil circuit. The 123 needs power too, and a good ground. Your white wire test showed the that MSD works. The 123 just supplies the ground circuit. You never explained the other Start circle.

-

5 speed clutch question

All of the transmissions are the same. The throwout bearing sleeve and the pressure plate need to match. Details were just posted in the recent "slave cylinder popping out" thread.

-

Very Cool Ignition Upgrade

Is there voltage on the red wire to the 123 when cranking? Start. Break it down. Run and Start are two different things. Your MSD white wire test is a "Run" test, or "IG" in your case. You need to check Start.

-

1974 260Z carb problem

So, does it always happen in the same way? Shift in to 4th, engine sputters and dies? Every time, only in 4th? Or is it RPM related? 260Z's have electronic ignition and they tend to fail after 40 some years. Good luck. More details = more ideas.

-

Very Cool Ignition Upgrade

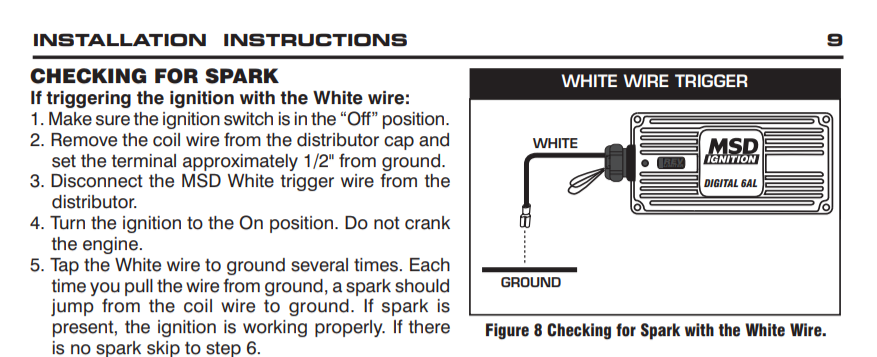

Here's the check to see if the MSD will work as wired. It replicates what the 123 should be doing. Providing a ground path for the white wire. If you do this test and get a spark then you can focus on the 123 as the problem. Break it down in to smaller problems.

-

Very Cool Ignition Upgrade

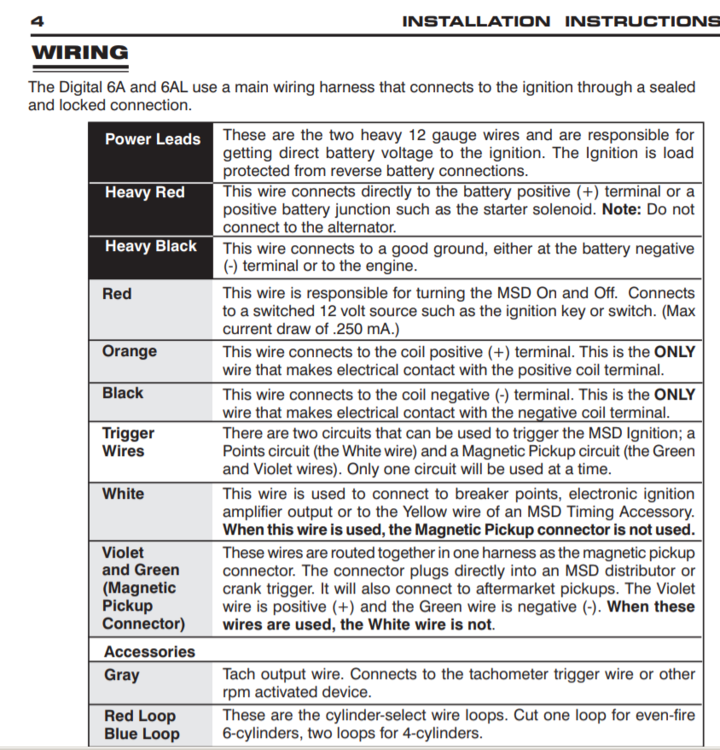

I could be wrong. MSD says that the white wire is used for points so it might work with the 123 as you have it wired. Check your grounds. https://static.summitracing.com/global/images/instructions/MSD-6425_frm29772.pdf

-

Very Cool Ignition Upgrade

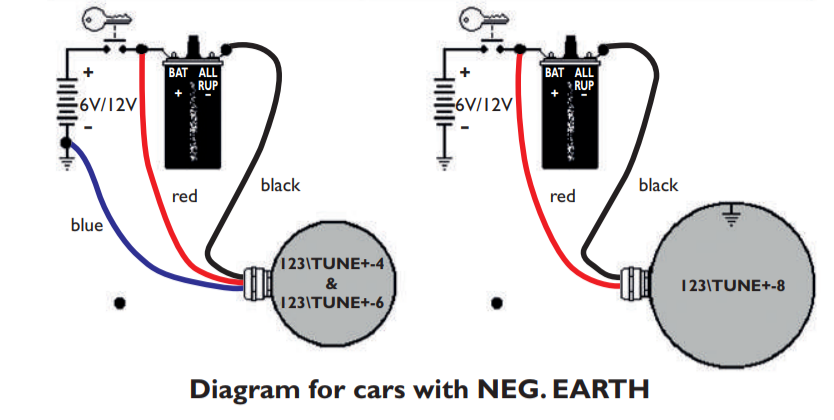

Here you go. The 123 black wire will just open and close a circuit to ground. But will not have any inherent current flow or voltage. The MSD won't see anything there. I think that MSD's white wire just counts voltage pulses. It would only see a change if it had voltage itself. And the link- http://www.123ignition.nl/files/manuals/123manual_TUNEPLUS.pdf

-

Very Cool Ignition Upgrade

Just realized that you had a thread going over at Hybridz. I'm NewZed over there. Edit - Never mind, I saw the first sentence of your post over there. Buying the 123 might not have been the best idea, if you just want to use the MSD 6AL. The 123 ignition system has its own ignition module and doesn't need the MSD 6AL. The MSD 6AL just needs a good trigger signal to work, but the 123 tach signal might not be right for it (if that's what 123 black is in your diagram). Why are you trying to combine the 123 with the MSD?

-

1974 260Z carb problem

You kind of mixed up the before and after. You said it ran perfectly until this problem came up. But then you said the problem came up today after you replaced parts to fix the problem. Did you fix one problem and new one came up? Or did you replace those parts and it din't fix the problem? Anyway, is the problem reproducible? It happens every time you shift in to 4th gear? Or did it happen once and you haven't tested it since then? If you can determine what conditions cause the problem it will be easier to solve.

-

Very Cool Ignition Upgrade

Looks like you're using the 123 tach signal to drive the MSD box? Is that what 123 black is? The 123 distributor has its own ignition module, not clear why you'd do that. You don't need the MSD. Also not clear what those other things are in your drawing. One looks like a toggle panel, but has a round thing that says Start. Is that a Start button? The other says "Start Btn" so is probably a momentary switch, or button. Looks like you have two buttons in series. You'll get better replies if you post the links to the 123 and MSD instructions, or at least tell what the wires do. No real urge to go dig them up myself. Is 123 blue a ground wire? 123 red power? Good luck.

-

1974 260Z carb problem

I can't find it in the FSM but maybe a 260Z owner can, if it exists. Some cars have a "top gear" switch that opens a solenoid valve to let the vacuum advance of the distributor work. I know that my 76 280Z had one. It's an emissions device, retarding timing in the low gears to give cleaner exhaust, and adding advance in high gear for fuel efficiency. So, any engine that has emissions devices might have it. Find the hose to the vacuum advance and follow it back to its source. Not even sure why that would cause the engine to die unless moving the breaker plater causes ignition problems, which does happen. You should give more info about your car, like how long you've had it, and whether it ever ran right.

-

Slave Cylinder Over-Extending

Sounds like you got a short throwout bearing sleeve with a short pressure plate, when you replaced your parts. The height of the pressure pate plus the height of the sleeve needs to be within a certain range. 92 mm from the flywheel to the ears of the sleeve seems to be about mid-range. If you search "92 mm throwout collar" on the site you'll probably find some discussion about it. You might be able to make it work by extending the rod but the "proper" way to do it is to take the transmission back out and use the right sleeve. AKA "collar". Here's an example of the different sleeves.

-

Power of Z article - GQ Style

This argument is especially odd since I think that both of you guys are old enough to have lived through the transition to "power brakes". Seems like hair-splitting for the sake of being contrary, rather than for the sake of getting things right, as the other guy likes to say. "Power brakes" and vacuum assist were synonymous when all of us were growing up. There's no difference, let alone a big one. https://en.wikipedia.org/wiki/Power_brakes

-

Electrical Fuel Pump Pressure Problems

That Bosch pump should get you about 120 psi. I don't think that they have a pressure relief inside. They just keep cranking until flow stops. Be careful you could easily pop a hose, or balloon your filter. The Bosch 044 is way over-spec. for what your engine needs. You might reconsider. https://www.highflowfuel.com/i-13775895-genuine-bosch-044-320lph-inline-fuel-pump-includes-an-fittings-of-choice-0580254044.html Did you say if you've checked the vacuum hose to the FPR for fuel? Your FPR really should be causing pressure to increase.

-

Power of Z article - GQ Style

The question wasn't about "power brakes". Everyone knows what that means. It was about whether or not the very first cars had power brakes. I'm guessing that Karl mis-spoke and threw brakes in with steering.

-

Power of Z article - GQ Style

I'd guess that those are transcribed from a tape. Maybe he mis-spoke. There was probably beer involved. Just wondered if maybe the very first Z's did come very primitive. Some of the other comments seem a little extreme. I'm pretty sure the stories about the European teams quitting after getting beat is told by the Ford GT-40 guys too. Some bench-racing going on maybe. The L6 was a hand grenade? The article is a fun read though. " The engine was designed by guys over at Nissan who had never built a race engine. In the end we took this engine that was an absolute hand grenade and we built one of the best production racing engines in the world. The car was unbeatable. We took it out for the first time, and we smoked the Porsches. And Porsche, unable to compete with us, quit. Triumph quit as well. "

-

Power of Z article - GQ Style

Motorman7 posted this link in his sale thread. Didn't want to mess it up. Somebody named Chris Karl says the first Z's didn't have power brakes. Is that correct? Other interesting words from the usual suspects. https://www.gq.com/story/datsun-240z-oral-history "Karl: And they're very mechanical, too. If you just look at the engine design, and watch one being revved, then you see all the mechanical linkage connected to the carburetor. You have to understand how to drive a machine. There were no driver aids. Power brakes, power steering—all these things that we take for granted, all of those components—didn't exist. "

-

Electrical Fuel Pump Pressure Problems

I see two gauges. Do they both read the same? There are a lot of questionable quality gauges out there. You've done so much work there that just pulling the pump and regulator and setting up a loop in to a gas can might be the simplest way to test the two main components. Avoid sparks, be aware of wind direction, have an extinguisher handy, etc. I put a filter in-line also to protect the parts when i do that kind of test.

-

Electrical Fuel Pump Pressure Problems

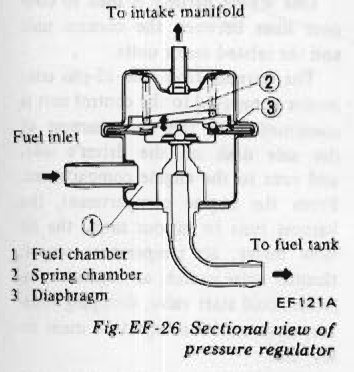

Just looking back here...this should have required very high pressure to do because in reverse the FPR has a very very small area to press on to get the valve to open. You might have actually blown a hole in the diaphragm, or maybe even expanded the FPR body. In normal flow direction the fuel has all of the diaphragm to press on to get the valve off of its seat. If you blew a hole inthe diaphragm you'll be pumping gasoline through the vacuum hose to the intake manifold. Imagine the fuel flow in reverse in the image. That's what would happen if you used compressed air from the return line at the tank.