Everything posted by HS30-H

-

My two swiss S30Z Fairlady Restoration build thread

Yes! You've got it. Definitely 'Conversion & Tuning Centre Ltd' of Brixton, South London. I didn't see the 'C T' logo cast into the manifold in your previous post. Very distinctive. The only other big London-based specialist supplier of carburettors, inlet manifolds and conversion kits from that early 70s I can remember was Chris Montague Carburettor Co. in North London (my side of town), and which I am old enough to have been a customer of. Gone now. They really knew their stuff. I bought my John Passini-authored Weber 'bibles' from them in the late 1970s. My *guess* is that Mangoletsi may have cast some manifolds for C & T London with their logo on them. It probably would have been too expensive for C & T London to have commissioned their own castings with such a relatively small market already covered by Mangoletsi. I would say - judging from the photos - that the C & T London version looks like a neater casting than my '470' Mangoletsi, but that may have been down to batch quality differences? Having said that, other '470' manifolds that have passed through my hands in the past (often from period 'Samuri Conversions' cars) are equally poor castings, so they seem to have been pretty consistently poor. Could C & T London have insisted on a better casting, with their name on them? Seems feasible. Just as an aside for your friend; if he uses this 40DCOE-24 setup on an L24-based engine he might want to try changing to short (10mm) accelerator pump rods and 0.45 accelerator pump jets, as used on the 40DCOE-18. I have recommended this a few times for others with positive results. The Nissan L6 seems to 'like' a short, sharp accelerator pump action on the DCOEs. John Passini covered the topic in his books. Recommended.

-

My two swiss S30Z Fairlady Restoration build thread

A cool part of DSSA history. Thank you for showing it to us. Intriguing! I'm surprised that they chose to use 40DCOE-24 series carbs. Weber's own recommendation as a conversion 'road' kit for the L24 engine was three 40DCOE-18 series and the 24 series was actually only offered as stock (factory) equipment on the 1600cc ALFA Giulia Super. The 24 series had 27mm chokes and 0.35 pump jets, whereas the 18 series had 30mm chokes and 0.45 pump jets. The 18 series also had an accelerator pump stroke more suited to the L24 than the 24 series did. My best guess (take that for what its worth) is that they sourced the 24 series carbs from ALFAs and/or already had them available. The manifold is a new one on me. I can't ever remember - even as a Londoner - seeing the name 'LONDON' cast into a manifold. Your illustration from the Janspeed catalogue shows the '470' casting that - I have always been told - was cast and supplied by Mangoletsi. Janspeed, and others, often supplied the Mangoletsi manifold with their conversion kits. I wonder if the 'LONDON' manifold was also something cast by Mangoletsi for a specific customer? However, I can't think of any L6 specialists in the London area or using the London name. Curious. Here's a Mangoletsi '470' casting manifold that I have in my loft, for comparison. Casting quality is - I have to say - fairly rough:

-

Chat GPT - AI Bot

Surely the old adage of SISO/'Sh*t In = Sh*t Out' applies here? All it will do is take the loudest/most often written and repeat it? For example: The 1969 New York Auto Show - held at the New York Coliseum, Columbus Circle, Manhattan - took place in April 1969. Of course, no '240Z' was there, so SISO. Where did Chat GPT get the bad information from? My bet is that it has something to do with the reality-warping 'history' of the Z's debut as delivered on zhome.com, and echoes thereon.

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

This is possibly the sequence of the show that troubles me most. I just don't understand how anyone can seriously imagine that the layout of the Nissan L-gata engine - with inlet and exhaust on the LH side - was somehow "...designed for the US market." Jay Ataka was pointing at the throttle linkage and waggling the vacuum booster hose when he was saying this. Yes, the throttle pedal and brake pedal/booster are on the RH side of the car in an RHD layout. So are the steering shaft and clutch pedal. Where else are they going to be? The key point is the handing of the inlet and outlet of the engine. Here on classiczcars we've had discussions in the past about the design 'inspiration' of Nissan's L-gata engine. One member was evangelically convinced that it was "copied" from the Mercedes Benz M180 engine (spoiler: it wasn't) which had inlet and exhaust on the RH side. Prince's G7 six sometimes gets a "Merc copy" mention (Prince and Nissan were competitors at the time) but the G7 had inlet and exhaust on the LH side, same as the Nissan. So, Nissan's L-gata engine range "...designed for the US market." Does anybody here want to try to convince me that's true? Go on, I dare you. 🙂

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

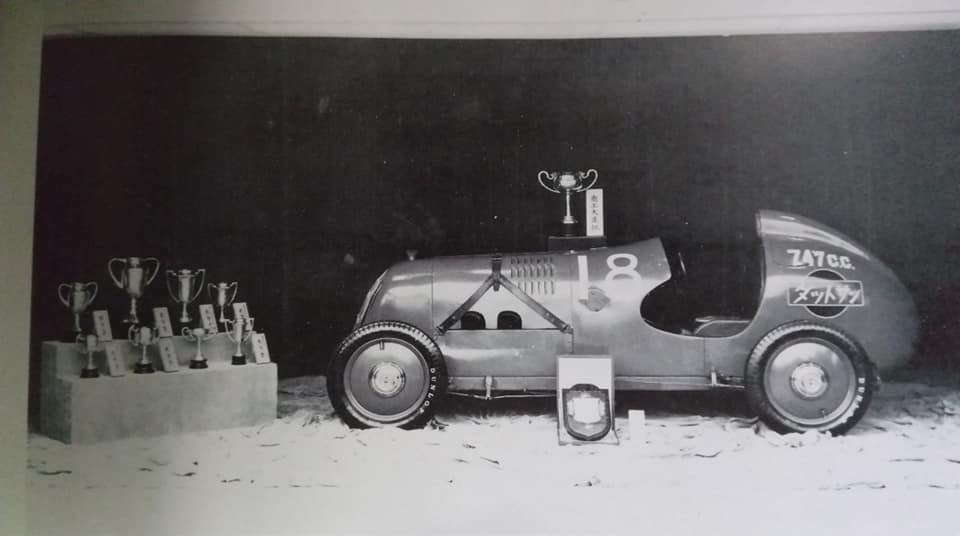

31:30 Leno again: "When this car came out, there was no Japanese heritage. You know, ALFA Romeo had heritage, Ferrari, Bentley... had all raced in the 1930s and whatnot. So they (Datsun/Nissan) were brand new. So this really was the beginning of Japanese heritage. And now, 50 years later, it's got a real line. You can trace it all the way back". As mentioned in my previous post, you can trace it back a lot further than 50 years. I think this is Leno viewing things through the lens of the USA again. Maybe it looks like that to him - and 99% of his YouTube viewers will swallow it whole - but it is wrong. He mentions ALFA Romeo (established in 1910), Ferrari (established as a racing team in 1929 and not a manufacturer until long after that) and Bentley (established in 1919). Notwithstanding the 'DAT' car of 1914, Nissan was founded in 1933 and was racing soon after. As a brand it is not that much younger than the companies he cites. It was making (and racing) cars before Ferrari, Porsche and many other manufacturers.

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

25:20 Jay Leno: "Cars didn't start to be introduced in Japan, for everybody, until after the war, correct? Not 'til the Sixties." OK, so this is an exaggeration that probably doesn't deserve to be taken so literally (especially considering "for everybody" as a caveat), but I think it warrants a little correction. All the more so when it was said by somebody who was driving along in a Japanese market Japanese car. Japan's automobile industry was a little late in getting started, but there was plenty of activity in the early part of the 20th Century. Japanese entrepreneurs and nascent industrialists were on the case, and 'our' brand (Datsun/Nissan) can trace its roots back at least to Masujiro Hashimoto's first commercial activities in 1911, establishing Kaishinsha Jidosha Kojo. By 1914 Kaishinsha had produced the first 'DAT' car, named in tribute to his three main investors. The car Leno was driving could arguably trace its DNA back to that 1914 'DAT' car. There were plenty of other automobile pioneers in Japan around that time too, so it's a little unfair to ignore them. It would also be unfair to Nihon Ford, who built their first factory in Yokohama to assemble the Model T in 1925. Within a few short years they had expanded the factory and fitted a conveyor line system which allowed them to produce 20,000 units per year. In the same period General Motors established a factory in Osaka which allowed them to produce 10,000 cars a year. Private and commercial motor vehicles were a common sight on Japanese roads in the 1920s and 1930s. A little bit of trouble in the mid 1940s (*polite cough*) set things back a little, but by the 1950s the Japanese domestic manufacturers were on the case again and a family car was becoming a realistic proposition for many. The Nissan Fairlady Z that Leno was driving is a product of that post-war rebuilding and re-tooling, but has a bloodline which can be traced back to the early 20th Century. Incidentally, if anyone wants to investigate the pioneering days of the Japanese automobile industry, I strongly recommend the National Science Museum of Japan (now renamed the National Museum of Nature and Science) in Ueno, Tokyo. They have an amazing reserve collection relating to the subject and it is very informative: https://www.kahaku.go.jp/english/#

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

23:51 Jay Ataka: "I would say the whole Z thing is about the American market". Saying this while riding along in the passenger seat of a Japanese market variant is - in my opinion - more than a little odd. We can probably all agree - obviously - that the US market was the biggest single market for many manufacturers, but the S30-series Z was conceived, designed, engineered and produced simultaneously for several different markets and in several different variants. The car that they are sitting in - and supposedly the subject of the show - is an example of that fact. So 'the whole Z thing' is about all the Zs, not just one variant.

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

Matsuo san told me several times that the car which surprised he and his fellow design team members the most - because they were shocked at how similar some of the key lines were to what they were working on at the time - was the Maserati Ghibli. Of course, they'd had no preview of the Ghibli or Giugiaro's work on it at Ghia, and the photos from the Turin Motor Show were a shock. Maybe another good example of the auto styling zeitgeist and two independent teams coming up with similar answers to similar questions?

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

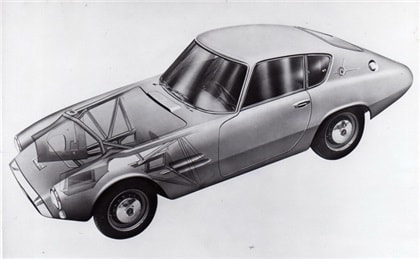

"Inspired by". Perhaps, but were Nissan's team unique in that respect? I don't see a single line or curve in the S30-series Z that directly references the E-Type. They would have been "inspired by" all manner of cars and objects, including Mother Nature. What educated artisan is not? OK, so far we've got Corvette, Thunderbird (LOL) and Mustang from Leno, E-Type, 911 and Ferrari Daytona from others. Peter Lyon (yes, I'm more than familiar with his work) says that "critics argued it borrowed styling hints from...", but that's not Peter Lyon saying it did, it's them... Hell of a mash-up there. But you see what's happening, right? Did all of those cars mentioned spring forth from their makers in a vacuum? When the 911 debuted, did people accuse Butzi Porsche of copying something? What did the E-Type copy? You end up dancing on the head of a pin. People only pursue this line with the Japanese designers and stylists because deep down they believe that 'Japan copies'. But nobody copied Japan, right? Automotive styling follows trends and responds to the prevailing zeitgeist just as much as anything else. Packaging wise it has to conform to numbers both set down on paper and dictated by hard components (like those 'Made For The USA' engines, pfft). I reckon there's a very good chance myself - and any other schoolboy who bought the same automotive magazines - could have doodled a rough outline of such a car in the late Sixties and not been far off. The difference was in the detail and the eye of the guy scraping at the clay (largely Yoshida san and Tamura san in the S30-series Z's case). Since we're at it, here's a name-check for the great styling houses of Ghia and Touring. Let's chuck these in the gumbo too:

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

LOL. Get over yourself! You take yourself far more seriously than I do. What point of view have you offered? All I see is your E-type and Aston comment, and if you honestly think those two front ends are stylistically related then you probably do need to get your eyes checked. Styling wise, they are miles apart.

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

You may have been spending a little too much time perusing the Boobs thread. Perhaps an appointment with an optometrist is in order? Here's an E-Type Jaguar in a fetching shade of yellow: And here's a Datsun 240Zee in that lovely factory silver: ...it would be rather careless to confuse one with the other.

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

11:16 Leno: "Did all the ones in Japan then go to 240 when America did, or did they stay two litre?". Again, this is where some sort of script or preparation could have been useful. Jay Ataka's answer doesn't really get the chance to make clear that Japan got the L24-engined Fairlady 240Z, Fairlady 240Z-L and 240ZG (which Ataka fails to mention) added to the domestic lineup alongside the four two-litre variants in late 1971, giving seven variants to choose from at that point. So the L24-engined versions were added to the lineup, rather than a switch from two litre to 2.4 litre. Leno appears to have never heard of the 432, which I find hard to believe. Maybe he just couldn't remember it at that point, in which case a little more pre-shooting preparation would have been fitting. Onto the engine bay. 11:51 Ataka: "You kind of see the throttle linkage is stretched all the way... to get there..." (pointing at the carburettors) "...and if you look at a left hand drive 240Z... everything comes natural. This vacuum hose is extended all the way here..." (pulling at the RHD vacuum booster hose) "...this whole thing was designed for the US market..." HUH? Is he saying that the layout of the L6 engine (and therefore the L4 engine too) was designed with the inlet and exhaust manifolds on the left hand side specifically for LHD markets, and the USA in particular? Wow. I'd like to hear him back that one up with some evidence. Ataka then goes on to talk about production and sales figures. Fine, but that's all after the fact and a function of economics as much as anything else. How does this relate to the actual car in front of them? And indeed, can we apply it directly to other marques and models? Lets try some of those British roadsters that Leno mentioned earlier, or how about a few Porsches and Ferraris? How about the VW Beetle? This talk of production and sales figures leads Leno into talking about the RRP in the US (even though the car in front of him wasn't sold in the US) and comparing that price to the contemporary Corvette and Mustang (again, nothing to do with the Japanese market car in front of him). Why not discuss the pricing structure for Japan, and some comparison with what the same money would buy you in Japan at that time? This is a rare opportunity to talk about a specifically Japanese variant, and to educate and inform viewers. Opportunity missed.

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

8:10 in and Leno asks about horsepower figures for 'the 240Z' (why?). Here's some topic for debate. Jay Ataka states that "...the USA 240Z had 130 (hp) at the beginning...", and "...it went down to 125 (hp) in 1971 and a half..." (Leno: "because of emissions?", Ataka: "probably"). Jay Ataka is probably citing real figures rather than published figures (net vs gross) and there's a chance to mention the car that's actually in front of them rather than 'the 240Z' - especially as it didn't carry any emissions-reducing add-ons and therefore was not far off the power of 'the 240Z' that Leno insists on discussing - but then Leno digresses again onto MGs and Triumphs. Leno talks about struggles with English cars, but he's comparing apples with oranges. The S30-series was closer to a GT than any of those old time roadsters (not to mention Nissan's own Roadsters...) so I don't get the direct comparison. Safety legislation was turning that avenue of car design into a cul-de-sac for a decade or so and the Z was specifically not going there. All we can say is that the people who had been buying open 'sports' cars now had an opportunity to buy sports GTs from several different manufacturers.

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

I'm going to skip over the usual 'Mr.K' stuff. That's a whole topic on its own. Anyway... At 6 minutes in, Leno asks "...tell us how this Japanese-only model is different from the American version". Great, maybe some informative content specific to the beautiful example in front of them is coming? Jay Ataka starts to explain, but do I detect an edit? It seems cut short, and Leno starts talking about all that (same old same old) cliched Datsun vs Nissan naming stuff. Which - incidentally - is just not correct. Why would Nissan choose to use their precious 'Datsun' branding on something that might 'fail' in an Export market? No, it's much more complicated than that. So Jay Ataka explains that the car in front of them is an example of the "base model", but doesn't get time to explain that - at launch - Japan had four variants of S30-series Z to choose from. The point that the "base model" was the cheapest, but that a 'Deluxe' model was available alongside it, seemed to go missing. It would have been useful context for the outward appearance of the car. Leno says "I guess they studied all the American cars, or at least the cars sold in America", ..."because you see some Thunderbird..." (?!) .."you see some Jaguar, you see sort of Corvette..." (?!). First of all I don't see much Thunderbird (and I used to own a '65 Thunderbird, God help me) or Corvette in there. But anyway, what Leno sees (or what I see) is kind of beside the point. Going down that line of thought sets you up for the implication that Japanese designers and stylists were - that old cliche again - copyists. Its like nobody can bring themselves to believe that the Japanese team which styled the body of the S30-series Z was influenced by the same mid-Sixties automotive design zeitgeist that their contemporaries in other countries were responding to. They were educated, not programmed. I just don't see how anyone can say that the S30-series Z is in any way "for America" in terms of its styling. The 'Made For The USA' thing is arguably more about ergonomics and economics than anything else. And as for dynamics...

-

Jay Leno's Garage - 'The Beginning Of Z Cars: Fairlady Z'. episode Feb. 20th 2023.

The latest episode (dated 20th February 2023) of JAY LENO'S GARAGE has just arrived on YouTube. It is titled 'The Beginning Of Z Cars: Fairlady Z', and features the 1971 S30-S Fairlady Z of Mr Jay Ataka: YouTube link A lovely car and a great opportunity to discuss the topic in accordance with the episode's title, but it doesn't go that way. It seems that Jay Leno didn't manage to comprehend the structure of the S30-series family through the stages of concept, design, engineering and production and - despite having a Japanese home market variant in front of him, he constantly refers to the American market. He seems somewhat.... confused. I think it's a missed opportunity. Jay Leno is a very influential broadcaster and his shows reach a wide audience. He entertains, but also informs. Not necessarily in any great depth, but he often touches on technicalities and historical context. This time he seems somewhat befuddled and insists - I think misguidedly - in viewing this specifically Japanese market Japanese car through the lens of the USA. In his introduction, standing in front of the car, he states "This is a car built for the American market". Well, no. This car was not... He then trots out many of the cliches relating to the early days of Nissan's exports to the North American market. "Not particularly durable", "smaller engines", "they weren't used to our super highways" etc. But all of that relates more to cars designed in the mid 1950s and the (somewhat strange) importing choices of Marubeni Corp. and early NMC USA. The implication is that 'Japan' didn't know how to make cars, let alone cars for the USA, but the truth is that Japan's industry was already embarked on a journey of rapid rebuilding after the devastation of the war years. Japanese designers and engineers, and the companies they worked for, were focused as much on Japan's rapidly changing needs as they were to any exporting concerns. Within a few short years the Japanese automotive industry (along with pretty much every other Japanese industry) was making better and better product for Japan. That journey was already well under way. The S30-series Z was an effect of that, not a cause. Leno then says "So this is a 1971 Fairlady, OK? When did it officially become the 240?". This is as good an example as any of the way the S30-series Z family is misunderstood and mis-explained. I have no idea how Leno and his team prepare for each show, but perhaps a little bit of briefing/scripting would have been useful here? It seems that he's starting out with a basic lack of comprehension with regard to the structure of the family, and - sorry to say this - but Jay Ataka's attempts to explain don't really help much. And that's at less than 4 minutes in...

-

Datsun-240z Vs Fairlady-z432

My impression would be the opposite. I feel that any closed-end nut being used in rally type conditions (with servicing/wheel changes being carried out in dust/snow/mud/gravel) would run the risk of accidental contamination inside (small stones? mud?) during changes, with obvious negative results. I don't see any reason why open-ended nuts would be a risk to the wheel studs, so there must have been other reasons why they changed from open-ended to closed-end (and dome) nuts. This is serious rivet counting! Kevin's theory was that the dome-headed nuts fitted neatly into the classic wheel braces that were in use at the time, and which were part of the tool kit on the Works cars. If you look inside one of that type of 'spider' or 'flat four' wheel brace, you can often see a negative dome inside. Kevin thought that the dome nuts fit neatly into this without 'cocking' (risking cross-threading) leading to faster and more reliable wheel changes. It sounds feasible to me... In terms of Works circuit racing cars, in period photos I see both open and closed-end nuts being used. Inconclusive. Heres's a Works mechanic using said 'spider' type wheel brace on the car of Tony Fall and Mike Wood, on the 1971 RAC Rally:

-

Datsun-240z Vs Fairlady-z432

Never say never. I should remember that myself... I think it is hard to discount it, knowing the provenance of your Works car. It may be the exception that proves the rule. I'm trying to think of any scenario(s) where a wheel using the classic tapered seat fixings might have been 'converted' to sleeve nuts, and have so far drawn a blank. I can't help thinking that it is more likely - citing Occam's Razor - to be original and correct for the car, and/or perhaps the whole '71 Monte Carlo Rallye batch (except RHD ex-'70 RAC car '694'...). The logistics of a Works team participating in a certain event dictate the it makes sense for all of the team cars to have the same method of wheel fixing. An event like the Monte Carlo Rallye - with tarmac stages, ice stages, snow stages and changing conditions between all three - requires multiple wheel and tyre changes. There would have been dozens of wheels - shared between the cars - with the Dunlop tyre trucks stationed at strategic points changing tyres on wheels, and team service cars out at designated service points carrying wheels and tyres to be changed according to the upcoming stages. Big churn. Obviously it would make sense for all team wheels to have the same fixing method/nuts. Even the ice note/recce/fast service team cars would follow suit. So without knowing for sure what the rest of the team cars used on the '71 Monte, I'd be reluctant to dismiss your sleeve-nutted wheels as 'incorrect'. There's even a slim possibility in my mind that they were something to do with the conditions on the Monte Carlo Rallye. Nissan's Works team had already contested the Monte Carlo Rallye several times before '71, so they knew what they were up against. There may have been some reasoning behind this...

-

Radiator lower support anomaly?

I think this mount is related to the air filter housing of the fuel injected models, superseded in August 1974 by another design?

-

Datsun-240z Vs Fairlady-z432

There was definitely an observable transition/evolution from open-ended wheel nuts to the chrome domed-end wheel nuts during 1971. Here's that 1970 RAC car (it is 'TKS 33 SA 696' by the way) again. Definitely open-enders:

-

My two swiss S30Z Fairlady Restoration build thread

Looks to be in A1 condition. Nice find! On an LHD car, where will you mount the Oscillator box?

-

Datsun-240z Vs Fairlady-z432

My impression is that the 7x14" Kobe Seiko 'Rally Mag' wheels on your Works car are something of an anomaly, in that they use the same 'Sleeve Nut' style fixing as the OEM '432' Kobe Seiko mags. Of course, there was constant evolution within the specifications of the Works cars - even to the stage where there were differences between cars made in the same 'batch', and for the same event - so the concept of what may be 'correct' or 'original' for one Works car may not necessarily be applicable to another. However, I have a pretty good collection of wheels made by Kobe Seiko for Nissan's race and rally teams (maybe 40+ wheels now) and they all - without exception - have a steel insert with a conventional (60 degree?) taper to suit wheel nuts with the same tapered washer. At least six of my Rally Mag wheels came from the batch of cars built for the 1970 RAC Rally here in the UK, so they have some provenance. From what I can see of the wheels, they don't seem to have been modified from parallel bore 'sleeve nut' fixing to tapered seat steel inserts. The inserts look original, and match the later wheels in my collection. Looking at period photos and original Works cars, I see plenty of evidence of tapered seat fixing. Doesn't mean that they were all that way, but it looks like majority share to me. A couple more period photos, perhaps illustrating the destructive nature of top flight rallying (and drivers who insist on getting to the end of a stage despite having a puncture...). Tapered seats in evidence:

-

Datsun-240z Vs Fairlady-z432

-

Datsun-240z Vs Fairlady-z432

Two basic different types of wheel nuts were used between the OEM '432' Kobe Seiko magnesium wheels and the Works 432-R/Works 'Rally Mag' wheel. The (narrow) '432' type used what I believe is called a 'Sleeve Nut', with a long parallel shank and a corresponding parallel hole in the wheel. These centred the wheels on the studs by having a close clearance between the shank on the nut and the hole in the wheel, and clamping force was distributed by a thick washer on the outside face. Personally speaking, I don't like this fixing method. It always seems to raise questions of balance and poor centering. The (wider) Works 'Rally Mag' type used a conventional nut with a (60 degree?) tapered washer that was pressed on - but free to spin to the short shank. The wheels had a steel insert with a matching taper. Clamping force was distributed around the tapered washer and centering was 'automatic' via the stud-centric nature of the tapered washers. These seem pretty much fool-proof to me. I've got a fairly big collection of Works Kobe Seiko wheels (7j x 14" Rally Mags, wide 15" 4-spoke circuit racing mags and 6j x 14" 'Violet' rally mags) and all of them use tapered steel inserts in the wheels to suit tapered nuts. Works rally cars started off in 1970 with open-ended wheel nuts, but switched to chromed dome nuts soon after.

-

Japanese RHD HS30 variations 70-74

I can see your dilemma. Ultimately it is up to you, but as you already have a good quality Grande Nose and overfenders (very likely a genuine factory 5-piece kit plus genuine factory overfenders) and it was clearly fitted a long time ago, then maybe it would be fitting to keep it. Part of the car's story. On the other hand, you could sell on the Grande Nose and overfenders and use the money they bring as an assist in a return to factory stock 240Z-L bodywork. Maybe factory body colour (white?) too? Period/period-sympathetic modifications and updates would not be out of place. Glenn Chiou's gorgeous blue Fairlady 240Z-L is a great role model. In any case, I'd like to see more photos when you are ready.

-

Japanese RHD HS30 variations 70-74

The three models in the photo I posted (it is a page from the October 1971 'Z-4' #272 Nissan Service Shuho model introduction booklet) are the three that I have been talking about; the 'HS30-S' Fairlady 240Z'/'HZS'/'HZ-Standard' model is the one on the bottom. It had the L24 engine the same as the other two models above it, and is implicitly included in the "2,600" conjectural figure from the graphic that we have been discussing.