-

Z's on BAT and other places collection

If a sermon could save even one soul it would be worth preaching. I think you'd find - if you gave it the benefit of the doubt - a smattering of eager listeners in "this crowd" who would appreciate the chance to hear what you have to say. If we don't deserve it, then who does? You might look at the current exchanges on this forum and see members eagerly conversing with what appears to be an Artificial Intelligence 'bot, but over the years some of us have drilled pretty deeply into the story of these cars, the people and circumstances behind them and into their very fabric. I can think of few other open source platforms where this has been made available in the English language. Hopefully (!?) much of that still exists here and is - with effort - searchable for those who are curious and/or passionate enough to know. At the very least, put it out there before you can't. Pro Bono. Thanks.

-

Z's on BAT and other places collection

You've pretty much answered your own question there. And when it comes down to it, we'd have to judge it as a success in those very marketing terms let alone anything else. The press loved it. The project caught the imagination and support of influential figures in the North American Z 'scene' - including the kind who insisted it was a first for a major manufacturer (it wasn't) and "unique" in the auto manufacturing world (it wasn't). Those same figures still vaunt it today. We've certainly discussed the topic here on classiczcars.com many times over the years and our fellow member @26th-Z wrote what I believe is the definitive essay on the VZ cars. It was - when all is all said and done - a big deal in the story of the Z car's mid-life crisis. But as is often the case, the hype and commentary from offstage created unrealistic expectations. The misleading term 'Factory Restoration' was thrown around a lot and many swallowed it whole, including members of the specialist press. The VZ cars often get judged as though they were intended to be 100% factory correct concours restorations when that was clearly never the case. You can see the same thing happening in the current BaT auction. LOL. Another bunch of answers to your "why are the Vintage Z valued so highly?" question in there. It's the kind of people appearing in that video - and mentioned in it - who are part of the hype. High profile figures in the old Z car world, but often too the Typhoid Mary-like spreaders of bad information. Whilst looking in the engine bay of a VZ car we get the words 'Nickel' and 'Cad' plating thrown around (its mostly Zinc...) and a false story about the commissioning of re-pop braided hoses (Nishi san of Revive Jalopy in Japan was responsible for this and for many other previously unobtainable parts too). We even see a modern fuel filter pointed at as though it is some kind of ancient relic. Some typical 'Mr K Lore' thrown in for good measure when discussing early cars/chassis numbers. Larry Chen asks "why is it that the US got the early cars and how come Japan didn't get the early numbers...?" and Jaffe's answer talks about the '240Z'. Japan did get early cars (they got them earlier than the US too...) but the problem here is the congenital misconception that the 'US 240Z' is something over and above the whole S30-series Z family as conceived, planned, designed, styled, engineered and produced before the end of 1969. To the point that anything else is some kind of afterthought. We get Katayama's "PUSH" related as a one-man quest to get 'his' project made rather than the more realistic scenario of him lobbying for influence on something that was already happening. Apparently Mr Carl Beck ('Z car encyclopaedia') "can tell you how many went to England, Australia and its all very limited...", but there's no mention of Japan in their 'Z car' story. You can look at pretty much any volume - and non-volume - selling sports car of the 60s and 70s period and see the same story; volume sales in the USA. But I've yet to see any Triumph, Austin-Healey, MG or Jaguar being vaunted as 'Made Expressly For The USA'. VW shipped just shy of 400,000 Type 1 Beetles into the USA in 1968 alone, so 'Made For The USA'? Mainland USA was the biggest single potential market for just about any product of the period concerned, but I would like to credit at least some US consumers as being sophisticated enough to see through all the "we made this for YOU" type sales slogans. So, why are the Vintage Z cars valued so highly? It's in large part due to the influence of the kind of people who had eight of them, and sold six of them to somebody who now has eight. Larry Chen will make a video about them! People listen, and look up to, movers and shakers like that. Our old BaT friend Larry Stepp (he's a BIG fan of the classiczcars forum) made a prediction the last time this current BaT auction VZ car was up for sale. He said it would be worth 250k USD in a few years. There's the hype. It's not so much to do with the physical details of the object (which is not too shabby, to say the least), it's the perceived kudos and status within a fairly small cohort of people who are looked up to as sooth-sayers and mystics. Buy "one of the 37" and - hey! - maybe you'll even get the pleasure of putting the hose clamps on 'the right way round'...

-

Euro / JDM taillight wiring

Both upper reds operate as side lights and brake lights.

-

HS30-H started following S30 World 'Test Drive' article , Euro / JDM taillight wiring , Check out this ATK crate L28 engine on BaT and 4 others

-

Euro / JDM taillight wiring

No, the Japanese market parking light system has its own bulb in each rear lamp unit. It's the one that is otherwise blanked off with the 'P' plug/grommet in the centre of the lamp unit.

-

Z's on BAT and other places collection

Nissan were caught out by changes to motor vehicle 'Construction & Use' regulations with regard to lighting for 1971-up in several European markets. Height from road level was particularly difficult to solve. The regulations even required changes to the illumination of the rear license plate. Of course such regulations applied to NEW cars and many private owners took the opportunity to move these aesthetically unpleasant front turn signals to a position UNDER the front bumper, or - even better - to revert to the configuration that the gods originally intended... A legacy of precedence. You may have heard of Mr James Watt? He found it necessary to use a unit of measurement in order to compare the power of steam engines to that of working horses. Of course he used the IMPERIAL system as METRIC horsepower didn't exist at that point, the Industrial Revolution not being a Continental phenomenon... You may also have heard of Sir Isaac NEWTON? That's him in your Nm measurement. (Posted from The United Kingdom of Great Britain and Northern Ireland, a small place off the coast of mainland Europe which used to rule much of the world for a while... LOL)

-

Z's on BAT and other places collection

1971 United Kingdom market HS30 'Datsun 240Z' with low recorded mileage. The usual inaccurate salesman's flimflam in the Bonhams write-up, but a nice car: https://carsonline.bonhams.com/en/listings/datsun/240z/62327cfd-fa98-45e5-9035-b38d20db87e2

-

My two swiss S30Z Fairlady Restoration build thread

Very nostalgic for me. Back in 1995 I was asked to accompany a couple of Japanese motoring journalists to the Le Mans 24hrs race to assist in press coverage of NISMO's GTR-LMs and their participation in the race for Club Le Mans. We had pit access, press room access, full catering and hospitality. A big contrast to my first visit to the LM24hrs in 1970 when I only ate frites and crepes and managed to catch just a few hours sleep whilst soaked through, laying on newspapers by the side of the track...!

-

Check out this ATK crate L28 engine on BaT

Japanese company. Try searching in Japanese: https://atk.co.jp/rebuild/

-

Gas Tank Order From J30 in Netherlands

Any chance of correcting this thread title's 'J30' to 'S30.world'? Might help future searches...

-

Wire identification

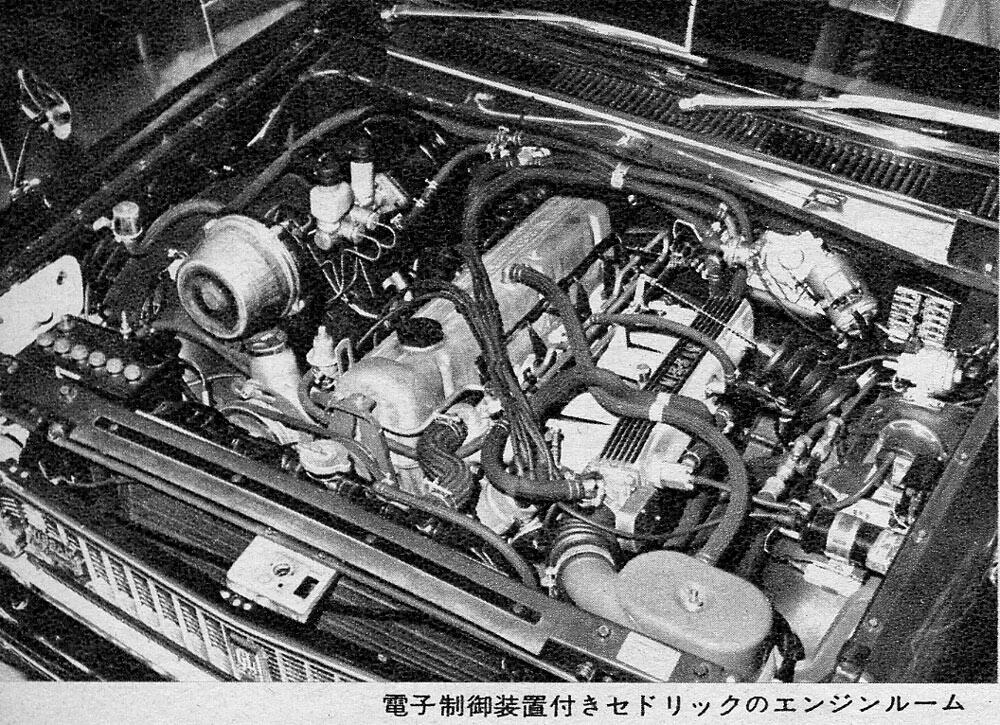

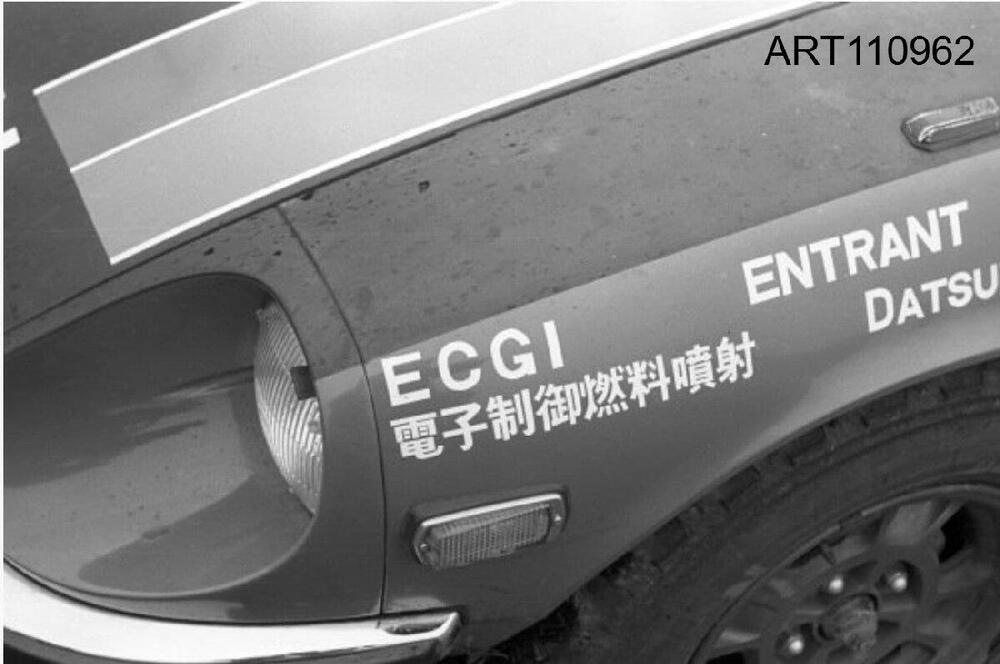

ECCS was first used on the 430-series Nissan Cedric in Japan (June 1979). ECCS stands for Electronic Concentrated (Engine) Control System. Electronically-controlled (via an ECU) injection was introduced on a 230-Series Nissan Cedric 'EL' model at the 1970 Tokyo Motor Show: Nissan was actively using a system ECGI (Electronic Controlled Gas Injection) back in 1971. Nissan group affiliate Diesel Kiki licensed the Bosch D-Jetronic system patents and re-engineered it to use with double and triple sidedraught throttle bodies on competition cars:

-

The Development Story & Specification Of The European Spec Datsun 240Z

Here's another great S30.world article, this time focusing on the development of the 'Euro' spec Datsun 240Z, exploring the circumstances which necessitated its creation and the people behind it. It includes some - precious! - original hand-written development note documents which we are privileged to have access to after all this time, thanks to our fellow member @kats Very nicely put together and written up by another of our fellow members here Nils @JDMjunkies.ch Tip of the hat to Florian at S30.world too. This is a topic not often acknowledged let alone discussed, and yet it is a fascinating window into a significant part of the S30-series Z's family tree. Recommended reading: https://s30.world/articles/european-spec-datsun-240z

-

1971 HLS30-14938 "Lily" build

As far as I understand it (and I've seen the same thing on several different makes of old cars) they act as a spring/damper, which has a positive effect on the sound quality and also insulates the mountings from high frequency vibration when the horn sounds. But they certainly have an air of late 1860s rather than late 1960s, so I empathise with your curiosity.

-

Z's on BAT and other places collection

It's quite hard to pin a current market value on a 432 or 432-R, but - in Japan, where the majority of them reside - they can change hands privately for stratospheric (in S30-series Z terms) figures. The 432-R is often valued at three or four times that of a 'normal' 432, but there's a limited data reference as so few Rs are sold 'on the record' and in public view. Japanese buyers and sellers can be very secretive (most individuals are circumspect with regard to their personal financial circumstances) and quite a few of these cars have been owned by people who are now of senior age, coming to the end of their safe driving life. That's a situation that can be taken advantage of by younger family members, friends and/or people in the old car business. @kats can tell you of a case late last year where a genuine 432-R, owned by an elderly gentleman, was bought at an unusually low price (by somebody in the right place at the right time) and was very soon being 'flipped' at a three or four times multiplied figure. Sad that the elderly vendor didn't get a more honest buyer. I feel that it's important for these cars to go to good homes, which I guess is not always about money. And that's something we can also say about this 'PS30-00218' for sale via Takeey's. It may well have a cloud over its authenticity (which all hinges on whether it's chassis number has been altered or not...) but it exists, is an attractive car in it's own right - nothing wrong with a 432-R 'tribute'/'replica' - and as long as any new owner knows exactly what they are buying, and the price paid reflects that, then OK. It just needs to find that 'Mr Right'.

-

Z's on BAT and other places collection

Hi Steve, This is a well-known - perhaps I should say somewhat 'notorious' - car with some er, baggage... I have it down in my notes as having a "re-stamped" (re-engraved?) firewall chassis number, and there has been a fair amount of gossip about the car between interested parties over a few years. I have photos of the car from when it was for sale in 2018, so it's been knocking around ostensibly 'For Sale' for a good few years now. The website you link to is actually for a somewhat parasitic forwarding company, hoping to get in on the sale of the car and the shipping/handling thereof and taking a margin from both seller and buyer. Best to look at the car with the actual seller, well-known Japanese old car vendor 'Takeey's' based in Hamamatsu City, Shizuoka prefecture. Here's their website: http://takeeys.com/index.html ...and here's the car for sale (price = 'ASK'...) on the Takeeys official site: https://www.goo-net.com/php/search/spread.php?baitai=0600834&area_cd=15&goo_car_id=700060083430240917001&ef_flag=1 Chassis number 'PS30-00218' is a genuine chassis number, but - more specifically - it is a known and official chassis number for a PS30-SB 'Fairlady Z432-R', the very limited production super lightweight variant of the 432. Genuine 432-Rs are on another level in terms of rarity, desirability and market value in comparison with 'ordinary' 432s. However, there are question marks around this particular car. You will note that Takeey's are not claiming it in writing as being a genuine 432-R. They are selling it as a '432', which it almost certainly is. The question is whether a standard 432 has been 'sexed up' with many 432-R specific parts and details and has - nefariously - assumed the identity of 'PS30-00218' which was a genuine 432-R. We can spot many 432-R specific details and parts on the car (console delete, trans tunnel-mounted ignition switch, plain vinyl trans tunnel cover, spare wheel well delete, 100 litre tank, etc etc etc - there are too many to list) but only a genuine 432-R would have the super lightweight type bodyshell with its thinner gauge sheetmetal. Almost impossible to fake that. @kats will be able to tell you much more than me, and perhaps a little more diplomatically!

-

S30 World 'Test Drive' article

S30.worldS30.world - S30.world – test driveS30.world – test driveWorth a read.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.