Everything posted by CanTechZ

-

Z's on BAT and other places collection

The silver '71 that went RNM is better described as a survivor. I say that based on comments by the seller. IMHO it was never really a "driver" in the daily driver sense. Only 12K miles from 1971 to 1975, and it must have been parked for winters, being a Canadian car from Ontario where roads are heavily sanded and salted. I was still very surprised that it was bid to $98K and still did not sell considering the lack of detailing. I much prefer a well restored to original car, like the current one up from @CW240Z72 over a survivor any day of the week. Although I'm a little biased as I'm restoring my own right now. Lol

-

Z's on BAT and other places collection

-

Early 240z oil pans

-

Detailed engine compartment

I know this is a restored example but if you haven't already you should check out the build discussion for @jayhawk's '73. It's absolutely beautiful.

-

Restoration of BringaTrailer 240z - HLS30-35883

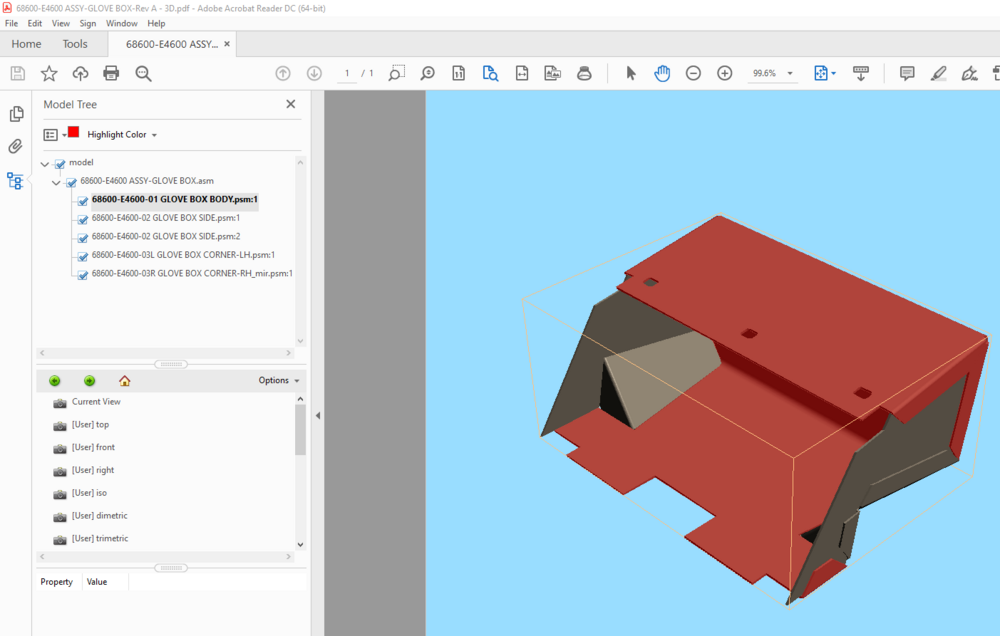

I used a 3D parametric cad software package called Solid Edge, made by Siemens. This is actually only the 3D model, it looks like a drawing because I imported a scaled image of the chassis from my 1970 FSM and inserted it as the background to build the model on. Still had to a lot of measuring off my car and the parts I have from Klassic Fab, but it's good to have the FSM drawing to confirm the main datums.

-

Restoration of BringaTrailer 240z - HLS30-35883

Great job, I did similar work to my fronts a few years ago but not quite to this level. It's very satisfying to see the end result after all of the effort it takes. So much nicer to use original parts and not just replace with reproductions.

-

Restoration of BringaTrailer 240z - HLS30-35883

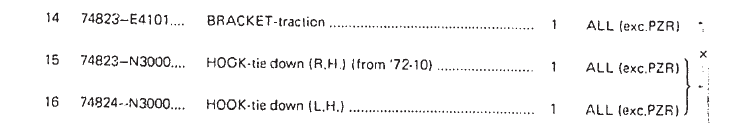

In case you might be interested, here is how I plan to make a rolling support frame for my shell using Unistrut. I'm using the same mounting points as you did. Hopefully I will be assembling it in a couple of weeks. Thanks for the inspiration, I will be posting the end result in my own resto thread.

-

73 240z restoration 904 White

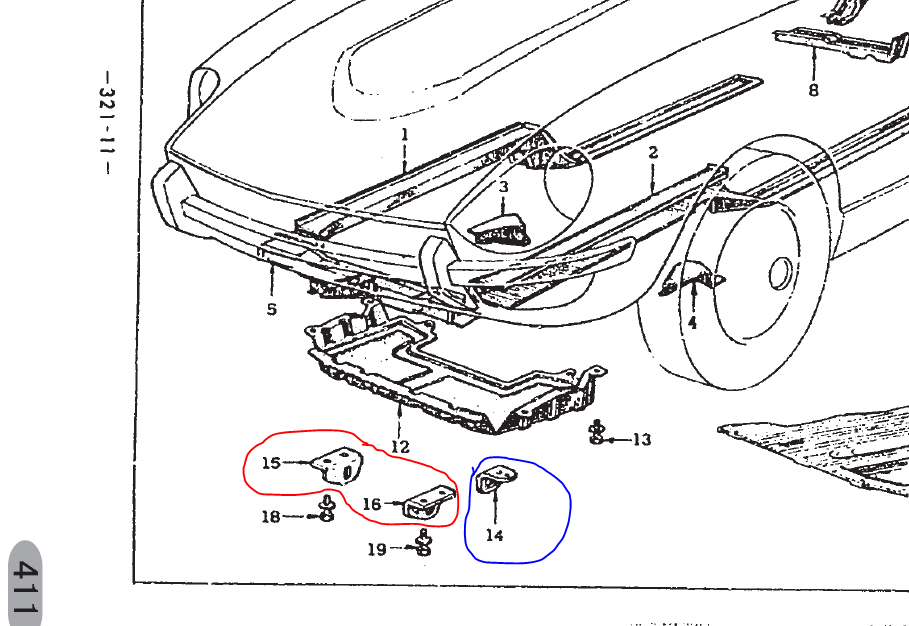

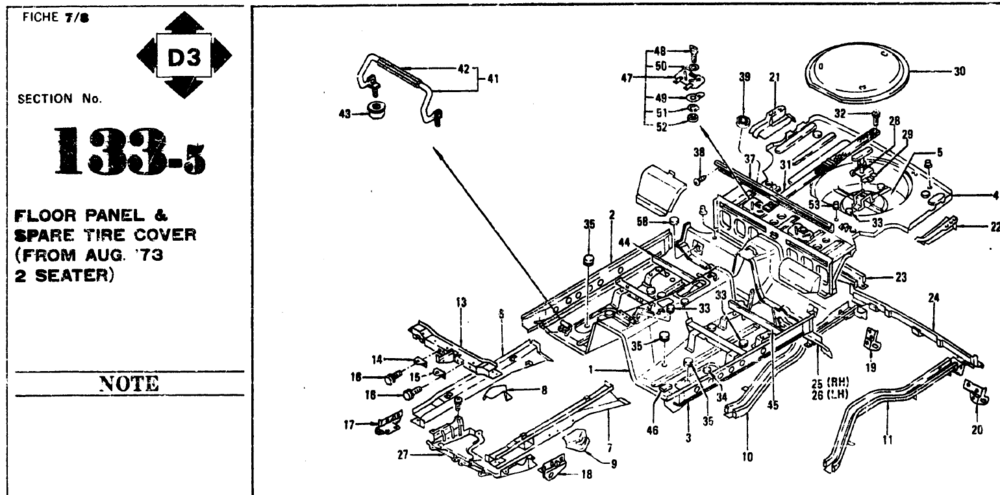

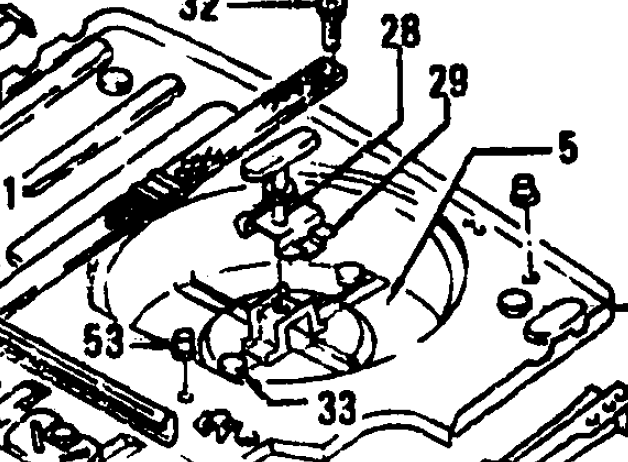

This might help from the 1973 JDM parts book, early circled in blue, 1973 circled in red. I would assume it was the same for North America. It's not shown very clearly in the N.A. parts book.

-

73 240z restoration 904 White

It seems to be a 1973 thing, here is a picture from a BaT auction of a 1973. Pic #206 from here: https://bringatrailer.com/listing/1973-datsun-240z-169/ And here's my 1970,

-

73 240z restoration 904 White

Since I now have both, here is a set of pictures comparing Klassic Fab rails with Zedd Findings. Both appear very good, but the KF rails are definitely much closer to original, at least when compared to the rails on my 1970. The ZF rails are more of a "universal' fit for 240/260/280, as they are formed, they are very straight. The KF rails I received have a little waviness to the lower horizontal flange, but it's not a show stopper. Regarding the shape of the rail near the rad support, I only just now noticed that in addition to the width being narrowed, the height is actually shorter as well. You can see this clearly in the pictures.

-

Brake master cylinder identification

@Captain Obviousbrings up some good points about likely differences between the early and later M/C's. To help visually show the internal differences I cut and pasted scanned cross section images from my 70 and 72 FSM's. I believe there has been discussion on this forum by others that have used the later M/C on early cars and the solution was to modify the brake tubes and not simply swap the reservoirs. Here is a link to one of the discussions on swapping M/C's

-

Restoration of BringaTrailer 240z - HLS30-35883

Over the holiday break I plan to layout and model supports using ideas from your pictures and @ConVerTT's jig pictures. While looking for framing ideas I found this vintage unistrut video, and couldn't resist sharing. Lol

-

73 240z restoration 904 White

One of the good things about being so slow on my own project is that they have added a lot of the parts I was looking for last year. Just received these recently...

-

My two swiss S30Z Fairlady Restoration build thread

Nice score, FYI those "mounting brackets" are for the front bumper.

-

Restoration of BringaTrailer 240z - HLS30-35883

Nice work on the rolling frame components. While I'm waiting for my body guy to pickup my shell, I have been considering doing something similar. I might use a combination of fabricated parts plus unistrut channel, fittings and hardware. I've used unistrut in the past for jig and fixturing and equipment frames and found it to be very useful for allowing adjustability and minimizing welding. It would make very easy to add braces and front to rear long members. Also when the time comes, it can be disassembled easily for storage or use in other projects. Here is an image of a past project and a link to a unistrut page showing some hardware examples. Their channel nuts and brackets make very rigid connections. https://www.unistrutohio.com/general-unistrut-fittings

-

Fiberglass glove box

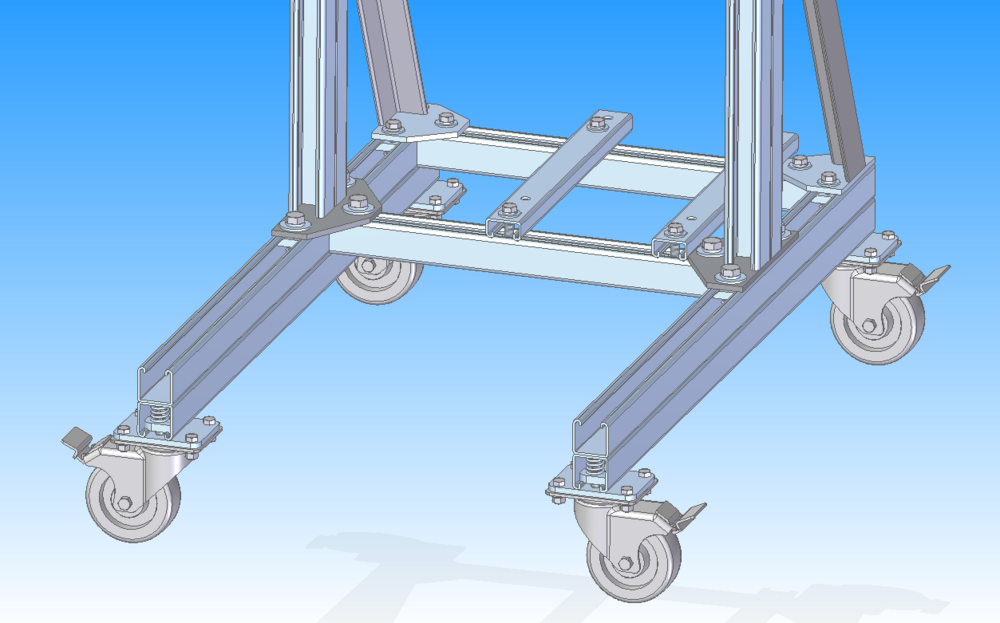

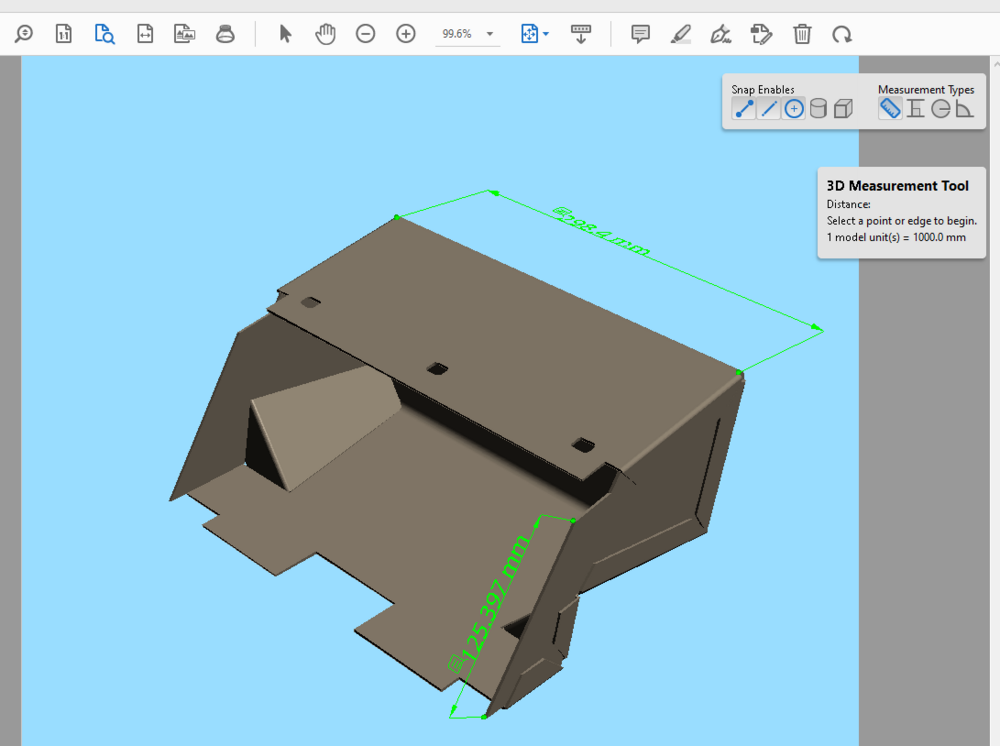

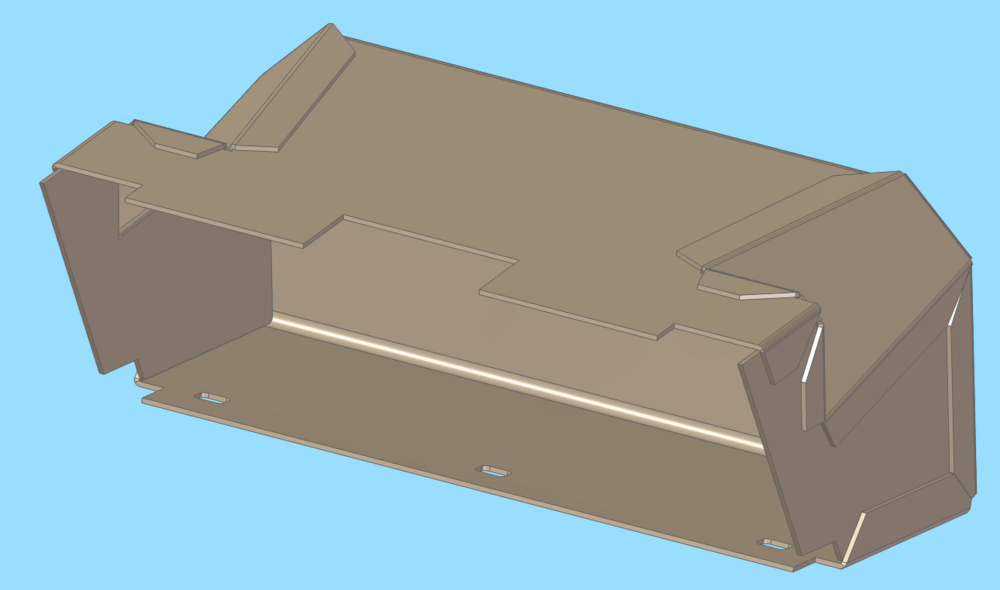

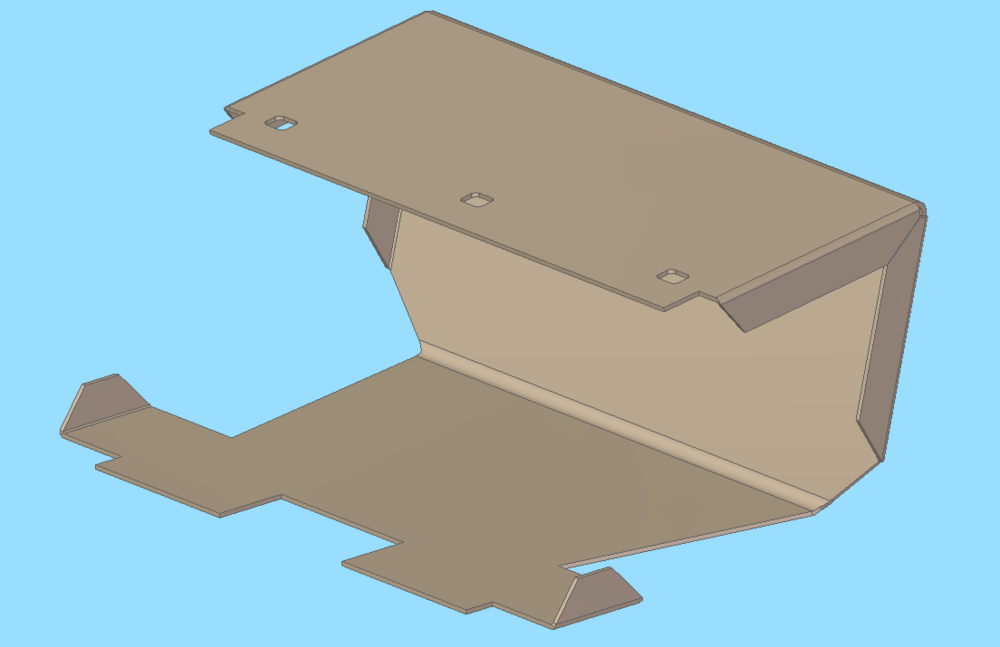

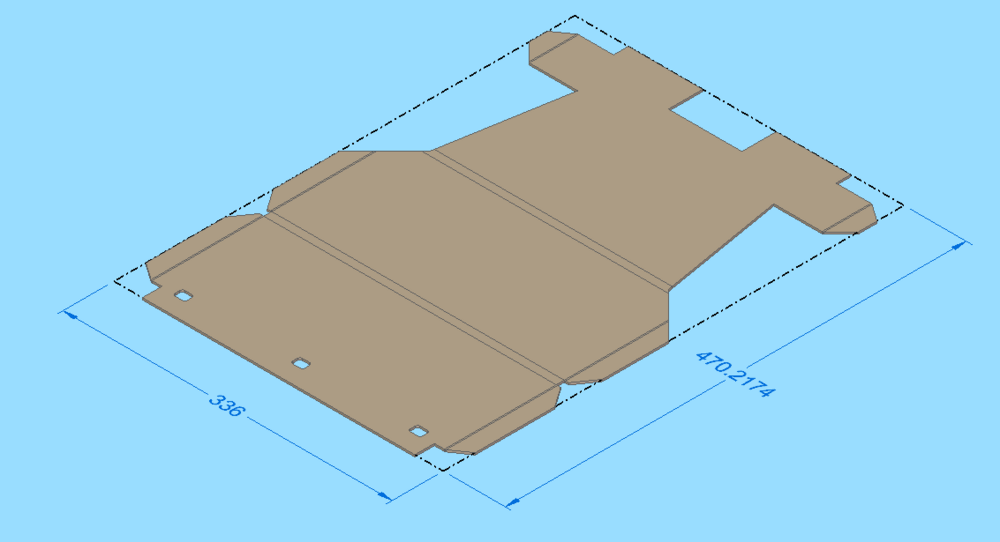

You're welcome @Seppi72. My plan, as mentioned previously, was only to make a 3D cad model and 1:1 scale flat patterns. I was not planning to create a complete set of fabrication documents. Anyone with a 3D cad package should be able to pull off any other dimensions they might need from the step file I uploaded. If anyone wants a specific dimension checked, I will try to do that if asked. FYI, In the files I uploaded I also included a 3D pdf file that can be opened with any recent Adobe Acrobat Reader. The 3D pdf viewer allows you to rotate, pan and zoom etc. and also to see a model tree and isolate individual parts. You can even use the measuring tools by right clicking to see the options, Hope this helps Cheers, Mike

-

Fiberglass glove box

I just finished uploading the 3D model and flat templates. The cad model is in step format (and 3D pdf). It was created using Solid Edge version 2020. The flat templates are exported to .dwg and .pdf formats. I was not happy with the result of the formed upper corners (modelled quick and dirty, LOL) so I included a scanned tracing of an original part.

-

1970 240Z Glove Box Templates & 3D Model

- 133 downloads

- Version 1.0.0

Templates and a 3D model (.stp format) for a 240Z glove box. the main formed body and flat sides were checked against disassembled and flattened original parts and are quite accurate. The smaller formed corner parts are not as accurate. Also included is a 1:1 scan of a tracing for the two formed corner parts, these parts were only roughly modelled and did not flatten exactly the same as the actual parts.Free -

Fiberglass glove box

Finished modelling the glove box, not perfect but reasonably close. On the weekend I will post the model and flat patterns to the club downloads area. @Seppi72 I hope all went well with your hip surgery. Best wishes, Mike

-

Fiberglass glove box

Had a little more time to work on the glove box project. For the cad people that might be interested, here is a preview of the main formed body.

-

Cheating heart

Careful, if you continue down that path this could happen to you... Thankfully I outgrew that phase and can now focus on my Zed. It was quite neglected during those years. Lol

-

My two swiss S30Z Fairlady Restoration build thread

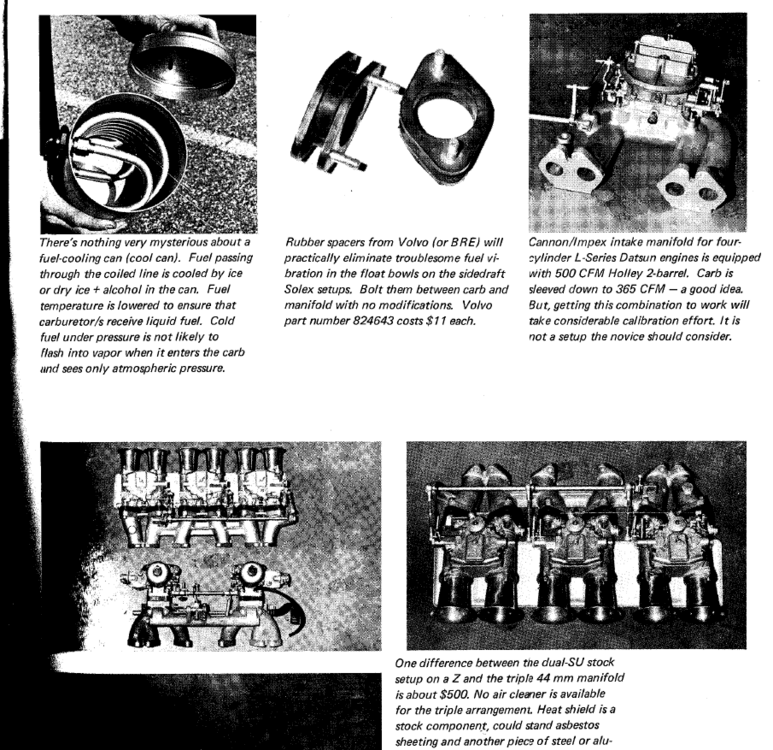

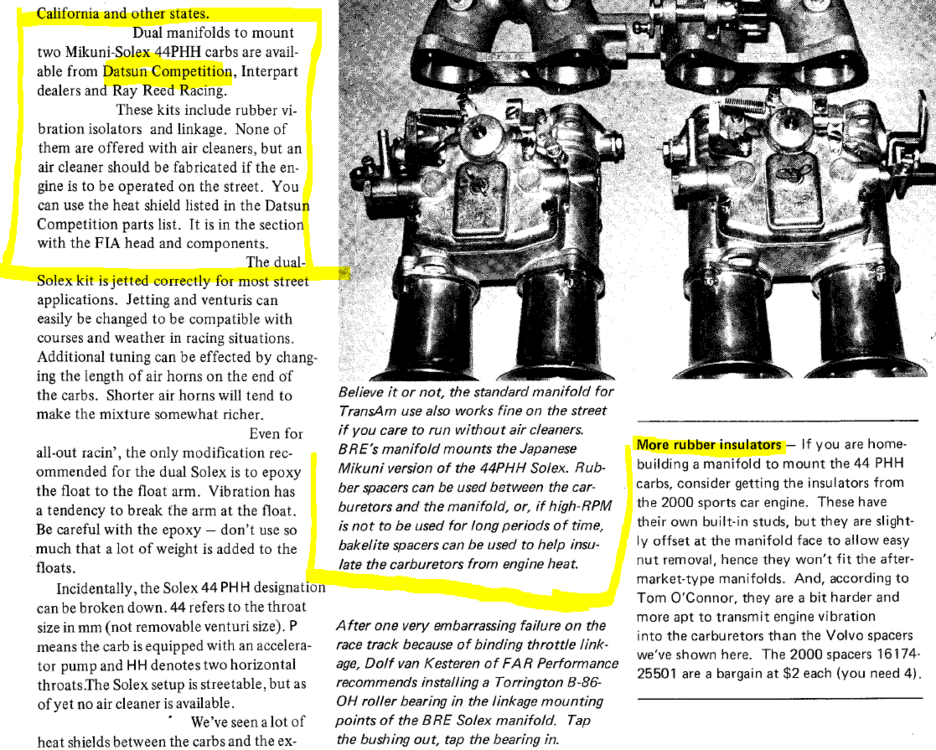

There's some interesting reading in Bill Fisher and Bob Waar's book: "how to modify DATSUN 510 610 240Z engines and chassis" I have a copy from 1973, it's a good read. Here are a few snippets related to isolators for Mikuni/Solex carbs,

- 1970 HLS30-06521 Re-Restoration

- 1970 HLS30-06521 Re-Restoration

-

Spare tire hold down identification