Everything posted by madkaw

-

F4W71A trans. - fix it or ditch it?

I worked on an early 71 that had the original 4 speed - A . The shifter was terrible and that’s what I learned what monkey motion meant - lol. Anyhow - I don’t even remember how I made the connection with Lou Mondello in Australia that had a make potion for the A trans shifter . I ended up sending the tail section down under to get reworked . It took time and money - but boy was it worth it . The owner texted me - OMG- YES ! It transformed that A trans . The shifter was great and made for fun shifting regardless that it was just a 4 speed .

-

Float level madness

I stand by my statement 🙂

-

Float level madness

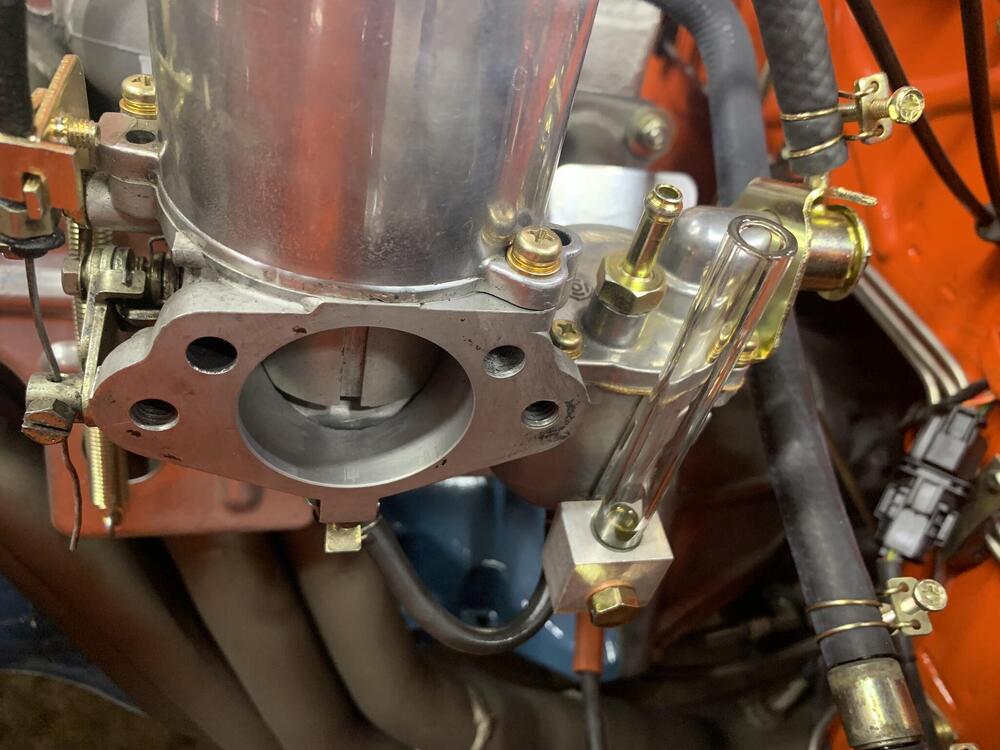

Well I did get another lid and have both short ears on there . I have my float sync tool and messed with float levels forever . I come up short- no matter what I try to get the correct height . I said time to try it . It seems the engine want at least 4 turns out to be happy . That also varies from start to start . I need to check the incoming fuel pressure to make sure it’s adequate or maybe too much . I do have my wideband working so I am shooting for about 13.5 at idle . . Did I say I hate carbs :-0

-

Float level advice, please.

Just got off the phone with my car friend and PHD physics guy. His thought was as long as you had a reasonable amount of fuel in the float bowl, the Venturi will pull the fuel pass the jet fine . It’s more critical that the jet and needle are the same on both carbs than it is to get max amount of fuel in the bowl . I like the idea of the floats being more level , but it doesn’t add any more fuel to the bowl ( volume ) . I think getting the float needle to sit in the float tang properly is important too - especially with these flat tipped float needles

-

Float level advice, please.

Very interesting read and right on target for I’m dealing with . I’m a little intimidated to boring holes in my SU’s , but might have to do that . I’m building a high performance engine for a customer and I can’t get the floats to comply . I’ve been at for days - literally . My floats are slammed against the lid to get proper level using a float sync. I can’t afford for this engine to go lean . Instead of a fancy slug I was thinking a coarse screw into the side of the float . Maybe a brass vs an aluminum would give me options as far as weight - even steel . Any thoughts on this approach ? I am using two short lids hoping I could duplicate my approach easier

-

Float level madness

Well it’s not my car or I would consider that option

-

Float level madness

Hey Cliff , if you have any pics of those tangs or maybe sketch out the shape of your tangs that worked . I’ve been at for days now and actually bought another set of SU’s so I had more floats to choose from . I got the front one nailed , but it’s seems whatever I do to the rear one comes up short .

-

Float level madness

So today I went for a pleasant 90 mile trip to meet with a fellow Z'er who had a crucial part for me . He said he found an extra float for a SU in his Weber stuff. Believing that the float was the issue I was happy to find one and try it out. So I noticed that the tang was longer on the replacement . I also noticed how flat the tang was compared to mine that was bent straight up it seems. I set it using the 'blow thru the needle and seat method. When I put fuel to it the fuel level actually stop rising and didn't overflow. It was too low so I proceeded to tweek it . And wouldn't you know it overflowed -SH!T So I made another adjustment . Long story short I come to realize that if I empty the bowl by completely draining it( usually when I remove the float sync tool) , the needle and seat had a harder time stopping the fuel then when there was fuel left in . I can only presume that the fast filling empty bowl made it harder for the valve to stop the incoming fuel. So I started making float changes by just removing the lid and leaving the float sync tool in place . I was able to get pretty close to the 23mm from the top of the lid. When I moved on to the front carb I saw another mangled float tang -ugh. To be continued

-

123 Ignition

I've done a lot of playing around with timing since I have a programmable ecu. You should have most of your advance in by 3000rpm, but sometimes you might have to drag out the last few degrees beyond there. You can run quite a bit of vacuum advance especially when you can control it with this 123 ignition. I run 45 degrees of advance on my stroker in high vacuum/low KPA areas .

-

Timing issue 75 280z

Probably the lack of use is the biggest culprit. Valve probably hung up and the rocker went off the rail. Worst thing you can do to these engines is to NOT use them. Just starting them up now and then is not enough. I'd put it back on and go thrash on it down a back road .

-

123 Ignition

You can only manage 28 degrees total ? That seems quite low even for 10:1 and 92 octane . Serious amount of power left on the table .

-

Float level madness

Thank you for the link . I should have known that there would be an extensive discussion here on this site ! The idea of a float that is hitting the wall had come across my little brain while dicking with this . The float metal structure actually looks bent to one side . Maybe I will swap floats from front to back and see what happens . I don’t think I have any spares .

-

Float level madness

Hey guys , I guess I’ve been away from carbs too long and now I can’t work on them . A customers car that hasn’t really run yet since rebuild . Trying to set my float levels and using a float sync tool to help assist . The problem I’m having is that I have one carb that wants to be ole faithful . Even if I adjust it for a low fuel level it will eventually overfill. I am using a Holley Black fuel pump that is rated for 4-7 psi . I also installed a Mr Gasket inline fuel pressure regulator set at 2psi . I had an extra needle and seat laying around and swapped it out , no difference . The carbs were lightly rebuilt with new needle and seats from Z Therapy . Not sure what to try next. The front carb seems to be doing fine and holding a certain level. I was considering swapping parts from front to back and see if the problem follows . Any thoughts ?

-

Overheating Only Under Load

Bizarre for sure . Laser temp gun to verify readings . Not sure what to suggest other than replacing the sender sensor to start

-

Is the Zcar Depot dead?

They won’t take calls - which sucks . They are usually good with replying to emails

-

L28 Engine rebuild

Nice set up. The n42 pair is not my favorite for modification . I would definitely want flat tops for the block - but that’s all the mods needed there . The head is going to be a lot more work . The best solution to keep down time to a minimum is to have another head rebuilt and ready to go . I would source a higher quench head - p90, p79, mn47 . They will do better with pump gas . Or maybe just find a zx motor and use the block and head . As far as the cam - going big or go home .

-

Frankenstien Engine for Junk Car race

All those heads should be drilled for carbs . N42 is your best bet for dished pistons .

-

Parts for Sale: 1970 fuel tank

View Advert 1970 fuel tank I had this extra tank that I decided to move along . I painted and sealed the inside of the tank . You can see by the pics that it was very clean inside even before I started . I used Por-15 tank sealer per their instructions. For some reason I had some bubbles pop up on the bottom of the tank . I contacted the reps for Por-15 and they acknowledged that this happens some time , but no worries on the integrity of the sealer . I painted the tank outside with SEM trim paint . It has newer Nissan sender and new drain plug . Asking 300$ Shipping will be thru FedEx and I will only charge actual shipping cost . Advertiser madkaw Date 06/22/2022 Price $300 Category Parts for Sale

-

Bad noises somewhere in my drive train

Stock r180 with a Rebello power and one weak point and bang . I’m with everyone here about checking diff . Try the Subi diff swap - it makes for a tougher r180

-

Parasite drag on battery

Well back to the shop with it

-

Parasite drag on battery

The drain stops when I pull the T plug . I can make the regulator click by removing and installing the T plug .

-

Parasite drag on battery

I thought about ditching this older style with an internally regulated style - but his electrical needs were so low . what’s the chance of having two bad regulators - that’s what’s weird . I don’t have a FSM . Maybe see if my Hanes has any info .

-

Parasite drag on battery

I have a .5A draw. Pulled all fuses one at a time Alternator and starter have been professionally rebuilt . Replaced voltage regulator which I thought was the issue . It clicks when connecting the battery cable . Old one and the new one . It also gets warm . 2 bad regulators ? When I pull the field plug it quits So my white 12v from the starter is intact . I have 12v at the plug for the regulator ( solid white ) I have continuity from the WB at the regulator to the WB at the field plug . That makes me think the regulator is not supplying the 12v at the plug .

-

Parts for Sale: Jeep Cam Angle Sensor

And it’s not the only Jeep part on my car - lol

-

Parts for Sale: Jeep Cam Angle Sensor

I do have a Datsun soul . It does work well and glad to see people using it