Everything posted by HusseinHolland

-

75 280 Rear Suspension Work & Disc Brake Conversion (MilkFab)

Started pulling apart the rear suspension after work today. Had to remove the exhaust first - since it's all one piece from the DP flange to the tailpipe, I cut it behind the cat. I'll add a junction there - maybe a V-band, or just a sleeve clamp. Ultimately the whole exhaust will be custom with the VQ35DE anyway. Looked over the undercarriage in general since this is the first time I've been under the back end Control arm bushing are all bad Tapered pin that retains the outer control arm bolt They came out without any drama. I had ordered new main bolts & these, as they typically are a problem. Murphy's Law - if I hadn't bought the new hardware, I would have needed it.. Damper on diff mount/control arm forward bracket had stripped bolts The diff mount is an absolute PITA to remove - the retaining bolt heads cannot be accessed with a socket - the lower half of the mount interferes. They also don't thread into the casing -there are 17mm head nuts that have to be counter held. had to re-tap to M10x1.5 , to avoid replacing the captive nuts or helicoils exhaust - still has the original shielding Shield over rear bumper shock original forward rear muffler hanger cut just behind cat Floors Poorly installed fuel feed hose - pretty heavy kink Limiter strap over top of diff snout Hopefully get more done on it tomorrow

-

Heater Core Alternative - Escort Core into 260/280

Seems I may be mistaken - the valve hoses are cold, if I run the car with the heat off, so the heat I felt must have been residual Another thing I had to address while under there - the center console harness connections. All re-pinned added some low temp electrical grease hile under there

-

Heater Core Alternative - Escort Core into 260/280

I recall reading at a couple of ppl have done so - I'm hoping that with a newer ball valve type, I won't need an auxiliary shut off. I could do that if there is no other way around it.

-

Heater valve

That is true - I'll have to check it after more than 20 minutes driving. I had left the valve open for about 20 minutes outbound drive, to make sure there were no air pockets, then drove back with it closed. My experience with other cars is that with the valve closed the hose on the output side of the core will be cooler than the input, the I/O still felt pretty even in temp. I'll check it again.

-

Replacing All Large Opening Seals & Hatch Small Seals

I had pulled the hatch to do the main seals & repair the faded paintwork in the upper trough. My hinges were loosely mounted, so they had pressed into the hinge seals at one spot on each side. I bought new seals from a (eBay) vendor in Thailand. They were not cheap, however less than you paid. I never test fitted them as they came after I had already put everything back, so I don't know if there is a fitment issue with them. I can't see water getting in there with good hatch seals, unless you open the hatch covered in rain & then it will dump into the car anyway.

-

Heater Core Alternative - Escort Core into 260/280

Have to switch out the stock valve - it doesn't completely close - the hoses are still mildly warm, so coolant is still passing. Not going to work for me, will interfere with working AC once I get to that.

-

Heater valve

I had a go at this, since I was waiting for the aftermarket 74627 valve to come. I replaced the body square cut seal with a Viton thick wall o-ring. No external leaks, however the valve doesn't fully shut - the I/O hoses still have warmth to them, indicating some passage of coolant. I'm going to switch it out for the 74627.

-

Replacing All Large Opening Seals & Hatch Small Seals

I had to readjust the latch, but I assumed that was purely due to the extra seal material previously missing. Still have to slam it pretty hard. The doors were the same initially, until the seals compressed somewhat.

- 75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

-

75 280Z Steering Wheel / Hub Help needed.

Because I like the one I bought, it's period correct. Still no luck on a hub, so it's a moot point

-

Heater Core Alternative - Escort Core into 260/280

So to continue with my version using the '91-02 Ford Escort heater core (thanks Capt. Obvious!) I ordered the heater valve mentioned by another -4 Seasons 74627 - but it didn't arrive until late this evening, so I dismantled the original & had a go at fixing it following the other thread Think it's pretty clear why the heat never shut off - large chunk of silicone wedged in there I forgot to take pics of the re-assembly, I used a Viton o-ring in place of the square cut outer seal, I left the inner one alone. Left it set on an angle filled with fluid to check for leaks. This is what my phone screen looks like (actually worse now, it's all dark) - so my pics are hit & miss I flipped the I/O for the heater hoses - the bulkhead upper is now the return & the outer/lower is the feed. I did it this way so that the feed is not too short, and the return is a straighter run. and so the inside feed is a plain elbow 90º. Determining hose lengths (cut from Volvo 700 formed hoses) here. SS tubing is 20.5". dogleg for the other end, test fit alignment of pipe & hoses Hoses cut & clamped (head fitting was removed, de-rusted, sealed & reinstalled, slight offset change -more vertical Far end adjusted & clamped With that end out of the way, I returned to the heater valve & core. Eyeballed holes for core pipes, based on the core being centered. Added closed cell foam on the sides to make it snug, and to the front to keep it pushed all the way in & cover up the old pipe holes. Was playing with hose routing - this way was to allow the 74627 straight pipe valve to sit above the feed pipe along these lines I'll revert to this layout if I need to switch to the 74627 valve When it became clear that the 74627 wasn't coming , I switched gears & worked on fitting the original repaired valve - Heater valve fitted using the upper existing mount screw, new hole drilled in plate. Cut a notch in the valve mount bracket to clear the lower screw. Checked that flap can open. Feed hose clamped. Cable attached & function tested. Test fitting (formed, Volvo) hoses to & from heater valve Added oetiker clamps after this. Since I wasn't able to flare the end of the core tubing, I prefer them as the clamping is typically more uniform than a worm clamp of any type.

-

Heater Core Alternative - Escort Core into 260/280

Took out the glovebox today, so I could see what's back there regarding the heater & AC pulled the blower housing, made it very easy to access all the heater hoses. Needs a good clean anyway. Heater core out. bulkhead fitting removed, M4 rivnut in place to retain the AN line fitting turns out the aluminum bracket/fitting has identical spacing to factory, makes things easier. Just have to drill the center hole to match the factory cover plate shown All kinds of crusty 'plastic' laying in the box - it seems the heater core end tanks were encased in it

-

75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

I understand the logic there - and also know from experience how the threads in the fixed fitting may or may not coincide with providing me the proper fitment - I've done exactly the same thing, with brake lines on the Fiat - those rarely come apart without damage, so if it's possible the spin the item off the line rather than undo the fitting, so much the better. I want the hose to end up nice & relaxed as my (one piece) front brake hoses 🙂

-

Replacing All Large Opening Seals & Hatch Small Seals

Thanks Gents - so not applicable to my 75 then. I'll have to figure out which vendor I bought them from. They have the Precision labels, so probably not ZcarDepot.

-

75 280Z Skillard Tall Grille & Skinny Bumper Install

Finally got back to this - assembled & installed the rear bumper today. I test-fitted it yesterday & marked the 2 drill locations for the side attachments. Primed & painted the holes prior to assembly. Had to do it jammed in the garage, it rained all day. I had to retap both the side captive nuts - neither would accept the M12x1.25 bolts. Also had to use 3M VHB tape to secure the rubber strips - otherwise they 'flop' away from the bumper in-between the mount studs. I had removed the fronts & done the same previously. The vendor claims you just have to pull the rubber & then tighten in place. That would work if the bolt holes were elongated, which they are not. The right side I had to shorten the bolt & grind the tip to a point to guide it into the bumper bracket. Not much room given the gas tank proximity Made sure both sides were level - holes were about 9" down from the side molding, and about 5.5" forward of the existing bumper side mount captive nut rubber sleeve over side bracket

-

Replacing All Large Opening Seals & Hatch Small Seals

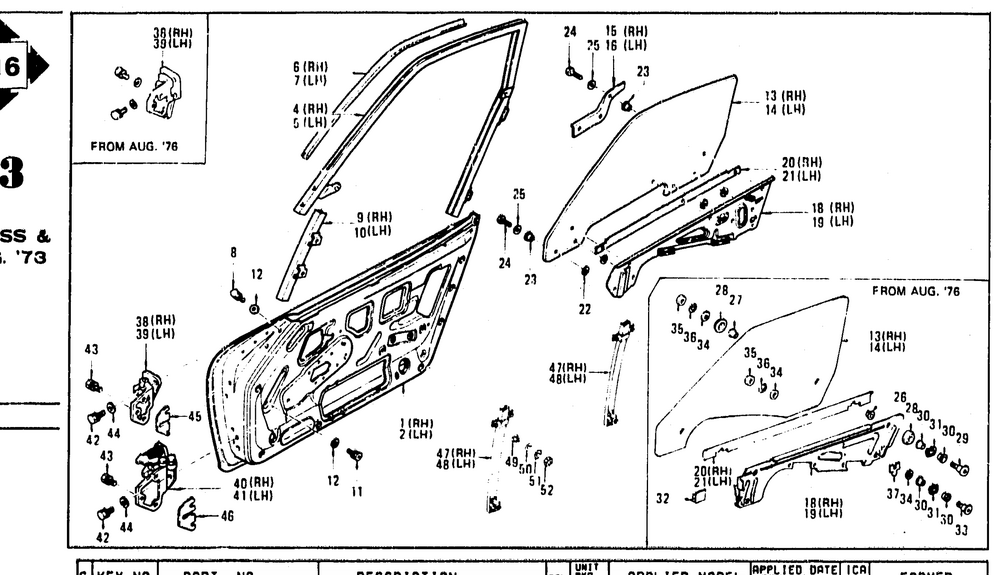

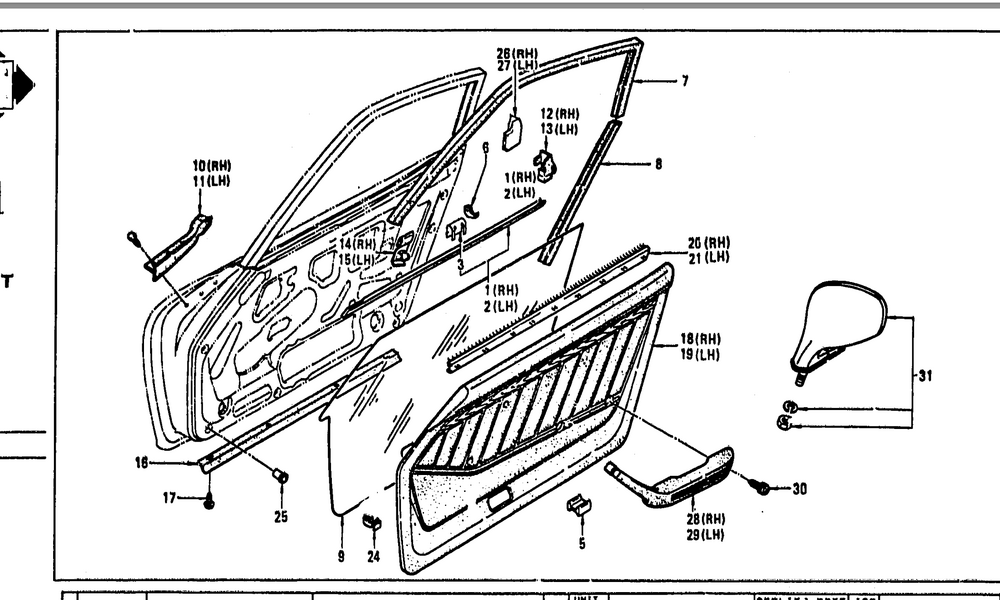

I have no idea. I've not seen a car that has them, so I can't visualize it. I can't say I've seen a channel groove in my door glass frame that these would attach to, which is how they are described in ZcarDepot's listing for them.

-

Replacing All Large Opening Seals & Hatch Small Seals

Question for those with more experience on these - I ordered what I thought were the door glass channel seals (6 & 7 in the catalog) - 80810-N4500 80811-N4500 but.... those are not glass seals, & I can't figure out where they actually go. Are they supposed to attach to the outside of the door frame? I don't think there is a ridge in mine that these would fit into. The actual channel seals seem to be in 2 parts (7 & 8), but I didn't see 2 parts in the listings I've found - 80335-N4520 is what I have ordered, looks like I also need to find 80336-N4600, not having much luck with that

-

75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

Not sure where I picked up the 'torsion' rod description, I assumed it was from somewhere in the FSM, however I see they call it a compression rod in the 75 manual I have in my possession. Volvo used a similar design, they called them caster rods. Indeed!! I have the parts, I was going to do it last week, however I couldn't get the clutch master reservoir cap off, and was not about to apply excessive force to that. I'm changing it in part because it was clearly improperly installed. I do understand how to properly install a hydraulic flex hose to ensure the line is not under tension as seen in my pic , but thanks for the concern 🙂

-

75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

Finally got back to the front end - removed the torsion rods & flipped the cone washers, moved the flat washer to the front side, installed one poly bush on the forward face, added a hardened washer under the nut I used the insert tube from the poly kit, it is slightly longer than the stock version used with only rubber. Torqued to 44ft/lbs. Didn't get to drive it, the rain is coming down too hard. I'll find out if that resolved it

-

75 280Z - Starter Motor intermittently clicks when restarting after car has been driven for several miles/in town driving

Today I removed the fusible links, and rewired the two circuits. The first link was fed directly from the starter, then that one goes to the shunt, then that feeds a connection somewhere under the dash, that then comes back & goes through the 2nd link. So, I eliminated the feed from the starter to the fusible link #1. Ran a new feed from the battery to the secondary panel, then added the output from the fusible link to a fused connection. Added a Maxi fuse to replace the second fusible link secured the Maxi fuse holder to the cover. While I had the harness open, I decided to add the H/L relays. The high beams didn't work at all, until I futzed with the connectors under the column - the withe one on the bottom left, and the black spade. Offloading this circuits seems like a very good idea Cut 4 wire circuit to headlights - Red: R/S +, Red-Yellow: L/S +, Red-White: High Beam, Red-Black: Low Beam relays fitted under relay box Harness spliced - original bulb feeds now feed relay coils for H & l added the fused relay feed (30) - need to get more lower amp fuses though, all I have left are 50Amp, so I'll swap that out later function test before wrapping wrapped cleaned up starter connections, just main cable & (30) to starter relay

- 75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

-

75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

I didn't note there being any flat washers in with the domed washers when I took it apart - I think I saw the ones that came with the Energy suspension having smaller washers as you have pictured though. I do have another pair of the larger flat washers, so perhaps that is where they originated. Again the FSM doesn't show the parts breakdown that would indicate the presence of the flat washer in addition to the 'cup' washer... I'm a public school teacher - there are sick teenagers all the time. Since we are now in Testing mode, they are packed into small classrooms with poor ventilation, and we have to proctor them for 3 hour intervals. That's how I got it this time. Last year, I got it within a week of the mask requirement being lifted for public schools.

-

'75 280Z - preparing for '06 350Z 6 speed drivetrain conversion

I don't see any other threads like this on here, so I hope this is not inappropriate. Honestly I don't care for the HybridZ website, so I don't feel inclined to post there much. This is my long term plan for the 280Z. A neighbor who is also an old car buff stopped by about a month ago, he told me his wife's uncle had an '06 350Z that wouldn't pass inspection in RI ( I had told him earlier that I was considering a drivetrain conversion at some point in the future). The car is mechanically sound, so having the entire vehicle for the cost of an used engine & CD009 trans of unknown pedigree made sense to me. My personal experience with buying JDM drivetrains has not been pleasant. I'm going to look into adding ABS as well. I always forgot I have to manually modulate the brakes in my Fiat, and with a large increase in HP, it is more of a concern. I may transfer the seats also, not a fan of the flat 280Z seats.

-

75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

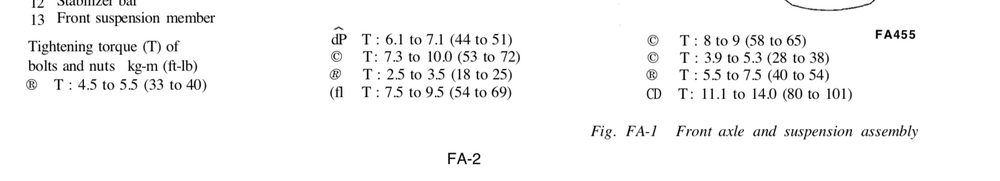

I am. Many thanks for the clarification. I do indeed have the conical washers set to 'cup' the bushing, so I will take it apart & properly torque them. Makes sense the bottom it against the sleeve. Hopefully that accounts for my vibrations - I must have excess fore/aft movement as it is. EDIT - putting it together with the suspension hanging at a pretty acute angle, the bushings don't seem nicely aligned with the seats, so I think I'll wait to torque them when it's on the ground, where the angle is in it's rest state. I think I'll also switch out the forward one for the poly, as you have in your pic. I tested positive for COvid yesterday, symptoms are pretty harsh this time. Figured I better reply while I have a window of clarity. Presumably the nut icon labelled A - H are the indicators of torque spec - I didn't get it as the legend at the bottom has gibberish inserted

-

75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

Drove the car to work again the past couple days. It has a vibration in the front end that varies, in other words it doesn't always come on at the same road speed, and will go away when the stars align (it seems). The only thing I haven't replaced are the inner tie rods, however there was no discernible play in them. When it happens, the steering wheel vibrates pretty harshly, and there is a 'chatter' in the steering column, it seems. The only thing that I couldn't find a spec on is the torsion rod bushing end nut - I just made them 'snug' - about 4-5 exposed threads outside the nut. Does anyone have a spec for that? I didn't find it in the FSM/Front Suspension section . Any other tips? Obviously I'm going to have to recheck the inner tie rods. Also wondering if just increasing the wheel & tire sizing has made it more susceptible. I did much the same on my '80's Fiat (with similar suspension design/layout) with no adverse effects, so that doesn't really seem to make sense.