Everything posted by chaseincats

-

Correct Hatch Removal Method?

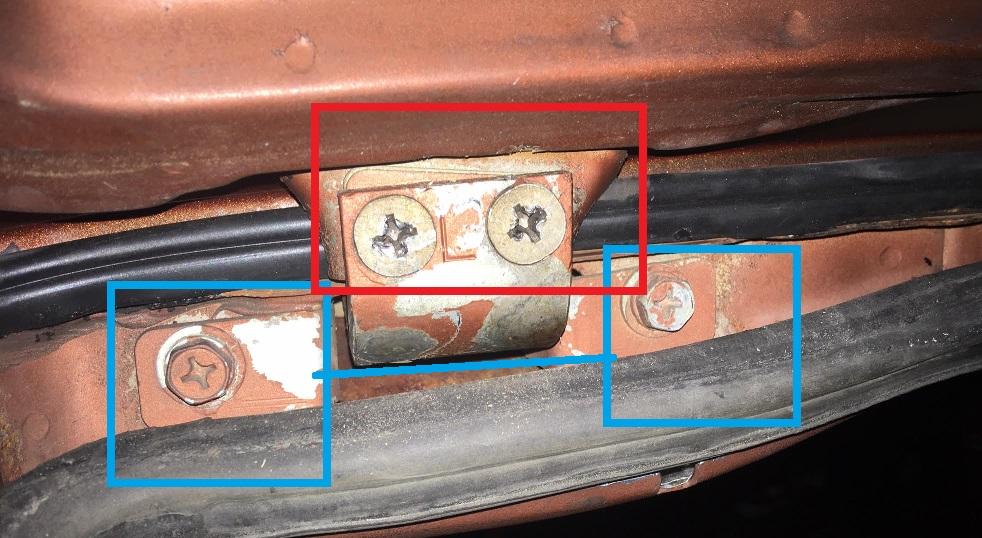

Quick question for you guys, I need to remove the hatch to glue some outer weatherstripping. I remember reading that if you take the wrong screws/bolts off the hatch, it's a pain to get the hatch to close again properly. Which should I take off in the below picture to not disturb the closing alignment of the hatch, the screws boxed in red or the bolts boxed in blue? Any ideas? -chase

-

Perplexing "FUEL" light malfunction

Right, they told me the same thing before they sent a replacement. 😕

-

Perplexing "FUEL" light malfunction

Gotcha - it's just strange that we have to do that on a brand new part

-

Perplexing "FUEL" light malfunction

Update: I received a replacement fuel sending unit after my first one from zcardept started to engage the fuel warning light when the tank wasn't low on fuel. After a few weeks of driving with the new sending unit, this new one started lighting the warning light even on a full tank. I'm not sure what the issue is with the thermister on these, but it just seems to be a design flaw.

-

Sudden no-spark situation

Coincidentally I cleaned the bullet connectors & afm connector a week before the car died and it ran better than it ever had. I also smoked the engine last week and no leaks could be found. Just checked the fpr and no leak. tach needle is perfect too. This is so strange... EDIT: the coolant temperature sensor connector bullet connector popped out. Thanks for the tip.

-

Sudden no-spark situation

Alright so I increased the idle, timed it to 10 degrees, then brought the idle back down to 800. It’s running so rich now that it burns your eyes when you stand behind it. this makes no sense at this point. any ideas?

-

Sudden no-spark situation

While it isn't 100% in the same area, it is very close (I'll be using a timing light today to get it back to 10 degrees). That said, regardless of how far forwards or backwards I turn the distributor, I cannot get it back up to the rpm it was before changing distributors. Would air gap affect this? EDIT: I just checked and the air-gap was definitely larger than it should be - so I adjusted it and will start the car after everyone is awake to test. But thinking back to yesterday I did notice yesterday that when it was running rich - after installing the new distributor - when I press on the throttle body accelerator connector, there was a noticeable lag between when you hear the engine suck air in from the filter and when the rpms rose. I'm not sure if this helps diagnose this at all but I figured disclosing that couldn't hurt.

-

Sudden no-spark situation

Update: I got a non-wobbly distributor with a pick-up coil that reads 720ish ohms, Popped it in and the car started right up but seems to be running a bit rich and is idling about 300-400 rpm lower than it had been. Could that happen if the pick-up coil's air gap is too large? Any ideas as to what could be going on?

-

Sudden no-spark situation

Fair enough, thanks!

-

Sudden no-spark situation

Gotcha. I wasn't sure how 'approximately 720 ohm' Datsun was felt comfy with ,haha. Regarding the new pick-up coil's air gap: The FSM says anywhere between 0.2 and 0.4mm works. Does it matter where in that area the pick-up coil sits? Basically im curious if there is a benefit to getting it closer to the reluctor (0.2mm) compared to 0.4. Any ideas?

-

Sudden no-spark situation

Update: My friend has a distributor I can have but said when he measured the pickup coil with a multimeter it ready around 760 ohms instead of 720. Would that still work?

-

Sudden no-spark situation

Yep, just got off the phone with them and they have it via special order. Rockauto has them too for half the price, so I'll probably go with them. In the meantime, a friend may have a distributor I can use. I'll grab a new pickup coil and swap it in there and report back in a week or so.

-

Sudden no-spark situation

-

Sudden no-spark situation

Just headed down to the garage to try that and unfortunately no luck on with the multimeter on any of the resistance settings

-

Sudden no-spark situation

It seems the re-manufactured ones are NLA. Is there a different distributor that is currently made that is swappable that you know of?

-

Sudden no-spark situation

Ah, do you mean if I move the coil, continuity should appear if it is the proper distance from the center shaft?

-

Sudden no-spark situation

Definitely agree but I just don't get how my pickup coil can be dead from that (isn't that block just a huge magnet)? I checked all of the wiring and there aren't any visible breaks, even under the cap.

-

Sudden no-spark situation

Update: I removed the distributor cap and the front of the pickup coil seems to be scratched, (almost like its been rubbing on the rotating portion of the distributor) there are also very small metal shavings magnetized to the back of the pickup coil. I tried to shake the main shaft around and it can be moved somewhat but is still very much connected to the engine (not sure if any of this information helps). Video I just filmed: https://youtu.be/N8R1Ps-r3Pk Would the pickup coil's outer casing being rubbed against ruin the internals? Also, if that is indeed what happened, it would probably be a good idea to purchase a new distributor, correct? -chase

-

Sudden no-spark situation

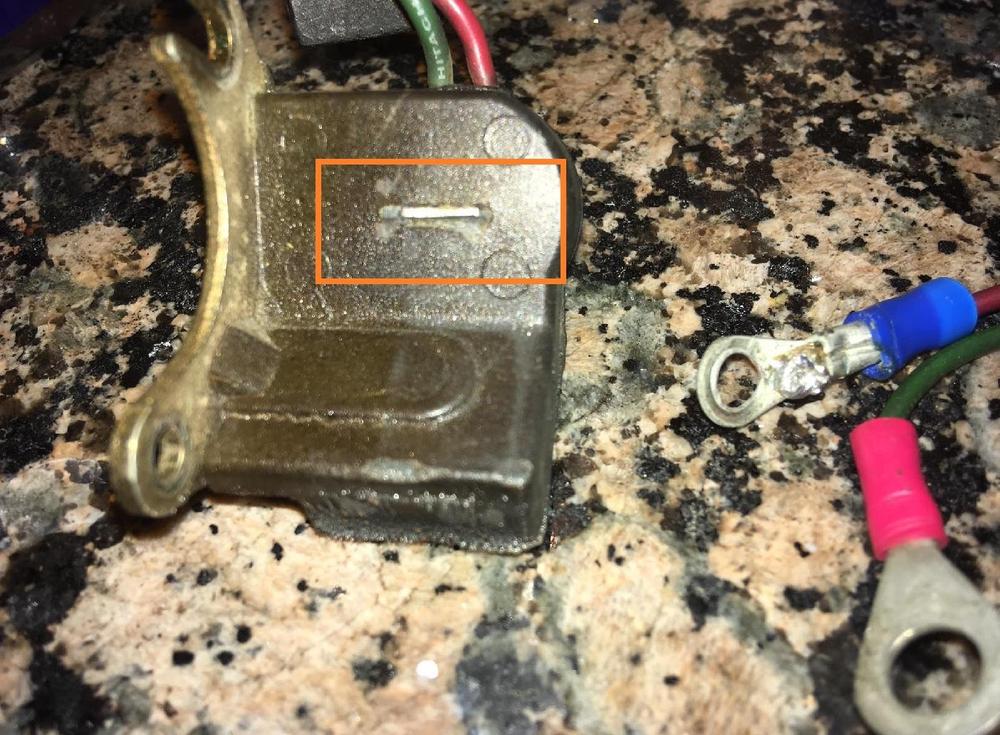

Hi guys, While taking the car out today, everything was running great until I went to wide-open throttle. After about 20 feet, the car flat out died and refused to start. The car was low on gas, so after pushing it to a gas station and refilling it, it started right up 3x in a row and was able to drive it home. I just went down to try and start it and it is now dead. I pulled the coil wire off of the distributor cap and grounded it against the body - and it seems I am not getting any spark now. I used a multimeter to poke the 2 coil poles and got less than 1.8ohms so according to the FSM it means the coil isn't bad. Any ideas as to where I should start to look? It seems like this is the result of an electrical part that was on its last legs or something... EDIT: I just checked for continuity at the end of the two pick-up coil wires (in the black box where they are bolted to the harness) and did not get continuity. Could that be the issue? Box on the right is what I'm referring to: https://www.classiczcars.com/uploads/monthly_2017_02/Screenshot_2017-02-21-14-44-04.png.07517510cbd3dcbe526420d18fa8092e.png -chase

-

Tach gauge indicator lights dead?

My rheostat works but I've always wanted to bypass it to see if the lights get any brighter because who knows how much/if its corroded on the inside.

-

Tach gauge indicator lights dead?

I have a 280z. If that's the case, then maybe somebody put a 240 tach in it? Either way, on mine, the indicator lights only had one BW wire each and once I cleaned the mounting bracket and bolted the housing down, they worked.

-

Tach gauge indicator lights dead?

On my tach On my tach, the turn signal wires are single wires (BW). The gauge illumination lights have 2 wires (GB/GR)

-

Tach gauge indicator lights dead?

Update for you: I was wrong about a burned out tach light - the bulbs are just too dim to illuminate the area where the redline+ bit is. The turn signal lights still aren't working however. I ended up using a test light to verify that I am indeed getting a light pulse to the harness connector for the signals and I am. I did some research online and found out that the indicator lights (unlike the illumination lights) are indeed 1 wire and not 2. So I'm guessing that means they aren't grounding properly to the housing (or the housing's ground is missing, right)? Update: Got the lights working. For those who have the same issue, the tach grounds to the body via the tach mount screw on the underside of the dash. Sand it down a bit and crank that screw and that should fix your grounding issue.

-

Tach gauge indicator lights dead?

Hi guys, Odd question for you. One of my tach illumination lights died (the other 4 still work). A week later, the left indicator dash tach light died, and today the right one died (the front & rear exterior indicator lights all work however). I tried to remove the tach but 90 minutes later I couldn't get it out (on account of the dash cap's lip that surrounds the gauge. I also was able to unplug the 2 general light connectors behind the dash after a bunch of fiddling hoping to see some corrosion, but they look brand new. I also took a look at the bulbs, and they aren't burned out. Anyone have any other ideas? -chase

-

Coolant Temp/Thermotime Switch Wire Colors?

Yeah, those are what are on my car. It makes sense that the sub harness and sensor connectors have matching colors. That said - if the bullet connectors are flip-flopped in the main harness, suddenly that little trick's helpfulness goes out the window haha. @SteveJ Yeah, that's what I ended up doing - checking the main harness wire colors then just following the wire to the plug rather than looking at the sub-harness wire colors