Everything posted by 240z70

-

Booster & MC compatibility

First of all, thank you all for your input. To clarify my specs: 11/69 240Z vin in the 300's 1982 F-54 280zx turbo block MN-47 high quench head. NA with 2 SU carbs revamped by Ztherapy Pertronix Electric Ignition and hi volt FLAME coil Low speed/High Torque starter. 6-3-2-1x2.5inch headers to muffler to 2x2inch dual side exaust. Super Light weight flywheel Stage II clutch Borg Warner T-5 5-speed transmission from 1982 ZX turbo car R180 3.364 rear end Panasport "For Racing Only" super light weight rims with 215/60-R15 tires 4-Core aluminum radiator. 16.9 gal custom aluminum tank. Brakes: Original front disks and back drums. Master Cylinder: 15/16 Booster 7" Dual Diaphragm (and yes i did have to make new holes to attach it) So this is the scenario issues that were mentioned above. Brake booster and appropriate master cylinder potential replacements due to very hard brakes with current system. Thinking about going original design but cant find them. Brake light on speedometer always on but not connected to the switch on the firewall Another issue that just came up this weekend is that the throttle rod from the accelerator to the pedal came out of the plastic round ball joint on the engine side. Looking for a new one. Anyway, as always, any info, suggestions or comments are greatly appreciated even if it does not directly apply, so thank you all for your input.

-

Booster & MC compatibility

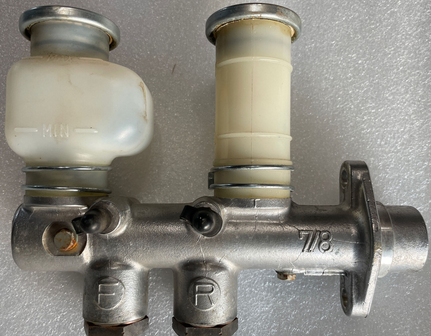

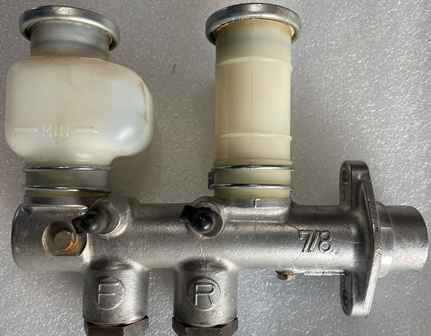

Well that was my original thought before my dual booster bolts failed. They were only pressure fitted on the vac canister. When I took it to the shop, he opened the unit and I waited while he pressed new bolts and then welded them on the inside of the canister. I mentioned to him about the reaction disc and he said no, it was not missing and showed me the little black piece inside the tube. I had several possibilities for the hard pedal condition: 1-The booster was bad...but that makes no sense. I unhooked the vacuum line and it swooshed air in. Then I put a vacuum pump w/meter to it and vacuumed it up to 22/Hg. It held for about 15 minutes without a drop. Then I ran the engine with a vacuum gauge connected to the other side of the hose and it produced 20/24 Hg (idle/rev 3000), so the engine is producing adequate vacuum in the manifold. The check valve is new (Z Depot). I know that with the larger MC I lose pressure on the calipers while gaining more volume (which is really not needed since they are stock). But maybe that is why the pedal is hard. The calipers cant accumulate more volume so the pedal is harder, and since it is bigger (MC) then I actually have less pressure at the calipers which might explain the slowness of the braking... The booster is a DUAL Diaphram so its supposed to give me more pressure on the MC so I thought it would compensate for the larger MC... Maybe not. I am getting frustrated and may just see if I can find an original 7" or maybe a 8 or 8.5 inch booster (hence the original question of compatibility and whether or not the 8 or 8.5 clear the clutch MC on the 240z). If I find it, then I will probably just get a 7/8 MC and stick with it. Not sure, just looking at options and availability. Also don't want to pony up all that cash for the all slotted disk and wilwood options. By the way, the aftermarket universal vacuum hose can be had from Amazon. It's Gates 27232 Power Brake Vacuum 11/32 inch x 36 inch (85 PSI) Hose - 3 ft for $18.15 - Looks and fits perfectly. https://www.amazon.com/Gates-27232-Power-Vacuum-Standard/dp/B000CRHL5S/ref=sr_1_1?crid=3OIUGPOCDN3NX&keywords=gates+27232+power+brake+vacuum+11%2F32+inch+x+36+inch+85+psi+hose&qid=1684941954&sprefix=gates+11%2F32+vacuum+%2Caps%2C123&sr=8-1 ANOTHER QUESTION: Not sure if this has any impact, but on the MC the front brakes are connected to the rear port and the rear brakes to the front as called out on the MC = R__F, but it is common knowledge that on the 69 thru mid/late 71 the ports on the original MC 7/8 were actually listed F__R and the F port was on the front of the MC and was connected to the front breaks.... Would it make a difference? The new MC is connected according to its R__F functionality/identification. 69/70/71 F__R port designation 72 and on R__F port designation ANOTHER QUESTION: The brake indicator light is always on on the tac. I have not been able to shut it off. I checked the handbrake switch and it works, and there is no wire connected to the distribution block on the firewall. That is the only two connections that the light is supposed to have... Ideas?

-

Booster & MC compatibility

PROBLEM: Brakes too stiff. Long braking distance required. SUMMARY: After changing adding a new booster a while 1-2 years back: Dual Diaphram 7 inch 15/16 bore and a 15/16 MC. Had to drill new holes but it fit. The brakes had a stiff pedal, and the bolts came out on the MC side after a while. Took the booster to a repair expert (booster revamp shop - who took the unit apart (booster) and pressed and welded the pressed on bolts, then put the booster back together, and told me it was good. I installed it back, used the tool to gauge the 20 mils gap between the MC and the Booster rod and installed it. Bled MC, then all 4 breaks in order of distance. The brakes worked but the pedal is stiff and braking distance is still too long. I have decided to change the system. DIFFICULTY: Cant seem to get an original/revamped booster/MC 7" for this car. No one carries it. QUESTION #1: Can I just install a 75-78 280 Z booster and MC on it? Does it FIT... It is bigger : 8.5 inch versus the 240z 7 inch. The ZX's were even bigger: 10 inch so those are out. QUESTION #2: IF SO WHICH YEAR IS BETTER? Is it a bolt in or have to change holes? Does it clear Clutch MC? QUESTION #3: What size hose ID is the Booster to Balance tube? I have heard 11.2mm but no one seems to carry it. Best place to get the proper sized hose? Car Info: Car: Model 1970 240z Production 11/69 Engine F54 2.8L/MN47Head/SU Carbs. Recommendations?

-

75 280Z Wiper Motor Conversion W/ Variable Intermittent Wipe

I did the Honda upgrade on my 240z and it is faster than OEM and also parks, but it is STILL TOO SLOW for a mid to heavy rain. I am still looking for something faster.....Have not found anything yet. So in summary, the upgrade (Honda) was worth it, BUT still not adequate.

-

SpinTech Muffler

Nope, never did find one and wound up getting a 2.5 in and 2x2 inch out. Exhausts are on both sides under the rear bumper. Not round but rectangular.

-

Intermitent start and no turn signals when it does not.

Yes I should have provided the most information I had available, and be clearer in my post. My apologies to all for my inadequate post. Additional info: Yes all lights work other than the signals, and I don't have a heater, so I can't check it thru there. When I said jump, I actually meant providing a direct signal from the battery to the solenoid ignition signal post, not putting cables from another battery to my battery. Both switches (turn and lights - left/right) were torn apart and rebuilt by Dave Irwin, so I feel very comfortable about their internal condition. The wiring underneath the dash going to them is a whole different thing, so I have to check that. Sometimes when we are trying to describe a situation, we tend to focus on some of the items and forget that other people can't actually see the whole situation and therefore are left looking for a needle in a haystack, without really knowing how big the stack is or how small the needle in question could be. A more descriptive explanation on my part should have been forthcoming in order to provide you with as much information as I actually was aware about the situation. I will check the other ideas you guys had and hopefully I can find the cause and eliminate this issue. Thank you all for your assistance, support and quick responses.

-

Intermitent start and no turn signals when it does not.

Scenarios: Dirty battery connections/ Old Battery: Dont think that is the problem. Battery is new, and all the connections were cleaned and "vaselined". Bad connector connection: Could be. Will check those with meter. Loose wire somewhere???: Maybe, will check since it seems that the starter does not get the ignition signal to start, BUT why would it affect the turn signals...? When i put a small lead from POS on the battery and touch the Ignition signal post on the solenoid it starts without a problem. That seems to indicate the problem is upwind to the ignition, not downwind to the battery. Back of ignition switch issue? Perhaps and will check, however that would not have anything to do with the turn signals that I can think of. Different under column area. Turn signal and Flasher not working when it wont start: Weird, EVERYTHING ELSE WORKS, (all lights), brake lights, headlights etc. As soon as I have time, i will check: 1-Loose wires under column. 2-Voltage/Current on the ignition signal wire to the starter when key turned to crank, if it does crank. 3-Will recheck all fuses, but this does not make sense, since it does start at times and I have already checked them all. 4-Bad fuselink: Cant be this since it does start half the times, but I will check with a meter. ---Is there a good place that anyone knows of that sells reputable 240z fuselinks? I should probably buy a couple to have on hand. ---I think there were 3 fuselinks on the early Z, but not sure. 1-Starter, 1-Alternator, not sure where the other was. ---Also, have not found the correct Factory Service Manual for this early type Z (prod: 11/69). Xenon posting says "Looking for Manual". ==Thoughts: Is the ignition signal wire in anyway sharing a factory relay with the turn signals for dash power? If I cant find the issue, i will have to install a temporary supplemental Push On/NOff switch connected to a fuse and a power relay in order to be able to hot wire it remotely from the drivers seat if the key wont crank. Dont want to have to open the hood everytime it doesnt crank..LOL. Anything else that you guys recommend or that I forgot to consider or mention?🙊

-

Intermitent start and no turn signals when it does not.

Background: 1970z-L28F54 engine- Starter sometimes would not crank, other times it would, so i figured that the starter was bad. Since its probably over 20+ years old minimum, I figured the Z could use a new starter, so I bought a new High Torque starter and installed. Then tested it. It did the same thing, (so I probably wasted the money, but at least I know that component is new) and THEN I NOTICED that whenever it would not start, the turn signals would not make any sound (flasher sounds) and the signals would not work. The funny (not really funny) thing is that IF i test it and crank it every 5 minutes for a half hour, some of the times it will crank, then it wont, then it will. When it does not crank, there is no noise from the solenoid. If I test the turn signals there is also no noise from the solenoid when this happens. I tried to jump start it and every time it did not crank, i would jump it and it would start immediately. This has me puzzled as to where to start. -The fuses all seem good. -Cant be the fusible link because 2 or 3 times out of 5 it will start just fine. -Not sure why the turn signals don't work when it does not crank. -Even tried to cheat and check the turn signals to see if they worked: If they did, the car would crank, if they did not, the car would not. Anyway any thoughts on this would be greatly appreciated, since i am tired of jump starting it (have not had time to start to trace all the wires for bad connections yet). Suggestions? Case studies from someone who had this happen to them?

-

Car history service

Perhaps only archived instead of discarded?? That would be ideal, but you never know. Thanks Patcon.

-

Car history service

Maybe if all the different forums got together and created a virtual HISTORICAL DATSUN 240 Ƶ SOCIETY they might have enough weight to make a formal request to each state's DMV to provide them with maybe just the basic information for each HLS30: First Sold, City/State Each Subsequent Sale, City/State If destroyed City/State This would be done for the public historical interest with no personal/confidential information required from DMV. If such a virtual Historical Society was created, then perhaps it could be headed by someone who is very much into the history of the Ƶ. I think that perhaps someone like Carl Beck would probably be a good candidate for its directorship, and then have a senior member from each Ƶ Club Forums to represent its Club as a Board Member of the Historical Society. Each club would select its Board Member, and the Board Members would select its Director. I think this would give a lot of cohesion and centralization to all the available information that each club seems to hold but is almost impossible to find without becoming a member of each club (us/ca/uk/eu/au/jp) which is a horrendous if not impossible task. The society would operate virtually, have links to all member clubs, have a glossary that could search all clubs at once (if possible) and a repository of historical information that would be linked to the respective club that owns or provides the material. Anyway, I know its a crazy idea, but perhaps someone has a better one for how the history on the z can be compiled and kept updated by all the clubs to ensure that anyone interested can easily find historical, important and pertinent information to the entire 240 Ƶ community worldwide. These cars are a treasure to most owners and are fast becoming a very expensive endeavor due to financial cost rise, parts availability, age, and scrap. It seems that almost half the people that own one either are parting or buying parts from others that are being parted and scrapped. The inventory is dwindling. Will the Ƶ last another 50 years?

-

Need to buy Brake Booster Reaction Disk (Disc)

For those who want more info on what a reaction disc is, here you go. Has pictures also. https://forums.hybridz.org/topic/69706-reaction-disk-pictures-and-walkthrough/#comments Without the reaction disk, the booster will not function correctly.

-

Brakeline question

Pat, could one just make one? I mean, if you have a metal lathe you could turn a big chunk of aluminum (very expensive..) or just a block of hard wood such a oak, etc. and make it. It should not be a problem if the wood is hard and can fend off damage from the pressure and it would be very cheap to make. almost any size bend you want. Add a bottom base and screw it onto your work bench when you need it. The other idea I had was just buy (fleamarket/craigslist) some cheap V-Groove Belt pulley/wheels that have the same shaft hole size, grab a small steel plate, weld a shaft on it vertically, and put all your different sized V-Groove pulleys on the shaft. Just make sure that the pulleys have the same center hole diameter size. Or make multiple shafts, one say for larger pulleys and others for smaller tubing sizes. That will let you do anything from small tube size up to whatever size you need. There is not many sizes that one would need. Anyway, just an idea of how to possibly do it on the cheap and easily accessible. As my dad use to say " Be frugal, when you need something, make use of what you have first, then look for the easiest solution to adaptation to fulfill the need'.

-

Brakeline question

Tweeds, hey what can I say? You were right on the money with that tool. Simple to use, no issues. Did not eve try the other type that I have since I did not want to waste time and definitely not waste line once I had it in place, isolated and secured....Thank you for the advice. Also, thanks to all who have provided input which I will follow. I will try to bleed the MC first, then I may just redo the wheels, and try again. I will also check for leaks. If I cant fix it, I will remove the booster and either make my own reaction disk if it is missing, redo the booster push rod adjustments or just plain replace the booster with a new one. If I go with the adjustments, and it still does not work, that will be an automatic decision to buy and replace the booster. If I don't feel like messing with the adjustments, then that will also be a decision to just replace the booster. Don't know yet how I will feel. Getting tired of bleeding brakes to no avail.... https://www.jegs.com/i/JEGS/555/631011/10002/-1

-

Brakeline question

Activities: Front to back Brake Line replacement, Rear Handbrake cable replaced, Clutch Line replaced due to visible wear and tear, MC pressure retention valve, remove & replace speedometer cable. MC Pressure retention valves were seen in both MC orifices. The one servicing the disk brakes was removed. Clutch Line Replacement: No problem, Adequately bled it afterwards. Clutch functions well. Rear Handbrake Cable: One heck of a job. Because of dual exhaust, and drive shaft were in place, this is one *itch of task. No room to maneuver. However it got done. May still need additional adjustment but for now it stops the car from rolling. Also, the cable is longer on one side than the other. Didn't know that.. Issues, one of the tabs securing the line to its holder in the tunnel broke, had to make one. Will need to buy replacement ones but they are narrower than the brake holding tabs and not sure where to get these new. Remove/Replace Speedometer Cable: R&R Speedometer cable. You have to be a circus contortionist to work upside down under the dash....Got done. When tested it was a bit jumpy/ delayed, but it did work. Could be because of years of non-operation and that fault may be inside the gauge itself...The old cable was rusty and had broke in half. The plastic/rubber outer casing was damaged and missing in some spots. Front to Back line replacement: Well, I actually did "OBVIOUSLY" forget, BUT the line was only flared on one side (back), since i cut it longer than needed because I want to place it first and then see how and where i would cut it....hah hah, before I attached it to the car. So the fitting was fed on the hood side and I tied a rope behind it, then pulled on the rope while underneath the car and the fitting made its way all the way to the back...Pretty easily, actually. Cut back the old line to the tunnel area so it would not be left in the engine compartment and leaving the securing tabs there free for the new line.Then I isolated the line, by getting two long pieces of fuel hose 5/16 or 3/8 and cutting it long ways in a spiral cut that would wrap around the line the entire length of the under-body. Then I zip tied the hose every 6 inches around the line. Did not cut the line on the back side, just bent it out of the way. The next thing was to now secure the line/hose along its way and out of the way of any pinch points and/or moving parts. Then the final touch was to bend and secure the line along the underside. Looked good. Now that left me free to bend and secure the new line into the brackets in the engine compartment that had held the old line. Now came the time to put on the front fitting and bend the line accordingly to the MC. Then I knew where to cut it and flared (once again ensuring that the fitting was on the line and facing the right way. Then I flared it and could now connect it to the MC. Bled all four wheels, and tested brakes: The brakes do stop the car BUT take 3 times the distance. The brake pedal does go all the way down and is soft, (feels almost like power ABS Brakes) not that traditional had mid way resistance. Will have to analyze and address again. I guess another way to put it is to compare it to the steering on a 240z compared to the powered steering on a new car.. Known: The MC is a 15/16 which provides additional stopping power (~20%+) versus the stock 7/8 MC, and the Booster is a 7" double diaphragm which also provides additional stopping power (~27%). Together, the added stopping power should make the car brake and curl on a dime. It does not. Suspected: The Booster reaction disk is missing, and the booster push rod is not correctly adjusted for length. This would create a long brake push. It does not have an airy mushy push like when a brake system has when it has air in the system, HOWEVER I did not bench bleed the MC and the fluid receptacle was empty. Path forward: Remove the MC, Remove the Booster, check for existence of reaction disk (if not there, buy/make one - 6mm thick I believe), Adjust booster push rod correctly, reinstall booster/MC, bleed MC. May also re-bleed the 4-wheels. Assistance: Any and all would be appreciated in the form of diagnosis, suggestions, and information on perhaps where to get a reaction disc and what the soft brake causes could be.

-

SpinTech Muffler

" An aggressive street muffler for the performance enthusiast where clearance and space issues need to be addressed and want a quieter sound." An aggressive street muffler with a quieter sound? Yeah it didnt make sense to me either when I read it...Aggressive usually means louder an possibly raspier, but quieter?? Interesting. I also do like the sound, but what I am trying to find is one that was installed in the 240Z. The sound would be a lot different than one on a V*...That is why i asked the question.

-

Car history service

Question: Is there a free/paid service where a currently REGISTERED Z owner can obtain all the history on on his/her own 240z down to the point of when it was first sold in the USA? Info: When it was first sold State/City Owner (maybe not due to privacy concerns-understandable) Every other time it was sold/bought/registered along with city/state. I don't think DMV in California provides that info. Or does it? Does any agency in any state do that?

-

SpinTech Muffler

Has anyone installed a SPINTECH Low profile 3000XLF Sportsman muffler on their Z without any resonators? If so, what did it sound like and do you know what the decibels on it were? https://spintechmufflers.com/3000xlf-sportsman-low-profile-muffler/ I looked extensively for some info, but the only thing I found were installations on non-240z vehicles which obviously will have a totally different sound and decibel numbers. Thanks for any info.

-

A-Pillar Upholstery

Issue: I need to install the A-Pillar. I know that it is glued on, however how does the edge trimming look like? Is it just glued on, or doe it have the metal trim on one or both of its edges? Progress: I bought: the A-Pillar kit, the Glue (Contact liquid and Spray), and I also have the metal strip. Have looked at pictures online, but cant really tell if the material is just glued on with the edges rolled over and glued or if it has the metal trim on the edges. Can anyone send me good pictures of both the top and the sides so I can see what it is supposed to look like? Thanks you.

- Brakeline question

-

Brakeline question

"OBVIOUS'ly CAPTAIN, I surely will try not to forget it...It would be detrimental to the success of the project...Wasted time, effort, and material. Thanks for the reminder. It would suck to forget that part of it..

-

Brakeline question

Well now I have two tools. I will try them and see which works better for me. As long as one of them works, then I should not have any downtime and can focus on how to secure the line properly,

-

Brakeline question

I decided to take Tweeds advice and bought that tool. I want to simplify the project and obtain a successful outcome. Not being able to make good flares is not an option that I want to consider.

-

Brakeline question

Yep, I bought the 25ft copper/nickel 3/16 line. I do have a flaring kit but its the other type...https://econosuperstore.com/itm/sae-metric-double-flaring-brake-line-tool-kit-with-mini-pipe-cutter-car-truck/ May have to invest in the other one.

-

Brakeline question

Yes, that might also be an option. I could jacket the line just at the zip tie points by sleeving it with 1/4 inch line to prevent rubbing and then secure it. Its only temporary for a couple of years until the transmission has to come out. Thanks for the input.

-

L28+(maxima)47 build

Awsome, great job.