Everything posted by inline6

-

What is the second oil sender on F54 block

The sender switch goes in a raised boss area directly on the block about 2 inches behind the oil filter. It is directly in line with the top of the oil filter, not quite as high up on the block as I indicated earlier. Anyone know what it is? Does it control the fan motor that blows air through the valve cover splitter onto the intake side of the engine? Seems kind of strange to use oil to trigger that fan, so I don't think that is it.

-

What is the second oil sender on F54 block

There are two oil senders on the right side of my 83 280ZX block that I am putting in my 240. The one part I threw away, a short sender switch with a fuel injector type (2 electrical pins) cnnnector is all that is keeping me from starting it up. It goes behind the oil filter (the other one is the canister that goes in front of the filter) and towards the top of the short block. Seems like it would be a oil temperture sender, but I can't find it anywhere on the microfiche at carfiche.com. What the heck is it? What is the nissan part #. I would get a plug, because I don't need the switch but the hole appears to be some funky pipe thread pitch (spec).

-

Broken head bolt

Another thing the machine shop could do is drill out the bolt. Basically by using a mill or precision equipment, the machine shop should be able to locate the exact center, and the drill out the center of the bolt so that just the thread of the bolt remains. Then remove the thread with a pick and or compressed air etc. What a pain, I'm going to clean those holes and put a drop of oil on the threads before I put the head on my new motor. I didn't realize that this was a common problem.

-

Need a new roof for my Z

Hi, I saw a couple of posts in this thread about drilling spot welds to replace the roof panel. That is what I did because my car had a sunroof. This page takes a long time to load but I have some good pictures and some write up of the process. I also put lead back on the roof joint to quarter panel like the factory. Structural integrity of the car was not compromised by doing it this way. http://members.tripod.com/trueweb/Zcar Let me know if you have questions.

-

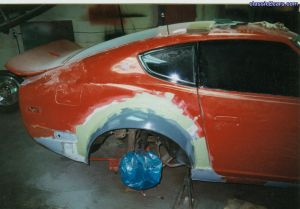

240Z flare work

What did you use to bond the fiberglass to steel? I used E6000 epoxy but have had separation issues.

-

Top Down Cooling?

Hi, I remember reading about the 1996 corvette LT1 motor getting some innovative improvements. One of which was reverse cooling. Instead of running the coolant into the engine block and then the heads and out, GM reversed flow and the coolant came to the heads first then the block. The main benefit was that it allowed them to bump compression to 10.4 to 1 for more power. Here is a link to some of the info: http://corvetteactioncenter.com/specs/1996/96technology.html Anyway, I am about to take an E-88 head that I had rebuilt (L-28 intake valves, hardened seats) back when I first fixed up my 240Z, and put it on a low miles F54 L-28 block with flat top pistons. I am going to cc the chambers on the head and rerun the calculation, but with the figures I have now, I show 10.1 to 1 Compression Ratio. Might be ok with 93 octane, but might not. An engineering friend of mine wants to take a look at what is involved in adding a belt tensioner bearing and converting the L series V belt to a ribbed belt like on more modern motors. I am thinking we can just wind the belt to reverse the flow of the water pump. Could just be a pipe dream as more would be involved like changing the propeller on the stock pump. Anyway, the idea intrigues me and we'll take a look and see if it is worth doing. Kind of trick if we can do it... Garrett

-

electric water pump

Conferred with an engineering friend of mine and he agrees with you HLS30. For dragsters, which is what these were originally built for, they are fine, as they are running off of battery power- a completely separate power source (ie no alternator). For street, using the crankshaft to turn the alternator to charge the battery, which runs the electric water pump, doesn't make sense. Just run the pump directly off of the crankshaft.

-

electric water pump

Hi, I found out about this the other day reading a back issue of SportZ magazine. I wonder if the polarity can be reversed to achieve top down cooling? I know that topic has come up before as a way of running higher compression without detonation problems. Of course the wheel would have to cut reverse as well. Garrett

-

Head Gasket TO Suit E88 F54 Combo.

So I put up a post looking for info about whether the F54/E88 combo will work for sure-- not getting replies-- and then come across your post. Tell me, is your car back together? Which E88 did you have? Which head gasket did you use? And what do you think of it? I calculate it to be around 10:1 CR. I have access to 93 octane fuel here. How about you? Any detonation problems? Finally got a chance to see and hear the video of your car that you posted a long time ago. Sounded great. If my new combo doesn't make my dual 2"s sound like that, I'm going back to glass packs. Garrett

-

1983 NA L-28 with E88 head?

Hi, Currently running a 77 L-28 with and E88 head. I just picked up a 83 280ZX F54 engine (Normally Aspirated with flat top pistons) and would like to use my E88 cyl head on it -- converting from the P79 and fuel injection back to the SU's for now. Looks like it will be a bump in Compression from about 8.3 to around 10:1. Anybody else out there done this combo? I'm about to buy gaskets and just want to make sure that there aren't any problems I am not aware of. Going programmable FI as the funds allow in the future, so no need to point out that going from FI to carbs is not a good idea. Garrett

-

Adding turbo to non-turbo ZX motor?

Actually Gav, I am an old school NA guy that is just getting intrigued about adding the turbo. In the past, wrote off turbocharging as being too expensive and sufferering from driveability issues. I really like power to be controllable and thottle response to be quick. What are BOV's? My goal for the motor would be minimal lag with moderate power. I autocross from time to time for fun so the idea of a big turbo coming on with lots of boost after lots of lag would be totally unacceptible. I need to do more research in the archives here on turbo set ups. Obviously there is no shortage of info on the subject. Thanks for the T3/T4 hybrid tip. I'm committing that to memory as I continue researching. Garrett

-

Adding turbo to non-turbo ZX motor?

The point of all this is HP of course. A bump to compression from 7.4 to 8.5 should be worth some HP, increase in efficiency, and thus, gas mileage. I am also wondering if I would get and driveability improvement-- specifically with turbo lag or lack thereof. Is it reasonable to conclude that the bump in compression would give a little better performance when off the boost? Seems like the bigger the turbo (or the more lag), the more the bump in CR would help? Sounds like the durability of the pistons between the turbo and non turbo are in question. I'll look at them next if I can. Questions would be location on the piston (how far down from the piston tops, and size of rings? Any others? Seems like nissan would use the same blank and machine the dish in the turbo piston for cost, but higher temps may have required a change in those specs. Thanks for the info, all.

-

Adding turbo to non-turbo ZX motor?

Ok. I should have titled this What compression ratio to run in a turbo? :classic: Here is a compression ratio calculator: http://www.turbofast.com.au/Tfcomp.html#readme I put in the following for the stock ZX turbo: Bore = 3.39 inches Stroke = 3.11 inches Deck Height = 0 Gasket Thickness .050 inches Head Volume in cc's = 53.6 + 10.9 for the dished piston = 64.5 CR result = 7.4 to 1 Now take out the dish and you get 8.53 to 1. Interesting... WRX compression ratio is 8.0 to 1... Mitsubishi Evo is 8.8 Even the 1996 300 ZX was 8.5 to 1 :classic: I'm thinking there is no reason to go with the 81-83 ZX turbo block. Garrett

-

Adding turbo to non-turbo ZX motor?

Looking at the How to Modify Your Nissan/Datsun OHC Engine, it does not appear to me that anything other than the pistons are different for 81-83 ZX turbo and non-turbo short blocks. The cranks and the rods share the same part number and so, must be identical. The block appears to be the same as well according to this taken from Honsowetz book, "On the L28 Turbo block 11010-P9080, introduced in the 280ZX Turbo in December, 1980, and non-turbo L28s in July, 1981, slits were put in the Siamesed cores to provide a coolant passage between the cylinders." On the question of strength of the pistons, hls30.com, you raise a good point. However, for what it is worth, both the turbo and the non-turbo motors use cast pistons from the factory, yes? Same crank, same rods means same pin height in the piston, right? Seems like a 10.9 cc dish is the only difference. What I have in mind is just a little different than that which is commonly done, I think... Instead of getting a ZX turbo motor and adding a bigger throttle body, and bigger turbo, and adding SDS or similar programmable electronic fuel injection/ingnition system, why not start with the NA-- higher compression short block and do those same mods? Fundamentally, what is the compression of a stock ZX NA short block with a P90 head in combination, and with the advances made in programmable fuel injection/ignition technology in the last 15 years, what CR can we safely run in a custom turbo motor setup these days? Anybody? I'll start looking. I wonder what the latest turbo cars are coming with (CR) from the factory. I bet that is a good place to start. WRX, EVO? Audi's? Garrett

-

Adding turbo to non-turbo ZX motor?

Anyone have info with regard to turbocharging the 81-83 ZX normally aspirated motors vs. starting with the ZX turbo motor? From what I can see, the norm. aspirated motor for the 81-83 is an F54 block which is stronger (same as turbo), but it has flat tops. The turbo on the other hand has dished pistons. Is that the only difference in the block? Obviously the turbo has a P90 or P90a cylinder head and the non-turbo has a P79. Where am I going with all of this? With the modern capabilities of the electronic fuel injection systems we have today, can we bump up the compression ratio a bit by running the flat top ZX block and do "better" than the turbo ZX motor? How much of a bump in compression am a looking at with a P90 cylinder head on the flat top ZX block? I am thinking about that combination with a medium to small sized turbo and a cam like they are running in the project car in sport Z. Thanks.

-

MSA Street Flare Picture

I'm not sure what their street flare is but I got flares from them. You can see them at my website. It has some pics during installation and may give you the view you are looking for. http://members.tripod.com/Trueweb/Zcar

-

240Z Emissions Items - WANTED!

I've got number 5 in good shape, and I'll see if I have number 4. Minimal cost plus shipping. Hopefully I have both. Garrett

-

Restored Dashes Question

I have been PM ing a few individuals up until now with my DR experience as I haven't felt comfortable airing what I perceived to be unique issues to my dash. Having read these posts and a couple others, I feel I can bring some clarity to the discussion. First, and foremost, I have contacted Jim at DR and he has been very understanding and did not hestitate to mention that they will make it right. Here is what my experience has been: Dash was extremely well packed and protected - no problems with shipping. :nervous: Upon removing the dash from the packing, I breathed a sigh of relief as the dash looks very good. I noticed a couple of very slight indentations in 2 places (one the size of a quarter - I guess the foam had a low spot there). Having done bodywork before and seeing a couple of imperfections in the new, factory series II dash that I have, I am ok with these as I think it unfair to expect perfection on a restoration. Putting the pad back on the frame proved to be a problem. I noticed that I was having to put a fair of amount force on the pad to get it to line up with the anchor points. With each fastener, it seemed the pad was getting more stressed. I loosened all the fasteners and tried massaging and retightening, but the pad still seemed under stress. This is especially so at the lower two corners of the heater panel opening. The pads corners seem to be about 1 and 1/2 inches wider than the frame. Pushing the pad to the metal, I secured them with screws and moved on. After all the screws were in, I noticed that the area of the pad under the speedo and tach was a little distorted or wavey. Next came the guages. The three middle ones went in easily. However, the Speedo and Tach were a bitch. Now that I read MikeW's post, I see that I am not the only one. Believe it or not MIke, I was able to get them to go in from the front, but it took over thirty minutes and a lot of pulling and prying. Looking at the new dash vs. the resto, I see that the eyebrow area is substantially thicker-- making the roof of the gauge hole reduced in diameter. Once I got the gauges deep enough in their holes, they loosened up quite a bit and could be rotated to align them vertically. Checking the fit of the heater panel in the center of the dash, I saw that the top of the opening on the pad did not fit the slight curvature of the top of the heater panel. The panel has a slight arc to it on the top edge as you look from side to side. The pad is perfectly straight from side to side. Because of this, the screw holes don't line up well with the captured nuts in the frame, and the fit at the top is not quite right. Coming back to the dash after a break, I looked at the area under the speedo and tach, and noticed that one of the metal anchors had pulled loose from the pad. :sick: That is where I stopped. In my communication with Jim at DR the possibility of a bent frame came up. Jim told me that they have a jig that they put the dashes on, that they destress them (as they sometimes have been bent in collisions or over time) and that they are recovered so that they fit the factory frame the way they should. So, in theory, there should not be any difficulty in putting the restored pad back on the frame. At this point, I plan on sending mine to the US office when it gets up and running in Feb, and having it redone. I will send my frame along to be checked for bends/damage. I also will send my original pad (the one I sent them was from a parts car) with the restored pad. Finally, I will provide ample details with photos to show them what I see. I am confident that they will be able to fix the issues. :classic: Hope this helps and is not disrespectful in any way to DR. Garrett

-

What bonds aluminium?

We used Loctite (Loctite Corp-- like the thread lock) products to bond an aluminum skin to the tubular steel frame on our SAE formula race car. They should have something that will work. SAE = society of automotive engineers Check out the most recent car here: http://www.vtmotorsports.com I was on the 1991 team. Garrett

-

Dashboards

I have a series 1 car and got a new series II dash that has never been installed. PM me or email me. Garrett

-

Ball Joints, etc: OEM or not?

I had a slight shimmy in my Z for a couple of years-- even after rebuilding the front end with everything. It was driving me nuts. From time to time, when I was in the mood, I would try to figure out what could be causing it. One day, I placed the jack under the outboard end of the lower control arm (careful- don't bend anything) and jacked a front corner up so I could do some prying. I was shocked to see the amount of play in a relatively new set of ball joints that were on the car when I bought it. They were the only parts I hadn't replaced when I rebuilt the front. Anyway, OEM were expensive at around $90 each, but I went for them and the problem was finally resolved. I have read that some people think that Z's front ends are just very sensitive and if you don't have everything (tires balanced well, tight tie rod ends, ball joints, tight rack, good rack bushings, etc.) they shimmy. At this point, I hypothesize that cheap after market ball joints could be the culprit on many Z's. My car had the shimmy so long-- obviously the previous owner had it too, that it wore down the center in the steering rack. I had to get a replacement rack when I rebuilt the front. Garrett

-

Hi po Radiator

I just realized that this post is under Regional Discussions. My apologies. I don't know how I came across it in the first place. G

-

Hi po Radiator

QLD would probably be Queensland? I am in the U.S., so that would be a problem. This is a secure page but if you can see it, check it out. This radiator should be really light and efficient. https://shell7.tdl.com/~jags/Pages/Parts_DATZ_Radiator.html Seems like a good option for those with easy access to them. I emailed JTR and am trying to confirm that it will fit in a 240Z without mods to the frame rails. Garrett

-

Hi po Radiator

Hi, I checked out Jags that Run (thanks for the info Carl). Has anyone put the 4.3L GM Radiator from Chevy vans 1985-1992 that they recommend in their 240Z? I measure the distance between the lower frame rails at 25.5 inches. The dimensions on the picture of the radiator and their custom mounting bracket at their site seem a bit big. I guess I could ask them... Garrett

-

Hi po Radiator

Do you know the part number of the Griffin radiator that will work best in a 240? Garrett

Subscriber

Subscriber