Everything posted by inline6

-

Restoration of BringaTrailer 240z - HLS30-35883

I couldn't quit find the right thing. This is on the right track. Not sure if these/vinyl thread protectors could be heated and stretched in length a bit?

-

Restoration of BringaTrailer 240z - HLS30-35883

The yellow tape end goes just outside the headlight bucket. I do have the caps that go over the headlight screw inserts. I have not put them on yet because I may need to hit the backside of the adjustment screws with a little bit of WD40 if they are tight, when I go to do final headlight beam adjustment.

-

Restoration of BringaTrailer 240z - HLS30-35883

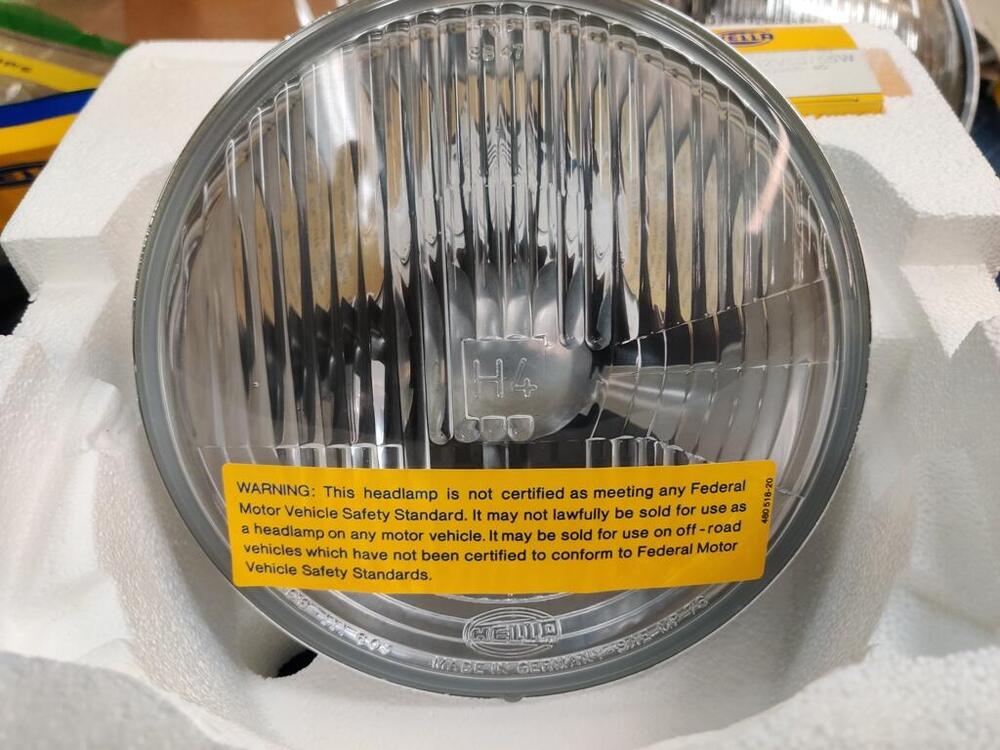

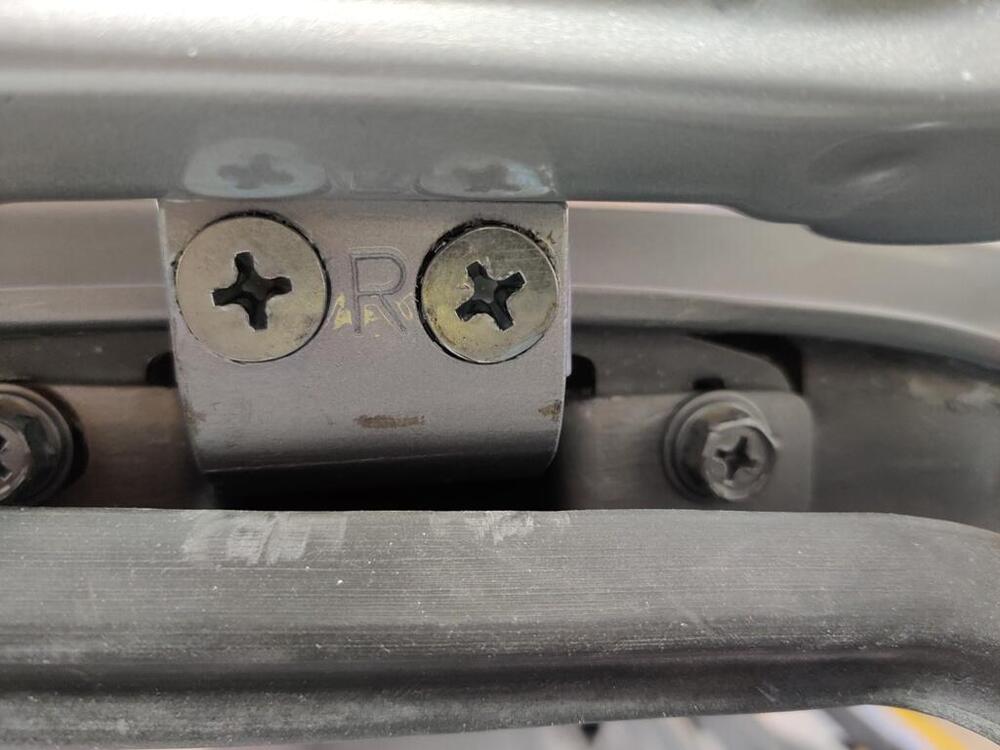

Today, I got the right side window regulator in and was successful in getting easy, and smooth operation of the widow. I also messed with the door hinges a bit to improve upon the door alignment. I still can't believe they removed the doors - I had the alignment nearly perfect! And, I assembled the other of the new headlight harnesses (it is a PITA to pull the wires through the new sleeves if you don't remove the electrical connectors from the wires, which I did not). I also replaced the plastic/nylon headlight screw receivers. When I had the buckets plated, I did not know that replacements existed. So, I had them plated with the receivers in place. They didn't "do well" with the plating process. To replace them, I heated up a single edged razor blade (in a holder) with a propane torch, and cut through them on the back side. Then I just used a hammer and punch and tapped the remainder out. Pressing the new receivers/inserts in place is easy with a 10 mm deep socket and a vise. The new ones come with smaller diameter screws. My original screws were re-plated and are in excellent condition. So I chose to use those instead. However, I had to open up the hole in the new nylon inserts to 13/64" and run a 6M X 1 mm tap through them in order to do so. Whether you use the original screws or the ones that come with the inserts, note that they do not have threads as received. Next, I ran the original, as they are in good condition, headlight gaskets through my glass bead cabinet to remove overspray for the prior repaint job on the car. I got ahead of myself and installed one of the headlight buckets with just a regular sealed beam headlight (not even halogen), before I remembered I bought some Hella H4 housings and bulbs a couple of years ago. I think these have some age on them, but that doesn't matter. So, I shouldn't bother with the H4 bulb - I should get some LED ones, yes? It is surprising how little I got done today given that I put about 8 hours in. Oh well. Things are going well... if slowly.

-

Restoration of BringaTrailer 240z - HLS30-35883

One month earlier - 3/71, which would be fine with me. My passenger side has some scratches as well. Can you clean both sides and send me some more pics?

-

Z's on BAT and other places collection

Z432 on BAT: https://bringatrailer.com/listing/1971-nissan-fairlady-z-432/

-

Restoration of BringaTrailer 240z - HLS30-35883

I do have the rubber stop installed at the bottom of both doors. I believe I have identified the problems with the left side window - there are three. Being from a 280z, the metal window frame/support is different. At least one of the channels for the wheels of the regulator is different. And, the nylon part on the front of the metal frame/support - the part that goes in the front guide is different. That is making the front part of the window stick. In addition to that, I believe I installed the lower weather strip in the back of the stainless frame incorrectly. I do not think it is fully seated, and I think the weather strip cement I used is keeping it from seating fully now. That is making the back of the window stick. So, even with no regulator, the left side window is not going up and down without excessive effort. Tonight, I installed the right side window. Like the driver side, I removed the old weather stripping, cleaned the old adhesive out of the stainless frame, and sanded the stainless frame with 1000 and 2000 grit sandpaper. I installed the window first, and then the front guide. I installed the new weather strip in the stainless frame. I put the top one in first, and then the one that goes in the bottom of the back of the frame. This time, I made sure to push that one all the way into the channel before the weather strip cement dried. I have had good success with locating the front guide by pushing the window all the way up to the full closed position, and then pulling the top of the front guide towards the window to "seat" it against the nylon slide part. Then I snug the top bolt of the guide. Then I lower the window to about half way down. While holding the window in that position, I grab the bottom of the front guide and pull back to seat it against the nylon slide part. Then I tighten the lower bolt of the front guide. And finally, I tighten the top bolt of the front guide. In theory, that puts the front guide in a position to keep the window as far back in the door a possible, both at the front and the bottom of the guide. I am happy to report that I am able to slide the right side window up and down without issue. It is a little heavy feeling, but I think that will go away with the installation of the window regulator and the channel guide on the door, as well as the upper rubber roller and inner panel and outer trim strip. Next, I have to "deep clean" the left regulator like I did to the right one tonight: I found that each moving part of the regulator moved easier after cleaning thoroughly with WD40. I removed all the old grease. With reduced friction for each wheel, each gear, and each pivot point, it made a very big difference in the amount of overall friction during operation. When revisiting the left door window, I also need to fix the lower weather strip. And, I need to source a 240z left window. I found one in CO today, but the date code is 73. I'd like to look a bit longer to see if I can find one that matches my passenger side.

-

Restoration of BringaTrailer 240z - HLS30-35883

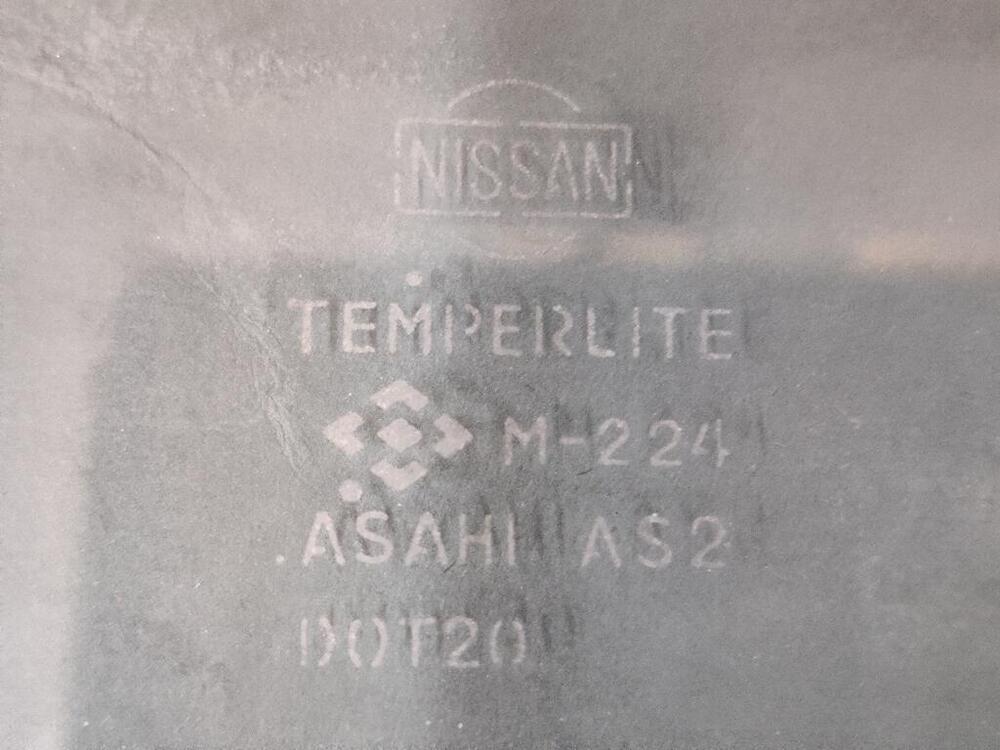

I did use a magnet, and they didn't stick. While using aluminum screws in that application does well to avoid galvanic corrosion on the sill itself, it doesn't help with the steel hole in the rocker panel it goes through! I am going to do the right side side tonight and see how that one goes. Thanks for the tip @grannyknot! Oh, and I received my Subaru parts. They cancelled the shim off the order without telling me, and sent me the remaining parts which were on the order - the side carrier shims. So, I have no solution for putting my differential together yet. Everyone, I am looking for a nice driver side window with correct date on the etching. I would like one that matches this pic, with a dot above the S in ASAHI and a dot above the M in TEMPERLITE. Please let me know if you can help me.

-

Restoration of BringaTrailer 240z - HLS30-35883

Thanks for the tips - keep them coming please! Yesterday evening, I ran into quite the puzzle of an issue. Tonight, I remained stumped for quite a while but I think I figured out what the problem is. So... I installed the driver side window glass last night. Like @jfa.series1, I could not put the window in without taking the frame out. No big deal, as I just put that in, so easy to take out. I put the window in and then the front guide, then the regulator, then the rear guide. Immediately, I ran into problems with getting the window to move up and down without excessive force. Things were not happy. I fiddled with adjusting the front and rear guides for quite a while. Nothing was helping. And with the window at full up, one of the wheels for the regulator was coming out of the track. I quit for the night, but kept thinking about the wheel coming out of the track at full up position, and the difficulty. I also found this in the archive, and read it before I went to bed. Today, I went to work pulling everything back out of the door. I had thoughts that perhaps the front guide was bent or worn, and perhaps some part or parts of my window are from a later car. The article gave me that idea. I should have just checked the window first, because that is looking like my issue, but I messed around with comparing guides and regulators from both sides of the car for quite a while first. Here are the etchings on the glass for the left and right sides respectively: Given this thread from @kats I think my left side door window assembly is from 9/1975. I am not quite sure how to read the one for the right side door window, but I believe it is indicating 4/1971 for my 6/71 car. Taking some measurements, there are clearly differences in the metal stampings that hold the glass and that the regulator works in conjunction with. So, for now, I am calling the replacement door window my problem. So, do I need to source another window, or just another window support structure? I will see what I can find. A few more pics of other progress: By the way, the factory door sill threshold screws are aluminum. Middle pic shows the slight difference between the original sill plates and the reproduction ones. The reproduction one is on the bottom below two new original ones. The "DATSUN" is not as pronounced.

-

Restoration of BringaTrailer 240z - HLS30-35883

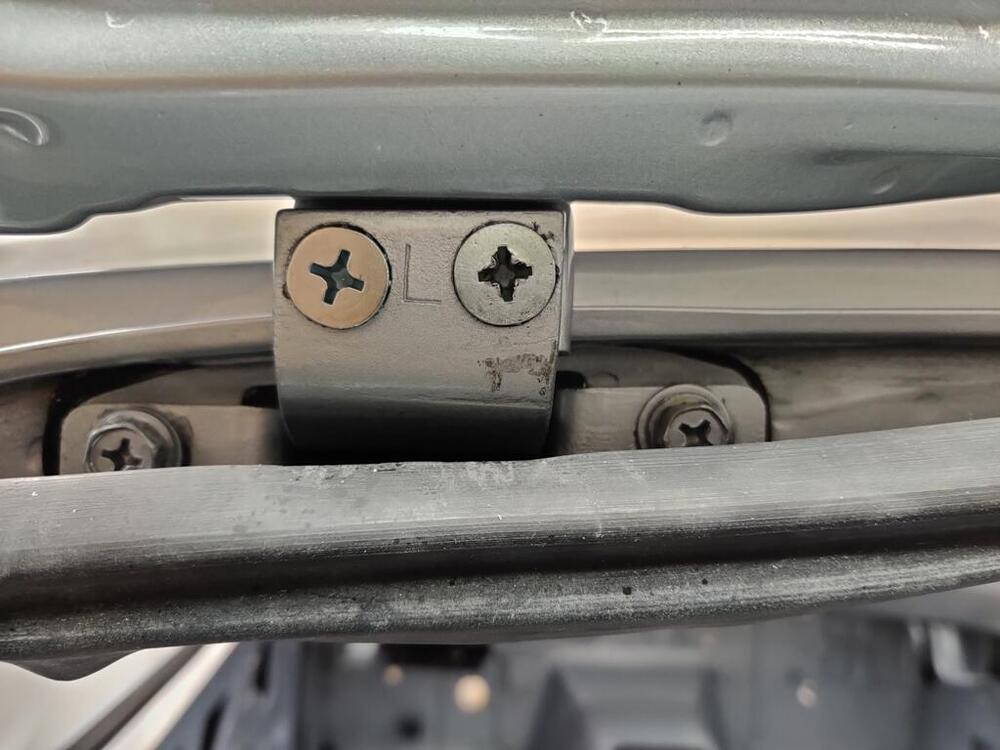

Here are some pics from the work completed this weekend. New factory original parts like this mirror and door handles are so nice to install! Little remnant of plastic piece (middle and third photos here) was a sleeve that sits on top of the door latch lever. When those disintegrate, the amount the door handle has to move increases. Obviously, you can adjust the height of the plastic part on this rod to achieve proper handle movement to operate the latch. I am second guessing the plating of the hardware for the bolts that attach the stainless window frame to the door shell. Yellow chromate on the washers isn't looking right to me. I think I have the original bolts here (clear zinc), but I think the lock washers and flat washers should also be clear zinc. Also, in the first pic here, I used some bolts that have a captive flat washer and no lock washer. I believe these are incorrect and I will have to swap them out. New window weather stripping is nice - it will make for some tight (and quiet) windows when they get installed. I mainly used 1000 grit on the stainless window frame to remove light scratches. I used 600 grit in a couple of places, as there were a couple of deeper scratches. Then followed with 1000, then 1200, then a light finish with 2000. I like the finish. You can still see some "grain" which is how the original finish appeared to me. I found another thing the body shop did that I was unhappy with. The hatch was not well aligned - the left side was a little low. I instructed them to align the hatch, and then remove only the hatch panel, leaving the hinges in place to be painted (as they did at the factory). I have no idea what they did here with the hinges. They didn't remove them to paint the inside of the hatch frame, as can be seen in the pic where I am lifting up the rubber hinge seal and you can see primer underneath. That is fine, and what I wanted, but why is the hatch hinge seal not painted, and yet the "seal cover plate" is? I don't know how they did that. The bolts securing the hatch hinge to the body were loosened and the hatch shifted/aligned after painting! I specifically wanted to avoid that. Now the paint on the bolts is chipped and there is an unpainted spot on the right hinge - you can see where the bolt was when the hinge was painted. And they managed to mess up the phillips screws... Fortunately, I had a spare set of screws on hand, so I swapped them out. Swapping out the messed up screw for a nice one (first pic below) makes a big difference cosmetically. Details like this matter to me. I wish this was done as I instructed. Live and learn. Next time, I will make sure I complete everything - everything, before I hand off for paint.

-

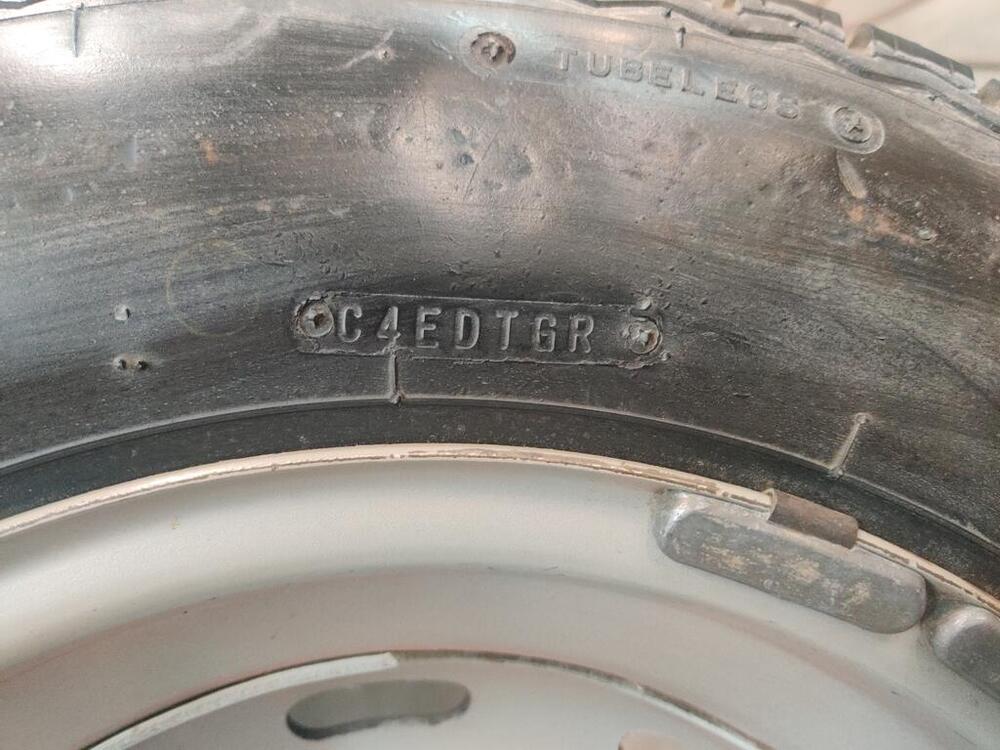

12/70 original spare tire - DOT 149

11/70 currently on ebay: https://www.ebay.com/itm/386199400448?hash=item59eb473000:g:lcwAAOSw5cxlKtGb&amdata=enc%3AAQAIAAAAwEBg9%2FdWu7nKPA0i7J29WlF0OtBSA4EH8Z6sbTca%2FT82FbIRphOkU4bLlbUJzdqWlkYrlG6hEHztMXzoCv63VQl9MPMRHAD1Tq5ykejshUMZ%2FrlRXJhO3k2iJ4IRftLC47feTmRcPRuOxNM0sXrXmjNV1yrYZ%2FylOK6aSwouV1rjpDUtLOWFtjIxVsucB72YZ0FFNvF5zOrDYDKjsiD4cV7ixNAZ3rynAgntzLRK2Ha7ixShbLDRwwuIQ7%2FJA0Lgmw%3D%3D|tkp%3ABk9SR9jSjoiYYw

-

12/70 original spare tire - DOT 149

Also, DOT 149. Odd. Also, someone looking for original tires could contact the two of us, the two BAT folks, and could purchase a matching set!

-

Restoration of BringaTrailer 240z - HLS30-35883

I also made a quick walk around video as the car sits now. There are still a lot of parts to add to the car. So, I am hopeful that the gap between the wheel wells and the tires shrinks quite a bit, giving the car a much more pleasing visual stance. I am guessing that the car is easily 500 lbs lighter as it sits now without hood, glass, interior, bumpers, fluids, etc.

-

Restoration of BringaTrailer 240z - HLS30-35883

Here are a bunch of pics of the door latches and receivers. I will say my efforts here were excessive... that I pulled apart two sets of latch components to acquire enough parts in very good condition to make one excellent pair. The plastic wedges can wear. So, a passenger side wedge to replace a driver side wedge that is worn is a good option. I had the parts plated individually. Springs received black, tubular rivets received yellow chromate, and the dove tails received clear zinc. NOS strikers were sourced along the way of my very many hours looking for parts for this car online. The new dove tails are symmetrical, while the old ones are not. Also, the new ones have much smaller openings for the screws and conical serrated washers. I used a deburring tool to open up the screw holes which allowed the screws to fit closer to flush - more like the originals. Semi tubular rivets were press out of the receivers, plated and will (hopefully) be reused after re-plating. I will need to fold over the metal pn the end of the rivet to secure the rivets in place:

-

Quaife LSD Installation in R180 - With Questions About Installation Also

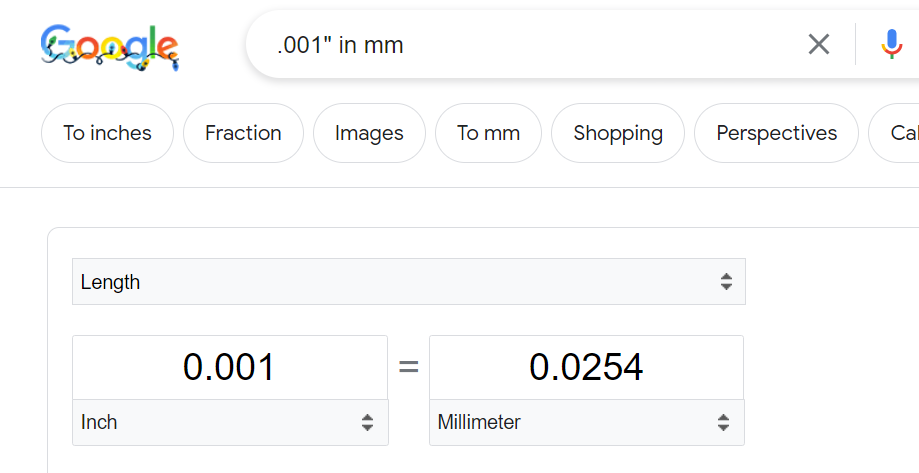

Oops - yes, I entered the wrong number there. The washer is .126" not .140" thick. I fixed it in my post above. When I was in grade school, we were taught the metric system because we were taught also that America would be transitioning over the next couple of decades. That did not happen, however. I found a comment from a machinist friend of mine about the metric system to be interesting. He said that the tolerances typically used for machining (thousandths of an inch) did not have a good equivalent in the metric system. Consider: So, when working with tolerances of thousandths or "tenths" (.0001") for machined parts, how well does the metric system work?

-

Quaife LSD Installation in R180 - With Questions About Installation Also

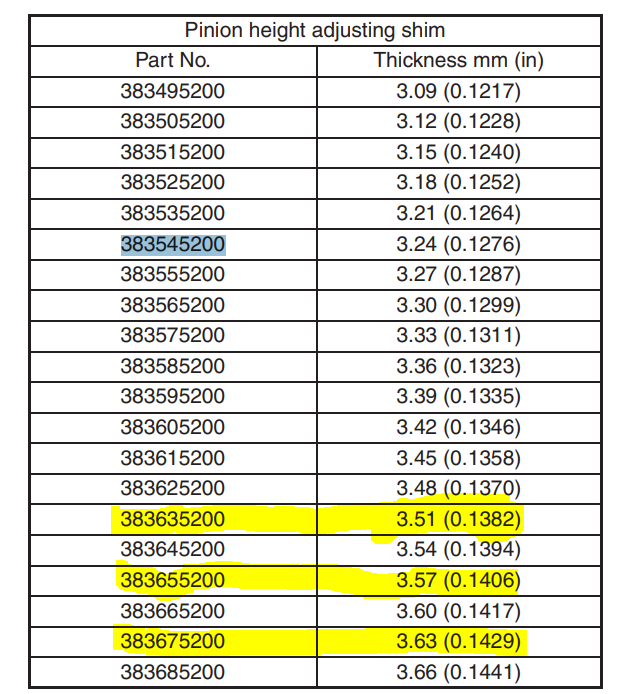

Yep - understood. I found this listing of part numbers (Subaru) - only the yellow highlighted ones sh ow as available: To make matters worse, I measured my shim's thickness today while off of the pinion shaft, and it is only 0.126" thick - not the 0.140" I measured before. So, the one that is coming (if it is coming) is many sizes thicker. I wonder if it would be a bad idea to surface grind the new washer to bring it to the necessary thickness after determining what that is with the shim stock from Amazon?

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Just spent a couple of hours trying to find shims from other applications that would work, but I didn't find anything.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

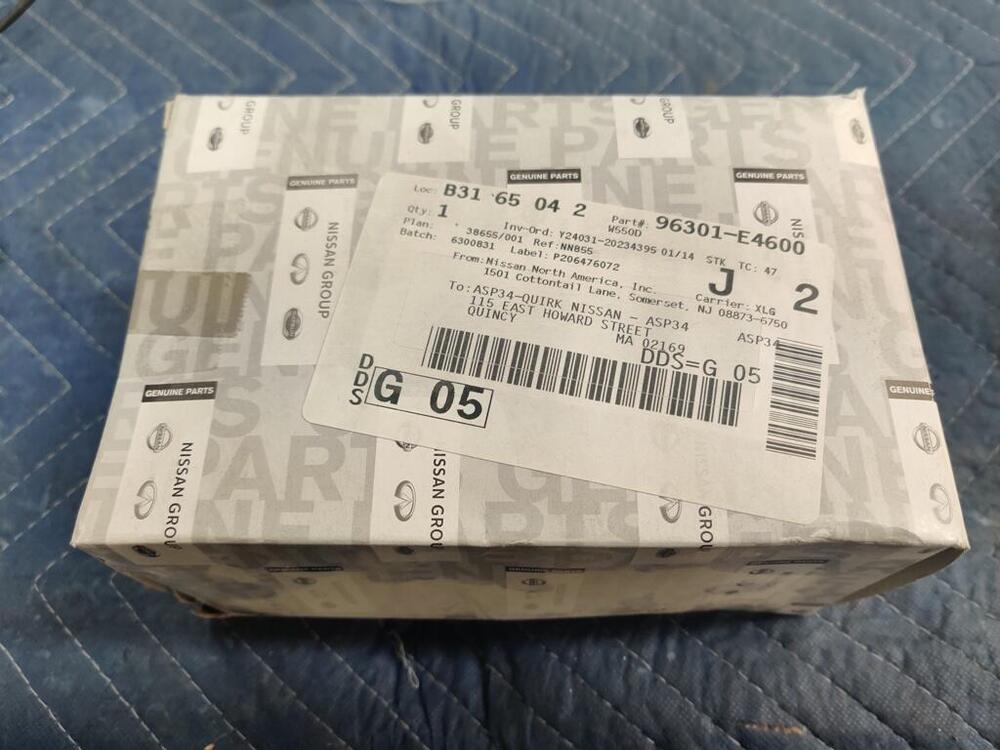

Thanks for the suggestions everyone! Unexpectedly, the order the shim was on has shipped! I am suspicious, however. I think they may have let the 90 day time frame they originally quoted for the "national backorder" run out and then crossed that shim off the order and shipped the rest (some side shims). I don't know that though. I will have to see what shows up. In the meantime, I was able to remove the rear pinion bearing today and free the existing shim for measuring and test filing: Shaft collar side and gear side, respectively: The OD is 53-54 mm and the ID is 35 mm. With regard to filing, I ran a fine single cut file across the surface of the left picture very lightly and it immediately started removing the dark coloring from the outer edge of the shim. I want to say that where the "collar" contacts... or sits against the shim, it is now lower (compressed?) than the outer edges of the shim. I did not want to, nor did I file more than a few light strokes on the surface of the shim. I also note some very light chaffing on the surface of the shim. I suspect that would be hard to achieve on a "hard" shim. I think this thing is actually pretty soft, for whatever that is worth.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

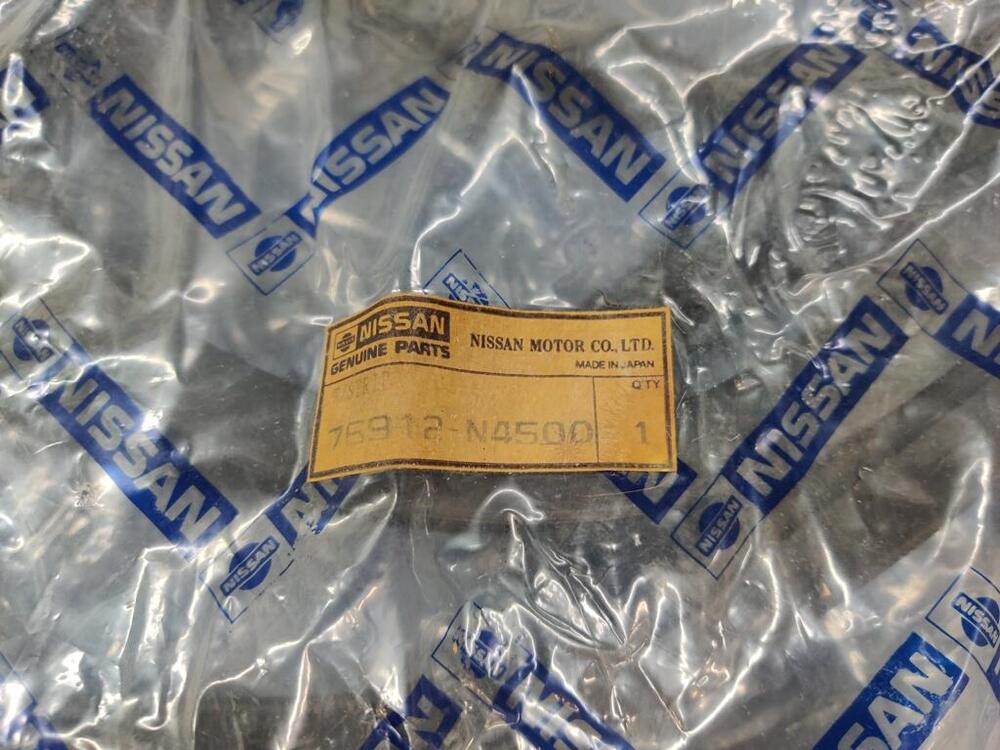

Hmmm. Running into a snag on the ones in Japan. Looks like they are for an R200 pinion. I assume they are different than the R180 ones. Link shows application. https://www.nissanpartsdeal.com/parts/nissan-washer-adj-drve~38154-p6034.html

-

Quaife LSD Installation in R180 - With Questions About Installation Also

So, it would appear that as of right now, I have options of: Buying the shim from an active auction (in Japan) Measuring the "id" and "od" of the existing shim and attempting to cross reference with shims available for other vehicle differentials - to get a suitable stack of shims that can replace the existing one Finding a suitably hard .003" shim to add to the existing one Having custom shims made Finding a suitably hard .003" may not be possible, however.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

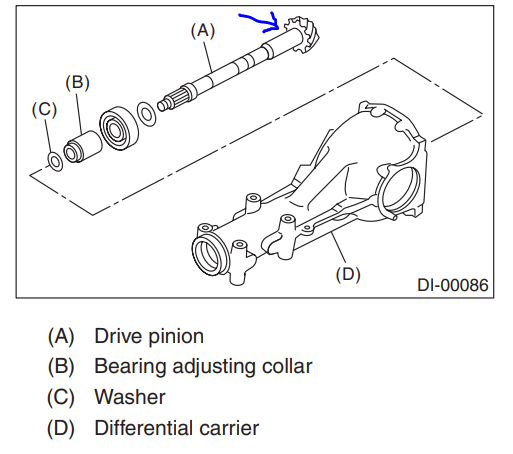

The shim I have on order from Subaru still hasn't shipped. At the time of my order, they indicated it was on national backorder and provided an eta of 90 days (they have no clue when it will be available again). That 90 days is up in a couple of days. I expect they will contact me to say it hasn't come in and I can either cancel my order or wait another 90 days. So, I find myself thinking of other options. Any engineers on here have thoughts on using a shim like this? https://www.amazon.com/Precision-Carbon-Assortment-Temper-Chemistry/dp/B00065UXD8/ref=sr_1_3?keywords=Steel+Shim+.003&qid=1703611083&s=industrial&sr=1-3 My thought is to use the existing shim I have, plus another shim or shims made from this shim material. I would put the new shim under the existing one to change the location of the pinion gear height in the case. For example, I would make a .003" shim from the new shim material, and then place it here on the pinion assembly:

-

Parts for Sale: Free 240 Z parts for the cost of shipping. I will mail and then let you know cost.

Hey Mike, does the roof still have a good head liner on it?

-

12/70 original spare tire - DOT 149

-

12/70 original spare tire - DOT 149

Here are some more pictures of my spare. VIN HLS16530 - 12/70: High resolution front and back: I claim that I have the earliest Toyo Z tire for 240z's still in existence - someone prove me wrong!

-

Restoration of BringaTrailer 240z - HLS30-35883

Yes, they are. Thank you!

-

Restoration of BringaTrailer 240z - HLS30-35883

I wasn't able to spend much time working on the car today. Just a few pics: I used silicone rubber between the master vac and the firewall to keep water from finding its way into the car in the future. I like how the master vac paint came out. I was able to save the original master vac sticker. I also pulled out the box of OEM rubber items that came with the car. I put the main hatch seal in place all the way around the hatch opening (without glue) and shut the hatch on it. I will leave it like that for a few days, which ought to help it relax/fit the opening a bit better than straight out of the bag. I also started assembling the headlight buckets with the new bits I got from 240zrubberparts.com. I bought the headlight harness rebuild kits, which include new rubber grommets to keep water from entering at the point where the wires go inside the bucket, new sleeves for the wiring, and new rubber enclosures for the plastic connector. Can anyone tell me which ends is supposed to have the yellow tape (bucket side or harness connector side? And finally, I also changed out my signature picture with a small version of this pic:

Subscriber

Subscriber