Everything posted by Captain Obvious

-

SpareTire

I found that exact situation when I was looking for a spare for my car. Now granted, I was limiting my search to donut space saver spares, but I had fitment issues with the front brakes. The little drums in the rear were fine, but I was hitting the caliper up front. And my car, being a 77, has the reduced size spare tire well. You don't have that complication.

-

1976 280Z Fuel Issues Troubleshooting

What he said. Hope you found the root problem!!

-

SpareTire

Hmmm... Try one. It might be OK. The diameter should be fine. The only thing that might be an issue is the width, but in theory, you're less than .400 inches wider than stock. Maybe you're looking at a non-problem!

-

1970 Wiring Diagram

Thanks for the files. I'll look that stuff over and see how they look!

-

1973 Rebuild

What he said. In fact, I wouldn't even deal with a tank... I'd just fill up the float bowls with a piece of tubing and a funnel. Round tops will run the engine for 30-60 seconds before the bowls get sucked empty. I would hope that your carbs would be in the same ballpark.

-

Parts for Sale: Distributor replacement magnet

Just wanted to pop in and say glad to help.

-

SpareTire

Why won't a full size fit? I thought the 75 had the big spare well? They didn't change to the smaller spare tire well until 77.

-

1970 Wiring Diagram

Anyone got anything different than the above before I take one of those and try to make improvements? Clean it up and fix the issues I've found (when compared to the car I'm working on).

-

1970 Wiring Diagram

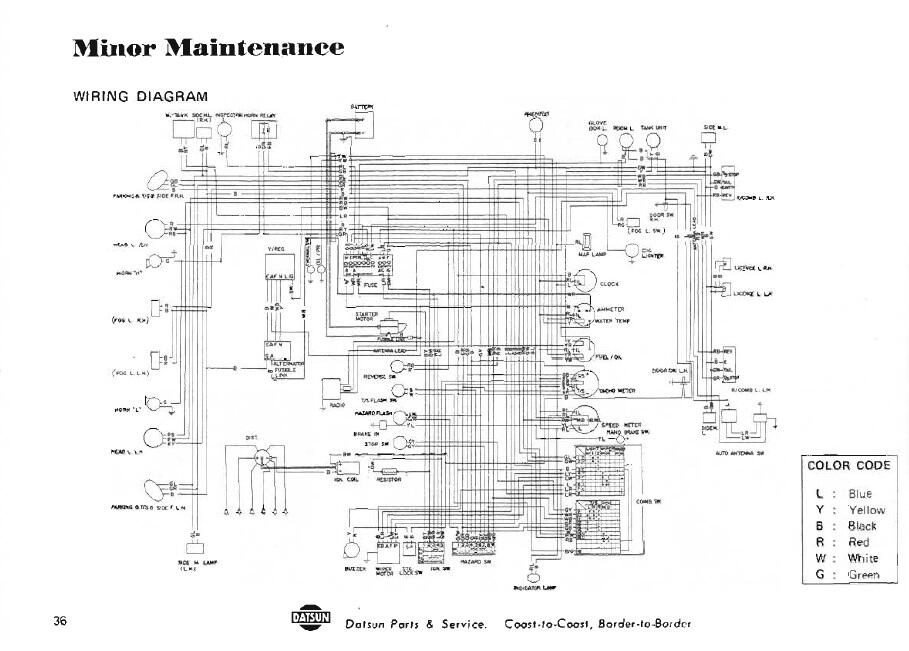

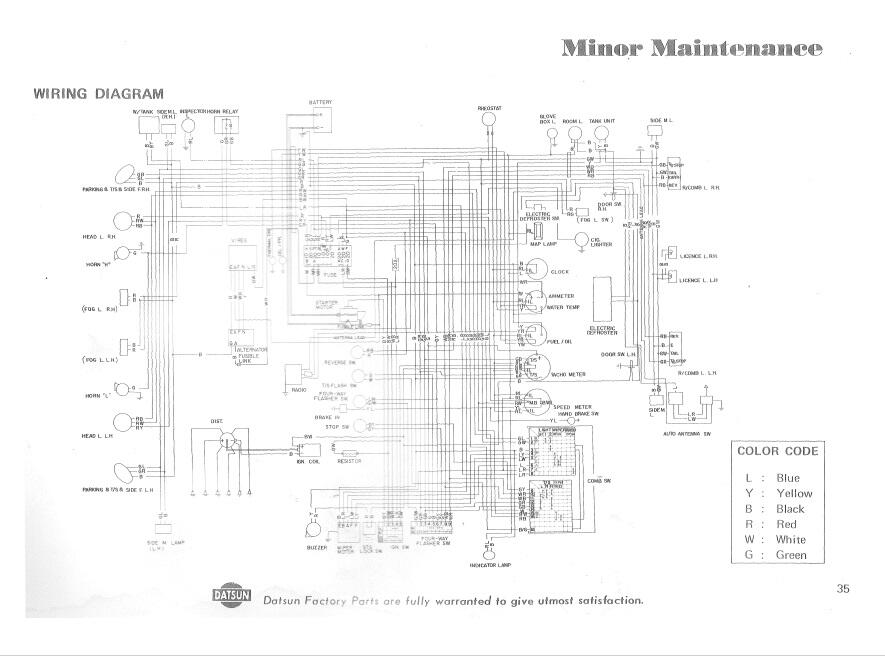

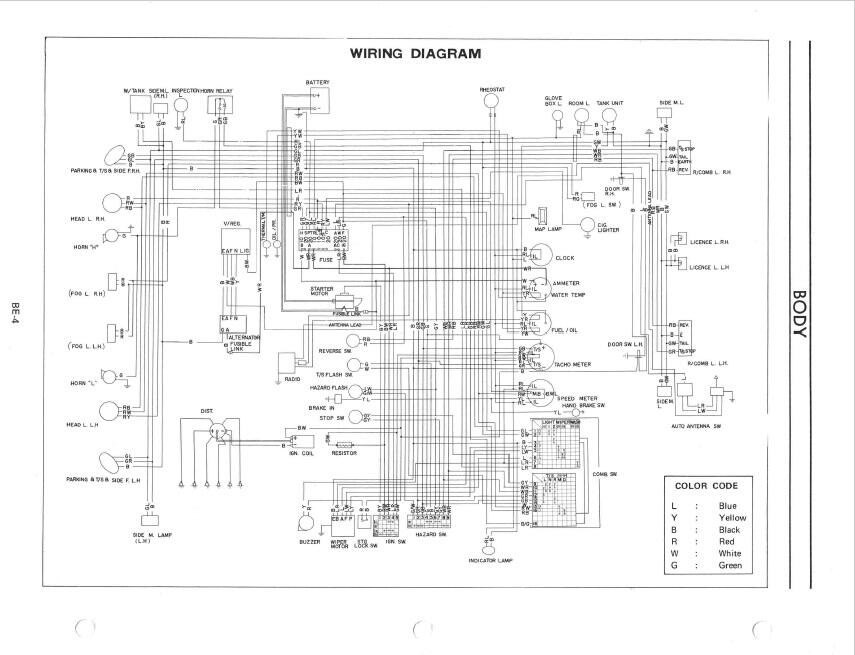

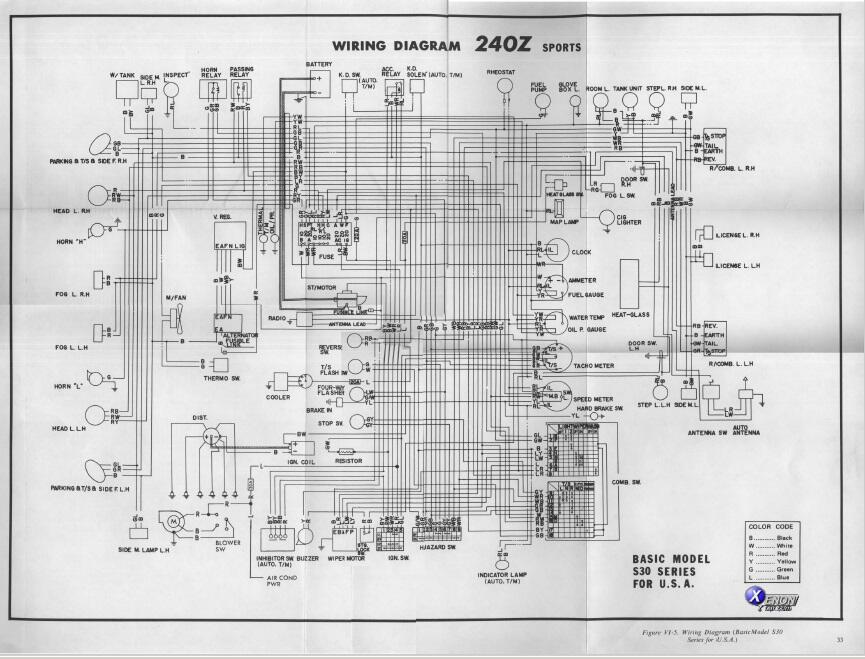

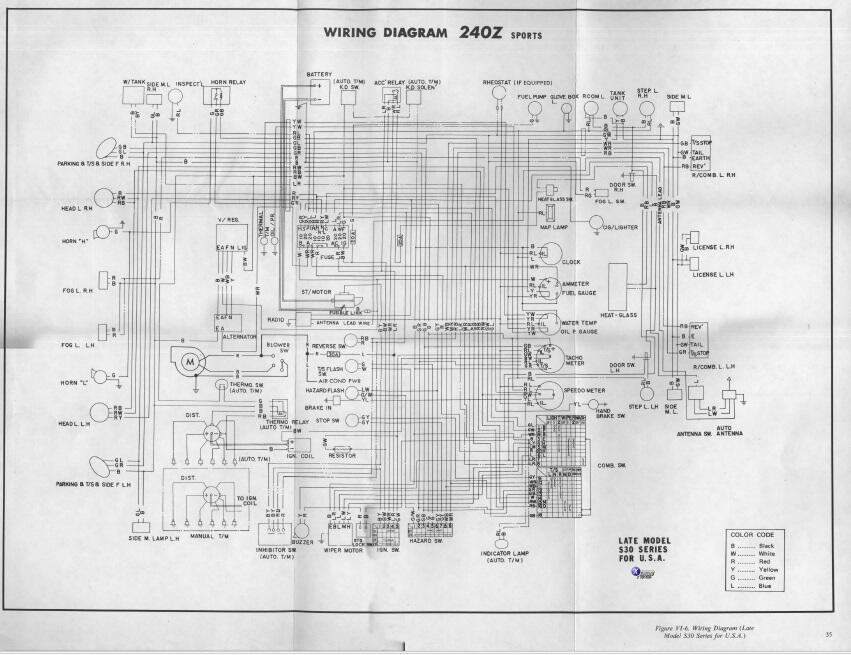

I've poked around looking for a wiring diagram for the early cars (1970) and haven't come up with anything really good. I've turned up five diagrams so far, and they all are questionable in accuracy. This is clipped from a 1970 owners manual: This is another version, supposedly from the owners manual: This is clipped from a 1970 Factory Service Manual - Body Electrical section: And here are two versions clipped from the Service Manual Supplement, which I believe came out for the 1971 model year:

-

Vapor Tank Question

Nope. Think about it like "the gas tank will spill over into" the vapor canister. It's not pulled to the tank. It runs over into. Thankfully, I don't smell gas fumes with my car ever. I've never messed with the vent hoses in the back by the tank, but I have no idea what (if anything) my previous owner did.

-

Vapor Tank Question

That's normal. The hose that leads to the gas tank is not directly connected to any vacuum source. Maybe try picturing it this way... The carbon canister is like a big open top bowl full of small rocks. No lid. And there are two tubes stuck deep into the bowl of rocks. One of those tubes goes to the intake manifold and the other tube goes to the gas tank. You can't ever pull a vacuum on the bowl because it's open on the top. There is no lid. There is a third tube involved, but that third tube doesn't go into the bowl at all. It just actuates a valve switch on the tube leading to the intake manifold. Not sure I'm helping or hurting at this point.

- 240Z SU Throttle Cable Kit

-

240Z SU Throttle Cable Kit

Really neat implementation. Certainly simpler than the complicated silver soldering thing that I did. So why didn't you just grab onto the original existing ball on the linkage? Is it simply that the Lokar* cable didn't come with the correct sized ball socket? * Ummm..... of the Hill People? Anyone?

-

Which Oil Pan Will Fit?

Gotcha. That's not at all what my buddy got. Thanks for the info.

-

Which Oil Pan Will Fit?

@texasz A local buddy of mine is having the same issue with a set of new headers he just bought. Out of curiosity, what headers are you using that caused you the interference with the shield?

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

The reason it doesn't thread in as far is probably because of the thread profile differences. NPT uses 60 degree threads, while BPT uses 55 degree "Whitworth" style threads. So while the pitch is the same, there are some minor differences in the shape of the peaks and valleys. That said... If you are working on one of the sizes where the BPT and NPT thread pitches actually lines up the same (some of them do and some don't) and you aren't intending to hold back a lot of pressure, you can usually get away with using an NPT plug in an application where the correct part is actually BPT. Put an extra wrap of teflon tape on it and crank it in. Of course, the right thing to do would be to source a BPT plug.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Word on the street is that the tapered pipe threads used (everywhere?) on the Z's was British standard... BPT. So the 14 TPI would be correct, but the thread profile is a little different than NPT.

-

Machine work on SU for roller bearings

Haha! Maybe they wanted some scratches in there to hold oil like piston ring cross hatch marks? Seals like a little lube,

-

Machine work on SU for roller bearings

Haha! I try! So as scary looking as that integral equation is, it is basically means "average". As in "Roughness average". And to make matters simpler, I think a surface finish of Ra at 8 u-in can be achieved with something around 400 grit sandpaper*. The typical (and best) means for achieving the appropriate surface finish would be by grinding the shafts and again... A well tooled machine shop should have that capability. * Note that I did see some indication that the UK numbering system for sanding paper grit is different than the US, so be aware of that.

-

Machine work on SU for roller bearings

Hardened and polished throttle shafts paired with bearings would be best. Those bearings are designed to run against a pretty high quality surface finish. For example, the versions offered by McMaster recommend a surface finish of Ra = 8 microinches Where... That said... Even without hardening, new stainless shafts with a good polished finish will be worlds better than worn soft brass.

-

Machine work on SU for roller bearings

I'm no carb expert, but on the ones I've messed with the wear appeared to be on the shaft. the chrome plating had been worn through, and once that happens, it exposes the (even softer) brass underneath, and things spiral quickly from there. billgtp posted a pic of one of his shafts, and it might be a trick of the camera, but I think I can see the brass color peeking out at both ends. Between the bearings and the marker lines? As for availability of new, I have no idea. Certainly any well tooled machine shop could make them, but at what cost?

-

[2024] What Did You Do To/with Your Z Today?

As a matter of fact.... Yes. There's no way I'm moving that old oil into the new motor.

-

[2024] What Did You Do To/with Your Z Today?

- Machine work on SU for roller bearings

Yup. That's the closed end version I was referring to. Using those on the outboard ends of the carbs would eliminate two of the four leaks:- Machine work on SU for roller bearings

Haha! I was serious about the intent. The joke part is the value of that mod on our (mostly stock) Z cars. - Machine work on SU for roller bearings

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.