Everything posted by Zed Head

-

New Centric rotors don't fit [shorter hat]

This part just clicked after I made my other post. You have the "early" hubs on your 1973 car. So RockAuto sent you the right parts for a 73, according to the data available. Interested to see what they do, I'm not even sure that there are real people there. It's a huge operation, many more brands and models than just Datsun and Z cars, and might be primarily robots and warehouses. From what I've seen, most parts houses are all working from the same database. So they all make the same mistakes. Try to find a transmission rebuild kit and you'll see. And, there are several threads on this forum about the early scalloped hubs and the rotors. Part of the puzzle...

-

New Centric rotors don't fit [shorter hat]

Aside from the fact that the internet is full of stories about Nissan changing things mid-stream, and blending parts as they make the change, what are the dimensions of the rotor that you have? At least you can confirm that you either got the wrong part or you got the right part for the wrong hub. Measure from the mating surface of the wheel to the disc surface. I can measure that through the slots in my wheels. Finding and getting the right parts is part of the fun. If you can't get a full refund, you might make your money back by just selling them to someone here. With the dimensions in hand at least they'll know they're getting the right part.

-

78' 280Z stumbles under throttle application

Take the small wire off of the starter solenoid and turn the key to Start. If the pump is wired right you'll hear it whining and you should hear some bubbles in the fuel tank as the air is pushed out. The pitch of the pump will change when the lines get full pressure. If you have a pressure gauge you'll see what's happening. Did you cut the ends off of the old wires? It's possible to wire these pumps backward. They'll run but they won't pump. Another possibility.

-

New Centric rotors don't fit [shorter hat]

You didn't say what year your 240Z is. Your profile says you've owned a 72 and a 73 240Z. the internet says that your part number is good for 73-78 2X0Z cars, so if you're talking about a 73, you're in the gray zone. Could also be that someone changed your front suspension. I would take the focus off assuming someone else made a mistake and make sure that you didn't first.

-

camshafts

I'm not an expert, that's just what I've read. Other sources say never remove the cam towers. But almost everybody says to get the matching rocker arms and pieces, unless you want to buy new rocker arms. The key to knowing if the cam is installed correctly is if it rotates easily. Also, don't use the torque specs. in the "How to Rebuild..." book. There's a typo, it's too high. Any idea why your cam broke in the first place? Is it the original cam shaft or a replacement?

-

camshafts

The recommended way to install a used camshaft is to get everything else that was used with the shaft along with it. The cam towers, the rocker arms, the wear pads, everything. Keep everything in the same order and orientation it was removed and reinstall that way. Your camshaft might have broke because someone installed just the shaft in the old towers and it flexed and fatigued.

-

A/C and heat problem

Have you checked the magnet valves (solenoids) for proper operation? That's where the vacuum is distributed to the hoses and actuators. Maybe you have one that's sticking and not opening to atmosphere to release the vacuum.

-

sensors on t-stat housing.

You're on the slippery slope of guess-and-hope...

-

How to Remove Rotors from '78

Groovy. Here's a trick I've seen used to loosen things that are on the hub that might help. Put the hub back on a wheel, tighten it down with a couple of lug nuts, place the wheel face down on the ground, then stand or sit on the wheel while you loosen the bolts. Or you might just hold the wheel with one hand and loosen with the other. Whatever works.

-

sensors on t-stat housing.

That might be a temperature switch for a dual point distributor. It's kind of a mystery mechanism that Nissan kept up through the early EFI cars. It's not mentioned in the Emissions chapters, only the Electrical chapters. It advances the timing when the engine is cold. Maybe to keep the idle up or maybe it really is for emissions. Described in the Ignition section of the Electrical chapter. Measure resistance on those wire ends and see if it's a switch or a sensor. If it's the switch, it only matters if you have a working dual point distributor.

-

How to Remove Rotors from '78

I haven't replaced rotors but I think that they are bolted on to the hub from the back. Do you have the hub and rotor assembly off of the car or are you trying to remove the rotor with it on the car? Sounds like you might have it still on the car since you're asking about bearings. If you had the hub and rotor off you'd already have removed half of the bearings and seen that they're pretty easy to replace, although some beating with a punch and hammer might be required. Use a brass or aluminum punch so you don't score the bearing race seats. Rockauto has some good tips on making sure the new rotors work right (click on a link for any rotor and a new window will open up). Runout needs to be checked.

-

is there a six spd transmission that will bolt to my 280z how do u bypass tach wires

Nothing wrong with wanting a more modern 6 speed transmission. If there was an easy swap, there would be a bunch of 6 speed Z cars out there. But there is no easy swap, not even an adapter you can buy. I think that I've seen some adapters that people have built for themselves, but they're not available for purchase.

-

Engine will only run above 4000 RPM. Carbs or timing?

Going to the most basic of basics, you should have been able to choke off the air supply to control idle speed. The engine will only spin as fast as it can pull in air to burn. The fact that you couldn't get the idle speed down suggests that you had extra air coming in from somewhere. The only air supply the distributor might supply would be from the vacuum advance canister, leaking. Just a thought.

-

Hight idle when AC on only

Check the hose from the solenoid to the actuator. Small vacuum leaks will cause an increase in idle speed.

-

Distributor & Ignition Timing Woes

Are you using the factory 1976 distributor or ZX or aftermarket? Could be a factor. Does your tang look like Picture #3 in Post #4 when the timing mark is at TDC on the compression stroke?

-

Fan Blower just stopped working

Check AC-38. There's a diagram. "L" means blue wire color. You should have a 4 speed switch. Looks like power is passed through a set of resistors to control speed. The two wires to the blower should be easy to find and hot wire since you're almost there in your picture.

-

Distributor & Ignition Timing Woes

Actually, you'd have to remove the oil pump and shift it over a tooth. The distributor only fits one way on to the quill. One thing to do before going too far would be to verify that the timing mark is at zero at TDC. Your damper might be bad. Why would anything have changed? Have you had the oil pump out? Rebuilt recently? Some background on what's been done recently might give some ideas. By the way, the line to the charcoal canister is ported vacuum, only applied when the throttle is off idle. It's the right place for it. And the thing on the intake manifold is probably the top gear solenoid. Doesn't help your problem, just adding.

-

Josh's 280Z VG30DE 5-speed swap!

Got my cutting pasting screwed up in Post #21. Here's the link to the modification - My cheap Z32/RB26 Tranny shifter Bracket. - Nissan RB Forum - HybridZ

-

Josh's 280Z VG30DE 5-speed swap!

It's for an RB swap but the concept should work. You'll have to measure for your project. - Z32 Transmission Shifter Relocaters - Group Buys - HybridZ and the 240hoke part mentioned, for an L6 - Z32 Transmission Shifter Relocaters - Group Buys - HybridZ Use Google and search "site:hybridz.org z32 shifter" and you'll find a bunch of reading.

-

Josh's 280Z VG30DE 5-speed swap!

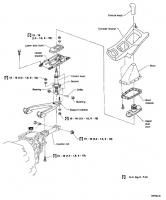

My S30 lessons have stalled recently also. I need something to break. Found a good reference on exhaust concepts, linked below. If you're tuning the exhaust system to generate pressure waves (think two-stroke engine pipes) at specific RPM ranges then a constriction can be useful. But just adding a random constriction to maintain velocity will just give random results. Why not go down to 2" or 1.5? Exhaust System Technology: Science and Implementation of High Performance Exhaust Systems On the shifter - there's a guy on Hybridz who came up with a very simple modification for the shifter bracket and rod on the Z32 transmission. A few cuts and welds and the lever is where it needs to be. The part is called a "support bracket" in the attached drawing.

-

Josh's 280Z VG30DE 5-speed swap!

I think that LeonV might be just disagreeing with your premise that restricting flow "should actually give the motor a little bit of a performance". That's been shown to be an urban legend, wive's tale, myth, etc. when referring to primary size for headers. You might be confusing your turbo principles with NA principles. You want hot gases in to the turbo so that they can do work on the turbine. With NA you want cool gases so that they take up less space and get out faster. Your vocabulary seems to be outpacing your knowledge. Actually doing something is the best way to learn.

-

Bent pinion flange R-180

I think that Eurodat was just pointing out the possibility of a whine. No guarantees that a simple flange swap will be easy and fix the problem without creating a new one. It seems to be that some people work on their diffs and end up with a whiner and others don't. But no guaranteed way to fix the whine if you get it. Nobody has asked how the flange could possibly get bent? It's pretty stout and would be surprising to have enough force to bend it without damaging something else. Are you sure it's bent, or could you just have internal damage or a bad bearing causing a pinion shaft wobble? You might be just wasting time with a flange swap.

-

Josh's 280Z VG30DE 5-speed swap!

classiczcars is a great site but this one might fit your project better - HybridZ

-

No spark on hot days

Sounds like you just jiggled a bad connection. You're not understanding how the coil works. Without current flow you'll see the same potential (voltage) on both terminals. You didn't force current to flow anywhere.

-

No spark on hot days

I saw a list of parts and a statement that new ZX parts were wired in. Not clear that all of the parts are ZX, and grammatically it is undefined! Could be just a ZX alternator and coil, which still gives plural ZX parts. Bonus - The terminals of module are wired to the negative and positive terminals of the coil. The negative and positive terminals of the coil both have battery power when the key is on. Therefore, the terminals of the module will have battery power when the key is on. Logic, gotta love it! Good luck with it.