Zed Head

Free Member

-

Joined

-

Last visited

-

Currently

Viewing Topic: Z's on BAT and other places collection

Everything posted by Zed Head

-

78 280Z Want Start

Maybe the clicking/knocking noise is the fuel pump. Not turning. The engine does not seem to be spraying any fuel. You did not mention fuel pressure. Very important.

-

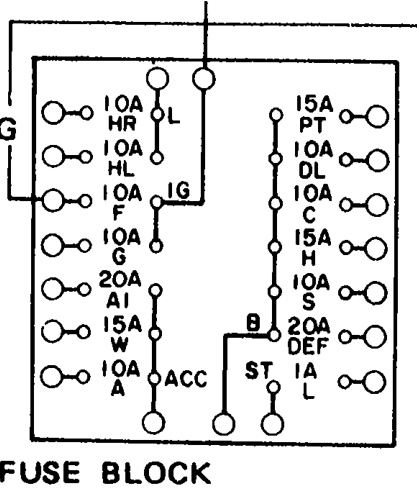

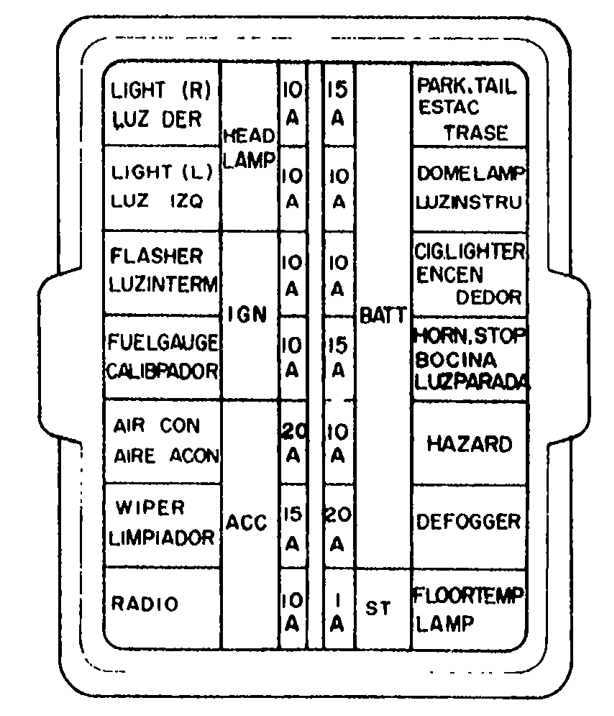

‘77 280z signal fuse keeps blowing up

Check the back of the fuse box. Fuses blow from heat. Maybe you have some corrosion, causing heat, or a short circuit to the AC circuit.

-

‘77 280z signal fuse keeps blowing up

-

Hot brakes

Any mechanical component from the brake pedal to the MC piston could be too tight. Each contact point is meant to have a small amount of play. The play at the pedal to MC can be hard to get right because of cramped quarters. I used to adjust mine so that I could feel when the MC rod was just contacting the MC piston and the clevis pin was loose in the holes. You can adjust the rod with a pair of pliers while everything is connected. It will spin when the locknut is loosened. People have had problems using the FSM numbers on their booster rod because of the variety of aftermarket parts and gaskets and adapter things. There's a tool you can get that will measure the depth then transfer it to the rod if you're not confident of your measurement technique. Somebody has posted it in the past, here's an example. https://www.amazon.com/Sunyat-Power-Booster-Pushrod-Adjustment/

-

Hot brakes

Might be that you have a hydraulic pressure buildup or hang up, not releasing quickly, but releasing slowly. So you're not catching it by the time you get a wheel lifted. You could lift the front end and confirm that the wheels spin freely then drop it down and go for a drive using only the parking brake. Check for heat. That would tell you if the pads are dragging all of the time or only when you pressurize the hydraulics. Or you could just let them cool down and go for a drive using only the parking brake. If it's a slow leakdown you'll get the same result.

-

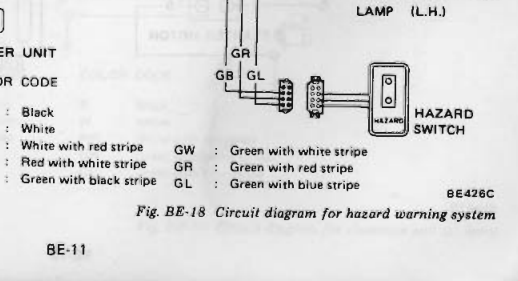

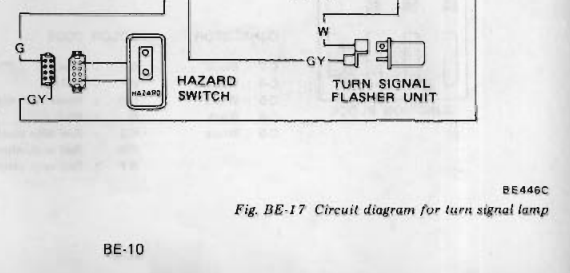

Turn Signals - Stumped

Just found an old thread where I was so focused on the turn signal that I didn't notice the involvement of the hazard switch. In case anybody finds it. Weird how the brain evolves...

-

Turn Signals - Stumped

I would plug it in and back probe. Or identify the trace and/or switches that go from G to GY and measure continuity. I can't remember what the inside of the switch looks like.

-

Turn Signals - Stumped

p.s. the Hazard switch just lets power pass through from G to GY when the switch is not activated. Looking at Post #16 it seems like you have a Hazard switch problem. The power is not getting through.

-

Turn Signals - Stumped

I haven't followed the whole thread but the wiring diagram shows a different power supply and a different output through the Hazard switch, for turn signal versus four way flashers. You're either not getting power or you're not getting output from the Hazard switch. I would confirm power in on G, then power out on GY, right at the Hazard switch, firstly.

-

Turn Signals - Stumped

Any chance it's the bulb(s) or their sockets? When you say "don't work" do you mean no light at all, or no flashing? I'd put a meter on the pins in the bulb socket. Sometimes they look okay but don't actually contact the bulb terminals. Plus you can test power supply and ground. A look at the wiring diagram will show which pins do which.

-

Wick Humble Second Edition

https://francieandfinch.indielite.org/book/9781931128407

-

Hot brakes

Maybe it's not the brakes. Could be wheel bearings.

-

1983 280zx turbo engine

How about pressurizing the cooling system and waiting to see which cylinder fills with coolant. Watched a youtube video where the guy forgot and left his pressurized overnight. The leak area was apparent.

-

77 280z Restoration

Curious, are your E12 modules Nissan brand or aftermarket? I think that that is one of the issues a person has to consider. The E12 aftermarket does not have much competition so the product quality is sketchy. Look at the price difference on the only two available on Rockauto and then look at the pictures. Who knows what's going on... https://www.rockauto.com/en/catalog/nissan,1981,280zx,2.8l+l6,1209338,ignition,ignition+control+module+(icm),7172 Anyway, you can get get lost down a rabbit hole when you start modifying things, as you've already found out. Here is a write-up about the HEI module from EuroDat. In short, there are five connections that you need to worry about. Get those five correct and you can put the module wherever you want to. I have seen people put it in place of the E12 module on the side of the distributor. The five points are the two trigger wires, red and green to G and W on the module, the B for battery, the C for coil negative, and the ground contact through the mounting hole. There is another writeup in the downloads area showing how to jumper the board in the E12 module but it seems overly complex to me. Just extend the green and red wire from inside the distributor. You have to put your electronics nerd hat on to get in to it.

-

1973 Rebuild

It really comes down to if you're trying to get the "most" out of the ignition system or not. It's a matter of degree, and what you're trying to achieve. The "high energy" (large plug gap) systems were designed to fire leaner fuel air mixtures I believe, with fewer misfires, for emissions purposes. And to be more consistent over time, unlike points which can cause poor running as they wear. One side benefit of using a coil with more primary resistance is that the ignition module should see less current. Which will generate less heat, which will make it last longer. When I installed a GM HEI module on my car I also used the GM HEI coil that it was matched to. It was a 0.6 ohm primary coil. Why try to out-engineer the engineers that designed it? But I had the 280Z voltage triggered tach. SteveJ's plan is good. Have options ready.

-

1973 Rebuild

The 240Z tachs are the Smiths type current sensing tachs. The instructions for the Crane ignition modules explain how to adjust the loop on the back of the tachometer to make them work correctly with ignition systems that pass more current. Near the end of this document. Pretty cool electronics nerd stuff! Make it work. -

-

77 280z Restoration

This is the standard test for the E12 module failures, from what I've read over the years. You can wire in a GM HEI module using the red and green trigger wires from the distributor if you find that that's the problem. People have even mounted them on the sides of the ZX distributor. It's the same type of module, just a different shape.

-

Hot Spark Ignition

It drops current. Lower spark energy for similar time. It's interesting.

-

Hot Spark Ignition

If you use your own coil it's about $70 versus $108. I just remembered something I saw on Rockauto a while ago. There are other versions of the "conversion" kit out there. https://www.rockauto.com/en/catalog/nissan,1973,240z,2.4l+l6,1209170,ignition,ignition+conversion+kit,11340 This Standard product even has green tape. https://www.rockauto.com/en/moreinfo.php?pk=50053&cc=1209170&pt=11340&jsn=375

-

Hot Spark Ignition

Some odd comments about charging voltage. The 240Z can generate up to 15 volts. An internally regulated alternator is typically 13.8 to 14.3. Pick, pick, pick... https://www.hot-spark.com/Installing-Hot-Spark-Hitachi.pdf It might be a sensitive system - "Test Maximum Charging System Voltage: If the charging system voltage, measured at the coil’s positive terminal, is more than 14.0 volts at any RPM level, the voltage regulator likely needs replacing. Too much voltage can destroy the ignition module and other electronic components. A maximum charging system voltage of 13.0 volts or so is plenty. A quick fix is to wire a 1.4 Ohm external ballast resistor between the coil's + terminal and the HotSpark ignition's red wire. Adding the ballast resistor is cheap insurance against voltage surges, etc"

-

Hot Spark Ignition

It looks like a version of the Pertronix I but doesn't seem to have the features of the Pertronix II. It needs the ballast and/or a 3.0 ohm coil. Not "high-energy", current-limiting. It could probably be used to trigger a Crane or MSD ignition module. I wonder if it gets damaged if you leave the key on like the Pertronix I. Definitely a money-saver though. Looks like you have to buy the coil separately. About $70 + $40 = $110. Versus $150. https://www.thezstore.com/page/TZS/PROD/12-4020B

-

Moog ball joints

That's a bummer. I'd contact Rockauto if it was me. At least let them know and see what happens. If they don't make it right, use Amazon next time. Free shipping, free returns, same price. https://www.amazon.com/Moog-K9011-Ball-Joint/dp/B000C560FC There's actually a review from 2010 that reports a similar problem. https://www.amazon.com/product-reviews/B000C560FC/ref=acr_dp_hist_1?ie=UTF8&filterByStar=one_star&reviewerType=all_reviews#reviews-filter-bar

-

Moog ball joints

Their picture shows a Zerk fitting though. Among the parts. So you get a fitting and a nice bolt to seal it up afterward. Looks like picture uploading still isn't working. The picture is in the link above.

-

Moog ball joints

You can re-use them. Take them off the old joint. Or break the bank and buy new... https://www.rockauto.com/en/tools/hardware,grease+fitting,grease+fitting+-+english+thread,172 At least they pre-tapped the hole. That was nice of them. https://www.rockauto.com/en/moreinfo.php?pk=203652&cc=1209226&pt=10070&jsn=378

-

Won't run if tach connect?

Look at the diagram and do what makes you feel comfortable. If the Crane module fails it will be easier to reconnect the old one.