Everything posted by Zed Head

-

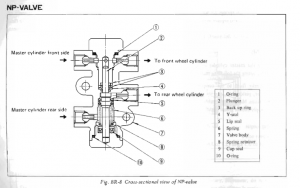

Bleeding rear brakes

You already said "that". Press on the pedal with the bleed screw open and see if anything comes out. They all work the same, master cylinder > brake lines > wheel cylinder. People have reported clogged NP valves. It's documented on this forum somewhere. You can take them apart and clean them up. I installed speed bleeders on mine so that I could push a lot of fluid through easily. Same general concept as SteveJ's method, but easier to set up (for me anyway) and doesn't pull fluid back once it's left.

-

5sp Shifting Problems

By "miss" do you mean the lever moves to the proper position but the gear is not engaged? That might be a broken or damaged shift fork. Under light load it will push the coupler in to place but under higher load it deforms or twists. If the problem is how fast the clutch releases, you'd expect it to scale with RPM and the speed that you move the lever. On the clutch though, is it the factory design, or something like Centerforce,with the inertia weights. I've read that the weights can hang at very high RPM. Transmissions that don't shift right tend to make people angry, and it's a downward spiral from the first few grinds. They start banging gears and pushing through the original problem, creating more problems. You might have one of those. I bought one for parts and for the front case, and there were so many broken parts inside it was hard to believe. Ball bearings missing from races, broken synchros, broken shift forks. But it still seemed to shift okay while sitting on the ground.

-

5sp Shifting Problems

With more pondering - I think that you're screwed. If you're already using MT90 and still using the word "horribly", on both upshfits and downshifts, odds are the synchros are worn out, or even broken. Only being blunt 'cause I know you can take it, but hate to see you waste your time. The guy started to take it apart then stopped. People don't take apart transmissions that work fine. The best sign of proper clutch operation, I think, is entry in to reverse. If you can press the pedal down and quickly pop it in to reverse, your clutch and clutch actuation are working.

-

To Buy or not to Buy. That is the Question! Series 1 240Z

It's already fixed. You drove it. Without knowing your plans all you're getting are reflections of what the people out here would do with it. The restore guys see lots of work to make it look like it came off the factory floor. The daily driver guys see a car that's ready to buy and go. Pick a plan, and ask worth relative to the the plan.

-

5sp Shifting Problems

The memory is fuzzy, but I think I feel a little bit bad about that...

-

5sp Shifting Problems

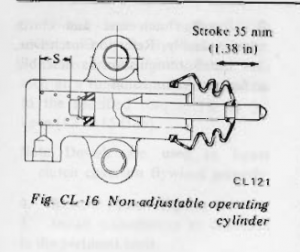

I had a similar grinding problem with a junkyard 1980 5 speed. I also had a 3rd gear grind with a 1978 5 speed. Fixed the 78 by switching from Valvoline fluid to Redline MT90. Moved the RPM range up substantially on the 1980 by using a 75/25 blend of Swepco 201 and AT fluid. The 1980 also got better with usage after the final switch. I thnk that there may have been rust on the gear cones. It had sat for a long time. Short post - try another fluid. On the throw - the later slave cylinders automatically adjust to max throw since its hydraulic. The fork can only push it back so far, to its new starting point. If the rod was too short the hydraulics would just push the cylinder out of the bore. The rubber boot is the only thing holding the cylinder in the bore with the newer slave cylinders. I don't know how the old ones are designed. Loss of potential throw would be at the MC rod and pedal adjustment. Pretty sure that's right, from my memory of past clutch problems. Posted a picture of a 1978 nonadjustable.

-

5sp Shifting Problems

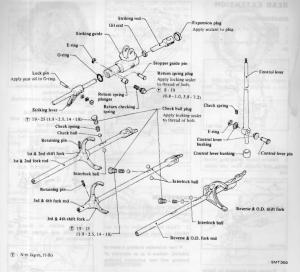

Most people don't even know those plugs and springs, return or check, even exist, and only find out after they have problems and get on the forums. The fact that yours was out is a bad sign. Along with the stopper guide pin. Nobody ever removes those unless they're trying to fix something. They are the first two steps of transmission disassembly. How are the shifter bushings?

-

240z Valve Train Tapping After Head Work - VIDEOS Inside

With the head on the engine shouldn't the cam lobe be sideways? That will put the piston partially down the bore,so you you don't hit it with the valve head, but still give the least movement necessary to slide the arm out. If the lobe is on the heel center that's pretty close to TDC I believe. It would be pretty much the same procedure as doing valve seals. Rossiz and S30Driver just did a set, I think. On the noise - people have been fooled by exhaust leaks at the head before. Apparently it sounds mechanical but it's just gases escaping.

-

Intermittent noise from front wheel

The area in the hub that the race is tapped/pounded/pressed in to is what I meant. The hub can get worn out. Probably from running worn out bearings which allow things to gain speed from side to side. Many tiny impacts.

-

Intermittent noise from front wheel

One more thing - people have just posted recently about having their bearing seats wallowed out. If that happens the bearings will still be loose even after you follow the factory torque and loosen procedure. Try grabbing the top of the wheel with the car on the ground and shaking back and forth. If they're loose you'll hear it at the bearing. I have a worn one and my new procedure is to tighten until the shake test sounds right. The Nissan procedure doesn't work anymore.

-

Intermittent noise from front wheel

Is the frequency of the sound a clue? There are some things that would have a consistent frequency; the four bolts to the hub, the four scallops if you have an early 240Z, four lug nuts, spokes on a mag wheel, the ribs on a vented rotor, etc Don't even know what kind of wheels you have or how fast you were going so it's hard to guess. Also, no offense, but how did the brakes start grinding after just 15,000 miles and what was grinding? Might be a clue. I found that one of my rotors had the inner dust shield (the actual formed in and machined ridge on the rotor) completely worn off from a pebble or some hard object that had been stuck there. Either that or the PO had ground it off for some reason. Must have made some noise.

-

L24 Rebuild -Again!

If the tops of the valves aren't ground square you should be able to rotate the valve and the wear pattern will follow the rotation, from side to side anyway. The valves can (do, I think) rotate during usage so that would be a problem if it was the case. You'd want to replace the valve or regrind the tip. The other possibility is that the valve guides aren't square to the came anymore. An off-center reaming could do that I suppose. A new valve guide should fix it. These are just guesses based on my limited knowledge of how these parts fit. Rotate the valve and see what you get. It should tell you something.

-

Project Boondoggle (or, so I went and bought a Z!)

A good paint job is 90% surface preparation. If the paint doesn't stick, but has fully cured/hardened, it's most likely not the paint but something on the surface that was painted. It could be something as simple as the fabric softener on that freshly washed rag you wiped the surface down with to be sure it was super-clean. Or the lubricating oil from your air compressor if you used an air hose to blow the dust off. Or residue from that carb cleaner that looks like it all evaporated. You should follow the instructions to the T and don't add anything more. No cleaning solvents of your own, no extra wipes with a rag, no tweaking the formulation for a faster cure. There are chemists out there who spent years developing those formulations and procedures to make it all seem so easy.

-

240z Valve Train Tapping After Head Work - VIDEOS Inside

Went back and looked at the valve work on the other thread. Looks like a lot of machine work on those bigger valve heads. And the seats look bronzish in color. That's where the problems with lash usually come from, sunken valves due to seat wear. Seems like a Datsun guy would have recommended new seats. Nobody has mentioned keeping the rockers matched with the cam lobes, but I'd assume you did that, based on your other meticulous work. On the wear lines - I've seen rocker arms with very visible wear lines, that can't be felt at all. Most builders use feel rather than sight to determine wear. I think the lines are visible pretty quickly once in use. Don't know enough to say if your guy's on the right path with keeping the seats and modifying valves or if he's way out in uncharted territory. It's interesting work though. Good luck.

-

Oil pressure uneven

All solid (no hydraulics) valve trains should always make some noise. You should recheck your valve lash and make sure it hasn't disappeared. If you lose valve lash a valve can stay open and be damaged. Check it before the ride, even during.

-

240z Valve Train Tapping After Head Work - VIDEOS Inside

You never really said how the machinist fixed the incorrect machine work n the #4 intake valve seat. I would guess that he might have shimmed it, since welding and remachining would be very expensive. And the fact you set lash, but it closed up again is a concern. Have you rechecked lash again? Don't assume that things can't keep getting worse. Finally, people that are very confident and say that they have tons of experience and don't make mistakes make me nervous. Just saying. even the pros can get things wrong sometimes. Could be that your guy's fix on the #4 valve seat didn't work.

-

240z Valve Train Tapping After Head Work - VIDEOS Inside

Works fine on my system. Windows 7, Chrome, old Compag desktop. The picture shows an arrow pointing at a rocker arm wear pad and a cam lobe. This probably is where the typical, normal, noise happens. I've pondered where that wear line on the rocker arm wear pad comes from and I'm pretty sure that it's where the pad drops back down (up) on to the cam lobe after it loses contact with the lobe as the high point goes by. Basically, the rocker arm jumps off the top of the lobe then falls back, clicking every time, and work-hardening that narrow line of contact. Same vein, but not really relevant - notice that many cam lobes are brown and unworn on the base circle. That's from the mousetrap springs holding the rocker arm down so it doesn't rattle. On the base circle there is no contact with the rocker arm wear pad. One easy quick way to get an idea of proper valve lash settings on an old engine. If it's shiny it may have been a while since lash was adjusted. Maybe, it's just a clue. Also, and I've seen this discussed before, sometimes the rocker arm wear pad is not ground on the same plane as the rocker arm lash pad contact surface. So the rocker arm will twist around its own axis as it one wear surface overpowers the other. The lobe wear surface probably wins until it gets around to the base circle, then the lash pad surface wins. This can probably cause some noise. For a fairly primitive looking piece, the wear surfaces probably need very precise and accurate work done to get a quiet valve train.

-

Oil pressure uneven

That wasn't my intent. Rossi just had some great pictures in his thread. I actually used Google to try and find some less controversial pictures, but there's not a lot out there. I would spend a little more time trying to figure out where the oil burning is coming from. Depending on which rings he used and how he finished the cylinders it could be that the engine is just not broken in yet. The oil scraper rings aren't seated. The compression test doesn't tell you anything about the oil rings. On the oil pressure - you haven't given any numbers. You just said uneven. Before going crazy,maybe install a mechanical gauge directly on the side of the engine and see what it says. The oil pressure gauge in the car is electromechanical and can fail at the gauge itself or the sender. Could be that oil pressure is fine, and the engine will wear-in over time and be fine.

-

240z Valve Train Tapping After Head Work - VIDEOS Inside

Your latest video requires a sign-in. You might try disabling each cylinder to see if you can narrow it down. I don't know if piston slap noise is combustion dependent, rocker noise probably isn't, but since you don't know for sure it might give a clue. Remove plug wires, one at a time. Make sure you ground them to the block though, some ignition systems don't like to have their spark path jammed. If you really wanted to go deeper, you could remove sets of rocker arms. Lots of work but if its rocker arm noise, it will tell the story. If the piston is down, you remove the arms with a screwdriver, by prying the valve down. It's described in the How To Modify book. I've done it on a head off the block. Pretty easy. Easier than removing the head, and looking for something that has no identity.

-

Oil pressure uneven

Here are some threads with pictures: Post #10 - http://www.classiczcars.com/topic/47101-cam-wear/ Here's another (sorry Rossi. And Al) - http://www.classiczcars.com/topic/50485-rocker-geometry-woes/page-1

-

240z Valve Train Tapping After Head Work - VIDEOS Inside

You said that you lost lash on one valve. Maybe the valve seat wasn't seated in the head and it dropped in as the engine ran. Not good, but not disastrous unless you burned the valve when you had no lash. Just a thought. I know also, that valve lash is lost over time in general as valve seats and valve faces wear. I'd imagine that some tightening of lash is normal during break-in. Would depend on what wears more, valve and seat or the cam lobs and rocker wear pads.

-

Datsun Parts LLC - gone to the dark side?

That's life. Most people have to pay for past actions, mistakes or not. If you want to be proactive, reply to the members here who had problems and show that those errors are gone. There are at least two. And by the way, there are at least two engine build vendors that get good reviews on this forum on a fairly regular basis. So it is possible to build a good reputation. Good luck.

-

Advice on what year my 280z is?

There should be a plate on the driver's side door jamb that has a date stamped, like 1/76. That's a clue, plus each year has some small differences. If you post a picture, it could probably be figured out. Or look at pictures of 280Z's on Google or on this site.

-

Is this 76 280Z worth getting?

I was joking, sort of. Purpose determines value. For your stated purpose though, that car looks like an excellent choice. If it's been maintained and driven, it's probably dependable. It's the "ran when parked " cars that sat for 10 years that have the problems.

-

Is this 76 280Z worth getting?

It looks in great shape. You could start a completely new forum on "worth". It could be a philosophy forum. Or a money forum. Or a time plus skill forum. An emotion forum. Family forum. The transmission swap isn't that hard. If you have the time and skill. And the extra money. And it makes you feel good, and your family is okay with you spending time away, on the car. Some would say it's not right to change an original car, but that can be debated.