Everything posted by Zed Head

-

Current Coilover Options For 280Z's

I went back and read the fine print and see that you're right. There's a thread on Hybridz about them, from JPN.

-

Current Coilover Options For 280Z's

Didn't realize that JPN and BC are the same company or JPN is distributing BC parts. Kind of confusing.

-

Recommendation for new radiator and elctrical fan for 280Z

I've looked for a good switch for a fan in the past (it was for an injector cooling fan, not radiator). Difficult to find. The ZX switch is set to a high temperature, it's more of an extreme heat switch, to battle the heat-soak problem. Probably wouldn't work well for radiator cooling fans, it turns on at 210 F or around there. I think that many people who use the electric cooling fans use programmable systems, with a thermocouple. Here's a general article. http://www.hotrod.com/how-to/engine/ccrp-1111-electric-radiator-fans/ Good luck on matching the thermostat housing threads. Most people just run a tap through the hole and repurpose it. Once they find a sensor that they like.

-

Current Coilover Options For 280Z's

Maybe the web site needs updating but they don't show a 280Z option. Only early S30, 240Z - 260Z. http://www.bc-racing.co.uk/applications/nissan-coilovers/nissan-240z-260z-51mm-strut-70-73.html http://www.bc-racing.co.uk/applications/nissan-coilovers/nissan-280z-260z-with-55mm-strut-75-78.html

-

NGK BPR6ES plug cap coming loose warning

I've seen the problem in the past but have noticed that the newer NGK's I bought have a different color electrode (darker, not shiny aluminum) and it doesn't seem to come loose anymore. Almost looks like the flange is part of the "cap" now. The issue might have been addressed with a modification. Could also have been a short-term problem caused by a manufacturing change. And there's always thread-locker. The threads are metal-to-metal contact on one side so conductivity isn't an issue. Plus contact with the flange.

-

Current Coilover Options For 280Z's

One negative of the T3 product might be the cost of the shocks. Koni's are expensive. If you can do the work then just buying an adjustable spring perch (basically a threaded tube with a perch on it) and sectioning would give you the most basic thing people look for, adjustability, pretty cheaply. The key to success is understanding that the sectioning is for getting the shock to fit properly and work within the desired range of travel. Choosing the shock is a result of choosing ride height and finding one with the range of travel to fit that ride height. The spring perch can be installed on any tube height. Basically answer the questions of "why am I cutting the strut tube to be this length", why am I using this shock, what is the purpose of the adjustable spring perch, where does the perch need to be with the springs I plan to use. Even if you buy a package or kit, it's good to think about those questions. People occasionally miss a question and end up with bottomed out shocks, or a car that sits too high or too low at full spring perch adjustment. Wheels factor in also since they affect ride height.

-

Very Cool Ignition Upgrade

It's fun to make things better. But the 123 ignition system has been around in the 3 ohm primary circuit form for many years and probably many miles. Seems like a design problem would have shown up in that time. Maybe you just got a bad cap.

-

Weird Wiper Issue

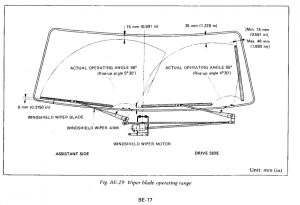

There was a guy on another forum who had installed the linkage at the motor 180 degrees off. His wipers worked but they tried to park on the hood. Maybe you're seeing the wipers move and park but what you're seeing out of the cowl area won't work once installed. Anyway, here's a drawing of how things are supposed to be.

-

1972 FSM

You're right. I actually have those three files also. Maybe I was thinking of 1970.

-

Weird Wiper Issue

Do you mean that you unbolt the motor and let it drop a bit? Or that you pull everything out and reassemble it? Just trying to figure out if you have everything in the same orientation when it works and when it doesn't. I remember how difficult it was on my 76 to get all of those parts in and out of the holes in the cowl. What if you leave the bolts holding the motor loose? I do know that the Z motors will definitely stop if there's too much force required to move things. Unlike my 1995 Pathfinder which will bull its way through all obstacles once the wipe command has been given. So it seems like a simple binding issue.

- Weird Wiper Issue

- Weird Wiper Issue

-

Weird Wiper Issue

Sorry, I got lost in the description and didn't see this part. Seems like a binding issue. Sometimes people install the linkage with the motor shaft in the wrong position. I think that it might also be possible to get the linkage installed in the wrong orientation. Pretty good drawings in the FSM. Have you confirmed proper installation or did you put it back the way you found it? Also, you might try running the wipers through their motion with them off the motor shaft. If you can't do it by hand, the motor probably can't either.

-

Weird Wiper Issue

That's a sign of a weak motor. Mine would get stuck occasionally, even after I had it rebuilt. It Before you take it apart again, you might lift the blades off the windshield (stand them straight up) and try it. This will be essentially like no wipers but will be minimum effort required. Might remove the weird factor and replace it with weak.

-

Very Cool Ignition Upgrade

An actual resistance number would be informative. You can't tell much by color. The other half of a "melting" problem would be heat dissipation. Heat is produced in all electrical components. My point is to look at the complete system. It's not just the material used, and as you pointed out, materials and their qualities can vary. All we really know about these "buttons" is that one looks like "carbon" and one is yellowish in color. long with that is the fact that many aftermarket perfromance parts are sold on old reputation and are, in effect, just brand names now. Quality has been lowered to maximize profits. Could be that 123 chose an inexpensive supplier. The original failure described was with the 3 ohm system. Definitely not high energy. Current flow should have been relatively low. The replacement parts might have damaged the 123 module, but the cap was already damaged. I'm using the stock GM HEI module with the stock GM HEI coil on the stock Nissan 280Z distributor and cap. 20,000 + miles, no problems. No need for an aftermarket coil, the stock GM system is plenty. I like to dig in to the real numbers behind these issues. It's just fun to do. Edit - overlapping posts. I see we're all headed the same direction...

-

Very Cool Ignition Upgrade

Destroyed distributor cap buttons does seem to be a problem with the GM HEI distributors but conductivity differences between "carbon" and "bronze" materials seems unlikely as the cause. Arcing and/or bouncing due to a weak spring and poor contact seem plausible since that would produce heat. But straight-up heating of the button from high current and resistance-heating, without overheating the coil or ignition module doesn't really fit. Just saying, check the other parts too: the spring strength and the contact point, and maybe put a dab of conductive grease on the point. They're probably more important than the button material used. Edit - forgot about the other half of the contact. The rotor (also sometimes called a "button") contact. It needs to be smooth and conductive also. That tiny little area is usually overlooked.

-

Need info on 1974 260z

SteveJ will probably figure it out. I forgot (again) that 1974 should have stock Nissan electronic ignition. The introduction of electronic to the Z's. Always good to confirm though, people do swap. Is it the stock unit, down by the fuse box, or aftermarket? Just trying to help. It's the details that will solve the problem. Pictures would be great.

-

New member from Oklahoma

The dual point problem is a problem. Apparently, it's for emissions purposes. It keeps idle speed up until the engine warms up. If you can live with a few minutes of low idle it's not a big deal to switch to a single system. My 76 had two magnetic pickups, electronic. Good work on the torch. I didn't see this until it was over but the bolt threads in to the transmission's aluminum housing so a torch would expand that well. ZTherapy is the source for carbs - http://www.ztherapy.com/

-

Need info on 1974 260z

Look under the distributor cap and describe what's there. We can't tell what " as far as I can tell" means. How long is "will not crank back up"? Seems tedious but the words are all we have. Make them count.

-

Beck Arnley Vs. Posi Quiet Plus That Voice In Your Head

My Posi Quiet pads (or maybe just one pad) started squealing very loudly when cold after the car sat in the garage for about a week. Maybe started by some rotor rust. After they warmed up, no more squeal. After a few days of driving the squeal dropped to almost nothing. Maybe a hard spot on the pad material. Just an update. They're not perfect. Thought I was going to have to put the factory shims back in.

-

Windshield Cleaning - Inside

I replaced the "rubber" backed Home Depot carpet with another that was a more typical sewn/glued fabric backing. Made a huge difference. The rubber was probably PVC with plasticizers, and they were vaporizing and redepositing on the windshield. The windshield still needs more cleaning than my other car but much less than before.

-

Checking cam wipe?

Just to add to your concern - in a discussion about wiping cam lobes (the bad wiping, like destroying) one of the engine builders described damaging the lobes just from turning the engine by hand. He could see things starting. Best to keep things over-lubed with the zinc additive lubes. Pressures at the rocker arm - cam lobe interface are still high, even at low speed. The old safe/sorry conundrum.

-

1976 280Z ECU and AFM question

A maybe helpful comment - the ECU's usually go completely bad, either running super rich or not running at all. Your lean popping symptoms indicate the need for more fuel, which is not a common bad ECU symptom. Also, I notice that you mentioned electrical testing but nothing about fuel pressure. Another potential cause. Anyway, good luck.

- 1976 280Z ECU and AFM question

-

1976 280Z ECU and AFM question

Fascinating that so many of us adjust the AFM to try to fix this problem. I did the same when I first got my car and ended up buying a new one from MSA. But my test numbers were way off. Still I might have been able to make it work using the other atlanticz Z "tweak". I have two, maybe three, AFM's that needs this tweak to work. It's the most direct way to get it done. http://atlanticz.ca/zclub/techtips/tempsensorpot/index.html Forgot to say - put your AFM back where it was. Blue's technique is for recalibrating to factory specs., not tuning. Many people just read the theory of what happens and use it for tuning. But it doesn't seem to a linear full spectrum fuel enrichment, like the potentiometer is.