Everything posted by darom

-

running lean '76 280z

Some ideas for an AAR 🙂 Manually operating heater valve: https://www.amazon.com/Universal-Conditioner-HV-2211C-Control/dp/B003R31YVQ/ref=m_crc_dp_lf_d_t1_sccl_3_3/138-5872620-2836123?pd_rd_w=UzJvp&content-id=amzn1.sym.76a0b561-a7b4-41dc-9467-a85a2fa27c1c&pf_rd_p=76a0b561-a7b4-41dc-9467-a85a2fa27c1c&pf_rd_r=34220AX20P78YFH9FKCE&pd_rd_wg=aMQD8&pd_rd_r=2ead7de1-3b51-42e0-b3bf-74fcaef91ae1&pd_rd_i=B003R31YVQ&psc=1 or this with the timer relay (I use a cheap timer relay for my injector rail blower/fan from a later model): https://www.amazon.com/4inch-Normally-Closed-Electric-Solenoid/dp/B074Z5SDG3/ref=sr_1_31?crid=3G17GRQMH50IC&keywords=solenoid+valve+1%2F2in+12V&qid=1700513498&sprefix=solenoid+valve+1%2F2in+12v%2Caps%2C84&sr=8-31

-

running lean '76 280z

Hi guys, I ran the smoke tests, found a few areas: 1. valve cover gasket, firewall side - big leak. 2. electric EGR solenoid (leaks inside, not vacuum hose), EGR valve (inside again, not the vacuum line). little leak. 3. oil pan gasket - medium leak here. 4. oil dipstick - little leak. I replaced the valve cover gasket with a cork one, it still leaked. The valve cover/cylinder head appear to be flat. I ordered a silicone one from Milkfab Engineering ($28), the new gasket sealed all the leaks. I made a delete metal plate for the EGR. Replaced all the old spark plugs with new NGKs, replaced the fuel filter. The aux air regulator was replaced with a 300zx unit, which was adjusted to shut. It takes about 6 minutes. The valves were adjusted. The car's ignition timing is set at 15 bdtc, idles at about 900 rpm. The vacuum is at 17. The car has a strong pull, no hesitation while accelerating. Observations: 1. I think once I replace the oil pan gasket, I might get another 1-2 of vacuum. This is a spring project (it is too cold in the garage). 2. The resistance pod is at 2k Ohms. I still can't kill the engine maxing it out at 5k. 3. The 'new' AAR is unpredictable. If I leave it alone, it will close (not completely) after 6 minutes. Two different days while testing - one day the idle is at 900-950 rpms, today it was at 800 rpms after warm-up. I feel the AAR shutter 'curtain' doesn't guarantee the same closure. I would like to replace it with a similar mechanical device (like the 240z choke inside). Does anyone know of a part that might work? This way I will open it up when the engine is cold, and close it when it warms up. Once closed, I can set the ideal 850 rpm at idle. 4. When the engine is cold, within those 5-6 minutes of warm-up period, if at idle once rev'ed up, the engine will pop through intake. 5. I still can't kill the engine with the idle adjustment screw. Hopefully, it is the oil pan gasket leak that causes it.

-

running lean '76 280z

Thanks Yarb, for looking it up. Just in case I ordered a gasket, Mahle MS16717 (composite) from rockauto. I found a forum chat in the Help Me section where a 280z owner compared it to the OEM from Nissan, they looked identical (with the exception of the price). The plan is to do a valve adjustment as well.

-

running lean '76 280z

Thanks for the resource! Found the part number, 14035-N3500, gasket manifold, looks like it is available. Will order/replace it once I confirm the leaks in that area.

-

running lean '76 280z

@Dave WM Thanks! I will run these tests next week. This was a great video. I will check the intake/exhaust bolts torque specs. I replaced the injectors, AAR, AFM, timing chain/front cover gasket along with intake/exhaust one (Fel-pro) 5 years ago. The car passed smog in CA. If this is an intake/exhaust gasket, any preference which brand to get? Rockauto lists some Fel-pro, Beck and other brands. Can I double stack these to get a better seal?

-

running lean '76 280z

The PCV hose was removed and checked, no cracks. The PCV valve is not stuck. Thanks. I am thinking my stuck open AAR might be the culprit, what bothers me is that pinching it I can completely shut the engine off. Basically, per Fuel Injection bible AAR provides more air when the engine is cold to increase the RPMs (speed up the warm up time). Once it shuts in 8-10 min, its function is over (there is still going to be some air escaping, but the amount is negligible). In my case, it is still open adding more air thus creating lean condition. I have a used AAR from a 300zx (?) with a removable cover. I can install it to test the theory.

-

running lean '76 280z

I did some testing tonight, and @Zed Head you might be onto something. I couldn't kill the engine with the idle speed screw. I could lower the engine's RPM's to 700s until the screw's end of travel, but it would still stay running. Another test with the potentiometer. Mine is a 5K unit, I couldn't use it to kill the engine either. The most noticeable difference is when it is at 0 Ohm (runs bad at idle when it is cold, when revved up, there is popping) and 2K Ohm - the RPMs will pick up, the engine vacuum will go up to 14. Putting it at 5K shows no difference. I can however kill the engine by pinching the Air Regulator's rubber hose. I bought a unit brand new years ago from a Nissan dealership. Per atlanticz.ca's site, it appears the valve never completely closes. I have another spare which I confirmed works by closing its plate completely after 7-8 minutes. I removed the AFM, the door is not stuck, opens/closes smoothly with slight pressure. No cuts/holes in the rubber AFM/intake hose. I ordered a small smoke machine from Amazon, it will be here next week. Hopefully I will be able to pin point the source of a vacuum leak (unless it is the AAR's which is feeding too much air?). Thanks, Den

-

running lean '76 280z

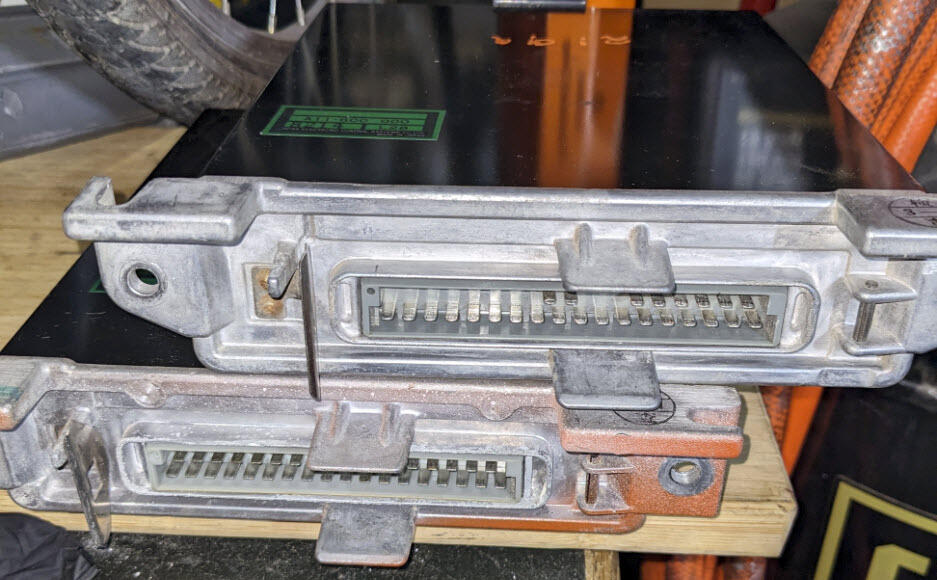

I ran the engine with the potentiometer on max (I might have a 5K unit), the engine ran on fast idle at 1500 RPMs. I couldn't kill it. Tomorrow I'd lower my idle speed to check for any vacuum leaks. Thanks, this is a good idea. Just for laughs I swapped my ECU with 1 spare unit I had. Same part number as my stock unit, A11-600 000, it has less pins than the one that was in my car. The can ran rich (I could tell by the exhaust smell), I turned off the potentiometer completely since it didn't make any changes. The fuel pressure at idle was 32 psi (vs 30 psi before), the vacuum was 12 (vs 14 before). No more popping through the exhaust when I was revving the engine. (in the picture: the bottom is my stock unit). It is good to know that if a problem doesn't go away with a potentiometer, an AFM adjustment won't help much. I'd hate opening it up and messing it up even worse. I put my old ECU back to look for vacuum leaks tomorrow. Appreciate your help.

-

running lean '76 280z

Even with 1200 Ohms added to the water temp sensor circuit, the car still runs lean, bogs down until is fully warmed up. When it is warmed up, I still can hear lean popping noises through exhaust. I don't have to smog it any more, maybe bump the BTDC to 15-16 degrees?

-

running lean '76 280z

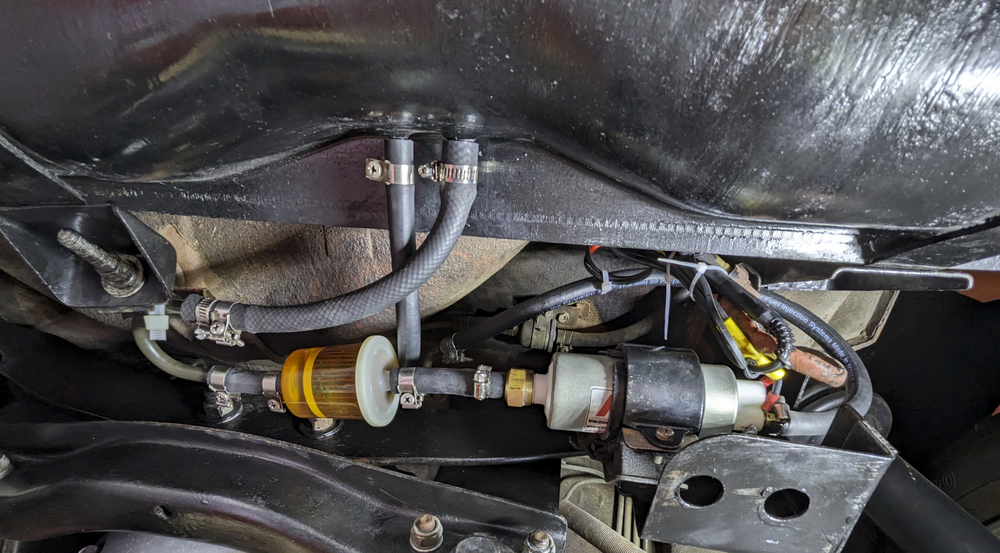

Hi guys, I am looking for your advice before I open my AFM unit and start messing with it. Symptoms: when the car is cold, it runs very lean, bogs down, popping noises, lack of power. When it warms up, more manageable to drive, although it occasionally makes the same popping noises. it also smells lean from the exhaust. What has been done: 1. Remanufactured AFM, sealed up. Adjustments to the air bypass screw don't help richen up the mixture. 2. I went through all the FI Book tests, the air temp sensor in the AFM/water temp sensor in the t-housing, all pass. Cold and warmed up. 3. Throttle positive switch - adjusted, at idle, middle position and at wide open per FSM. 4. The fuel pressure gauge shows 30 psi and idle, 36 psi at acceleration. New fuel MSD-2225 fuel pump with a pre-filter, clear gas, no rust in the tank. 5. Vacuum gauge shows 14-15. I am guessing this is a low reading. 6. Idle - 850/900 rpm, 11 BDTC 7. Some time ago I installed an inline pod resistor for the t-stat water temp sensor. If it is at 0 Ohm, the car runs lean, revving up from idle produces lean popping. If I set it at 1000-1200 Ohm, the car can be revved up. 8. This is a CA car, came with a functioning EGR valve, while testing I disconnected it. 9. New intake/exhaust gasket, valve cover gasket, no air leaks around the oil pickup/oil filler. Removing the oil filler cap, reduces the RPMs, engine wants to stall. 10. Air regulator was tested, it closes up after 10 minutes. Pinching the hose produces engine stumbling. 11. The injectors were replaced with brand new units a while back. 12. The timing chain was replaced a while back. I haven't done any valve adjustments. I am wondering if there is anything else I missed before I open up the remanufactured sealed AFM and start messing with its CCW movement to richen up my mixture. I also have another used ECU unit I can swap. What bothers me is why the AFM's bypass screw doesn't make any changes? The car spent all its life in CA and was a joy to drive. Once we moved to WI with colder climate and mornings, I found myself adjusting the in-line pod resistor to add 1000-1200 Ohm. This week-end we had temps in the 40s, I went to fill it up and noticed this leaning mess. Thanks! Den

-

280z 1976 fuel pump saga

I ended up installing my new spare MSD-2225 fuel pump. If (or better, when) this one fails, I will go Dephi route with its lifetime warranty. Thanks to all for your insight.

-

280z 1976 fuel pump saga

@SteveJThanks for the link to the curved fuel hose. I wish I found it before I made a U-shaped 3/8" line out of the brake line. @Zed Head My bad, I have had 2 Ultra-Power fuel pumps. They look identical to the previous owner's Airtex, even share the same 8312 part number. Delphi shows the maximum pressure of 107 psi, I can't find the minimum one. The OEM part it referenced is E8312 (Amazon link: https://www.amazon.com/Delphi-FD0035-Electric-Motor-Solenoid/dp/B000CGFV2Y) The Delphi's warranty PDF mentions that "This Limited Lifetime warranty lasts as long you own the vehicle in which the Delphi Electric Fuel Pump or Fuel Pump Assembly is installed. This warranty is not transferrable and applies only to the original purchaserof the product." I guess I can give it a shot, although swapping fuel pumps even when they are offered for free, is still a messy time consuming job. Thanks for the pump refernce.

-

280z 1976 fuel pump saga

Hello guys, My car has been sitting for 3 weeks. My E8312 fuel pump didn't work today. Cold winters apparently have nothing to do with my issues :-( There is a 12V directly at the pump's terminals. The clear plastic pre-filter was full of fuel since the tank is full and previously I lowered the pump/filter. Rockauto is going to give me a refund (minus FedEx s&h fee to send the faulty unit back to them), since this is the 2nd unit that failed on me within a year. I have put about 40 miles on the car since the installation. I am going to improvise and put the MSD 2225 unit there. I also have an old E8312 laying around, I found a youtube video of a guy who takes it apart and cleans it. Not sure if I want to go this route since the aluminum pump's canister edges need to be pried apart. Any ideas why I am facing such bad luck with fuel pumps? Here in WI they sell high octane gas without ethanol. Should I put that instead of the regular 10% ethanol one? Thanks!

-

280z 1976 fuel pump saga

Installed a u-shaped 3/8" brake line to take care of 90 degree kinks with the replacement 8312 fuel pump. Will keep my fingers crossed that it will last.

-

280z 1976 fuel pump saga

@HusseinHolland Thanks. I am going to either try to find a 3/8 u-shaped fuel hose for this or will use a U-shaped 3/8" aluminum joint (I have a brake line terminating kit). I do have a fuel pressure gauge inside and monitor my fuel pressure. Usually it is around 30-36 psi (idle, full throttle).

-

280z 1976 fuel pump saga

@siteunseen The picture was taken when I just installed the pump. The pre-filter is full of fuel - that was the first thing I checked this morning. It has become a habit to check on rust coloring of the inside of the tank. @Yarb The previous car owner replaced the original Bosch with an Autozone unit (looked like the 8312) which later quit on me (that was when I installed my 1st MSD unit). Would it be a good idea during the winter to occasionally run the pump?

-

280z 1976 fuel pump saga

-

280z 1976 fuel pump saga

Hi guys, It seems that bad karma is following my 76's fuel pumps. After 4 years, the MSD 2225 fuel pump quit on me (installed vertically), I bought a new one, that one lasted less than a year (same orientation). Due to the covid supply issues, instead of waiting for a warranty replacement (weeks), I decided to replace it with the Ultra-power's E8312 unit. I installed it in November in the horizontal position after reading a lot of people saying that it should be horizontal as close to the bottom of the fuel tank line as possible. In all my cases there is a small see-through fuel filter installed just before the pump. The fuel is clear, no rust. I use non-Ethanol fuel. The car ran great, after a few test runs last year, I left the full tank of non-ethanol gas, and stored the car for the winter. Yesterday, I found out that the pump is dead. I register voltage at the terminals (while cranking 10.4V). Applying direct 12V from the battery positive to the pump's terminal doesn't make it run. It is still under 1 year warranty, I just ordered a replacement one. Now I have a question. Should I trust the MSD brand and install my new replacement MSD fuel pump or try my luck with the E8312 unit? The only pain is that MSD doesn't come with a 90 degree fuel hose connector. What is the killing factor of fuel pumps in my case? Cold winters of Wisconsin? The car is in the non-heated garage (maybe it gets in 20-30s F inside). Or just bad luck? Thanks!

-

So we're doing a 73 restoration project

I have one of those $3.99 Harbor Freight mirror tools (what is left of it). Just be careful extending it too far - I was inspecting one of my 04 Ford's powerstroke's cylinder heads (valve cover removed, injectors and high pressure oil rail out) when the telescopic tube got disconnected and I dropped 2 metal little flat plates down my engine. I found one. The other ended up in my IPR valve blowing a hole through its metal screen. These plates are used in the H&F tool to hold telescopic pieces together.

-

Smog Fail - headers and EGR

DoubleYOOHZ, it is probably too late to mention this, but you could have visited some local salvage yards in your area. Just bring your own tools to remove parts. I know that our cars are getting harder to find in junk yards, but occasionally I see one 280z/280zx with smog parts still attached to it (you won't find catalytic converter though).

-

1978 Z - Fuel Pump Control Relay

I have a similar relay part number 25236P7102 which passed all the Nissan tests (grounded, not grounded post 4). I am assuming the part number is different due to the absense of the mounting tab. PM me if you are interested. Regards, Den

-

ignition relay interchangeability

Hi Pamato, Have you sorted your electrical issues? Re: the ebrake switch - make sure the parking brake switch at the base of the handle makes a good contact with the ground. Check the BE-36 page for the diagram. Headlights - they are all routed through the combo switch (page BE-11). I had to find a used combo switch for my '76 and rebuilt it. While troubleshooting the electrical gremlins, I modified the headlight wiring with dedicated 2 30AMP relays to give them more juice and take the load off the combo switch. There was a diagram on hybridz on how to do it. Regards and Merry Christmas! Den

-

OFFICIAL 280Z "Fuel Damper" thread!

I've been running my 76 for 2 years without the damper (MSD fuel pump). My old damper leaked. I installed an inline fuel pressure sending unit/gauge and don't see any fuel pressure abnormal fluctuations during idle/driving. The idle is steady.

-

Sealing an oil pan

I removed the oil pan 3 times trying to fix oil leaks. The oil pan mating surface was straight. Bolt torque tightening technique was followed. Tried it dry with cork and rubber gaskets, then just RTV alone. The last time I got so frustrated that I used the rubber gasket sandwiched between the grey Permatex RTV layers. That finally did it. That was 2 years ago. No leaks so far. I realize this is a wrong method of sealing the oil pan, but it worked for me :-)

-

Hot-start issue with EFI - who has it, who doesn't

1976, stock exhaust manifold, catalytic converter, heat shield, 1979 fuel rail and injector fan (with eBay time relay circuit set for 12 minutes), new fuel pump, FPR, ignition timing 15*, inline resistance pod. Previously I had heat soak issues, esp here in Bako town in the summer. After installing the 79 injector rail fan with a timer relay, there are no more incidents.