Everything posted by zKars

-

76 Locking Gas Cap

OMG Steve, ROFL, I'm just recovering now about the Chevy Chase scene... Oh my aching sides I've learned my lesson with you guys for sure. Ok, after staring at the ring and BMW cap for 10 minutes, the solution is really pretty simple. You just need a stop block at the right spot. Pictures are worth 1176 words.. First weld in a scrap of metal, here. Put BMW cap in, twist to stop position, turn key to lock, lock tab now protruding and trapped behind welded in tab. A pic with the key in open position, free to turn CCW to unlock. Had to use the rubber gasket from the stock cap, which is thicker. The tabs on the BMW cap are angled away from the body and will leave the cap loose if you don't have enough gasket thickness. Stock is about .012, BMW was only .08 ish Another issue is the cap OD verses the ID of the mounting ring. Dang tight fit. I just did a little hammer tap tap around the inside to roll the lip just a smig and it slips in easy. Ok who wants a modified mounting ring? Choice of powder coat, CAD plated, spray paint or sand blasted bare DIY.

-

76 Locking Gas Cap

Steve, yes the OD of the BMW cap as it fits in the ID of the filler ring is a very snug fit. Wouldn't take much of a tweak of the ring to make it too tight. As to the venting, I believe these caps are not vented. there is no obvious opening. Mind you, I can blow into the lock cylinder area, lips sealed around it (no comments....) and air comes out somewhere inside the cap. Can't tell if its through the locator or locking tab openings or between the inner and outer layer. Will have to do some testing.

-

76 Locking Gas Cap

Thank god I'm not the only fool who bought that BMW cap. What a scam! Yes, it "locks", yes it "fits", just doesn't lock to the car.... Man. However, I just pulled it out of it's hidey hole, and grapped a gas filler opening ring to understand how this looks and why it doesn't lock.. I may see a way to modify the ring so these caps actually lock.. Give me a day or two to fiddle....

- Harmonic Damper

-

Very Cool Ignition Upgrade

I just received and installed the latest and greatest BlueToorth version of the distributor. Absolutely love the thing. The iphone app for it is designed very well and works great.. It is SO much better to have this on my iphone rather than having to drag out the old laptop and USB cable to tune this thing. The real time gauge displays of advance/RPM/Vacuum/temp/Voltage is very slick. It's also able to display GPS speed from your phone's GPS system. Nice integrated analog gauge display. It even has a cool security feature. You can disable the distributor from the app with one click and turn it back on when you return! Just remember to change your Bluetooth PIN from the default or anybody can defeat that. It does allow you to alter the tune when driving, but only to either add or remove timing. So a proper review would not be complete mentioned a couple of backward steps. They have removed the "dual tune switchable while driving" feature, and the ability to save and restore a library of tunes. You can only have one timing and vacuum advance map in the device, and you can't store it and retrieve another. Not sure if I think this is a problem, the real time advance up/down ability compensates for some of what's lost. Anyway, generally very pleased! Thanks Ed for the great service.

-

Stock tire choices...what do you like?

Right Size, Great Handling, Available. Pick two. Well except, Right Size and Available.... or Right SIze and Great Handling.... Wait....

-

Stock tire choices...what do you like?

Definitely watching. There are more than a few "purists" on here with quite stock restorations that should share what they've shod their beasties with... Zup etc?

-

differential question

Yes. The cap has an arrow on it that is to face forward, and is a snap on loose fit.

-

high idle after attempt to tune SU's

I'll put my 2cent bet at a rather large vacuum leak.

-

Windshield wiper motor bag got painted in white

Recently discussed including a new option

-

Windshield wiper motor bag got painted in white

DOT 3 brake fluid is a wonderful paint remover (look at your brake vacuum booster and below the master if you need proof) and will not harm plastics. Give it a shot.

- 123ignition forum discount

- 123ignition forum discount

-

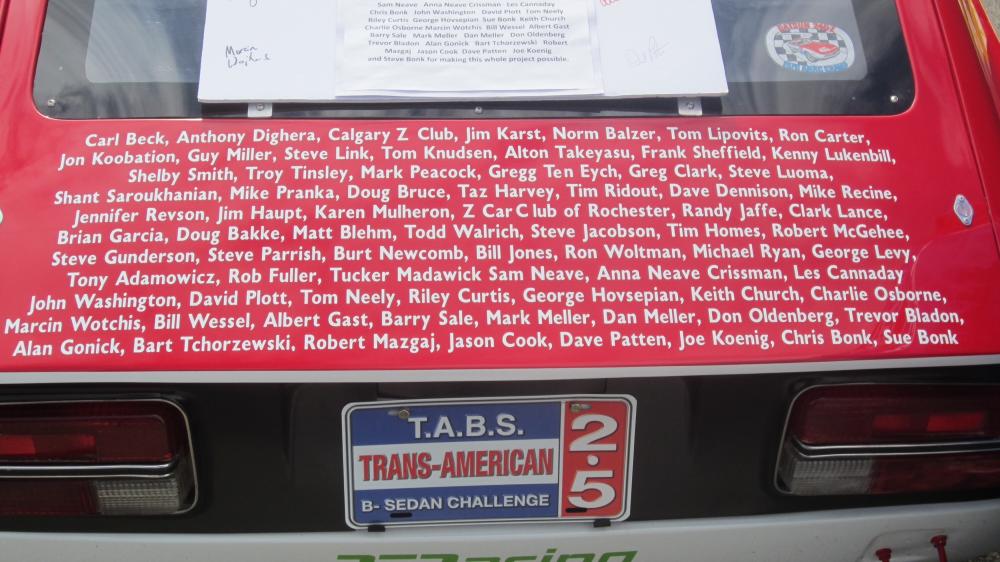

John Morton #48 car For Sale

Note this article and auction are from May 2014. That car has my name on it. Literally. And several others here as well. Thanks at least for the reminder of that special time back at the run-offs in 2013.

-

Trying to source new door glass

The door glass is not the same over all 8 years of production. 77-78 glass is quite different in how it mounts to the frame that connects to the regulator arms and is thus not interchangable with other years. The glass mount frame is also different for 74-76 but the glass is the same 70-76. The two short "C" channels where the regulator arms rollers run are positioned differently in the 74-76 frames than earlier ones. You will have problems with arms falling off the frame if you mix regulators and glass frames. Even the door mounted guide channel at the front changed for 74-76. The 74-76 regulators are different too as they have a wider offset where they mount to the door. I assume they were "improving" the glass fit and function and moving the regulator inboard 1/4" and tweeking the various guide channels made it work better. Then they gave up and totally changed the glass mechanism for 77-78. That stuff works fantastic. Thanks for the overall advice about glass polishing. I have a polish kit coming. Time to freshen up some old glass!

- Correct scuff plate installation

- Late 260Z Smog Pump adjusting arm

-

Outer Control Arm Poly Bushing Too Wide?

Let's get a couple of thing straight about the correct function of these bushings. In the stock bushings, the inner and outer steel shells are BONDED to the bushing rubber between them. When you assemble the strut to the control arm, you leave the pin loose until the car is at normal right height. THEN you torque everything down. This LOCKS the center sleeve of the bushings in the control arm to the strut and leaves the rubber in a neutral un-twisted position. From this point on, ANY suspension motion twists the rubber in the bushing, there is no rotation of the pin in the bushing or in the strut. Poly bushings are completely different as the bushing is not bonded to the control arm hole (you remove the stock bushing outer tube that WAS bonded to the control arm hole, that hole becomes the outer constraint) or to its center tube that the spindle pin passes through. They allow rotation of the center tube in the bushing. hence the need for that sticky lube so they don't squeak. They are too stiff a material to use them like stock rubber bushings. The center bushing tube is still locked to the control arm when it's all torqued correctly. It matters little what sort of bolt you use to create this lock up condition, spindle pin or 5/8's bolt. Although the slightly smaller OD 5/8 bolt does allow for a tiny bit of slop in the strut hole. But if its all locked up correctly, there ain't no room for schnanigans..

-

Late 260Z Smog Pump adjusting arm

The smog pump will have no effect on under hood temps. Don't bother. Check your fuel system to ensure correct volume and pressure specs. Change the filter at least. Possibly also replace the needle and seat in the carb where you see the overflow. This is either excess pressure or a poor needle seal.

-

Factory initialed mistake?

That's the funniest damn thing I've seen in days!! Just regular folk working the line. Monday morning or the local cultural equivalant for sure. That one is going up on the shop wall for sure. Thanks for sharing! And who knew they had an official "Nissan" logo stamp! Any one seen that used any where else on a Nissan product?

- Outer Control Arm Poly Bushing Too Wide?

- Outer Control Arm Poly Bushing Too Wide?

- Outer Control Arm Poly Bushing Too Wide?

-

I just Retired, Moved, Drove Z to it's new garage.

Happy Retirement! Nothing better as long as it was your decision! Spend more time with at Z!

-

Rear Wheel Bearings

I would be very curious why the mech. thinks it needs shims. Ask him to explain how the measurements were made. There are no shims in the stock factory configuration, just a choice of three different "Distance Pieces" stampled A, B and C. I've personnally never seen anything other than 'B"'s. If shims are needed, you either find a different strut housing or make shims. Or have a new piece of pipe made to make a distanct piece that is the right length as mentioned above. This is basic machine shop stuff. Shim stock is nearly free. Another thought, for 240 stubs, you will often find a copper "shim" on top of the inner bearing between the inner axle flange and the bearing.This is not a spacer, it is (I've heard it here!) a noise reducing trick. It has nothing to do with positioning the bearings in the races.

Subscriber

Subscriber