Everything posted by zKars

-

C’mon! Own up ...

I salute you. Mental faculties intact under those conditions is exceedingly rare. Even basic survival is to be commended.

-

Intake water bypass question

It’s intent is to warm the carbs when the engine is cold, to improve drivability and reduce emissions. It was found with the issues around heat soak and vapor lock that they wanted to turn that hot water source off so they added a heat activated valve at the back of the last carb to turn the hot water off once the engine was fully warmed. No need to heat the carbs once the whole thing is all toasty. You can see the 73 version in your picture above just behind the red circle. The early Z’s had that line with no restriction. The common thing to do is just lose that coolant line altogether and, if you drive in cool weather, put up with maybe slightly poorer drivability until the car warms up. If you want to keep all the lines and such for nice correct appearance and ease of plumbing, then I’d plug the line internally at some hose connection and get the best of both worlds

-

Hatch Lock Button

Can’t see how the arm bar that came with that new hatch lock will work with the z hatch release. Look at my picture of the stock lock and arm bar, and imagine the location of that little bolt that’s threaded into the end of the stock arm, relative to the body of the lock. It is above the end of the lock. That bolt head is what touches the release thingy that unlocks the hatch when you push down on the lock body to release it. The new arm, and its long threaded bolt, are much much farther below the end of the lock body. It cannot rotate over into the open position and be located properly above the release arm on the latch. Unless you bend that new arm to resemble the stock one, I don’t think you have a workable solution

-

Heater hardware

I shall compare and see what i have spare. I do declare. Now where.....

-

Hatch Lock Button

Great news that the lock barrel fits the hole in the hatch. Did you not have the original lock with its attached arm on the back? The flat arm with the rectangular slot on the one you just bought isn’t the same shape as the stock one, and isn’t likely to work. I can send you one of my spare lock sets to scavenge the arm off of it if you don’t don’t have one.

-

Hatch slam shut

Fantastic! Glad you found it. No calibration. About the only requirement (other than a decent fit with the body when the hatch is closed ) is that it touches the seal all the way around and doesn't let exhaust in! I worked on a friends car few weeks back. Bad exhaust smell, maybe the worst ever. Checked and or plugged all the usual holes. The worst was that wide trim panel under the hatch with the 10 fasteners. It was warped and nasty. Replaced that, and still had bad fumes. I did check the hatch seal weather strip, it was brand spanking new and installed well. Finally, I put a piece of letter paper over the seal at the back and closed the hatch, then tugged on the paper to see how tight the seal was against the hatch. Well the paper fell out on its own. Got down there and looked into the hatch area and saw daylight!!! Lots of it! Holy wind tunnel Batman! Turns out the slam panel had been replaced during the recent restoration, but it was done wrong. It was flat and positioned too low. Seal never had a chance to touch or seal most of the way across the back. Had to resort to adding a good 1/2-3/4" additional foam stick-on weather-strip to the underside of the hatch so that it touched the seal when the hatch was closed. Far from ideal, but how do you fix that without making a real mess?

-

Hatch slam shut

Hopefully the striker is attached to the patch panel in the same way as stock. It has two M6 bolts through slotted holes in the striker. You can move it up and down a bit. Remove the license plate light to gain access to the bolts and raise the striker a bit at a time and see if that helps.

- "The Orange"

-

Hatch Lock Button

Pretty similar. Bet the rear arms fit the same way, just swap on your Z arm. at the very worst you might have to file off or modify the little protrusions that fit the notches, or file out the notches to fit the new lock. Hmmmm, someone needs to add better lighting on this parts room table.....

-

Quality 240Z Floor Pans & Frame Rails Finally Available

Damn, makes me want to do large scale rust repair again (I'm sure I'll come to my senses shortly). Using pieces like these, assuming they fit, would have made life SO much better on past jobs.

-

FS5W71B transmission identification (close-ratio vs. wide ratio) - with pictures

Excellent Pictures! Best I've ever seen. Thank you. Let's not forget the 1980 variant that shares the same external appearance with the close ratio box, but has short shifter ears. The ratios are listed below. 81-83CR 1980 1977-79 3.062 3.062 3.321 1.858 1.858 2.077 1.308 1.308 1.308 1.000 1.000 1.000 0.745 0.773 0.864 The transmissions in discussion here the ones found in North American 77-78 280Z's then 79-83 ZX's. As Dutchzcarguy guy said, there are other 5 speeds that don't fit these descriptions. It is simply what most north american's are going to run across when you they find a 5 speed. Use with care.

-

Just Another Damned Z Car Project Thread

I do nothing of a commercial nature. When I see needs, I attempt to help. I have a good plater here and built a good relationship. Send me a PM and we can see if I can help with your project.

-

Just Another Damned Z Car Project Thread

-

Correct Hatch Removal Method?

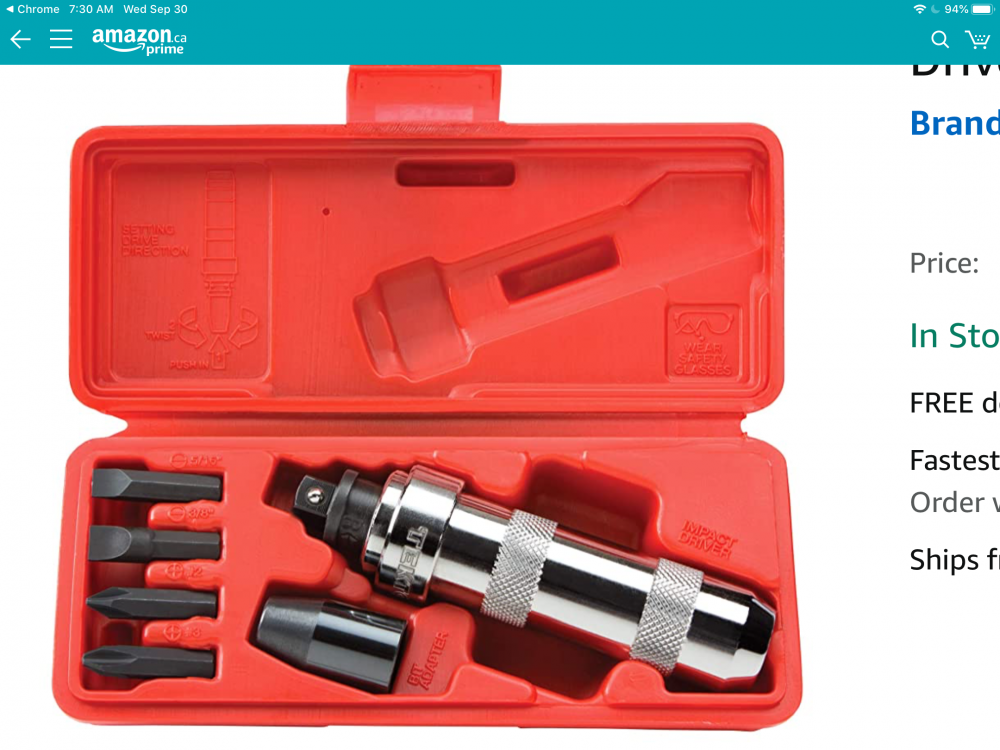

For whatever reason, if you felt you had to remove the hinge to body bolts (blue), you could always draw around the hinge with a Sharpy pen to show you where to put the hinge back. I do this with the hood hinges all the time before I take the hood off. Clearly the red flat head red bolts are your best bet. Don’t try to take them out with a screw driver, get a Philips bit in a ratchet and socket to give you good leverage. They are tight. Make sure the bit you choose fits the Philips head tightly. Might have to use an impact type bolt remover to get them started. Even though the possible problems may be swaying you toward removing the body bolts, don’t...

-

How Flush Should Sway Bar Link Ends Be?

Captain O, you have earned the right to now produce the sway bar end link Torque limiting position sleeve product (SBELTPS) and sell it to the masses as it clearly is both an excellent idea and a glaring omission in the original design. These things are used in millions of cars throughout the world, the market is massive. It will require custom bushings as well as the ID has to be slightly bigger to allow room for the sleeves. Millions of happy users will result and cars will handle better and make less noise from loose bushings, and preserve the holes in their control arms. At the very least, sell the idea to Energy Suspension and get rich doing nothing. You’re welcome.

-

Beware Roadster Parts - Brake Safety Switch - Tubing Nut Thread Size Trap

sorry

-

Beware Roadster Parts - Brake Safety Switch - Tubing Nut Thread Size Trap

Glad to help. I might have a few spares I could part with... They are easy to open and clean up.

-

How Flush Should Sway Bar Link Ends Be?

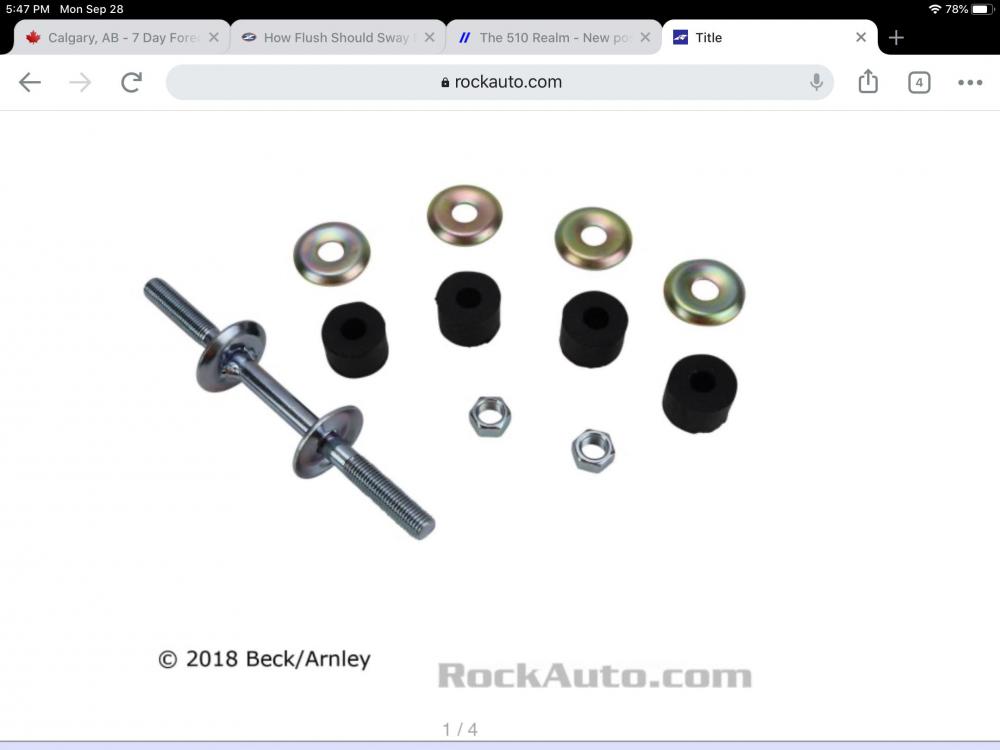

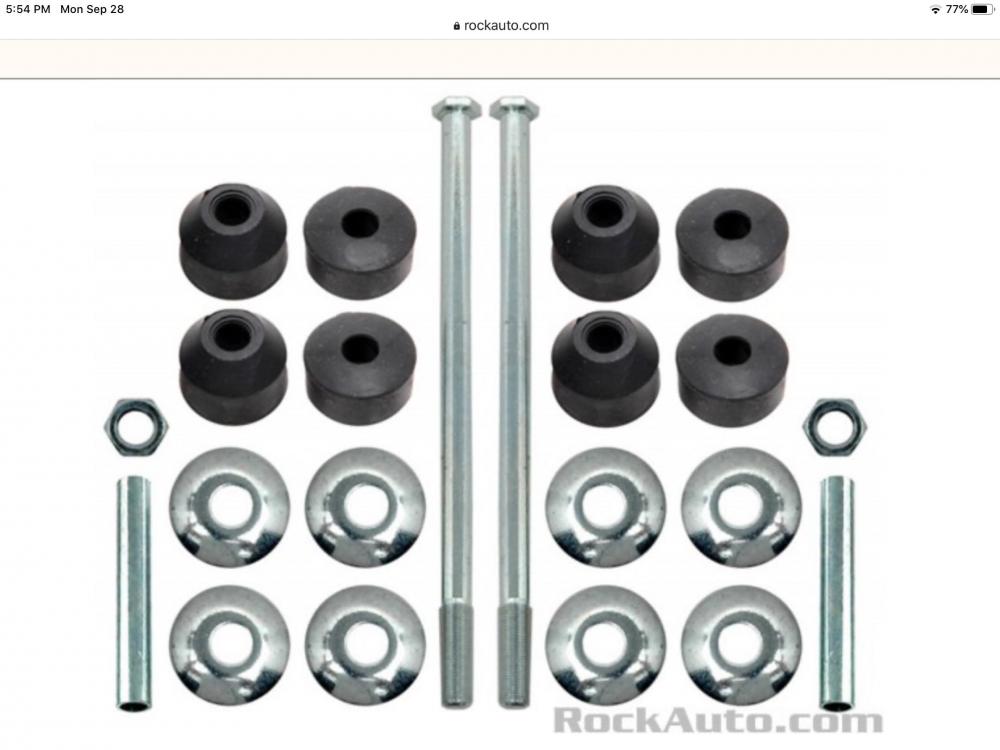

Interesting. I’ve never seen a metal sleeve that fits inside the ID of the bushings. Just the ones that set the spacing between the two bushing stacks. Stock end links that I’ve cut off, or any of the after market ones I’ve bought since have never had one. What you get is in the picture below. I totally agree there SHOULD be a sleeve to set the bushing compression, that would eliminate the guesswork of how much to tighten them, but that’s not the usual reality of what you have to work with. Tighten enough so bushings are compressed so that no metal to metal contact is possible and the bushings can still compress enough in use during travel. If your sway bar hole or hole in the control arm is all ovalized out, they weren’t tight enough.

-

Beware Roadster Parts - Brake Safety Switch - Tubing Nut Thread Size Trap

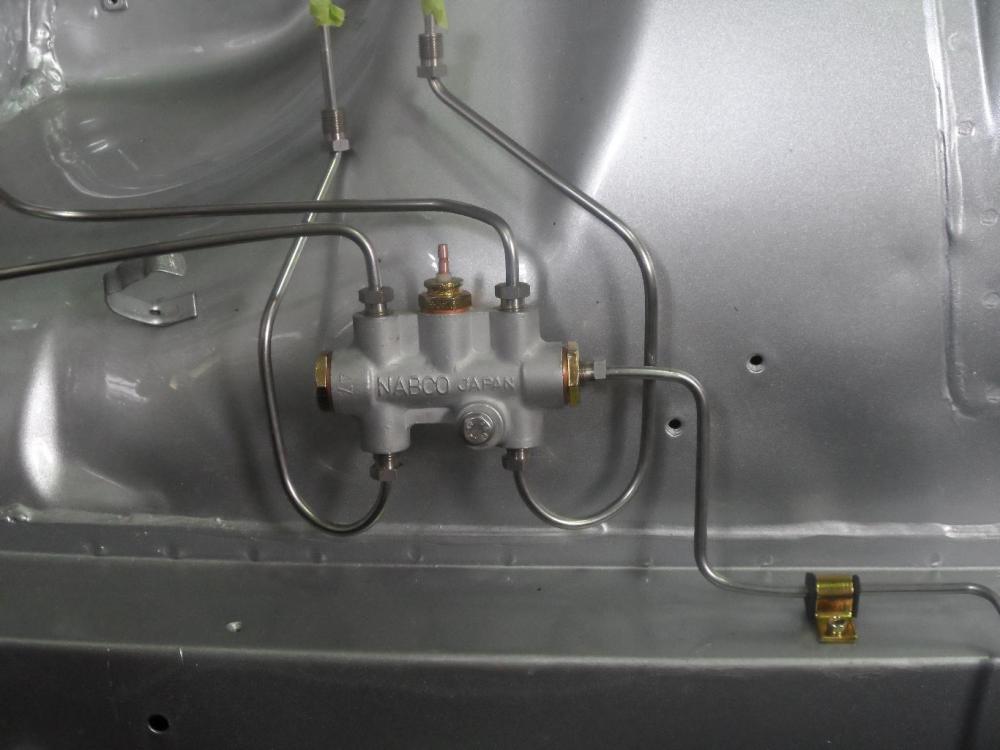

Dear Datsun Brethren I try from time to time to come to the aid of all manner and nature of Datsun people, and last weekend I had the good (cough cough) fortune to work on a 69 Datsun Roadster. It had leaking brake lines after replacement, and I was able to assist the owner with the repair. Something about "just tighten the nut more. It won't break"... But along the way, I discovered something that we need to be aware of as righteous Z owners. Chances are it will never happen to you, or me, but you need to know. As part of the trouble shooting, the owner of said Roadster brought a spare "Switch - Brake", you know, that safety brake light switch block on the fender well that turns on your dash BRAKE light if either side of the brakes loses pressure. We have discussed it's care and feeding previously. Here it is on a Z in case you visual learners need a picture. Here is the one he brought with him from his Roadster. I was questioning whether perhaps his ancient beast used DIN flares or some craziness and that might the source of his leakage, so he brought an example for me to examine. Looks da same to me as our Z part, right? We use the same one a 510 and I'm sure many other models, right? WRONG!!!! The tube nut threads on this abomination are some SAE nonsense, yikes 3/8-24!! Yes the horror of it all. SAE parts on a Datsun. As if having SAE seat belt bolts isn't enough of a embarrassment for most Datsun owners already. Now this comes as no surprise to any Roadster owner I'm sure, as they preach that the front half is SAE and the back half is Metric. Talk about fake news! Anyway, some day, some kind hearted Roadster-owning soul may offer us unexpecting trusting Z owners his spare "Switch-Brake" when we are at our most vulnerable, stuck on the side of the road (in Podunk Kansas of course), and yee shall be sorely disappointed and down hearted should you attempt to install it. Ensure he attempts to thread in both M10x1.0mm nut and a 3/8-24 before bothering to send it. It is true what is written... 46100-26001 is not the same as 46100-U5200 (maybe the insides are the same, doubt it though!) You've been warned, my job is done here. Go forth and merrily forget this nugget of truth.

-

Starter Motor went south! Recommended choice for 1972 240z manual tranny

Recently discussed. 100% new. Not cheap, not stock looking. Likely to last forever and not fail at the whim of the rebuilt junk suppliers. “Oh we are so sorry the fifth one in a row failed on your, here’s another! Be happy!” Do I have to bring up the Podunk Kansas story again? https://www.autoelectricsupplies.co.uk/product/1114/category/218 They have alternators as well. Get a stock looking 120 Amp one wire and never look back again.

-

Rear Axle Grease Catcher - Needed for Disc Conversion?

The grease rarely migrates anywhere. By design, it stays put. I love to make fun of people who fill the front spindle caps with grease to keep the bearings safe. What, there are little men with little shovels in there that will monitor the bearing grease and toss some at the bearing if they get a little dry? This isn’t a coal fed steam locomotive. More likely its to prevent outside dust and crap from getting into the seal area. It is not required. Maybe if you rally in the dirt a lot...

-

918 Orange. I’m confused.

Let me know what you find out Richard. I can have my body shop guy tell me the exact mix he used. He has to mix some more too, there are couple things that need to get painted that didn’t get done.... Then you can compare to what your guy did. Here is a picture I took in crappy light (daylight at least) of the new paint job on the car. Same phone camera used for both at least. It is slightly less peachy than it was, and definitely more orange. Still not as orange as I think it should be but.... The pictures I see on my ipad here are really more orange than the paint really looks in person. The car was completed repainted from what the original body shop Used, that I commented on above. They used a 918 formula, they did not scan and try to match the paint that was on portions of the car. I had a chat with the shop owner about this, he told me, it greatly depends on the quality of the paint you select no matter how carefully you follow the code mix. Lots of experience, I believe his opinion. I have to go look if I have a tool bin door or something that is stock 918 somewhere.....

-

Wiper arm linkage assembly parts

Glad you enjoyed today’s little treasure. Now off to google “How to make small coil springs by hand”

-

Wiper arm linkage assembly parts

As I am today rebuilding another wiper linkage, I thought I would contribute some more detailed pictures of the fancy wiper park components for future posterity. Out of, ahem, "several" available wiper linkages, I have only a single one that has an unbroken spring. Thought I would include detailed pictures of it in hopes of some day creating new ones, as well as to show the assembly order and position of all the components Here is the little spring with oft-broken off hook engaged where it belongs Complete and broken example for comparison of where the break happens and how long the bent tang is Clever photography (ie move it around until you can see it), shows the shiny spots and wear on the bottom of the spring. All the bits and pieces in order from top to bottom. Top is defined as having the end with the (poor excuse for a ) snap ring/C-clip pointing up when you're taking it apart. I have used a real compatible sized E clip to replace that obnoxious soft C clip thing. This gives you a visual idea of how the eccentric cam part fits with the hole in the arm, effectively changing the arm length as the cam rotates. Another shot showing how the spring and the "millennium falcon" part with the slot are arranged in the assembly. Clearly this proves the designer of said space ship in the movie was a Datsun owner.

-

ISO 280Z damper bracket

Subscriber

Subscriber