Everything posted by crayZlair

-

New T3 Steering Rack

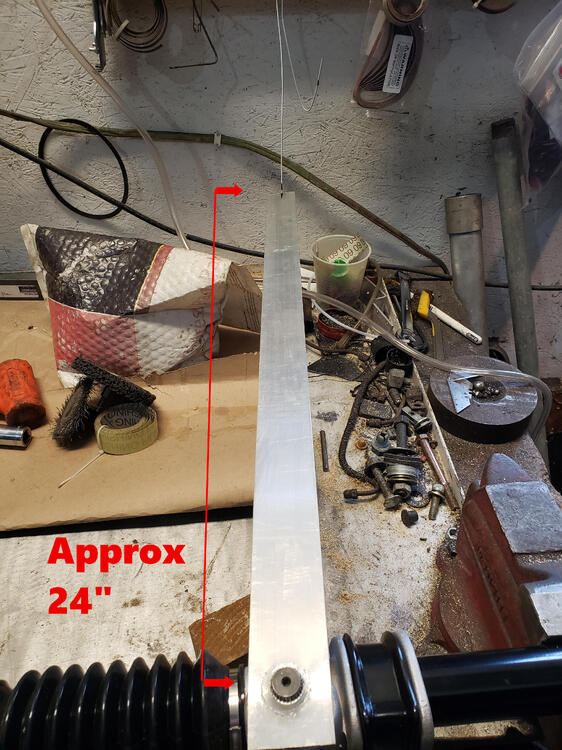

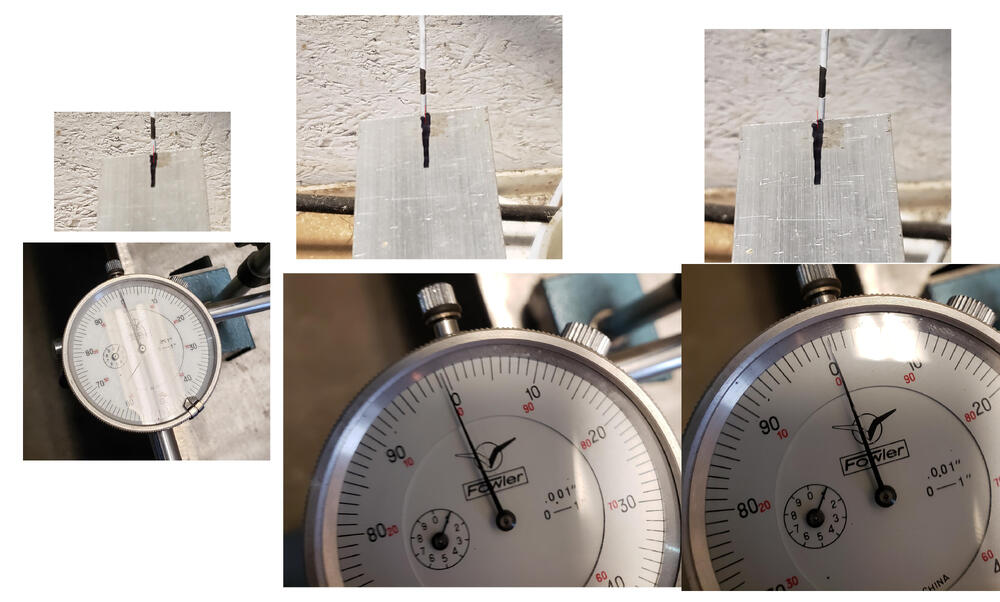

I got a new rack from T3 before the holidays. Just now took it out of the box. Being curious, I set up a test fixture of sorts to check for free play. Using a 24" piece of aluminum, and a dial indicator, I came up with the following results: I'm not very good at math, but I think that the rotation measured at 24" is very minimal. My results show no play. After doing a little research, I am moving about .2 degree in my testing.

-

Plastic Windshields!!

Nope. Just traced out a paper template from an existing windshield, copied to the Lexan. Then I just carefully bent it to the contour of the frame, held with Cleco's and clamps, then pop-riveted it in place.

-

Plastic Windshields!!

Made my own for less than half the price......................... Note: The car is NOT street legal !

-

Setting rear toe

I agree with cgsheen1 They claim 2 degrees of camber with these, but when I used similar bushings years ago, I could only get about 1/2 degree of negative camber. I just adjusted the for max. (Offset the bushings so that the control arms are both at the farthest point from the center of the car. If you want to get serious, you need something along these lines. https://www.arizonazcar.com/suspension

-

Unsure how to lock doors

-

Machine work on SU for roller bearings

I worked for a Chrysler plant that made torque converters. The hub (the part that goes into the transmission) was ground to size, and then "polished" to make the ideal surface for seal wear. The funny thing is that the "polishing" actually produced a rougher finish than the grinding.

-

Cruise Control in 240Z

The downside to using GPS for speed is that you need a good solid signal. The more satellites received, the more accurate. If you are in a wooded area, or an extremely cloudy day, the cruise might not work as well as intended.

-

Engine Block Breather Tube Installation

On my Autocross car I use the outlet strictly for a breather. Took a 3/4" hose barb and turned the threads down for a tight fit. Gooped it up with metal-type JB Weld, and it hasn't moved in eight seasons. I call that a win.

-

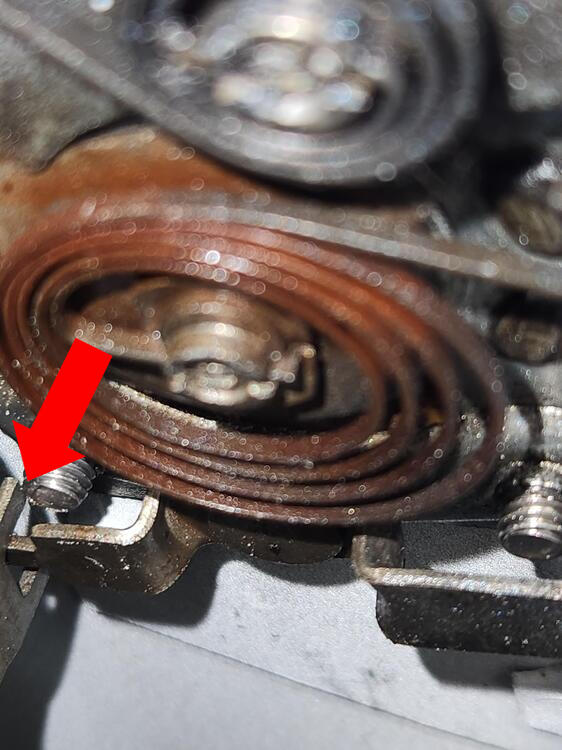

Wiper linkages stuck

Kano Kroil is your friend !! https://www.kroil.com/

-

Help Identifying Gold Wheel/Finish

If nothing more than durability, I would suggest seeing what a powder coating business could do for you.

- Leftovers!

-

12/70 original spare tire - DOT 149

"Just In Time" manufacturing was just starting to ramp up in the early 70's, so it's possible that it didn't apply to tires, especially spares, at the time.

-

Advice needed for Autocross tires and tire configuration.

You are going to be limited on your front camber adjustment (more negative camber), unless: 1. You install lower control arm offset bushings (or use adjustable lower control arms) 2. You install some type of camber adjusting plate in your front upper control towers. I use Ground Control (along with their coilover kit) in my '73 autocross car, but there are many other options available since I did the conversion 10 or so years ago. Ground Control was the only player at the time. 3. Rear camber is not as important, but it helps.

-

Advice needed for Autocross tires and tire configuration.

Been to 42 a few times with my '73 FP car. Fast and fun. Q1. It's probably best to use the same tires front and rear. You want the car to be as "neutral" as possible. Too much front traction can induce oversteer, to much rear traction can induce understeer. Q2. No Q3. I see that you are running HCS. The rules only allow for an 8" rim width. When I drove my '76 car in BSP, I went with a 16x7 rim with a 225-50-16 tire. I tried 16x8 rims, but they rubbed a little. You should probably stay away from steel rims. They are less expensive than alloy, but much heavier. Un-sprung weight is your friend. I have a Gleason Torsen carrier in my R200, but I got it back in the 80's. Probably hard to find anymore. Quaiffe makes a similar unit, but they are expensive. Come on over to Toledo Express Airport next season!

-

Custom 3 Piece wheels???

Good luck! I looked and looked for an alternative to the Reals. I did find a steel wheel in a 16x10, but it didn't clear my front calipers, and it was way too heavy.

-

Custom 3 Piece wheels???

Real Wheels in Independence, Iowa. www.realwheel.net 1-800-722-3847 I run a 16x10 with 5" backspacing on my Autocross car. Very light wheels, but expensive.

-

1977 280z Dash Harness Connectors

Link ???

-

1977 280z Dash Harness Connectors

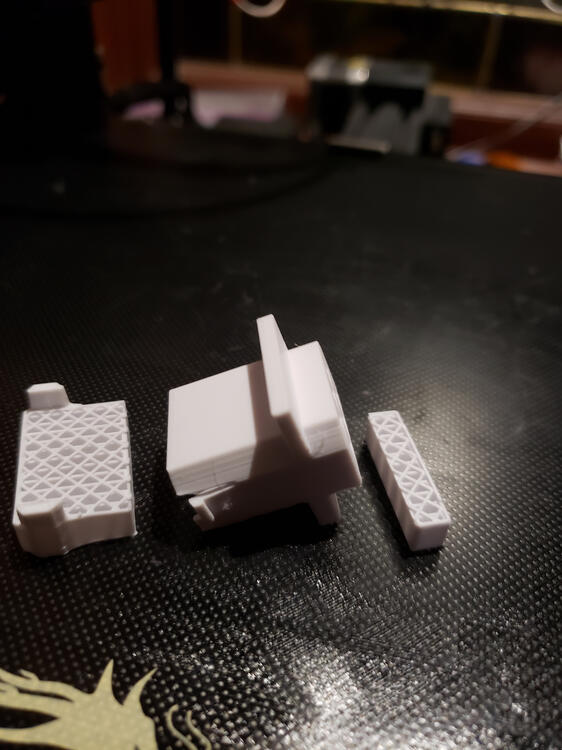

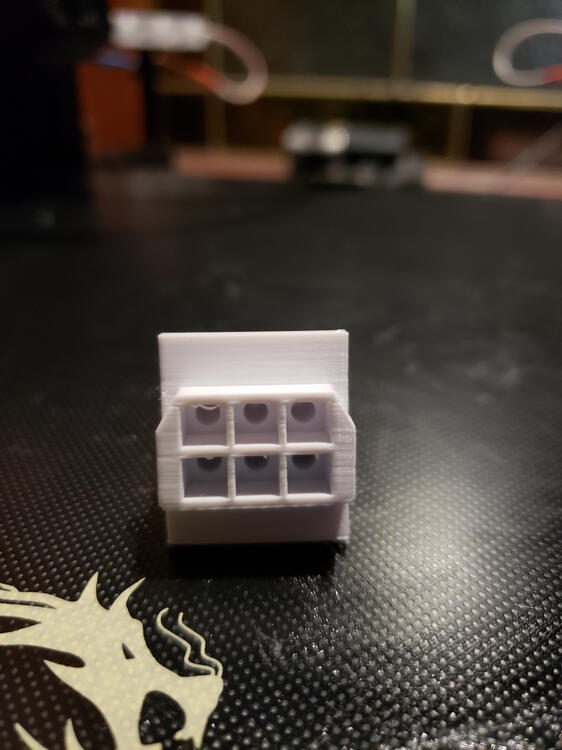

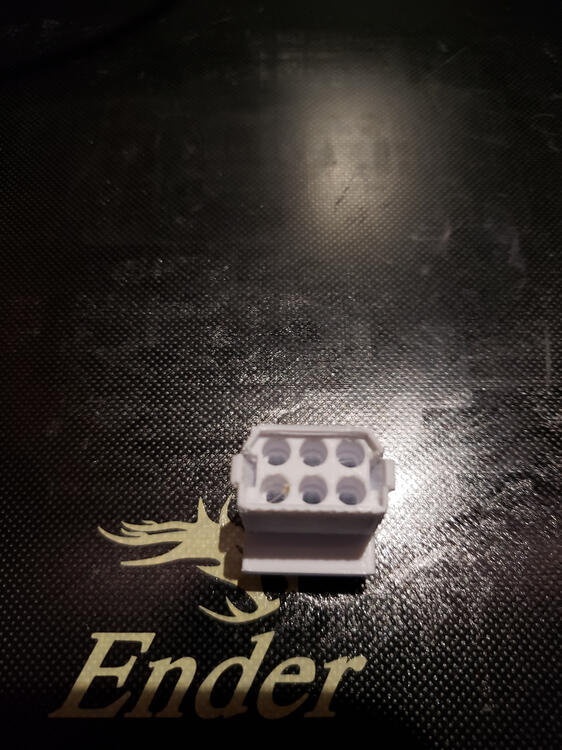

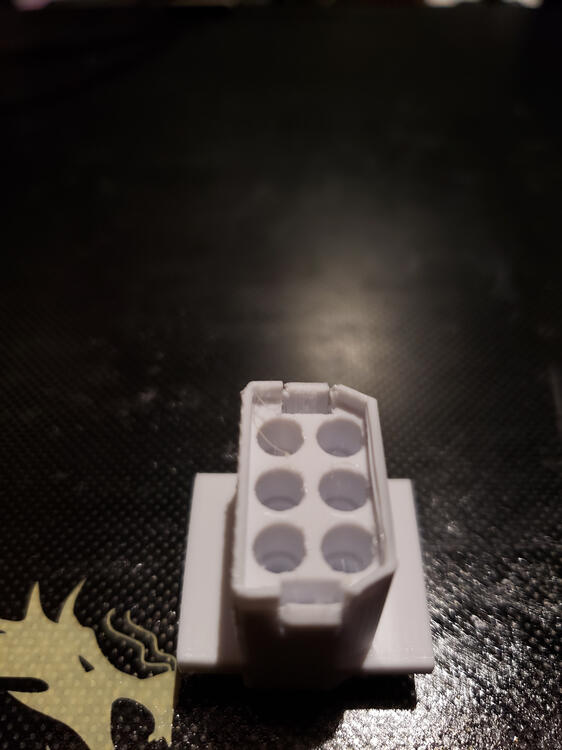

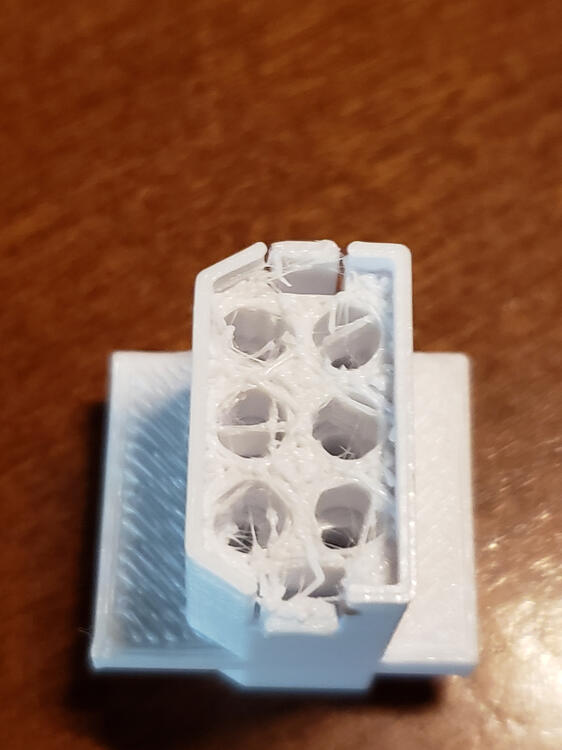

Success! The orientation along with a general support instead of tree support seemed to do the trick. No Exacto trimming needed. @ckurtz2 message me your mailing address and I will send it to you.

-

1977 280z Dash Harness Connectors

I am using E-Sun brand PLA+ That's all I have. I am going to try a different orientation of the part, so that the "grain" goes with the height of the tab instead of the width.

-

1977 280z Dash Harness Connectors

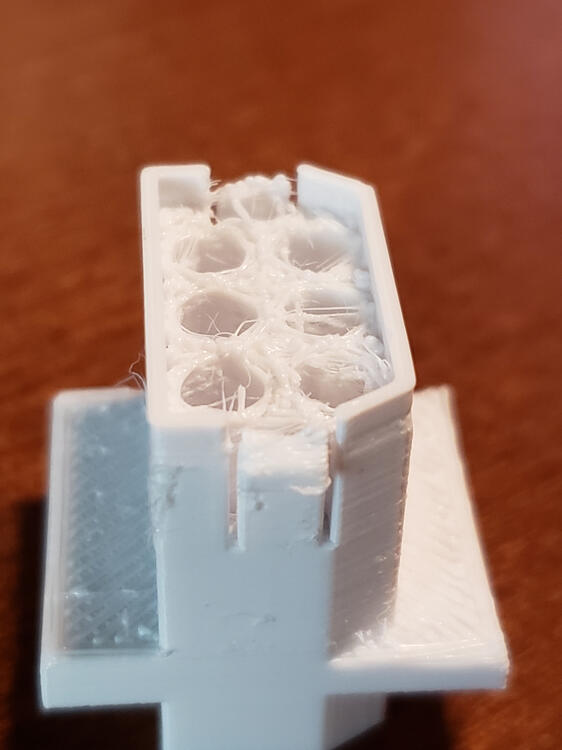

My second attempt didn't turn out much better than the first. As for the tabs, I compressed them, and they immediately snapped. I measured them at 1.5mm thick, is this correct?

-

1977 280z Dash Harness Connectors

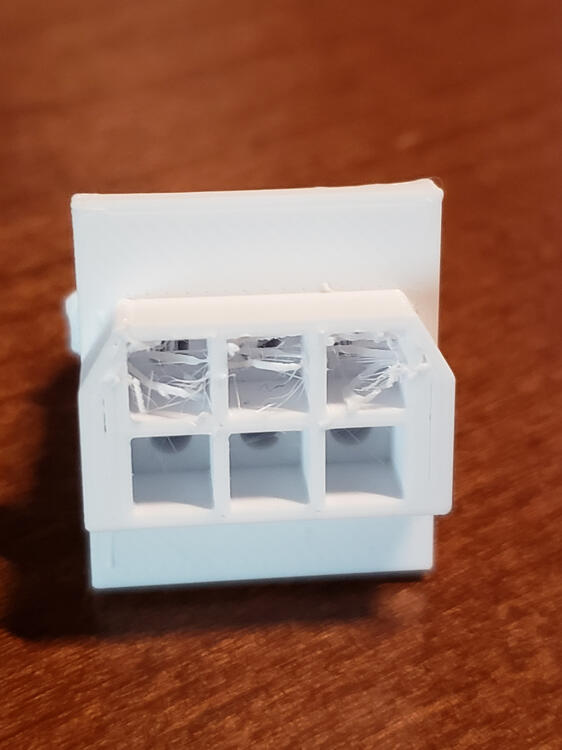

First attempt! A little stringing, but I think that most of it will clean up with a little Exacto knife trimming. I will try to tweak the settings , and print again tonight.

-

1977 280z Dash Harness Connectors

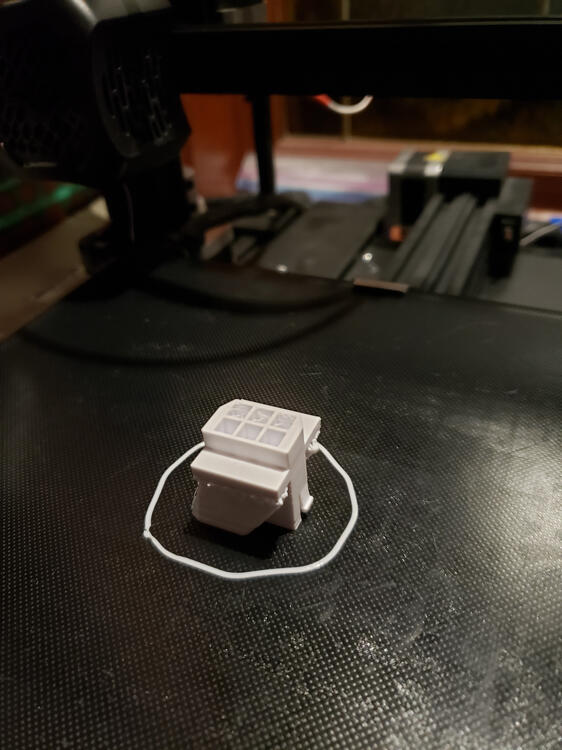

Print is in progress. Supposed to take about 3 hours. I will let you know how it turns out.

-

1977 280z Dash Harness Connectors

Creality Ender-3 V2 Can you convert your .SDLPRT to a .STL? I use UltiMaker Cura to generate the .gcode files

-

1977 280z Dash Harness Connectors

PLA material is somewhat flexible (not as much as nylon), but the main function of the shell is alignment and insulation. The pins do all of the electrical connection. Underhood connectors need moisture barriers, underdash not so much.

-

1977 280z Dash Harness Connectors

I have a 3-D printer, and could try your designs. However, it is the middle of Autocross and lawn mowing season, so my free time is very limited.