Everything posted by CanTechZ

-

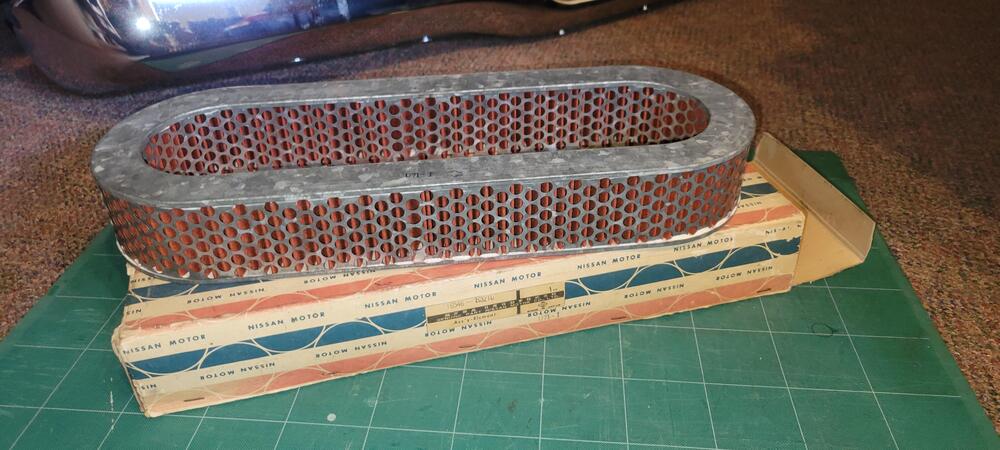

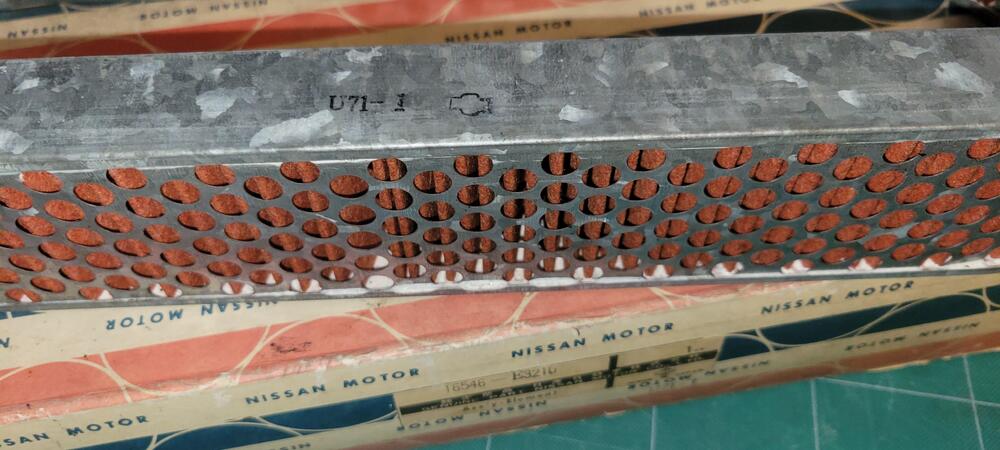

Poor fit of OEM air filter

Interesting stuff here. I will add a few OE air filter pics, from the parts that came with my recent purchase of #957, a 1/70 HLS30. It came with a pickup load of spare parts. Some of which are early OEM items. This air cleaner is the early part number 16546-E3210. Not related to this topic but I have to share this pic of two packages of OE spark plugs, NGK in Nissan branded packaging, 10 plugs per package.

-

New Source For S30 Door Seals

You're welcome. Yes the thin half loop on the weatherstrip goes on to the pinch weld first and then the welting goes over the weatherstrip. It's a good tight fit. Believe it or not. Lol

-

New Source For S30 Door Seals

For reference, here are a few pics of the OE welt and weather strip to show how the two piece design worked.

-

Restoration of BringaTrailer 240z - HLS30-35883

I just checked the restoration receipts that came with #957 and the seat covers and foam came from Les at Classic Datsun Motorsports. The receipt (from 2016) doesn't mention whose product the foam is, but you might want to check with him. The issue you are describing is evident on the front of the bases but it's barely noticeable when the seats are installed. It was actually not that easy to get down that low to get a picture. Lol Here are a few pics from #957 for reference And a couple of pics of the the removed passenger side OE seat bottom that is un-restored from #6521. The issue is only slightly evident.

-

Reference 1970 Grapefruit Alternator Pictures

-

Canadian Window Sticker

Thanks for the translation, very cool.

-

Canadian Window Sticker

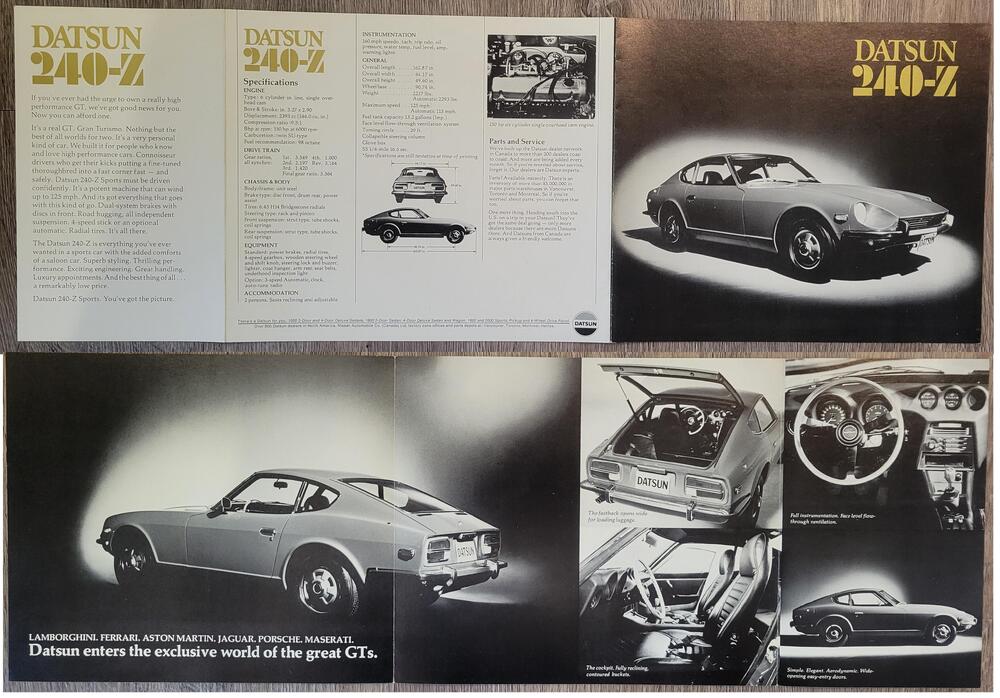

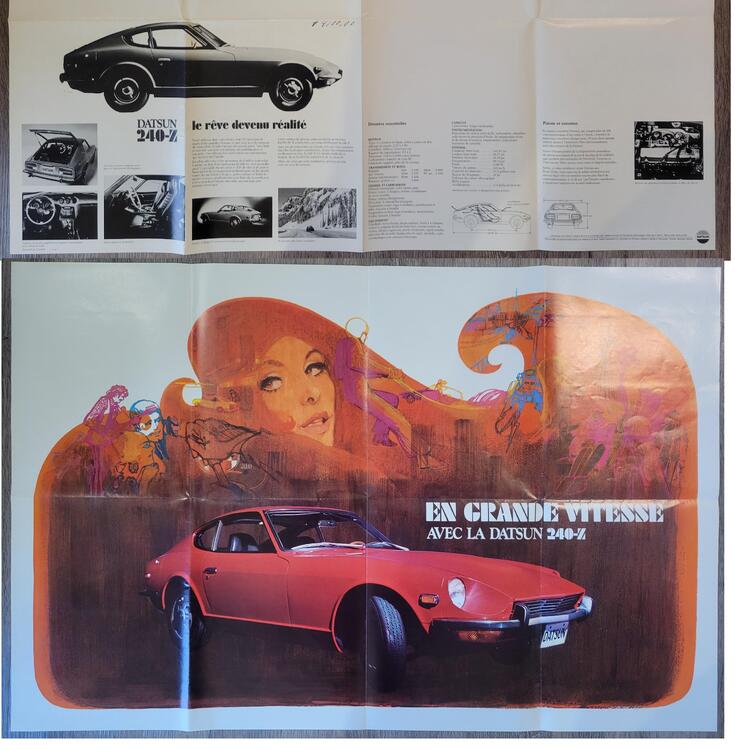

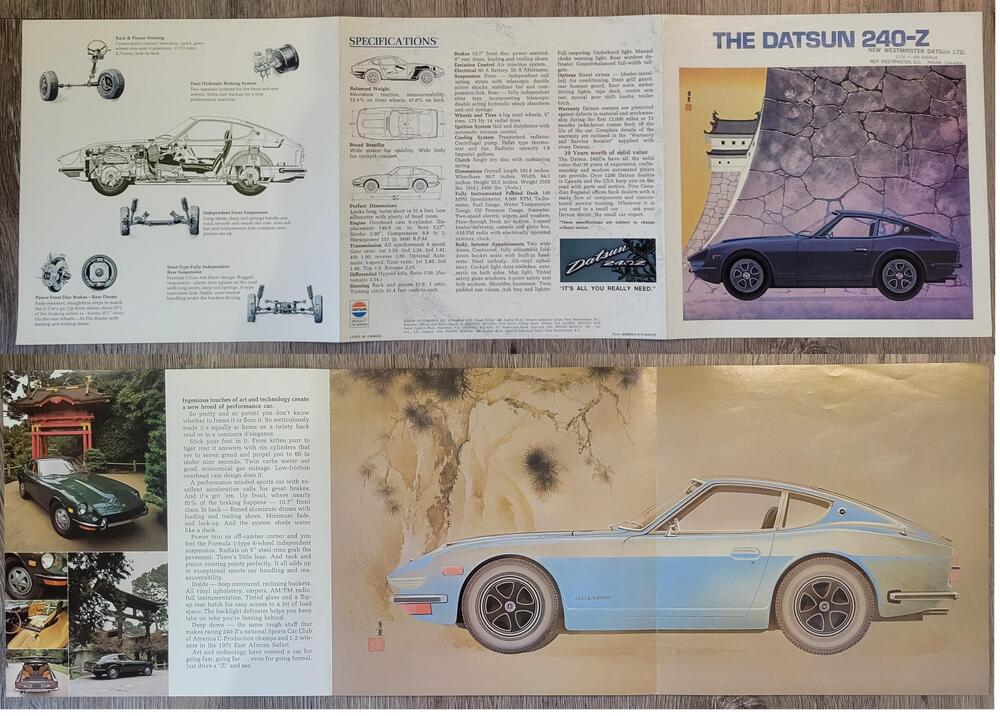

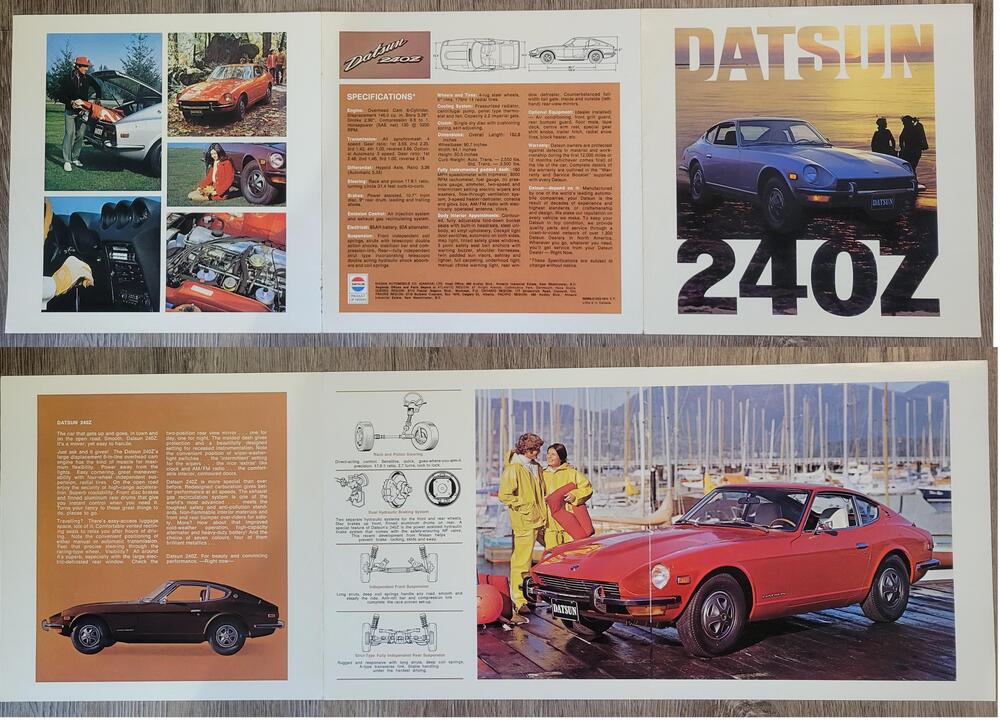

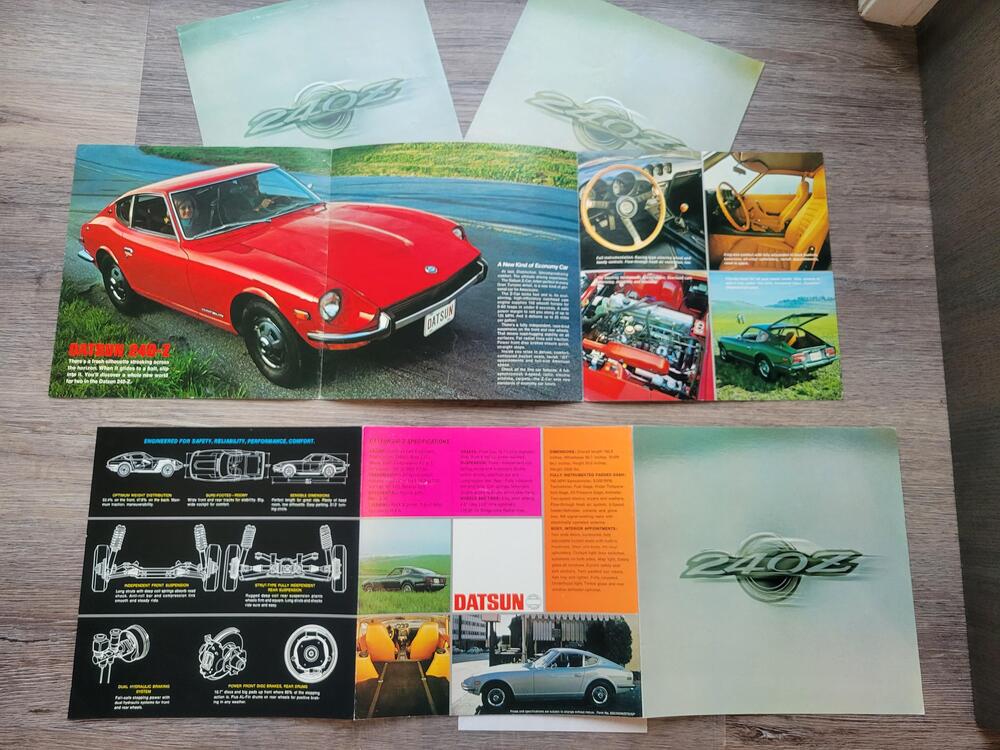

Here is my collection of Canadian printed brochures, one is in French. These were included with my recent purchase of HLS30-00957. 1970 Printed in Canada (English) 1970 Printed in Canada (French) Poster Size 1972 Printed in Canada (English) 1973 Printed in Canada (English)

-

Z's on BAT and other places collection

I agree in your opinion about the market being depressed, it applies to the majority of the classic car market. The dip in prices is one of the reasons that I recently purchased number 957.

- 1970 HLS30-06521 Re-Restoration

- 1970 HLS30-06521 Re-Restoration

- 1970 HLS30-06521 Re-Restoration

-

1970 HLS30-06521 Re-Restoration

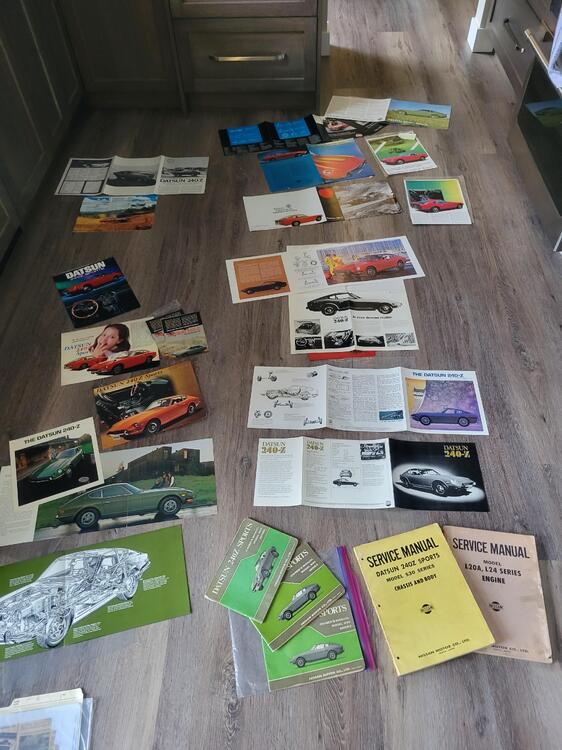

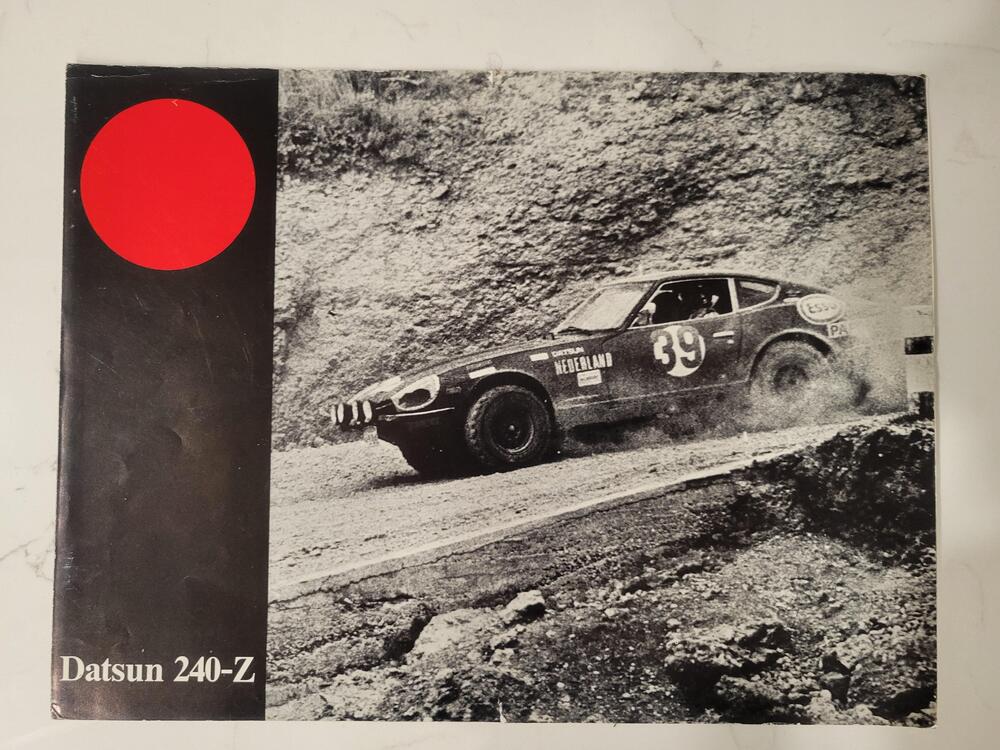

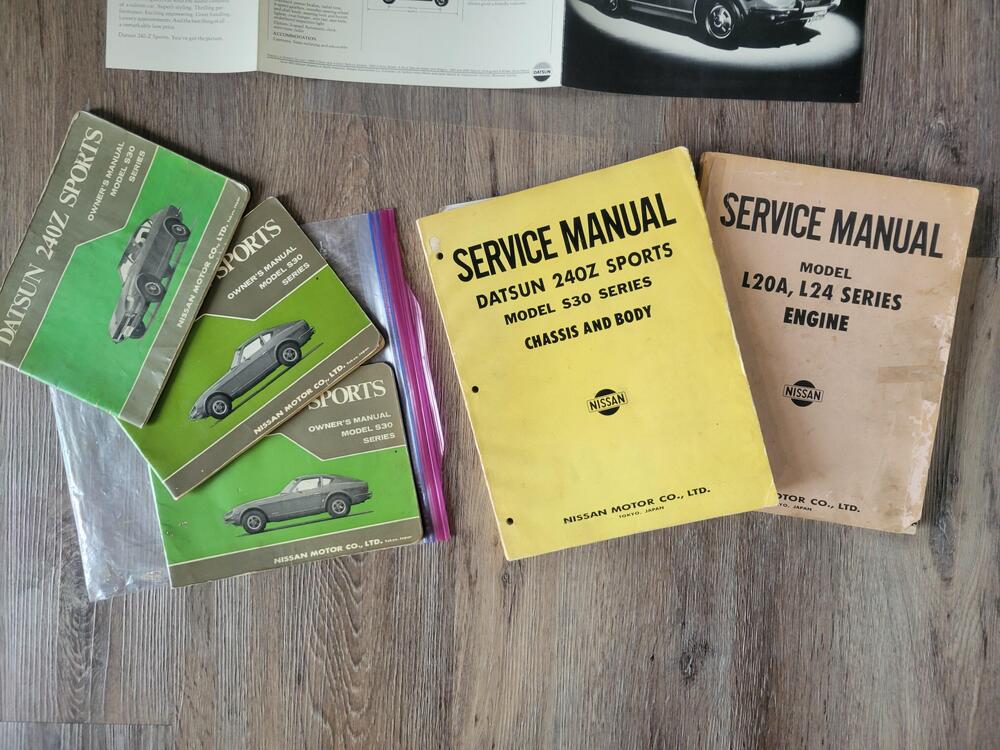

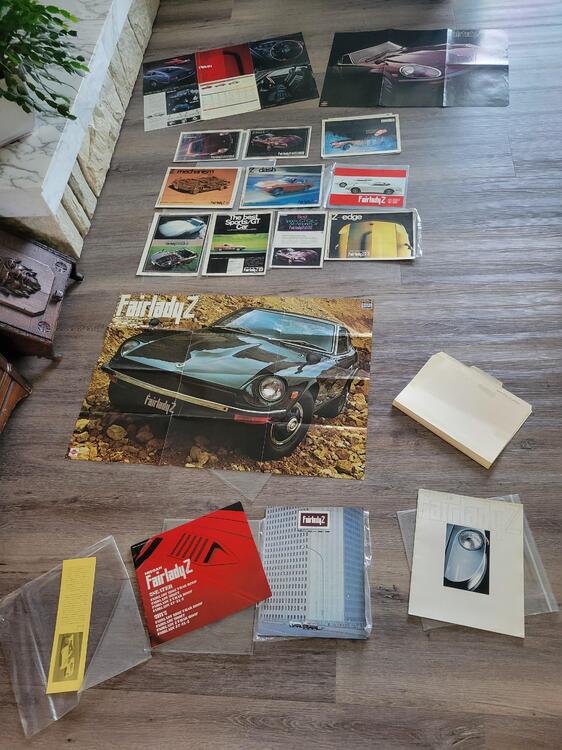

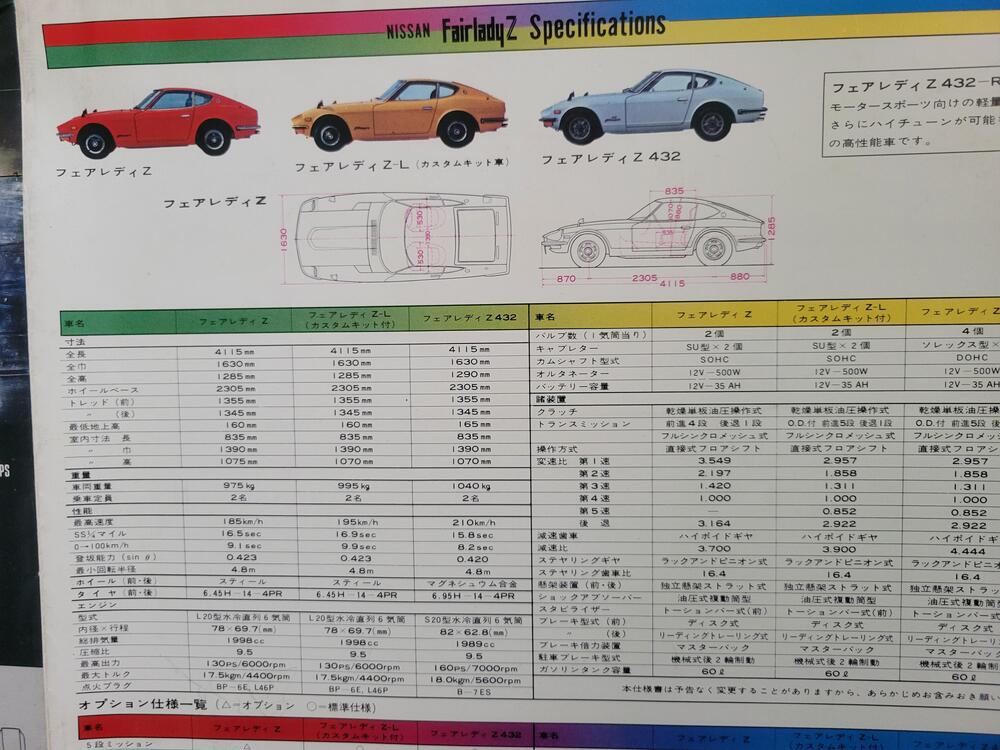

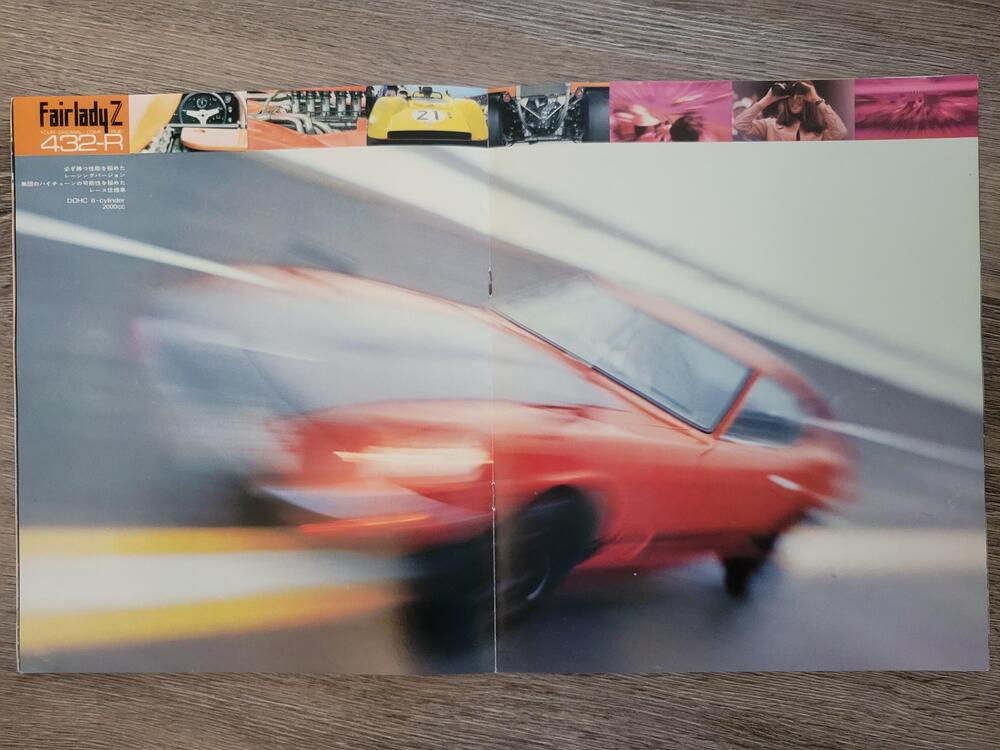

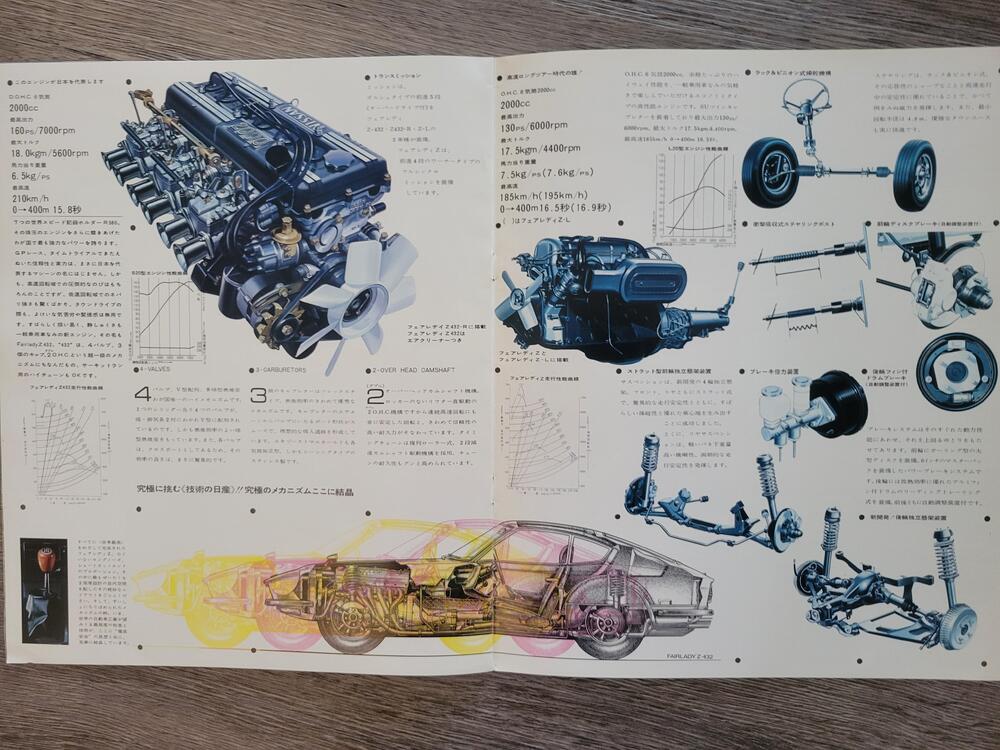

I forgot to mention that the previous owner, Pete, was a prolific collector of automotive literature and a huge amount of Datsun/Nissan literature was included with HLS30-00957 when I went to pick it up from his son. I will show a sampling here. Later I will search for a more appropriate thread to do a more thorough post. 1970 Owners Manuals from 12/69, 3/70 and 7/70 plus a factory service manual set from November 1, 1969. Many brochures from Canada, US, UK, Belgium, Finland, Netherlands, and Australia. Plus four copies on this 1970 brochure you will recognize. Also a large selection from the Japanese domestic market, some of which are poster on one side and specs on the back, very cool. One multi page booklet even includes the Z432 and Z432-R

- 1970 HLS30-06521 Re-Restoration

-

1970 HLS30-06521 Re-Restoration

Thanks for being a good sport, Mart. Lol I do have a todo list of things I will be doing on 957, so I am re-evaluating my timeline for the resto of 6521. I will likely make it a retirement project as I'm only a few years away. You are definitely correct regular day or evening work. Slow and steady gets the job done and hopefully enjoy the process. Cheers, Mike

- 1970 HLS30-06521 Re-Restoration

-

1970 HLS30-06521 Re-Restoration

Okay, time to come clean. I found this car for sale on Vancouver Island and couldn't resist buying it. My Canadian girl, number 6521 now has an American cousin, Number 957, a 1/70 car. When I finish restoring 6521 they will be twins. HLS30-00957 was owned by a member here, @M3333hp. sadly he passed away in 2020, mid way through the restoration. Rest in peace Pete. Pete's son completed (except for a few small details) the restoration with great attention to originality in 2022, exactly as his dad would have wanted. Pete would be proud. He recently decided it was time to let the car go to another enthusiast. I was very happy to be that guy, and yes I still do plan to complete the resto of 6521. Not that haven't already, I will be taking my time on the current resto, leaving the final work to enjoy when I retire in a few years. I have really missed having a Zed to drive and for club cruises and shows, etc., number 957 will definitely take care of that. Here are of few more pics of 957. I will be starting a new thread soon to document the number 957, and the short list of items on my new todo list.

- 1970 HLS30-06521 Re-Restoration

-

Dashboard Wiring Question

I'm a little late to the table, but for what it's worth here are some pictures from when I was taking my 7'70 apart for my on-going restoration. For some reason I'm getting an error trying attach pictures. 😕 I will try sending you a PM Well it's seems I get the same error with pics in a PM. I will try later or in the morning.

-

240z rack lube

Passenger side I think.

-

Z's on BAT and other places collection

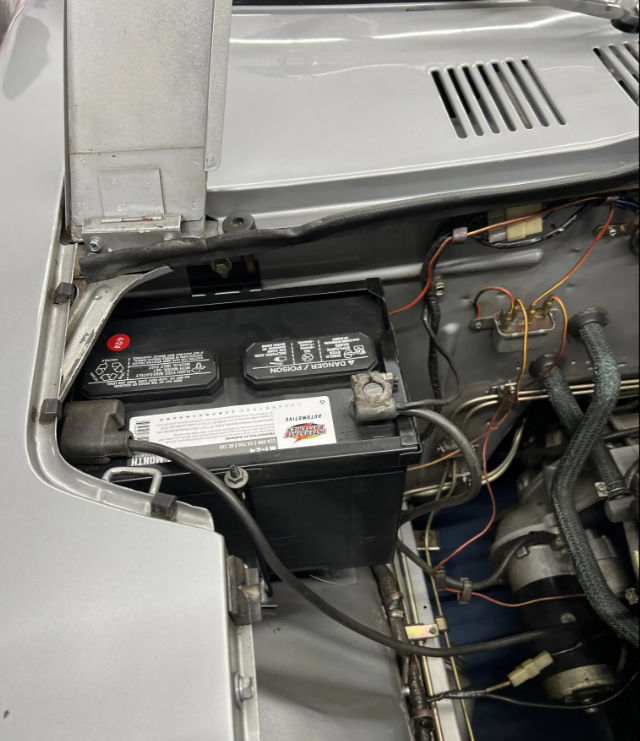

Good to see that it still has the original battery cables. Even though the battery cover is missing, as pointed out by @Carl Beck

-

Z's on BAT and other places collection

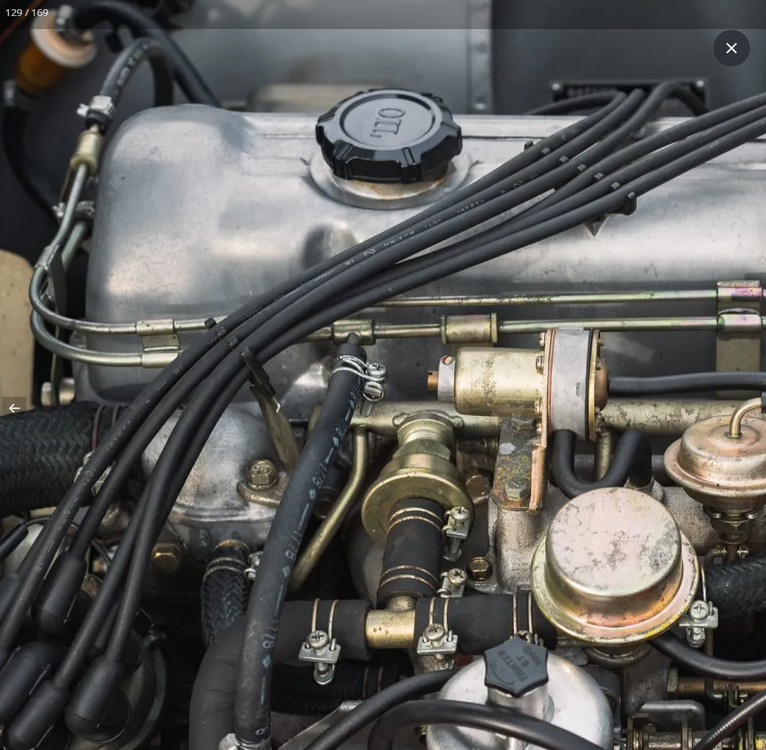

The spark plug leads do appear to be correct, Yazaki, 1971 date coded with white labelling (not yellow as was used in 1970).

- 1970 HLS30-06521 Re-Restoration

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Are you talking about mine, I resemble that comment. Lol

-

Online Parts Catalog Changes

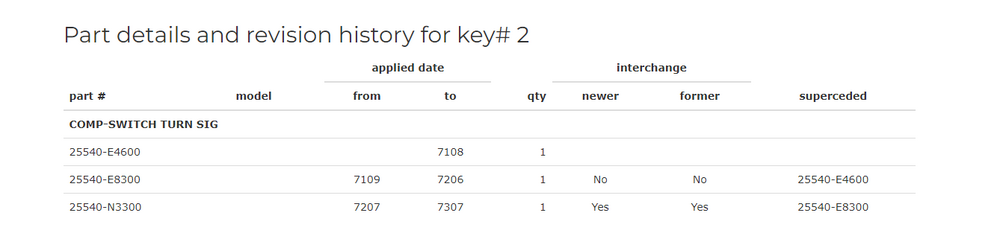

I have also noticed that issue on the on-line version, not all part numbers are shown for a particular date range. It is misleading, however if you click on one of the part numbers you do seem to get the correct list with proper date ranges, for the most part. The thing that bothers me the most is the truncated descriptions. I have the CD version of the 1970 - 1978 parts book that was sold by Courtesy Nissan years ago and I prefer to use it. Here is what you see when you click on 22540-N3300 under item #2

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

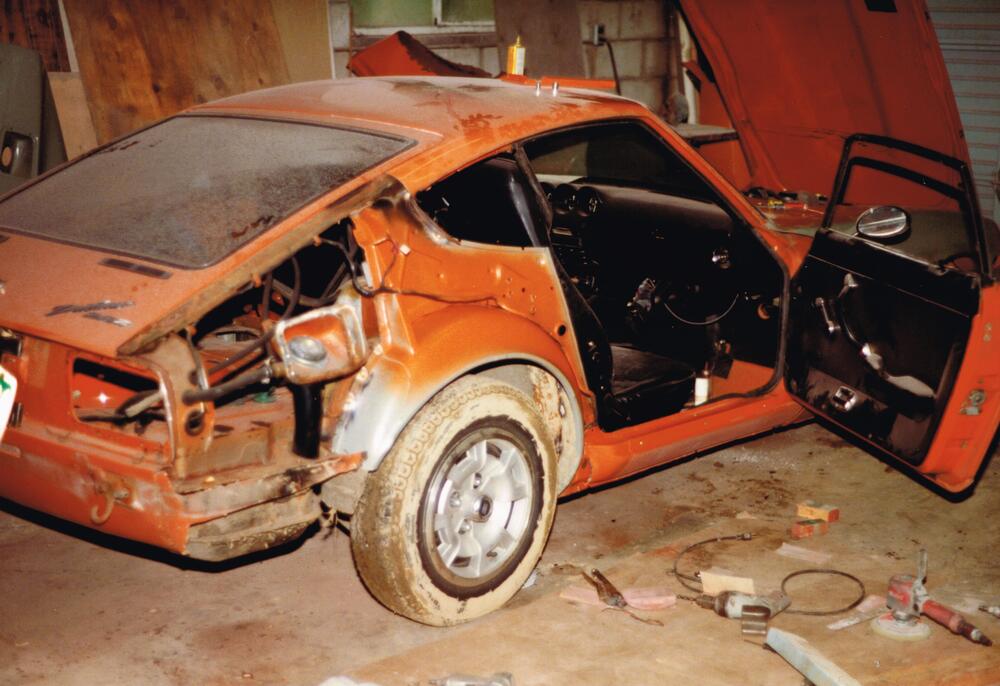

Here are a few pics from the early eighties when I had my rear quarters replaced. Sorry that they don't show more detail. The left side was actually done about a year before the right, as someone lightly backed into me and due to the existing shoddy bondo repair, a pile of rusty bits was left on the ground similar to the second pic, during the more complete resto. At the time of the incident I didn't have the funds to do the full resto. The left side was cut back to the factory joint but on the right side it is cut further down, I'm not sure why? Or if it was cut more later in the repair process? Anyways you can see a little of the detail. I wish I had taken more closeup pictures back then.

.thumb.jpg.a53a36a31645408df74298532849e830.jpg)