Everything posted by zclocks

-

Timing issue 75 280z

Thanks , that's what mine look like. Have you ever had a rocker come off the rocker guide?

-

Timing issue 75 280z

Thanks , that's what mine look like. Have you ever had a rocker come off the rocker guide?

-

Timing issue 75 280z

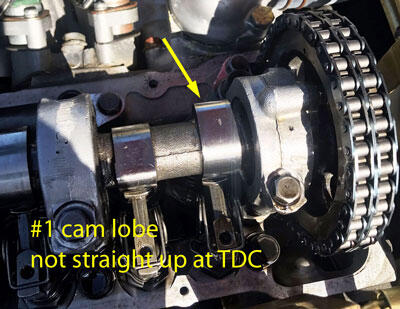

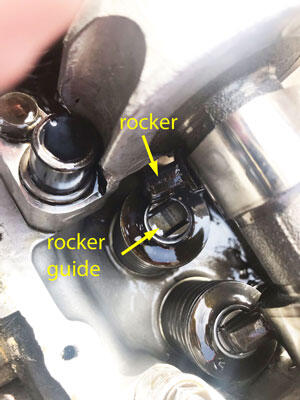

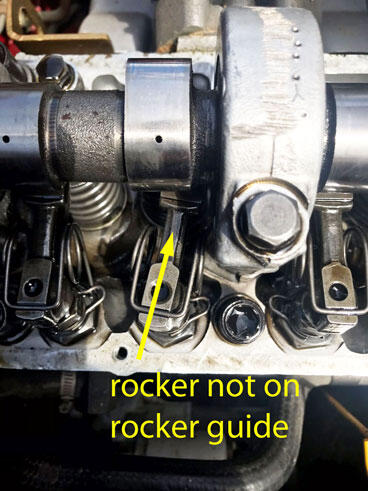

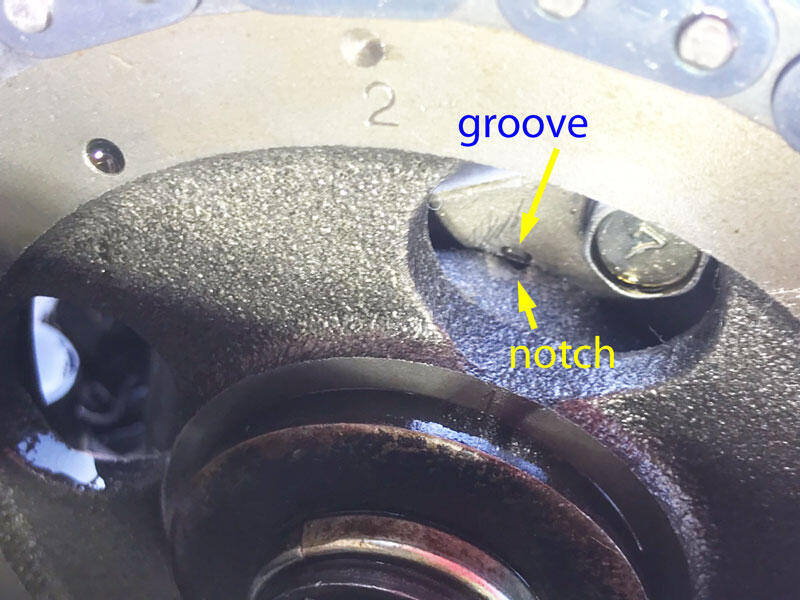

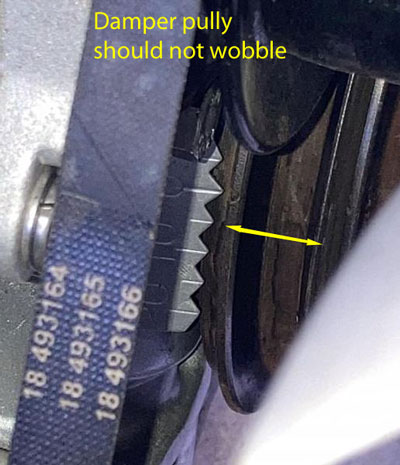

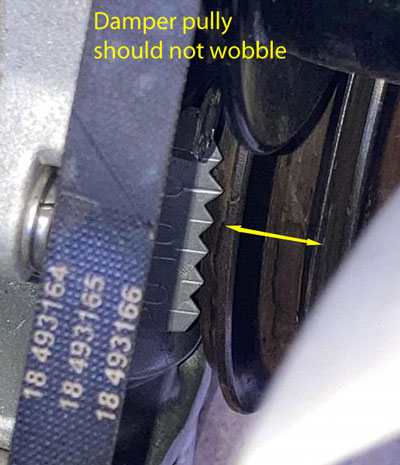

I have a timing issue that I need help with. 8 months ago I had my damper pulley rebuilt on my 75 280. I replaced the damper and everything was fine. I haven’t put the car on the street in several years , but start and let it run every couple of weeks. So for months the motor would start and run fairly well. The motor always had a very small mis at idle and up to about 1500 rpm. This was unusual as I never have been able to get the motor to run as smooth as I wanted. I should also mention that the motor was totally rebuilt many years ago and only has about 50 miles on the clock. I tried to start the car several days ago and it was hard to start, several back fires, very rough, and wouldn’t idle. I realized it was a timing issue so I removed the valve cover with the intention of checking valves and timing. To my surprise I found that the intake rocker on #5 cyl had jumped off the rocker guide. The adjustment nut was locked so the valve lash had not changed. I finally got the rocker back in place and set the # 1 cyl to TDC. In the past I understood that the lobe of the #1 cyl was to be pointing straight up at TDC. At TDC my cam lobe is at about 45 deg . I know it’s at TDC and I rotated the motor stopping on the timing mark to make sure that the piston was at TDC, also measured piston position, and both valves are closed. I checked the vale lash on all the valves and all were in speck (cold). At this point I was worried about a valve problem with the #5 cylinder so I did a compression check on all cylinders, everything was good and no leak down. I also checked the timing chain position and mine is #2 position and just slightly left of the notch. See photos for all the above. Here are my questions: -- Is the cam lobe on #1 cylinder supposed to straight up at TDC? --Is there a possibility that the damper pulley key was severed and the damper pulley has rotated on the crank shaft? --Why did the intake rocker on #5 cylinder jump off the rocker guide? At this point I want to check all possible timing adjustments before I restart the motor. Any help will be very much appreciated. Thanks…Ron

-

1977 280z clock issue #xx of yy

The adj knob is pressed on to the metal shaft in your photo. This can be disassembled, but is very difficult. The 240 knob is different from the 280, but is still pressed on. R

-

NGK BP6ES spark plugs

NGK BP6ES-11 plugs are no longer available? I guess I’ve fallen behind the times . Nine months ago I replace my 75 280 NGK BP6ES plugs and no problems finding them. I just tried to purchase new plugs at my local parts store and all they have is the resistor version. My research indicates that NGK is no longer making this plug? Has anyone used these in the 240/280 without problems?

-

Parts Wanted: WTB Quartz clocks

View Advert WTB Quartz clocks If you have either of the quartz clocks as pictured for sale please PM with quantity and price. Thanks..... Ron Advertiser zclocks Date 05/17/2022 Price Category Parts Wanted Year 77 Model 280

-

Clock repair/restore

Hey Steve did you find the pictures of your 200sx clock? Would like to see which one you have. Ron

-

Clock repair/restore

Steve, Sure I'd like to see what you have . I might even have one the 200sx clocks. Ron

-

Clock repair/restore

Just thought I would add a couple of comments. The prices that are being mentioned are from 2012. This was for a 240 clock converted to a quartz unit. Costs on everything has really gone up. Look at what gas prices are today. If your talking about converting to a quartz mechanism you first have to find a quartz clock and then refurbish/repair the mechanism. The cost for a quartz mechanism, Kanto Seiki, use to be $20, in 2012 , but today everyone thinks their clock is worth over $100 because it says quartz. Most quartz clocks don't work correctly or need major repair. This gets into trying to find parts, which are not available. In my shop I have to mold gears for the mechanisms I use because parts are not available . Finally you have to modify any quartz mechanism you use to fit the clock housing, especially the 240. This all takes time and patience. The current Kanto Seiki quartz mechanism I use has 17 unique parts I have to fabricated/modify so that it will work in the 240 clock housing. I'm currently working on using a different quartz mechanism that is available, cost effective, and will work in the 240 clock housing. However, it 's not a plug and play as and will still require many modification to the mechanism. My goal is to significantly reduce the price of a 240/280 clock converted to a quartz unit. The right up on the Equss quartz clock was good , but left out a lot of detail. I have done this conversion years ago and it's not easy and you have to fabricate or modify nearly every part. It can be done, but plan on spending several weeks getting everything to fit and work. Just my 2c......Ron

-

Scammers

Well, I'll join in with my spam story. On this site I had a spammer send me a picture of a clock he was trying to sell. The numb nuts sent me one of my own clock pictures I used several months ago in an add. Oh, and another tell is "my paypal has problems, but I can use my son's" or "please send payment with friends and family and send me a copy of the transaction". right.

-

Parts Wanted: 1975-1978 280z Original Clock

Where did you get the picture of the clock ? You might look at the site where you pilfered it from as there is a copyright infringement.

-

Parts Wanted: Datsun quartz clock 77-83

View Advert Datsun quartz clock 77-83 Wanted : Datsun analog quartz clocks, 77-83. Must be in fair condition and working condition not required. Just to make this add clear I'm only interested the analog QUARTZ CLOCKS from 77-83. If you have a quartz clock(s) of the years pictured and only those that says QUARTZ on the clock face please PM me. Thanks....Ron Advertiser zclocks Date 02/17/2022 Price Category Parts Wanted Year 77 Model 280z

-

Clock question

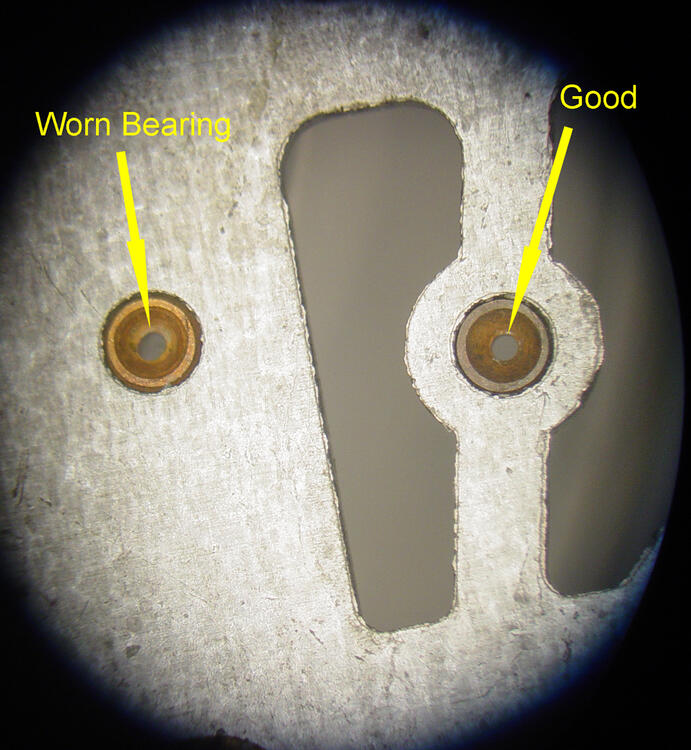

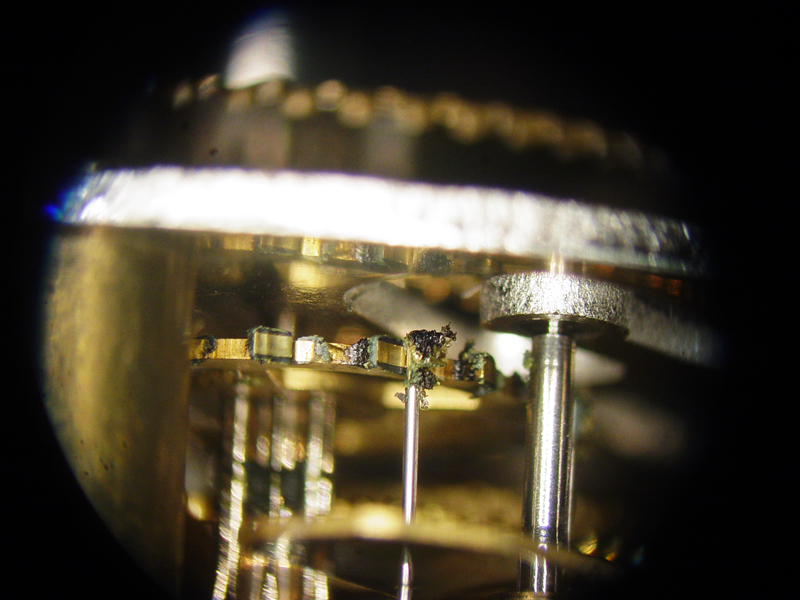

I noticed this tread and have a couple of comments. There are three clocks talked about here which are all different and have unique problems. The 74 260z was delivered with two clocks. Very early 74 the clock was the same as the 240zand the later clock was the 280 version. So we have the 240, 280 and what appears to be a VDO clock that are all different. As far as the 240z goes if you put 21volts on any of the clocks you will cook the parts. This clock is very sensitive to dirt, grease and oil. If you look at the enclosed you will see what oil does to the clock gears. Oil collects dirt like a magnet and turns into grease. This is what stops the 240 clocks. Disassembly and cleaning is the only way to put the clock back in service for many years. Also, inspection of the bearing points in necessary or you will be disassembling the clock within a short time. Again the enclosed shows a worn bearing and this part needs to be re-bushed. All the oil in the world won't help this condition. The 280z mechanism has very few bearing points and does not need any oil. The caps on the circuit board are the main problem and the spring is the second as well as the pink gear (missing teeth) on the enclosed. The other problem is the coils on the circuit board. Either of the two can be open,shorted, or incorrect resistance. As far as cleaning DO NOT use the cleaning solution as mentioned. This is an old clock makes formula and is VERY VERY caustic / dangerous. This is as dangerous to your lungs as using epoxy paint without a respirator. The cost to make such a formula is about $60--80 depending on where you can get the items. Also, the ammonia(20%) can only be purchased at a chemical supply house and runs about $35 / quart! Also, this formula will destroy and degrade the nylon and plastic of your clocks. DO NOT use it. Isopropyl alcohol is the best solvent and yes it takes a little elbow grease, but it works. I am not a clock maker, but I have repaired , cleaned and refurbished many grandfather clocks as well as hundreds of 240- 280 clocks. Oiling is something you should due for a grandfather clock as it has weights that drive the mechanisms that weight several pounds. With this kind of force on pivot points and bearings need to be oiled. Our Datsun clocks do not have this kind of force on the pivots. The 280z mechanical clock has several bearing that support pivots that are plastic and they do not need to be oiled. The correct way to oil something, if you must, is one drop of oil on the bearing/pivot and wipe off all visible oil. Clock oils today are synthetic and have a much higher load and degree of temperature resistant than organic based oils of the past. Hope this helps. Ron

-

Need Help Finding a Harmonic Balancer with an AC Pulley Groove or Finding a Pulley Addon for my Current Balancer

If ZKar doesn't have one I have a couple of other sources that might. If you do find one I would have it rebuilt. There's a good place in nothern CA which charges like $190 , but they do a really good job. My damper looked go after I removed ,but the rubber was cracked. On the car it was wobbling about 1/4 in.

-

Need Help Finding a Harmonic Balancer with an AC Pulley Groove or Finding a Pulley Addon for my Current Balancer

You might e-mail zKars and see if he has one. I tried to find one for my 280 and couldn't so I had mine rebuilt. Not cheap , but better than no air. Ron

- Engine leans out over 2400 rpm

-

1977 280z EFI Nightmare

So you had a internal oil cam and spray bar? I was told by a Z mechanic if you used both you wold have very low oil pressure. Ron

-

1977 280z EFI Nightmare

Good pix of the cam. Looks like you have so damage. Could be the oil galleries in the spray bar are plugged. I would remove the spray bar and make sure they are not plugged. Also check the holes in head that attach to the spray bar to make sure they are open. Also, I think there are gaskets the the spray bar attaches. Make sure these are not leaking. As a note: I'm not sure that the 77 had a spray bar. My 75 cam was damaged (loud lifter noise/couldn't adjust out) I replace the cam with a 77 or I believe it was a 77 cam. The new cam was used and had holes in the cam lobes . This eliminate the need for the spray bar. Maybe someone else can chime in on this.

-

1977 280z EFI Nightmare

When that happens I usually say" I 'm here to take the secretary out to dinner! Something else I saw in a previous thread about damper pulley. This is near and dear to me as I just had to do mine several months ago. The damper should not wobble.

-

1977 280z EFI Nightmare

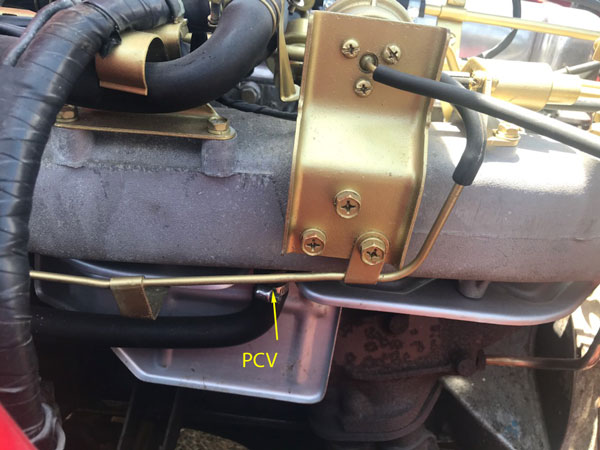

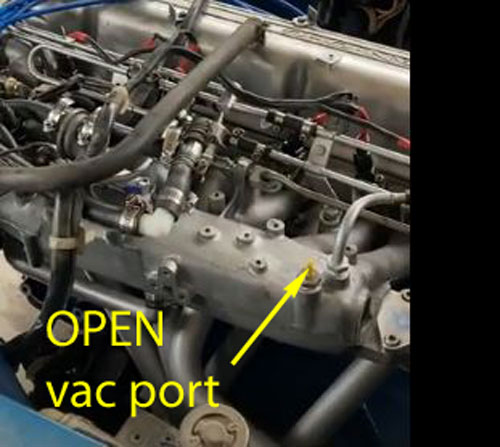

I snipped it from your video , but couldn't tell if it was plugged. A couple of vac sources are all vac lines suspect due to age, dip stick seal, pan gasket, maybe, cover plate, like where yours is plugged off on intake manifold. and valve cover gasket.

-

1977 280z EFI Nightmare

-

1977 280z EFI Nightmare

I've tried to follow this thread and it appears you a have a lot going on. Been there and done that . Don't give up you have to work one problem at a time and you will get there. The valves should not make that much noise. If they were adjusted correctly you should hear an even clatter. If they are tooo tight they wouldn't make much noise. In an earlier thread you mentioned spray bar gaskets. Do you have a spry bar on this car or do you have an oil hole in each lobe? you can't do both or you will have very low oil pressure. If you have a very flat lobe you can not adjust out the noise. Second it appears that you have NO vaccuun if i'm reading your gauge correctly. Where are you connecting the vacuum gauge? Third did you check the fuel pressure? The way use started the car it appears the pressure was low and it took three try to reach the 30 psi to start.

-

battery chargers

Patcon, Yes, I think most of the time the chargers can be repaired. Their not like a clock....LOL Ron

-

battery chargers

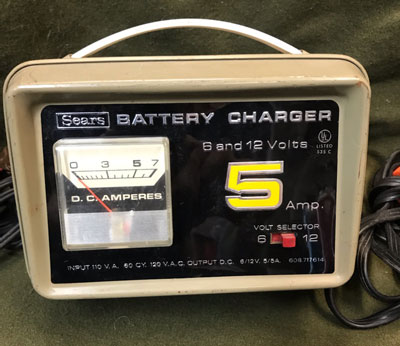

This is a great topic especially if your looking for a trickle battery charger or one to replace a dead charger. I had the tan 5 AMP charger pictured for over 40 years and it finally died. Well my neighbor helped by hosing down the charger with water. Anyway, Instead of replacing the diodes I just tossed the charger and started looking for a new one, what a shock. I tried three new charges that died before I went looking for a SEARS unit like my old charger. I found the two Sears charges as pictured on eBay. The 5 AMP is my " go to" and the 6/2 AMP is a backup. These are very heaving duty, work all the time and never overcharge the battery. I had to change the power cords and the battery clamps, but this is the only charger I will use. You can find them on eBay for no more $ than the newer chargers that are JUNK! SEARS use to contract different company's to build quality products , but that time has long passed. The garbage we see today is from CHINA! end rant

-

Parts Wanted: Quartz clocks

View Advert Quartz clocks If you have either of these two Quartz clocks and would like to sell them please contact me at: ron@zclocks.com or PM me . Thanks Advertiser zclocks Date 03/06/2021 Price Category Parts Wanted Year 0 Model 280