Everything posted by HusseinHolland

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

When I tested it with a timing light & held the rpm steady at 2500-3K, the timing would surge slightly in time with rpm drop, but that would seem pretty normal, no? If there is a flow restriction in the feed side of the rail, that would also do it. I've seen cases where a 'flap' of debris moves & chokes flow under high demand. I'm only thinking of this now because when I pulled the feed hose, there were particles(old hose breaking down, perhaps) in the inlet to the metal feed tube. I'll put a noid light on it, to see if the EMS is dropping out , does also seem plausible. Trying to go over systems I have specifically altered in some way that could be the cause.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

That is correct. Since it's not due to the HEI module conversion, the only other obvious thing I had worked on was replacing the fuel lines at the rail. It seems plausible that there is debris in the line(s) that chokes the flow under higher demand. Regulated fuel pressure is good, but that doesn't mean the volume is there. Can't think of anything else I have done that could cause the issue at this point.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

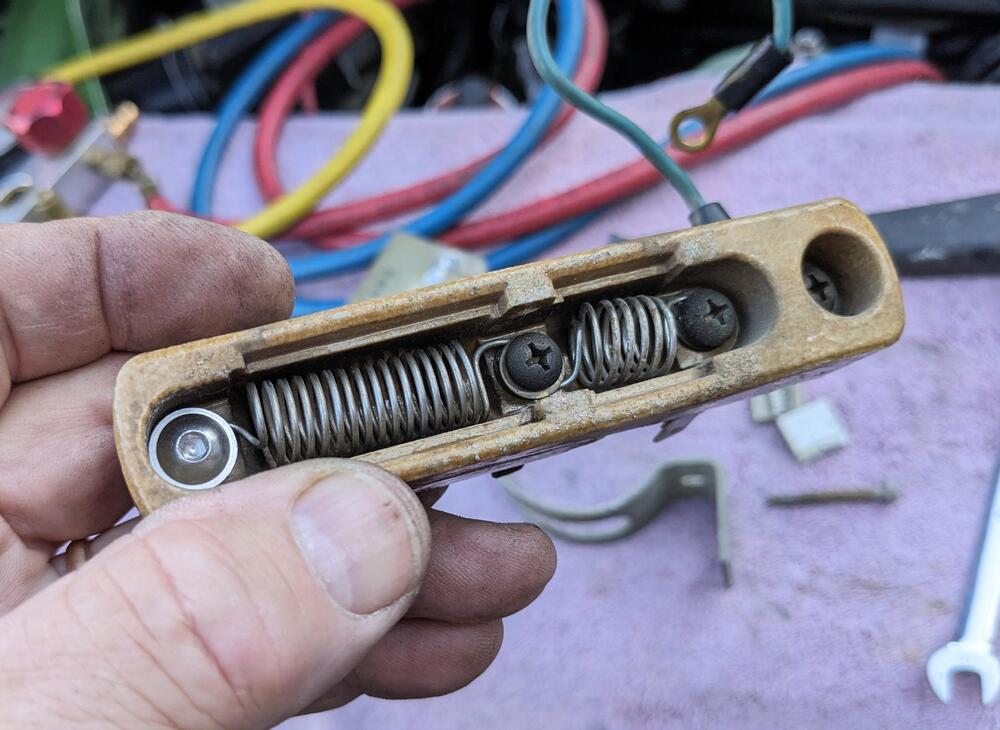

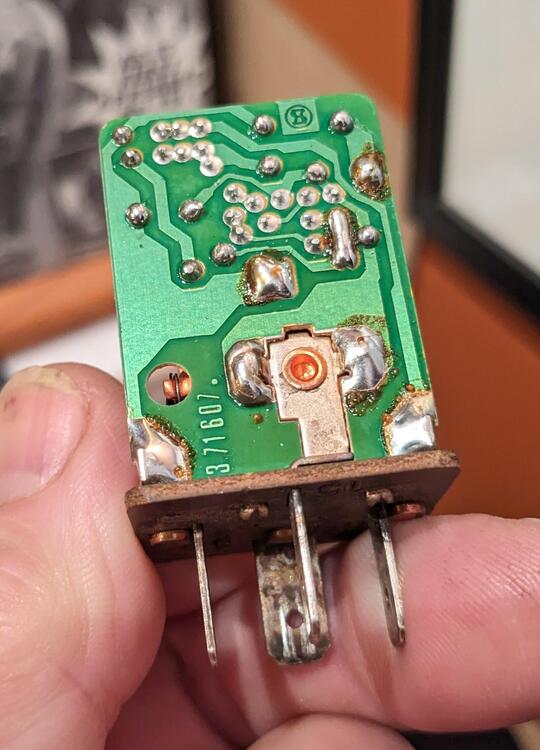

So the issue with the ballast was that without the center post, there is no continuity. repaired, then reassembled in outer casing Started right up....but.... still hunts 2500-3000K rpm with stock module setup. So, moving on from ignition as the cause, most likely at this point would seem to actually be hunting due to lack of fuel volume - possibly crud in the fuel rail, since I did have all that apart to change the hoses. YT vid of symptom

-

Replacement External Door Scraper Molding (Silvermine)

I put the rollers & brackets (from ZcarDepot) in some time ago - forgot to update. As far as the fitting moldings go, Silvermine has been useless. His sugeestion is to gorilla glue the molding to the the door, after you (somehow) bend them to fit the compound curve of the door without damaging them. I will never buy from him again, that's for sure.

-

1975 280Z Cold Start Circuit Issues

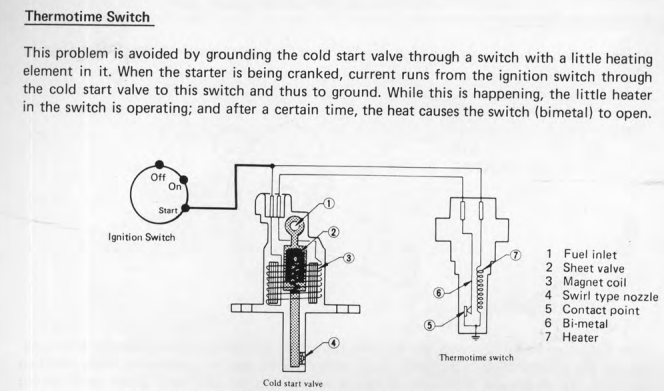

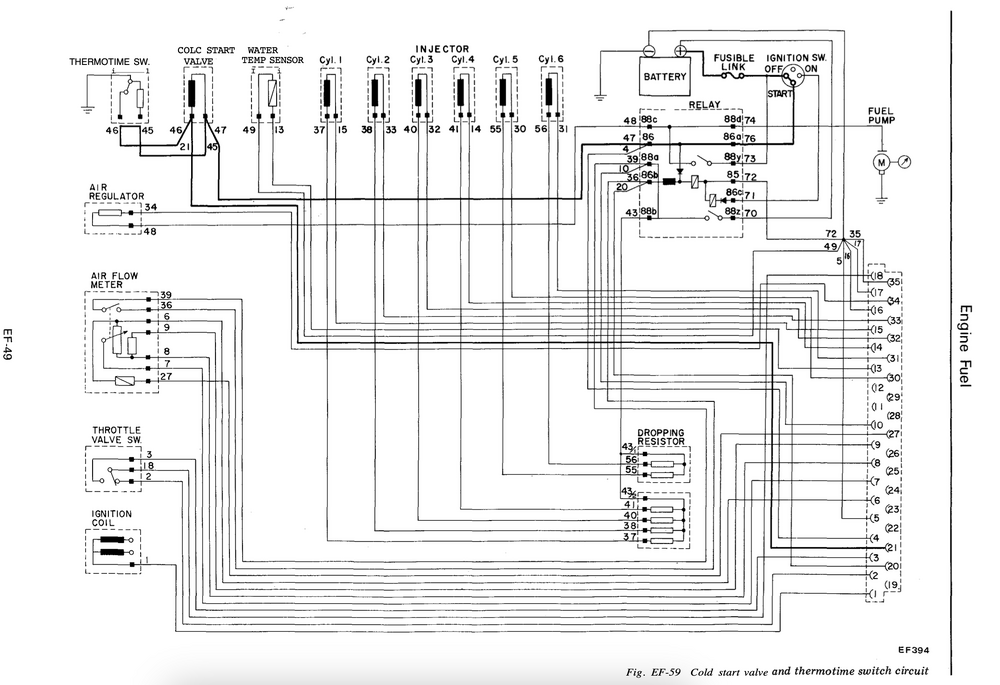

Would have been nice if the CSV had been ECU governed. Volvo didn't get that until the adoption of Bosch LH-2.2 in the early 80's, but they never used earlier L-Jet air-flap meter configurations . They used D-Jet and K-Jet before that, which also used the TTS like the Datsun.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

I definitely had none of these particular concerns prior to messing with the ignition system. When cranking (with reluctor wires flipped), it felt like a motor that is way out of time, so perhaps that was causing the excessive drain. As it stands, with stock parts (and no increased voltage to ballast when cranking) within a short crank time, the voltage at the ballast is dropping to around 9v, according to my voltmeter.In any event, it won't start as is. So, I think I'll remove the ballast to see if I can fix it, and swap back the HEI connection & later coil, as at least I can run the engine at idle speeds that way & check the CSV operation again.

-

1975 280Z Cold Start Circuit Issues

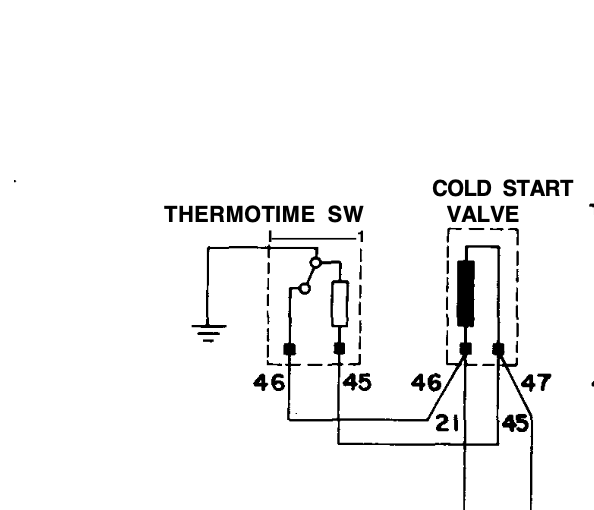

So I have discovered. It appears the only point to the #21 connection is to allow circuit continuity check, per the FSM. I tested my TTS today, and I have ground between 46 & the t/stat housing with a cold (uncranked) motor.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

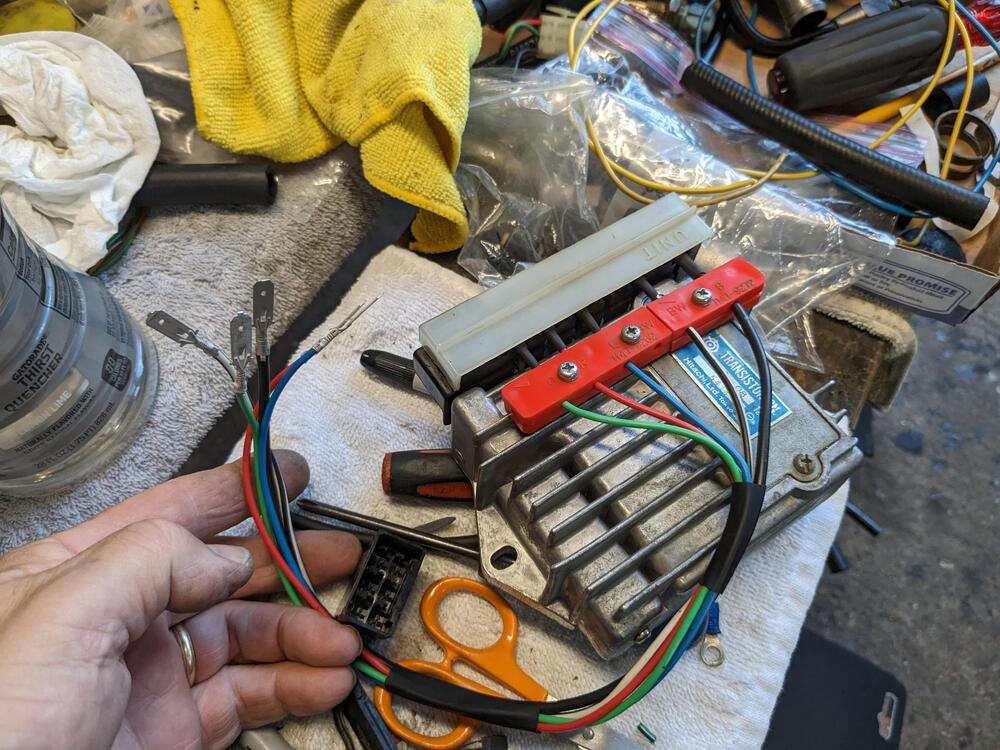

Swapped the coil & transistor module back in, however the middle post on the ballast snapped off when I did the conversion. Without that increased voltage when cranking, the engine is not starting. I'll have to see if I can get inside the ballast to add the intermediate post back tomorrow. In the meantime, I think I have to assume the SMP HEI module I bought is defective, the wiring is definitely correct. I've ordered a genuine AC Delco D1906 module to replace it.

-

1975 280Z Cold Start Circuit Issues

A Fiat forum member pointed out what I was missing, and is not including in the FSM circuit testing - the TTS grounds the CSV, so with the TTS circuit bridged to check continuity of the wiring, the CSV cannot fire. I'll have to check the resistance of the TTS when cold & make sure it's OK, then I can reconnect it to verify CSV operation. The operation is described in the manuals, I've read it many times - I just blew right by it, 'assuming' the ground was ECU controlled, not within the TTS

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

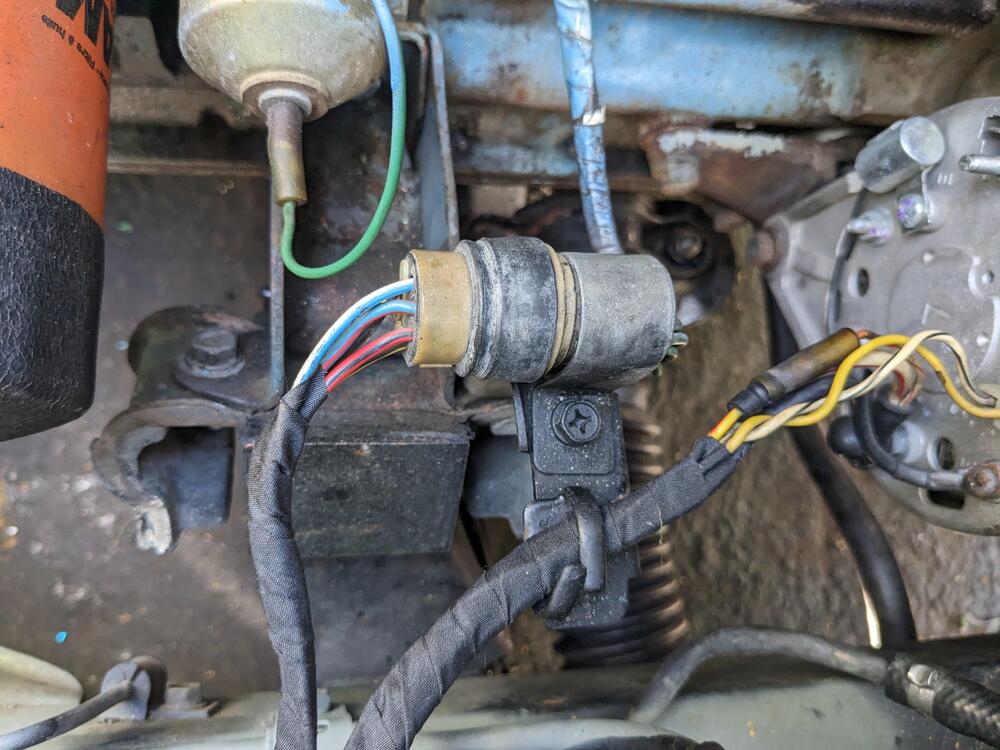

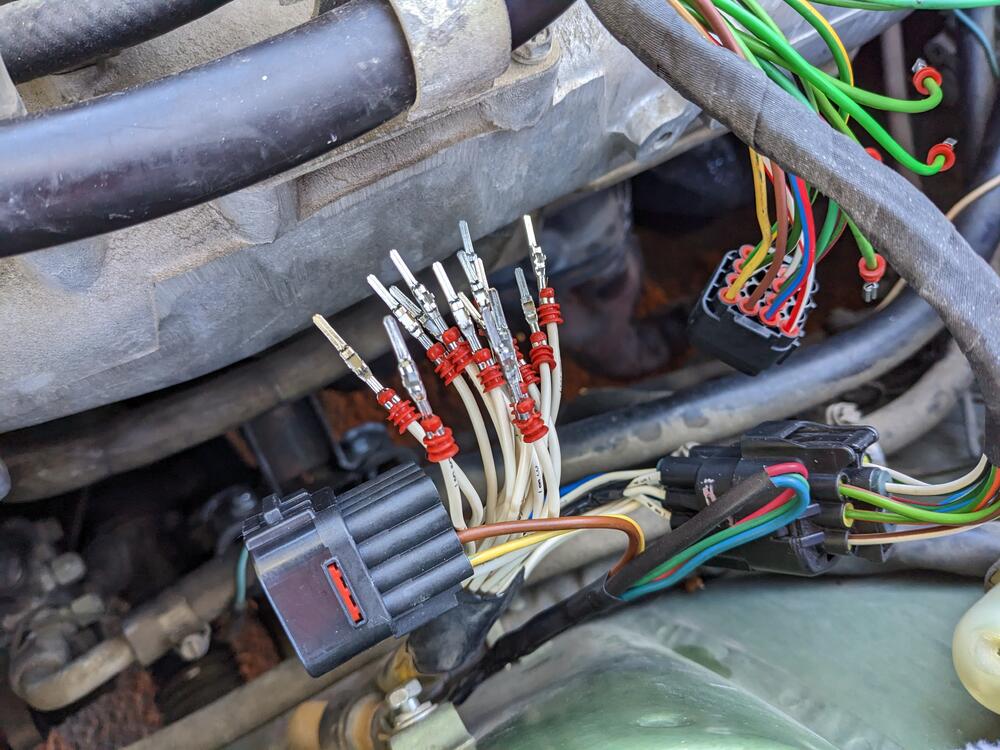

I ran the motor & used the timing light, leaned over & revved the motor. Timing advances as expected when revved, and sits at approx 8º BTDC at idle. The motor goes completely flat when revved & held at around 2500-3K. Fuel pressure does not falter, I have a line gauge after the filter. I tried reversing the wires from the reluctor, and that had very bad results. It cranked normally for a few revolutions, then turned over very slowly, then not at all. After that, it was completely dead. I thought the battery was drained - I found that cranking like that blew the 125 Amp fuse breaker on the starter cable from the battery. I replaced that, put the wires back & it started again normally. I don't understand why the ignition system is creating such an extreme current draw when the reluctor wires are switched. No one has previously mentioned any issues with reversing the reluctor wires. I tried another coil, in case that was an issue. I'm going to put the stock module and coil back in & confirm whether the issue is with the HEI conversion or not. re-wired to plug into the modded harness

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

The motor goes flat when revved, It is acting as described earlier in this thread. I'll put a timing light on it after work & see what's up. I'm going to reverse the reluctor wires first to see if that resolves it, since I can't rev the motor and watch the timing marker at the same time by myself. I have not touched the distributor other than to replace the cap & rotor.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Indeed - however the only recent change to the EMS I've made is the HEI module - 'hunt' may not be the ideal term, even though it kinda feels like it - the motor won't rev as described by others in this thread when the reluctor signal is reversed.

-

1975 280Z Cold Start Circuit Issues

Still back & forth with the cold start circuit. I have continuity in the harness from 21 at the ECU to the CSV & TTS. The factory test is to disconnect the ECU connector & use a voltmeter on pin 21 - if there is battery voltage when cranking, the circuit has integrity. I did that, and got the desired result. However, the CSV does not fire, even though I know the valve is functional when wired independently of the circuit. What I'm having trouble with is the way it's all wired - looking at the diagram, it appears the TTS is in parallel, not series, so HTF it would interrupt the current to the CSV? Makes no sense to me. The reality of the circuit wiring is thus: FSM diagram crop Further investigation is required.

-

Source For Replacement Bulb Sockets / Holders for instrumentation ?

They are kinda loose in the hole - 16mm I think I measured the orifice at - so I added a thin strip of heat shrink to make it snug

-

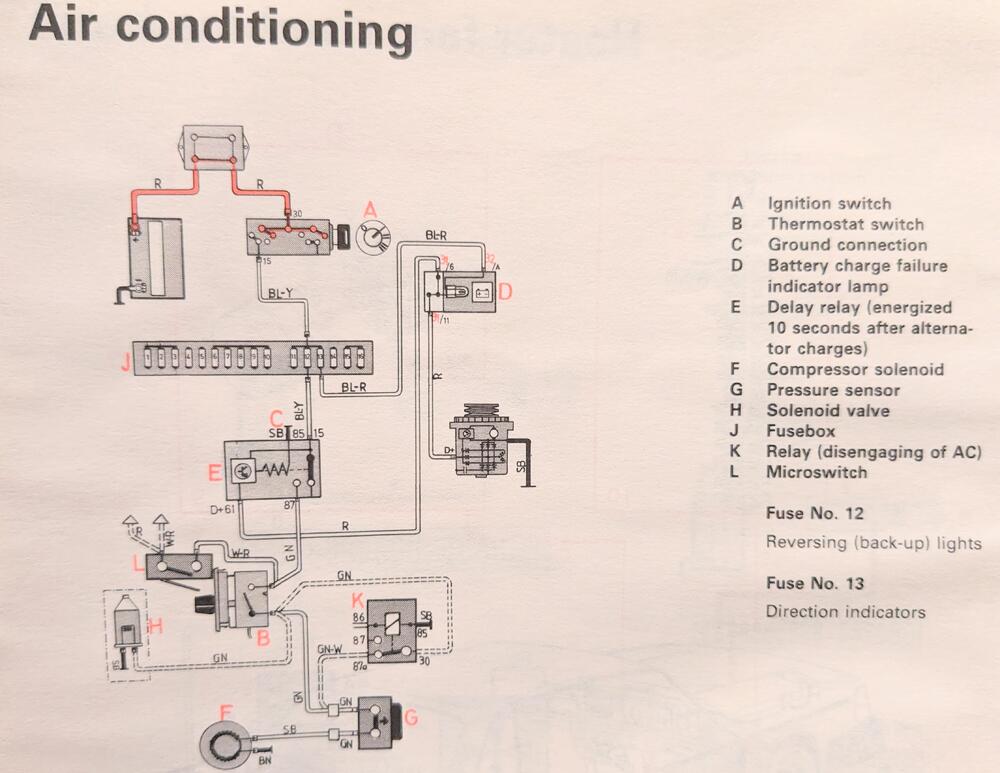

Designing A/C System Using Other Cars Parts?

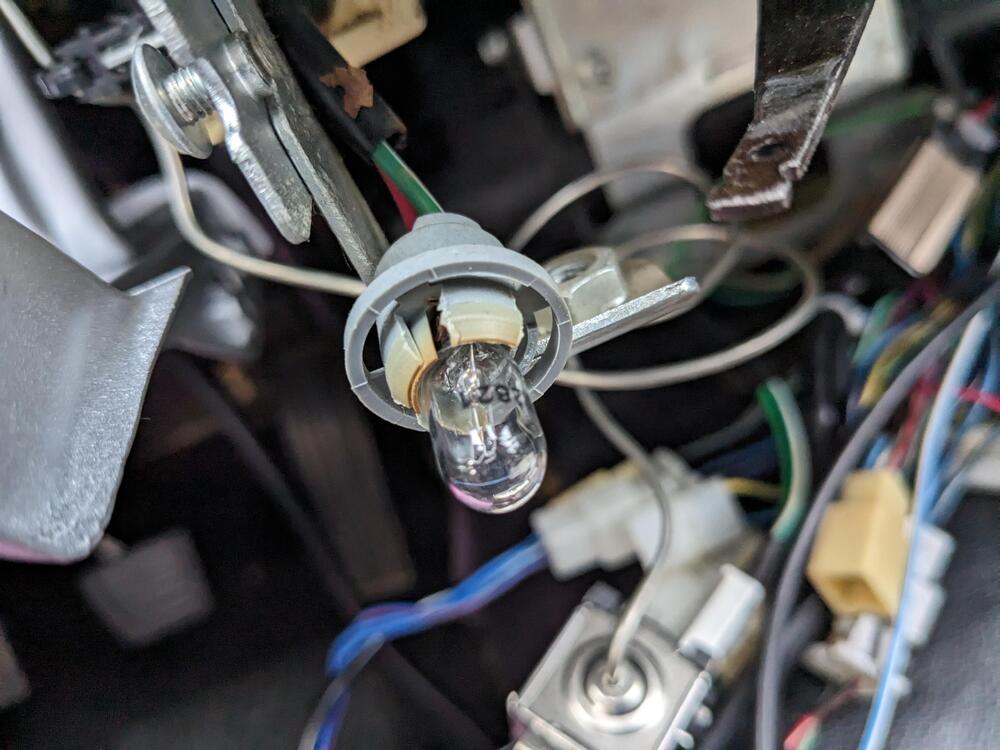

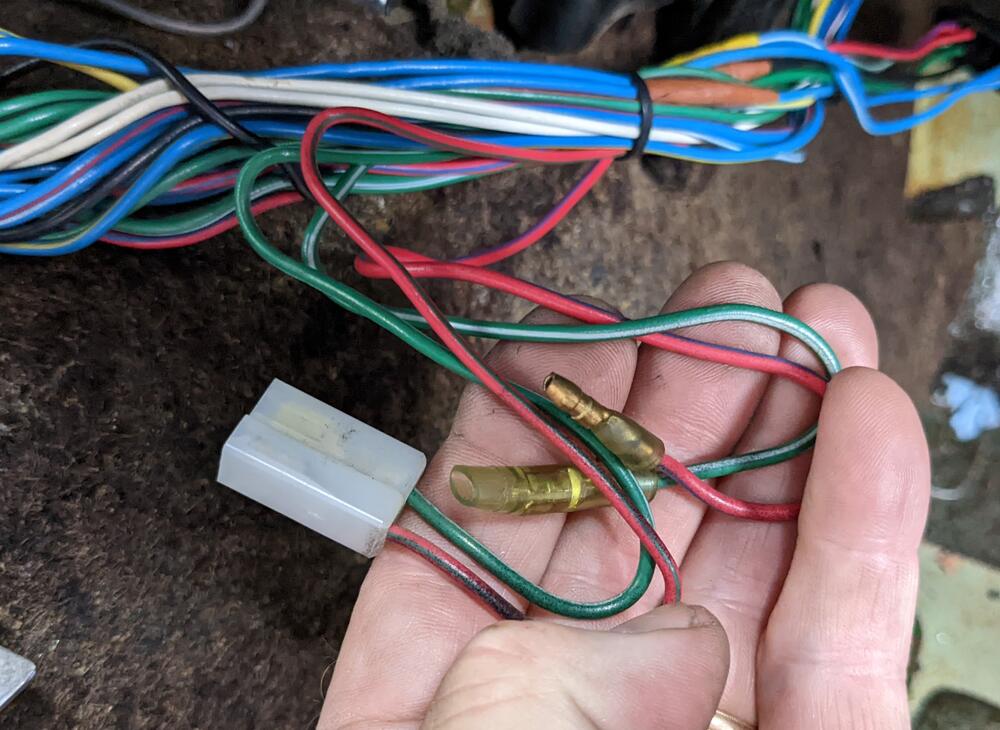

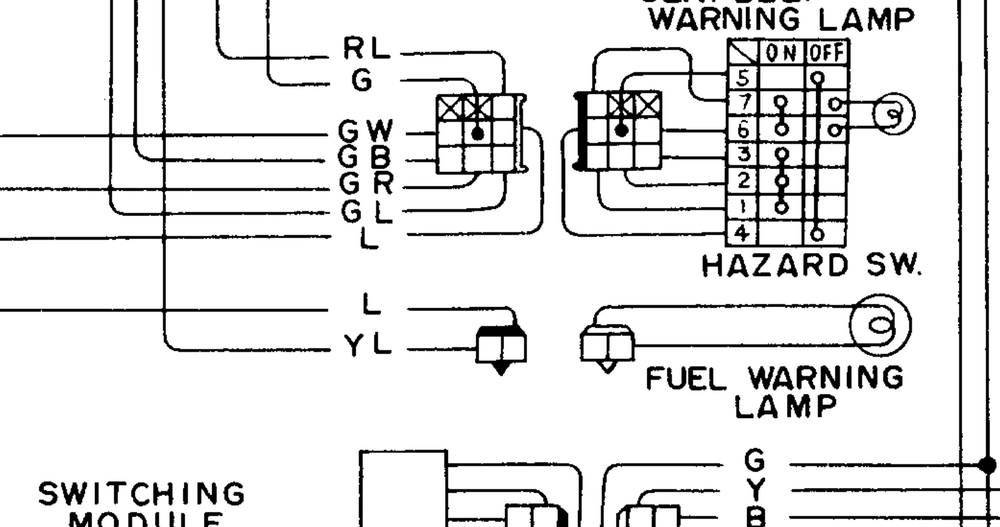

Did the AC relay signal re-wire using the L terminal and repurposed the low fuel lamp for the charge indicator lamp. Works as expected. V/reg connector, with wh-bl connected while I was in the bay I repurposed unused AC system wires and moved them to the engine harness connector for Oil temp sender (Bl-Wh) and to the alternator for Voltmeter (Y-R) I need a spot for the charge indicator lamp, so I removed the massive "Rear Defogger" lamp & fitted a red lens, then added a bulb socket plate to the rear defogger switch, similar to what the Hazard switch has. I had to cut a hole in the rear defogger & add a color plate w/icon for the defogger re-drilled the backside to accept a bulb socket w/spade terminals making the bulb plate marked area to be cut out build plate fitted illuminated Last thing, the 1363449 AC relay is dead - I re-flowed the solder joints, but it still doesn't switch after the 10sec delay, so I have ordered another

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

So today I ran the motor until it was warm , after checking the cold start circuit. I found that if I rev the motor to around 2k & hold it there, it hunts. Is this the condition others described that requires the reluctor wires to be reversed?

-

75 280Z Clock Repair?

So, I have the clock sitting on a shelf running. It loses about 5min over 48 hours. There is an speed adjustment marked S & F. Question is, doesn't that mean rotate toward S to slow it down, and toward F to speed it up, or vice-versa?

-

1975 280Z Cold Start Circuit Issues

Did you mean to post in the bulb socket thread? 🙂

-

1975 280Z Cold Start Circuit Issues

So, now that the ambient temps have dropped, I see that the cold start system is not actually operational. When I rewired the EFI harness I found the ECT & TTS were mis-wired. I don't know if that caused an issue at the ECU. In any event, I bridged the TTS connector, and have voltage output from the EFI relay 86 terminal to the cold start valve when cranking (checked with test lamp on pin 86 at relay, and 45 at CSV.) I confirmed the CSV functions by powering & grounding the CSV to the battery with the fuel system pressurized. The CSV does not inject fuel however, and if I put the test light across the pins of the connector, it does not light, which would indicate to me that the ground side of the circuit is non-functional. I tested the continuity of the harness from the TTS connector (pin 46) and the CSV connector (pin 46) and both have continuity back to the harness plug I made. Tomorrow I'll have to check the continuity of the ground side of the harness from there back to the ECU connector. My question is, does anyone have experience with this aspect of the system that would indicate a common failure point? The wiring diagram is not accurate in terms of the actual wiring of this circuit - the bridge circuit for the TTS in not at the CSV, is it back in the harness on the inner fender, where 47 is T'd off into to 45 wires, and 21 is T'd into 2 46 wires. I discovered that when I did the re-wiring.

-

Source For Replacement Bulb Sockets / Holders for instrumentation ?

Thank you Steve! I ordered those to see if they fit OK.

-

Source For Replacement Bulb Sockets / Holders for instrumentation ?

I have at least one socket with broken/dried out tabs for the HVC control panel - I'm not finding anything searching for repalcement sockets in general - has anyone found a generic / aftermarket bulb holder/ socket that will clip in place, that also has the correct bulb depth? I know the bulb socket for the low fuel light will fit here - so I will likely cut the harness on that & use it here. I'd still like to know if there are any useable options for the instrumentation.

-

Changing an Amp gauge for a Volt gauge

-

Changing an Amp gauge for a Volt gauge

Found some old Volvo fog lamp switches - I think I'll add one & then I can just put some fog/driving lamps behind the lower grille..

-

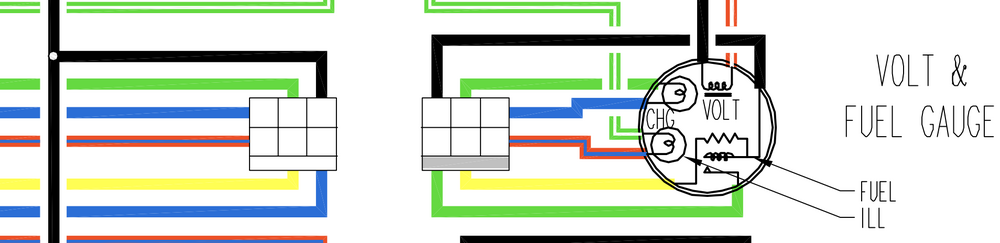

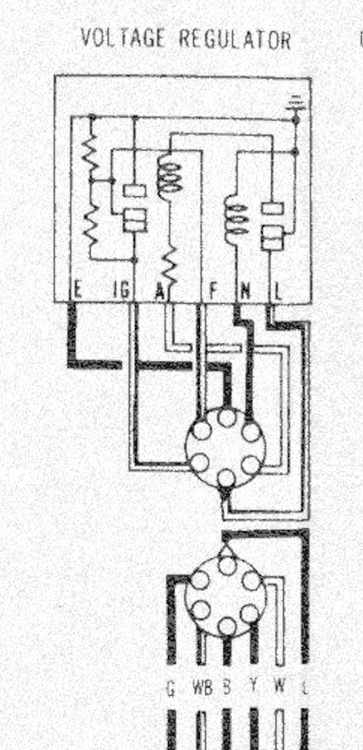

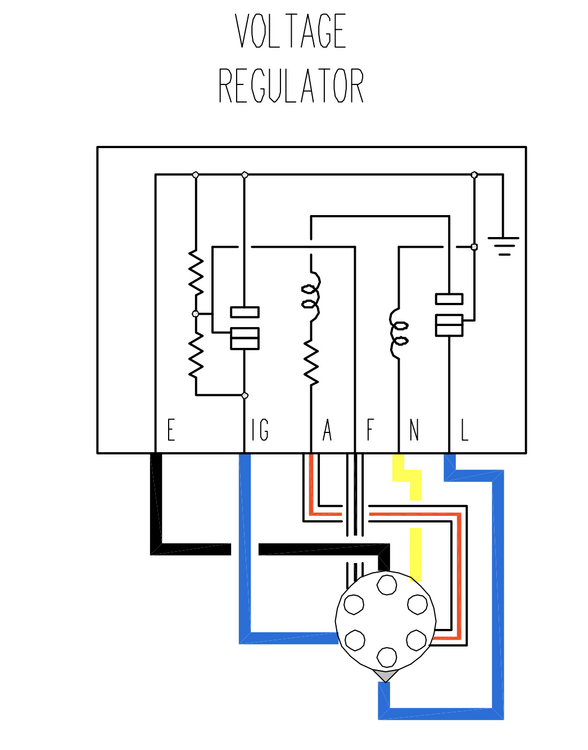

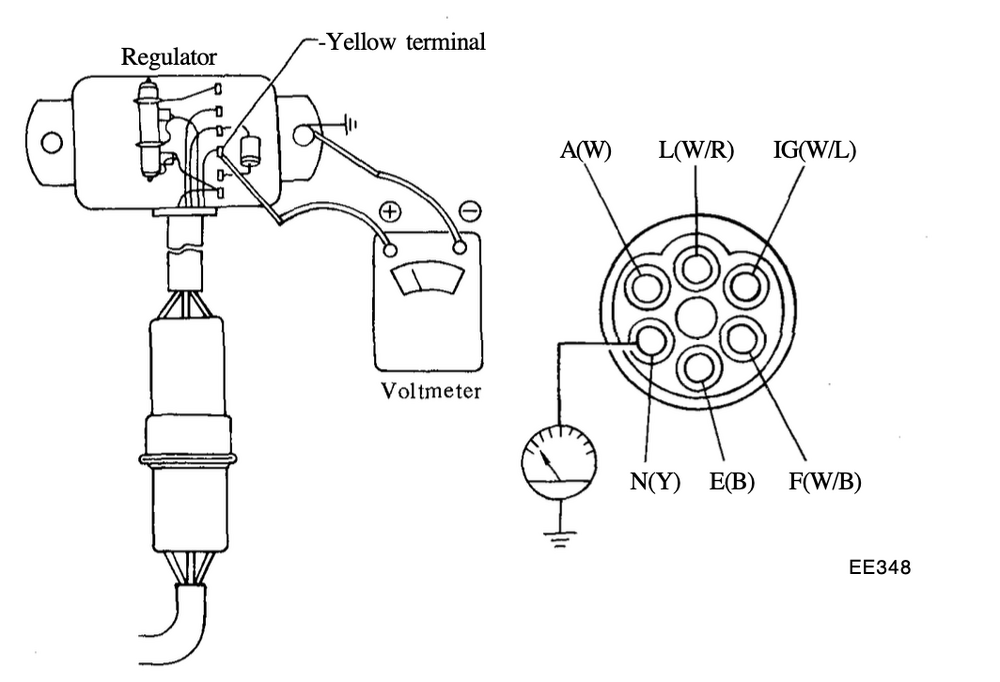

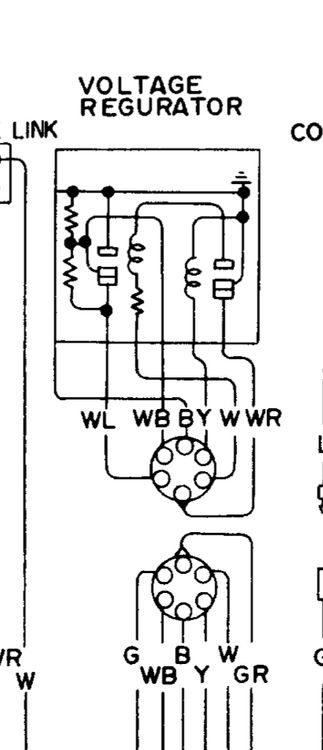

1975 280Z Using Voltage Regulator Wiring (L terminal?) To Add Charge Indicator Lamp

Thanks Steve - I have the 75 FSM (original hardcopy). It matches the online copy that I have, besides the glitches from scanning There is no charge lamp on my 4/75 280Z. I do have the ammeter . Manual shows an interlock relay, but I don't have that either. EDIT - when the rain stops, hopefully Sunday - I'll look at the actual harness plug & see if I can wire a test lamp to the L circuit. Should be easy enough to determine from there if it will suit my needs. Thank you for pointing out the L terminal in the other thread. from page EE-14: EDIT -lookng through my earlier pics - I have an empty spot in the v/reg harness for the L terminal EDIT - thinking about the actual lamp - I can repurpose the non-functional low fuel indicator. I'll cut the Bl/Y wire back in the harness & connect that to the L terminal & Blk/Wh wire at my AC relay. I've taken a Volvo seat belt warning lamp & sanded off the symbol, so I can fit that in the console for the charge indicator lamp

-

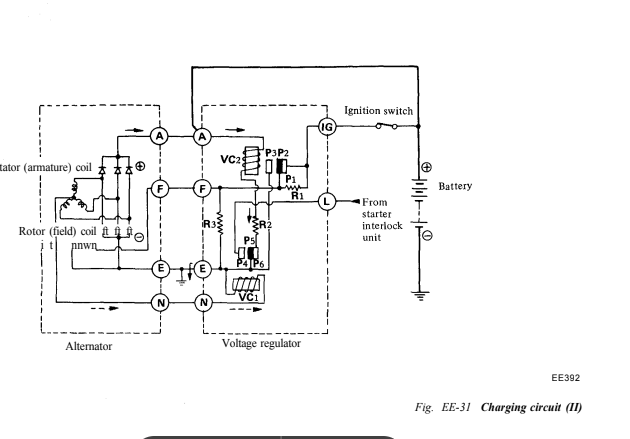

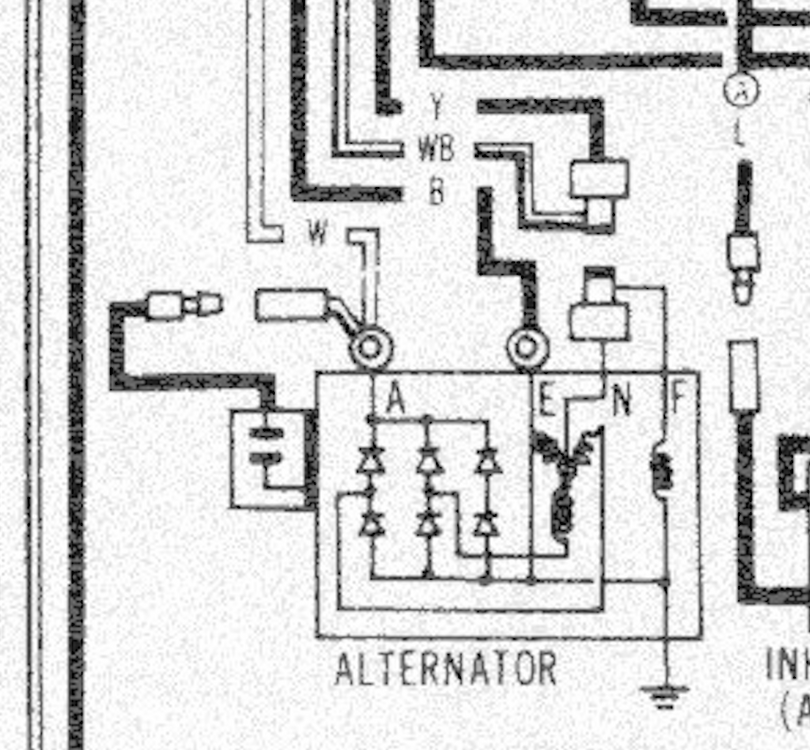

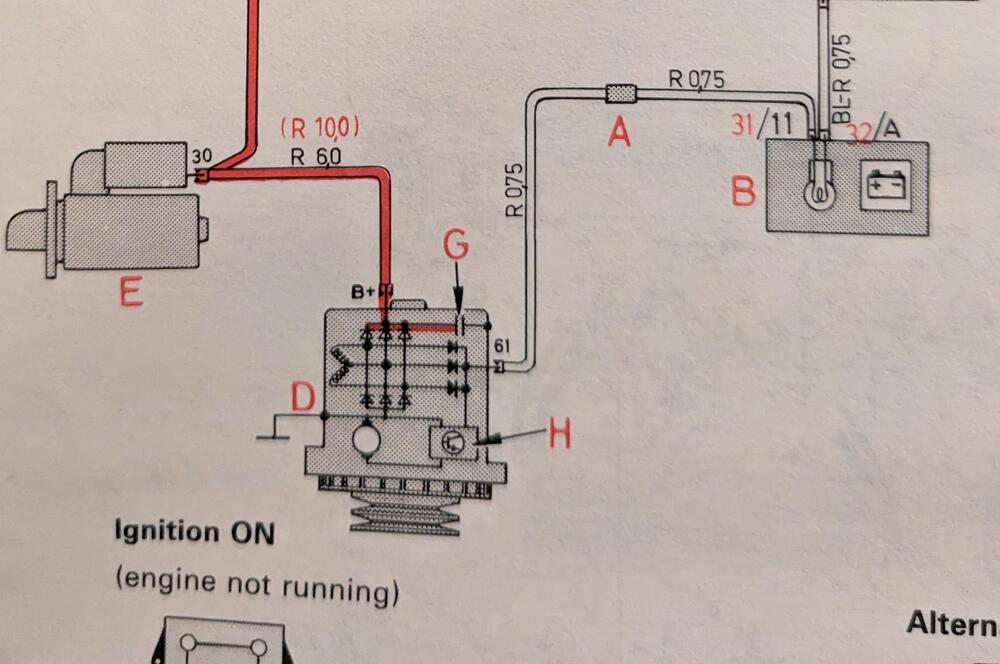

1975 280Z Using Voltage Regulator Wiring (L terminal?) To Add Charge Indicator Lamp

So, a little background. For my AC system control relay, I need a signal that ties into the charging circuit (D+61). On a Volvo, this would travel to the ground side of the idiot light, and ground through the alternator (D+61 terminal) when the engine is not running. As far as I can tell, there is no way to wire this to the alternator, as it doesn't have a equivalent connection 75 280Z Volvo alternator, has an additional diode pack. I don't even know if using a later internally regulated Datsun alternator would fit the bill. I read in another thread (can't quote it here) @SteveJ - That the L terminal of the V reg would serve to provide the charge indicator lamp circuit I need The 1975 wiring diagram shows a wire connected to the L terminal, but it also shows a voltmeter, so I'm assuming that is an error 77 color diagram shows the wiring through to the voltmeter & charge indicator lamp 75 diagram - The wiring diagrams I have show a Blue or a Grey connected to the harness side of this. Following it through, it seems to go to the Interlock Relay (which my car doesn't have) FSM shows a W/R wire connected to the L terminal though. So, to get to the point, does the '75 voltage regulator in fact have that L terminal & internal circuit that I could utilize?