Everything posted by 240260280

-

Triple Weber throttle connector hitting mounting point on carb??

Try tightening nut first. If it still binds then file the top of the bolt. You can buy longer arms if all else fails.

- Water ****

-

Datsun-240z Vs Fairlady-z432

I asked Mr. Matsuo and he did not know their purpose. Your idea makes sense. Another similar mystery: My Honda Ridgeline has a funny piece of metal at the rear base of the driver side (LHD) front wheel well but it is not on the right. It turned out it helped compliance with front left-side head-on collision requirements..... so sometimes it is safety rather than function that can make the answer difficult to determine.

-

Thinking about installing an BMW M6 engine in my Z

- Datsun-240z Vs Fairlady-z432

Hi Kats, The pistons can bind if the domes are out of alignment. The way to check is to remove the plungers then lift and drop the pistons with your fingers in the throat on the bottom of the piston lifting it up and down. You should be able to feel any binding. The final calibration check is to lift both up to the top and release at the same time. They should "clunk" on the bottom at the same time. If not, it is possible that the margins have carbon or that the domes and pistons were mixed up at some time (or the springs are not matched or the nylon stop washer is missing in one). Sometimes you can swap the two pistons and the fall calibration will work better. Pistons and domes are matched in the factory but wear and mix-ups do happen. Binding is usually caused when screwing down the domes. If the dome is clocked (rotated) too much from its natural position, or if one screw is tightened too much at one time (to tilt the dome toward it) then binding will occur. The trick to optimally installing a dome is: 1. Fit the dome w/o screws and rotate it cw and ccw while visually noting the stopping points. You can mark with a pencil. Usually there is ~ 1mm of arc in each direction from the center. 2. Insert the screws to their middle depth (ensure no pressure on dome flange) and repeat the rotating the dome to note the stopping points. 3. Turn all 4 screws down evenly and in a cross pattern (like lug nuts on a wheel) but again, do not tighten so that the dome can not be rotated. You just want the screws to apply minimal pressure and just kiss the flange so that you can still rotate the dome but this time with a slight resistance caused by the screws. 4. Rotate the dome while lifting and dropping the piston. Note that in the center of rotation, the piston will not bind. This is where you want the dome to be. 5. Once the dome is in the sweet spot, Turn all 4 screws down evenly and in a cross pattern (like lug nuts on a wheel). Be sure to give each only a 1/4 to 1/2 turn at a time. Continue lifting and dropping the piston to ensure all goes well. 6. After both domes are screwed down, do the drop test to ensure both fall at the same rate. 7. Add oil and the plunger then repeat the drop test to ensure both fall at the same time. Finally, when considering an oil, the important item to note is what the damper does: It only slows transitions of the piston to smoothly meter fuel. Here are the key transitions: 1. Engine vibrations: without the damper, the pistons would shake in the dome and wear it out the edges. 2. Road bumps: without the damper, the pistons would clunk up and down when going over bumps and dips causing the fuel flow to change radically in short bursts. 3. Acceleration: the damper reduces the fuel metering during acceleration by keeping the needle deeper in the fuel jet orifice. Another opposite effect of the delayed piston rising is the increase of fuel flow caused by the manifold vacuum creeping forward of the throttle plate to draw more air over the annular fuel puddle. This also increases the venturi pull of the fuel as more air is now flowing over the bridge and through the smaller opened area above it. The net effect is more fuel during the acceleration stage but not too much. 4. Deceleration: the damper increases the fuel metering during deceleration by keeping the needle higher in the fuel jet orifice. Another opposite effect of the delayed piston falling is the decrease of fuel flow caused by the manifold vacuum being stopped completely in the throat by the closed throttle plate. The result is less air to draw from the surface of annular fuel puddle as the venturi pull of the fuel is low (Less air is now flowing directly over the bridge and through the very large opening area above it. The net effect is reduced fuel during the deceleration stage but not too little. Ultimately the damper oil you chose will only be noticed during acceleration. Thicker oil will enrich the acceleration mixture, thinner oil will lean the acceleration mixture.- Datsun-240z Vs Fairlady-z432

Hurray Alan!!! Finally an answer!!! Mystery solved.- Weber selection and initial jet tuning

Great stuff for the repeatable measurements. You are testing like a pro! Put bolts in the bottom of the fuel bowls to kill the acceleration jets. Replace those 0 bleed back spill jets with the bolts. Quick and efficient. Once you do this and measure, you will see what that squirt of liquid fuel is doing. I think it is significant, especially with the bleed-back blocked in those 00 spill jets you have at the bottom of the bowls now. I would continue to tune with the bolts in place then do your final tune with the accelerations jets back in place. To attack the curve, a change from 155main to 150main will lean out the whole WOT run. Hopefully it will go from you current average ~12 towards 12.5-13.0. You can then go to 145 if needed. To lean out the high end, a change in the air corrector from 185 to 195 may do it.- Weber selection and initial jet tuning

It is not that bad. There are a few things you can try: Overall you are in the ball park and it should be nice to drive. There are just two items to consider for tweaking further: 1. The low end richness is either the E-Tube being richer in the low end or the acceleration jet kicking in too much. If you punched the pedal then maybe we are seeing the effect of the squirt of too much liquid fuel. 2. The tapering from middle to the end is minor. You go from 12.7 to 11.7. It could be due to the air tube being a tick too small or the E-Tube again. Here are a few first steps to try: 1. Repeat the test a few times to make sure the shape we see above is consistent and real. Testing has to be repeatable. 2. To address the start of the main richness, first repeat the test but try not to stomp and see what happens. 3. If there is a difference from "squeezing" the accelerator rather than stomping, then remove the accelerator jets and do a few runs to see how the mains engage without the acceleration jets. This will give us their leanest limit. Report back to us with the data. Here are some other tuning items but please hold off for now as changing too many parameters will cloudy the waters: 1. If you look at the shape of the mains during the pull, there is a peak in the middle of the pull. You can flatten it by smashing down the middle or bringing up the ends. The only way to attack the middle would be with E-tubes so it is too expensive and too exploratory. 2. The high end looks simple to play with. A larger air corrector will lean out more as the RPM's increase. This will flatten things nicely. 3. The whole shape will rise if you reduce the main fuel jet. 4. You may be able to lean the low end by using smaller acceleration jets.- A book for Nissan Racing History Buffs

http://www.ebay.com/itm/Age-of-Nissan-Omori-Works-20th-year-book-Ichi-Mechanic-saw-2016-8-Contents-/122517576244?hash=item1c869dda34:g:O9sAAOSwfRdZKJz1- All-new Z car (code-named Z35) will honor the legendary Datsun

It ain't 50 years yet.... fall 2019 is the time to look. Maybe a west coast memorial drive from LA to Edmonton in order for '19- Sato Wins!

I'm wondering what celebrations are going on in Japan. How does car racing compare to baseball in Japan? In Canada only a very small number would know who won Indy, most people are Facebooking these days and events around the world are ignored unless they can raise the interest more than legalized pot or the Kardasians.- ZCON Austin roll call

Of course I owe you dinner with the family!- So I have the original 69,561 mile L24 out of my 71 240Z

Kind of looks like the original Silvia https://seattle.craigslist.org/see/ctd/6115722731.html- ZCON Austin roll call

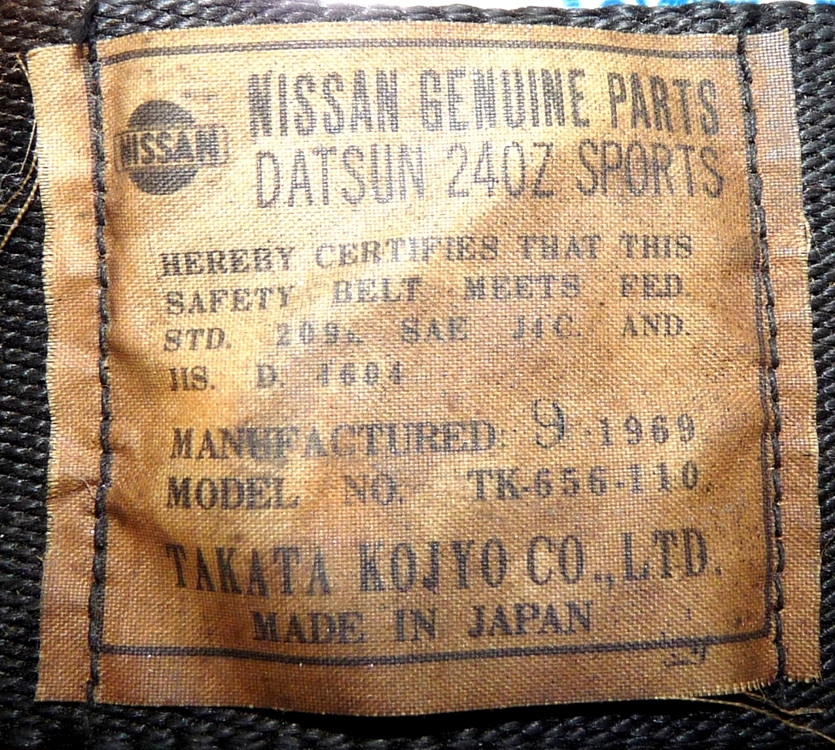

Sounds good! Janet and I are in an air B&B with kitchen so we may cook and entertain- 1969 & up 240Z seat belt tags - Reproduction

- ZCON Austin roll call

That BBQ has me drooling for Texas! Can't get there. Janet and I'll be heading out to the County Line restaurant (lake) one evening if anyone is interested. http://www.countyline.com/CountyLineLake.html https://www.google.com/maps/@30.3569996,-97.7857747,3a,75y,190.94h,85.76t/data=!3m6!1e1!3m4!1syUYYToMvtDYAAAQJOIRyYw!2e0!7i13312!8i6656- So I have the original 69,561 mile L24 out of my 71 240Z

- So I have the original 69,561 mile L24 out of my 71 240Z

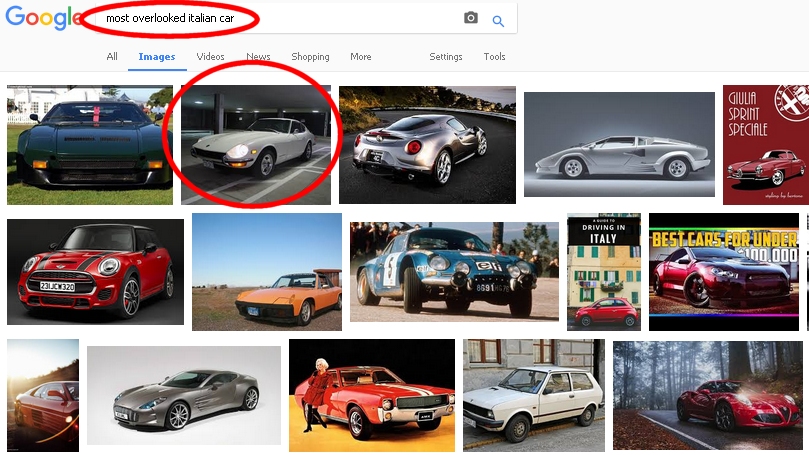

Zedyone's affinity is genetic. He just needs guidance on which Italian car. For me, I am from Newfoundland and have the genetic affinity to club seals.- ZCON Austin roll call

If anyone wants SU's or Triples tuned, I can bring instruments. Just let me know.- So I have the original 69,561 mile L24 out of my 71 240Z

Give up on the GTV....they are only 4cyl. and not as fast as Datsuns.... it is proven: https://www.youtube.com/watch?v=U5XAP4pCRps You really need to look at Ferrari or Lamborghini or Lancia- Sato Wins!

Poor Alonso. Honda Engine failed him again.- ZCON Austin roll call

WOW Janet and I loved Fredericksburg. Very cool town. We are looking forward to homemade peach ice cream at a small vegetable stand on the eastern outskirts. We will be down on the Saturday.... probably head to San Antonio on Sunday and Fburg on Monday. Looking forward to seeing y'all!- Datsun-240z Vs Fairlady-z432

I agree. As well there is a heck of a lot of adjustment in the linkage. On some cars I repaired with loose linkage, I shortened rods and re-threaded to allow the nylon sockets to screw further in. A few important steps for adjustment that may be missed: 0. As Zup says, clean and lubricate all joints. 1. Do not use the fast idle setting screw as a stop (this screw is only used for tuning). 2. Adjust all rods to take up slack (shorten and cut new threads if needed) 3. Adjust maximum-throw stop and lock nut behind gas pedal 4. Make sure choke wires are not holding jets down at idle. A bit of slack is needed.- Series-1 Hatch Vent Duct Clips & Restoration Info Needed

only $500 http://www.ebay.com/itm/240Z-Series-1-Datsun-OEM-Factory-NOS-90820-E4100-Nissan-FRESH-AIR-VENT-SET-of-2-/162527544140?hash=item25d765834c:g:vx8AAOSwurZZJZ8k&vxp=mtr- Alan... you may be interested in this racer suff on ebay

http://www.ebay.com/itm/Oct-1969-Fuji-Japan-Grand-Prix-Race-Speedway-Supple-Regulations-Brochure-ww1445-/291841803607?hash=item43f3208557:g:dHYAAOSwdzVXqkSo http://www.ebay.com/itm/May-1969-Fuji-Japan-Grand-Prix-Race-Speedway-Supple-Regulations-ww1446-/371706458166?hash=item568b6e7036:g:7mQAAOSwIgNXqkSw - Datsun-240z Vs Fairlady-z432

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.