Everything posted by 240260280

-

The S30 design isn't helped by....

I believe Goertz's contract started in May 1963 and ended in November 1964. 1.5 Years. His last duty was the Nov 1963 Tokyo Motor show and the CSP-311 release. I have seen his name raised in the very early British 240z articles in Q1, 1970. I think that is the source of the Myth.

-

Need Front Windshield Dimensions

Jeff, Here is how it fit on my friend's 71 at the same point. The Precision rubber kit was used. It fit tight so I had to tape it to keep from pulling off.

- sweatys rebuild

-

Weber selection and initial jet tuning

Imperial Drill size to Weber Jet Size 3/64" = 119 1/16" = 159 5/64" = 198 3/32" = 238 7/64" = 278

-

Weber selection and initial jet tuning

If you can get a 3/32" drill bit, you can drill out your 185's to "238" as an experiment. Home Depot has them: http://www.homedepot.com/p/DEWALT-3-32-in-Titanium-Split-Point-Drill-Bit-2-Pack-DW1372/202248725

-

Fitzy's #38 280zx BAT

http://bringatrailer.com/listing/1979-datsun-280zx-3/

-

Weber selection and initial jet tuning

I wish I was there with my jet drills! They make tuning faster and cheaper. Below is the 150 & 195 run graph (black) fitted over the 155 & 185 run graph (purple). This overlay confirms the overall shape did not change so the air corrector was not enough to lean the high end. Below is the 150 & 195 run graph (black) with the 155 & 185 run graph (purple). They are matched to the A/F scale The change in air and fuel simply leaned the overall curve by 1 point. So to flatten the top end you need to go larger with the air corrector. Try the 155 main with the 195 corrector to give us another data set then we may be able to estimate air corrector size. To summarize: You may have to keep the 155 and go larger on the air corrector or simply drill the 150 to 152/153 and live with the slight lack of flatness. I recommend trying to attack the shape with the air corrector first.

-

when to replace SU CARBURETORS SM NEEDLES?

Idle is Idle is Idle. The only thing to worry about is too rich a mixture that stinks and fouls plugs. Anything from 13 to 16 usually works. 14 to 15 is the least stinky. 13 is more tractable and sounds better.

-

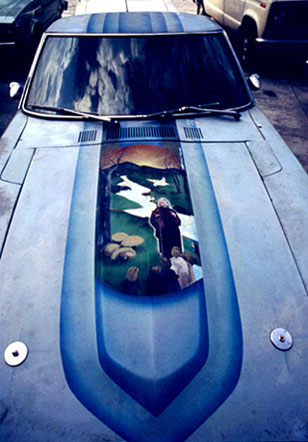

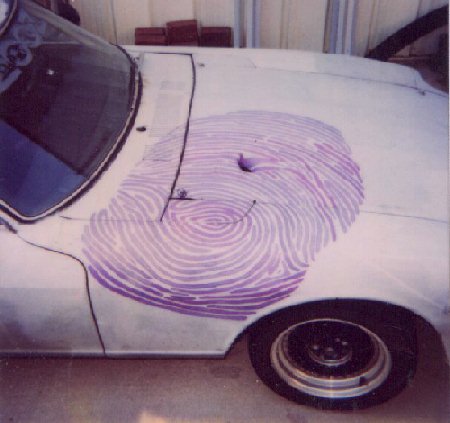

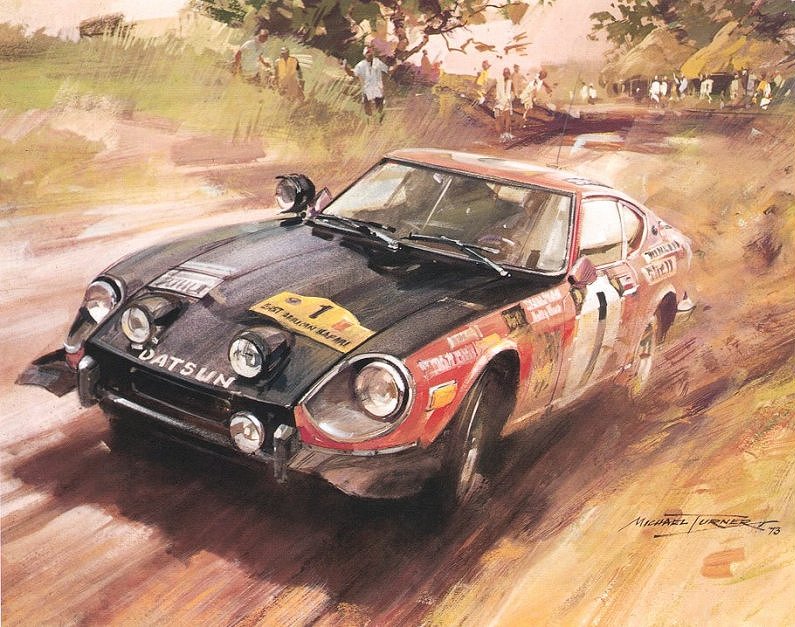

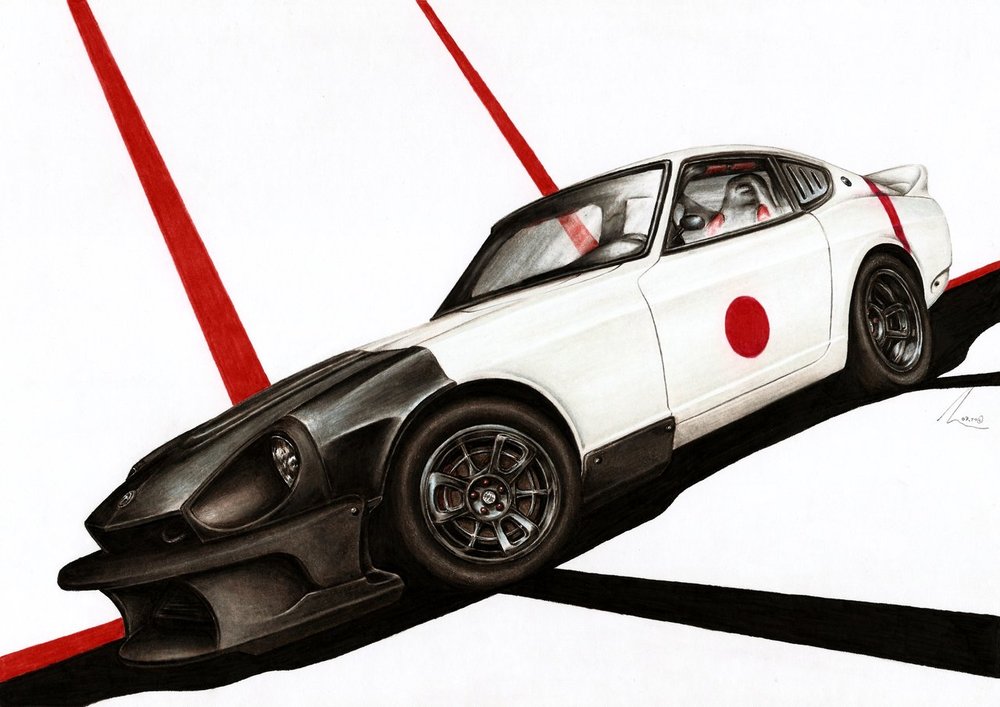

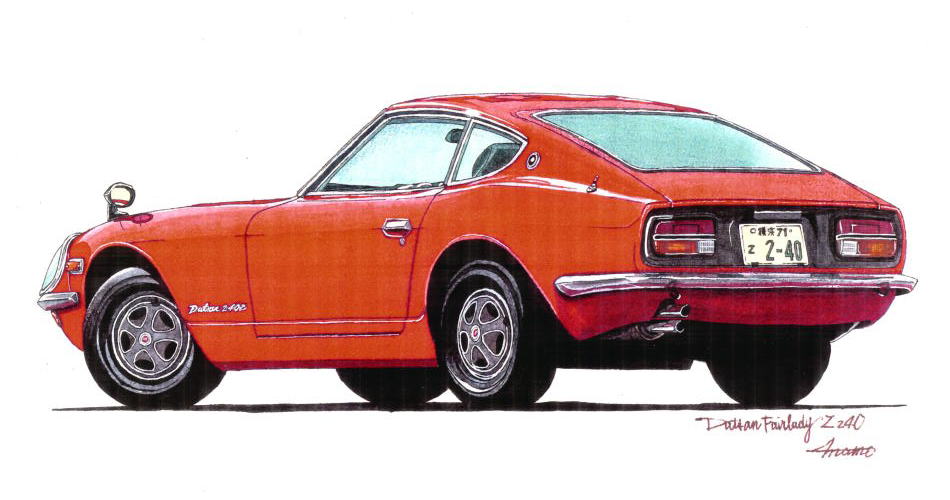

A touch of art

-

A touch of art

-

Trouble tuning SU carbs

12-13 at idle is stinky. 16.5 up a hill is lean. That is the catch 22 you have to deal with. You can enrich the jet at the sacrifice of idle and cruise.

-

A touch of art

-

Mama's new Z

Good choice in colour too! Congrats to S.

-

Trouble tuning SU carbs

You are stuck with having to reshape the needle or buy new ones.

-

Datsun-240z Vs Fairlady-z432

Well the only items in the vicinity are bumper, gnose, lights, horn, and radiator. I think the part pre-dates the gnose so that is crossed off. Bumper reinforcements also came in late 74 so that could be ruled out. As Kats said it seems too big and structural for just holding horns. As well it is not on all bodies so that is another part of the puzzle. For this it would make more sense to be part of an option like AC rather than for factory alignment (which one would think to be on all bodies). Sometimes oil coolers are hung out there... could it be for that? Or maybe it is a mount for some sort of front accessory... snow plow, bike rack, rally fog lights, a really big hood emblem,?

-

Datsun-240z Vs Fairlady-z432

Kats, I forgot that @Captain Obvious made a discovery that the small pistons in the damper plunger can cause problems with binding. You may want to simply unscrew these plungers and swap to see if the problem moves with the plunger.

-

3 screws round top SU CARB tuning correct or not?

Air/Fuel O2 measurement is best method.

-

Thinking about installing an BMW M6 engine in my Z

The anvil slipped onto the accelerator pedal and the car shot through the wall like a scaled cat. It was last seen in Kingston heading east.

-

3 screws round top SU CARB tuning correct or not?

I agree. A great tool is a timing light with built-in tach. and advance. I use mine all the time.

-

Windshield Sealant

I applied the thicker sealant in the channel that takes the pinch weld. You can use a small long-nose bottle of the fluid stuff to place under the lip touching the glass after it is installed to finish the job. Better to be safe as a leak has to work through the dash then puddle on the floor and not evaporate before you usually notice it.

-

3 screws round top SU CARB tuning correct or not?

2000 is just a ball park to give the engine a bit more air and speed. Go as high as you feel comfortable with. The key is to make sure they have the same air flow then adjust the fuel jet height to make sure they each drop to the same RPM. It is iterative so you have to repeat a few times to get it dialed in.

-

brake proportioning valve

GnoseZ gets his testing skills from a driver that often goes on the dirt shoulder to make things tougher on the guys behind him thus the dirt road testing.

-

3 screws round top SU CARB tuning correct or not?

Try the piston lift experiment but with the engine at 2000rpm (use the fast idle screw in the middle of the carb linkage to get the 2000 rpm). If both carbs are getting the same air and same fuel, the rpm drop should be the same when you lift a piston. Note: 1. SU's are air balanced at idle using the stop screws on each side of the carb and a flow meter. 2. SU's are air balanced at 2,000 to 3000rm using the screw in the linkage near the back carb (the back carb's air is matched to the front carb). 3. The fuel is matched by jet height and needle shape.

-

Weber selection and initial jet tuning

I'm lost on the bolts in the bowls part. Replace the exhaust jets with bolts? Aren't the 00 jets basically a block already? I believe the 00 means there is no bleed black hole so the accel pump chamber (under the piston) can only empty into the throat of the carb. It can not "bleed back" into the fuel bowl. The trick to disable the accel. jets is to replace this component at the bottom of each fuel bowl with a small bolt. By doing this, no fuel can flow into accel jet passages. Note: at high RPM's the strong venturi effect in the throat can pull raw fuel out of the accel circuit. This scavenging effect can enrich the higher RPM part of the curve so it is good to tune w/o the accel circuit first then tune it last to see what impact it has on transitions and also at high RPM's

-

Did I Just get ZONCed?

Mail is a standard. Email is a standard. Facebook is a company......that has nearly fooled everyone.

.gif.11dcb3e694ba0e374392af2f1480b8bd.gif)

.jpg.1e739a145bf849185372adaefd4f76b9.jpg)