Everything posted by 240260280

-

F54/P79 Swap Project

Nope. I disagree. ?

-

F54/P79 Swap Project

Nope. The fact the chain is not constrained nor the cam constrained nor the crank constrained along with many teeth pulling as a team seems to be confusing you all.

-

L28+(maxima)47 build

Exactly, it is hard to build pressure on the compression stroke when the exhaust overlaps and leaks your effort.

-

F54/P79 Swap Project

Just think if you could stretch the chain so that only 10 links were between the cam sprocket and the crank sprocket rather than the ~42? You would have 32 extra links now on the slop side and it would be quite obvious. I am talking about tension to put sprocket back on when advancing the cam ON THE CAR. I have done it about 10 times and it "seems" like there is more tension. This is what @siteunseen described. It is relative and not real. I have also put sprockets on 4 times when rebuilding engines and it is no problem as the tensioner and guides are not in place. Of course the tension on the chain varies as the engine runs when the valve springs compress and unload but we never discussed this. Our discussion is on advancing the cam timing. When you hand crank at the snout with a 27mm socket, you can feel the variations due to the valve springs.

-

Car wont run triple webers

These work too:

-

Car wont run triple webers

What are the idle jets, main jet, main air corrector, and choke size? This works for a higher compression L24: 40DCOE151 (3) 30mm Choke Fuel Height: ~30mm down from top of body Idle Jet: 55F9 Enrichment Screws: 2.25 turns Emulsion Tube: F11 Air: 170 Main: 120

-

Mr.Uemura wrote a book "making story of a Fairlady-Z"

OK so that explains the apparent M180 Engine Lineage. It was a tribute/replica-like borrowing. Now we know the complete story! Interesting the development went L6 >> L4 >> L6.

-

Car wont run triple webers

Is it a 2.4, 2.6 or 2.8 litre engine?

-

F54/P79 Swap Project

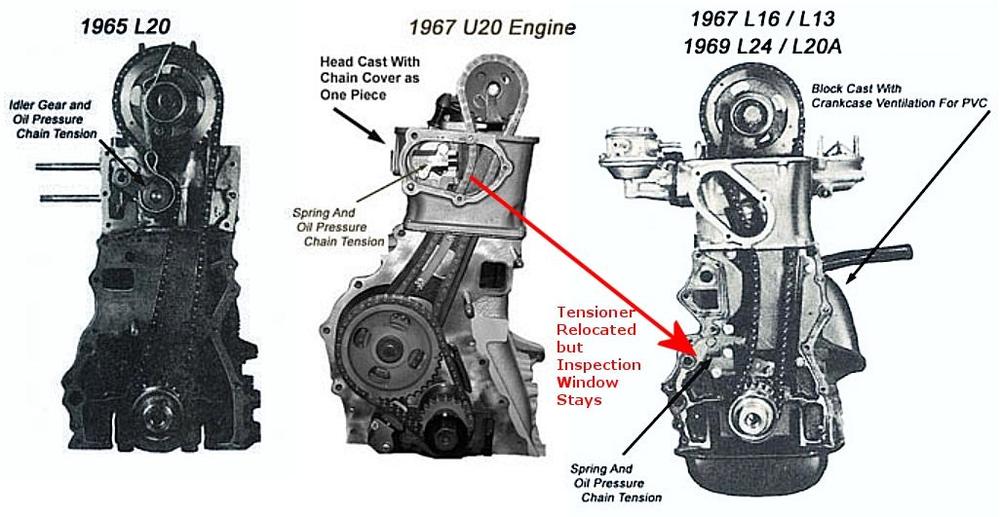

You can see the evolution of the tensioner position on Nissan engines. Thanks to @Carl Beck here: http://zhome.com/History/LSeries/LSeriesR1.htm The inspection plate on the top seems like the tensioner was going to be placed behind it but it was later moved lower.

-

Car wont run triple webers

Initial Tuning of Weber DCOE or other Side Draft Carbs What are the model and series numbers on each of the 3 carbs? e.g. 40DCOE151 Important: Make sure fuel level is same on all carbs. Ignore any web sites that say 25mm down from jet bridge as fuel will spill into carb throat. ~ 29mm down is where to aim according to many sources. Idle Balance: 1. Set all the idle enrichment screws to the same number of turns out. If you have 151's (made in Spain) then turn all the 6 idle enrichment screws all the way in then each turn out 1.75 turns (1-3/4). Also close the air bypass screws. If you have others (made in Italy) then turn all the 6 idle enrichment screws all the way in then turn out 0.75(3/4) turns 2. Warm up the car, disconnect the 3 push rods, and then adjust the idle air flow for each of the 3 carbs. measure the flow to all 6 carbs adjust the idle stop on each carb so that all 6 are equal in air flow. if the flow between two throats is different on the same carb AND you have 151's then us the air-bypass on the lower flowing throat to increase its air flow to match its partner. if the flow between two throats is different on the same carb AND you have non-151's then you may have a bent throttle shaft and drilling a small hole in the lower flowing throttle plate can bring back the balance. (Don't do this until you take carb apart and inspect for other possible problems like throttle plate wear, etc.) Off-Idle Balance: 1. Install throttle arms and make sure they do not push on carbs so as to increase idle rpm or air flow. These arms should have no influence at idle. You can do this by not tightening the three throttle arms at the main throttle linkage bar on the manifold until all push rods are attached to the carb lever arms. 2. Have a way to solidly turn and hold the linkage to off idle ~ 2000 rpm and measure air flow. 3. Note the carb flowing the least and use the turnbuckle adjuster on its push rod to extend the push rod so that the air flow increases. 4. Loosen all push rods at main throttle linkage bar and repeat #1 to #4 until the off-idle is as balanced as you can make it. The next tuning steps are to get jets and air correctors right. You need an a/f wideband O2 setup to do this precisely otherwise note engine note, plugs, and driving and adjust to taste. We can give suggestions for jetting if you share engine displacement and mods.

-

Source for BRAND NEW Gear Reduction Starters

I guess the crap ones should be called stoppers.

-

F54/P79 Swap Project

Nope. Distance and tension are not the same. When you take up the slack by rotation change of the sprocket, there is less chain under tension between the sprocket and the crank on the drivers side, so there is more chain under slack on the passenger side. . It is a bit confusing as there are many teeth grabbing the chain at the same time and it is continuous. An easier way is to think of the chain as a string tied to a fixed crank. When you go from 1 to 3, you are pulling tighter on that string so the excess string falls behind the puller on the slack side. For an observer working from the top of the engine like @siteunseen did, moving the sprocket from 1 to 3 while keeping the crank at TDC, it appears that the chain is getting tighter but this illusion is because they can not observe the resultant extra slack hidden inside the timing cover area. For an observer like @Captain Obvious with the timing cover exposed, they can see they are making more slack and the tensioner is protruding more to correct it. See it is special relativity and is dependent on the viewer ?

-

F54/P79 Swap Project

FYI I did the same thing years ago when everyone said you needed Head Saver Shims. It seemed to me they were not needed from the geometry. I found one person on zcar.com who did what I thought and that was enough to try it. No problems after I did it. If you have a hot cam, the shaving will bring the valves closer to to piston top so that is the only case where the shims may be helpful.

-

F54/P79 Swap Project

There is less chain under tension on the tight side and more on the slack when you take up the slack (as mentioned above). You can tighten by one whole link if you want to push to more easily understand what I mean and why @siteunseen found moving the sprocket to seem like it tightened and took up slack. Don't think of it as quantized to number of links.

-

Source for BRAND NEW Gear Reduction Starters

Good find. Will some parts interchange? It would be nice to transplant some Japanese metal and electrics to replace the Chinese risky metal and electrical bits.

-

Happy 2019! A lot of 50 year milestones coming up!

@lonetreesteve have a look at this thread: https://www.classiczcars.com/forums/topic/56826-hls30-00006-at-the-crusher/#comments

-

Cataloging 240z factory manufacture paint marks

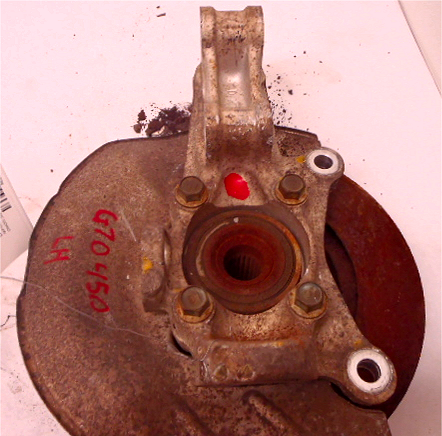

I'm replacing a few parts on my Honda Insight and they have also have yellow dabs to show "fastened correctly". Makes me smile ? When I do work, I now use a yellow paint marker. Works nicely when double checking. https://www.princessauto.com/en/detail/pen-paint-yellow-bright/A-p8848145e Here is an ebay photo of an Insight Steering Knuckle with yellow dabs (Red would be from Junk Yard):

-

Happy 2019! A lot of 50 year milestones coming up!

Sept 1969. Production was 9 domestics and two exports. It would seem these two exports align with testing in North America in October. These would be the two cars manufactured 50 years ago: HLS30-00004 (Silver and Manual) HLS30-00005 (Silver and Automatic) They were returned to Japan after testing in Dec 1969. No details on where they are now.

-

49ème salon de l'automobile (Bruxelles, 01.1970) First Z in Europe?

That is for sure! India is now the proponent ? https://www.ebay.com/itm/CAR-BADGE-DATSUN-Z-SPORT-240-Z-CAR-GRILL-BADGE-EMBLEM-ENAMLED-BADGE-EMBLEM/163858687442?hash=item2626bd25d2:g:Ak0AAOSw5cJaqsF~

-

Mr.Uemura wrote a book "making story of a Fairlady-Z"

An I6 (L20) was first produced in 1965.( Reference). Planning, design, and development for this engine must have been in 1964 or earlier. S30 design and Nissan I6 are well aligned in time for anyone to say the obvious: "Hey lets put that big engine in that car!".

-

Piston on carb getting stuck

Try doing this without the needle in place and without the damper in place. Here are some causes of piston binding when dropping. 1. buildup of carbon on dome-to-piston margin. The piston binds in the dome. 2. mechanical alignment of dome (as @siteunseen addressed). The piston binds in the dome. 3. nozzle holder misaligned and hole centre does not align with needle. The needle binds in the nozzle. 4. bent needle. The needle binds in the nozzle. 5. debris in damper tube or damaged damper piston. The small piston in the damper assembly jams in the piston's damper tube. I am guessing #3 or #4 is your problem.

-

F54/P79 Swap Project

@siteunseen @Captain Obvious I believe both of you to be correct. Adjusting the Cam Sprocket makes the chain feel tighter and more difficult to install on the Cam nose; so it seems like taking up the slack when doing the operation. It however, puts more chain on the slack side of the assembly. Moving the chain guide inward takes up the slack by making the chain run along a longer path. btw when moving the cam spocket, it is ok to turn the cam a degree or so as needed to help get the sprocket back on the cam nose.

-

49ème salon de l'automobile (Bruxelles, 01.1970) First Z in Europe?

I blame England on the Goertz Myth....started in 1970 and continued past 1995....over 25 years of it documented below!

- The Captain's Old Ride?

-

YUM Cooked Bearings! The good fresh kind