Everything posted by 240260280

-

I don't know what this is

It is a fuel pressure regulator.

-

Tool or materials to deep clean all the light bulb female sockets

Metallic Silver. Happy New Year!

-

Tool or materials to deep clean all the light bulb female sockets

1. Pull the assembly out 2. Disconnect wire from harness 3. Remove rubber seal around metal body 4. remove rust and treat metal. 5. paint metallic silver To refresh bulb socket, push the wire through from back then clean the centre contact. Push back in then clean sides with wire wheel or abrasive.

-

Interesting 1973 E88 240z head info

Looks nice. No corrosion evidence at water passages...that is a nice head!

-

[2018] What Did You Do To/with Your Z Today?

Whooohoo! 2018. I almost remotely controlled* my neglected 280z into the garage for its refresh but the Ridgeline developed an oil leak so it went in the garage... -15C outside. I'll have the truck fixed when the stores open on Tuesday then ol' Blue goes under the knife/welder. An experiment in rust. * walking beside it while pressing a remote starter and the transmission in 1st gear.

-

Tool or materials to deep clean all the light bulb female sockets

If the metal you are cleaning is solid then any brush will work. If the metal you are cleaning is plated, a correct chemical solution for saving the plate and a plastic brush is best. "Chemical solutions" would be metal polishes for brass, nickle, etc.

-

Caswell Plating

Physics: 1. Charged particles take the shortest path (thus the shadowing effect). 2. Charge intensity varies across non-uniform surfaces. 3. Charge is stronger at edges/points (related to #2 above). FYI: By using a rolling drum in a bath, the parts move randomly and the charge intensity on the part surfaces is always changing so there is less shadowing effect and less edge effect. A rectangular bath solution with a stationary part could be optimized by: 2 zinc plates running end to end and crossing in the middle bottom then running up the walls. The power supply output would connect to the middle of each side/plate (split it 4 ways). The part to be plated (if big and odd shaped like the throttle shaft) would need two or more wires connected to it and turned occasionally As Nix says, a circulation of the electrolytic will also redistribute the zinc ions so there are no pockets of depleted solution. An alternative to this would be to move the part in the bath. A string connected to a disc on a motor could lift the part up and down within the solution (or it could lift one side of the hanging rod). Some use an aquarium bubbler to mix the solution.

-

HLS30-07848

Could be corrosion through front cover behind water pump.

-

Interesting 1973 E88 240z head info

Thank @Lumens for sharing the TSB's. Glad to be the messenger. I look forward to meeting in October!

-

Tool or materials to deep clean all the light bulb female sockets

You can get copper pipe cleaners at most pluming shops for a few dollars: https://www.homedepot.com/b/Plumbing-Plumbing-Tools-Brushes/N-5yc1vZbqnb

-

Tank mod: Pros and Cons?

-

Tank mod: Pros and Cons?

I want to do two things on my 280z: 1. Hide gas tank from view from rear. 2. Run exhaust straight to back below rear license plate. Here is a crude scratch pad idea... a bit of Opel GT I am currently planning the tank and one idea is to have the bottom thinned so that it tucks up higher under the rear valance. The modded tank will also fill both areas behind the wheel wells (now that the driver side exhaust will not be located there). This will regain some of the tanks volume. A vent on the driver's bulge will need to feed back to the passenger side. A heat shield between the exhaust and tank above may be suitable for heat issues. Thoughts?

-

Taste like Two Fingers to me!

Happy New Year!

-

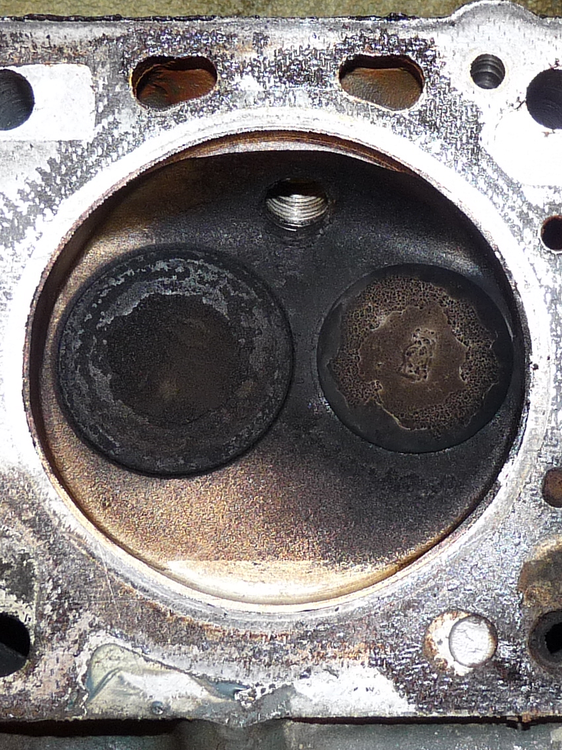

Interesting 1973 E88 240z head info

Below is photo of stock E88 combustion chamber from an earlier 260z. It seems to have the deeper pocket for the piston. I wish I cc'd it. It is now at machine shop getting 1mm shave and valve job. I'll check deck height soon. The pistons do not have fly cuts however the link below shows 260z pistons with fly cuts and 38.1mm compression height. I wonder if the odd pistons were for 73 and part of 74? https://www.uempistons.com/index.php?main_page=product_silvolite_info&cPath=6_25_27&products_id=1533 The carpartsmanual site is not clear on dates: http://www.carpartsmanual.com/datsun/Z-1969-1978/engine-240z-260z/piston-crankshaft The 1973 FSM gives a compression ratio of 8.8 to 1 so working backwards the volume of the 1973 E88 is ~49cc.

-

#305 on Bring a Trailer

Take a look at old posts by @26th-Z and @Mike B They are resident 1969 experts on this side of the pond.

-

#305 on Bring a Trailer

I have #249 with all of the '69 goodies including original glass. Slowly gathering parts for #147.

-

Fender removal

yes, that will work. The weld heat will break the corrosion.

-

Interesting 1973 E88 240z head info

Shhhhhh!

-

Fender removal

As Patcon says, a penetrating oil is best. WD40 is a light oil for displacing water (WD = Water Displacement). A penetrating oil has a penetrating fluid that weeps into the threads and carries the oil with it. A 50:50 mix of ATF and Acetone is a good home-brew. I like Liquid wrench over PB blaster. If you have a high current/wattage soldering iron you can place it on the head of the bolt and heat it up for 10min then cool with the penetrating oil to break the crusty corrosion.

-

Fender removal

Try some liquid wrench penetrating oil.

-

Interesting 1973 E88 240z head info

Hi Guy, I pulled a few measured values from some reputable builders on line and included in the engine planner: Nissan HG was measured at 1.14mm and 1.20mm by "Phred" and 1.25mm by "Zya" both are great Z builders. Felpro was measured at 1.15mm by "Braap" and 1.20mm by" @madkaw" likewise experienced builders. Ishino was measured at 1.00mm by @Lazeum. Weber and engine expert from "The Continent"! I have an L26 HG that I am about to measure to add to the mix. Any data from your engine building is welcome! Here is what you should be able to assume with closest proximity: 1.00mm Ishino 1.15mm Felpro 1.15mm Nissan

-

Interesting 1973 E88 240z head info

You can use it here: http://www.240260280.com/Tech/Engine/Planner/S30 Engine Modeller V3.html You can manually enter bore, HG, thickness etc. if your configuration is not there. I'll also add parts or correct parts as needed. Just PM me.

-

Interesting 1973 E88 240z head info

BMC in Arizona state 0.7mm to be the target squish. They did a lot of work with Maxima N47 and P90 heads. Note that Rebello recommended 0.9mm to be the target squish. Valves colliding are more dependent on the cam however they must always be considered and checked during assembly.

-

#305 on Bring a Trailer

It was blue with black interior. Lots missing (hood and hatch) and welded on (front clip). Chassis and doors are original. Engine is now L26 but I picked up a 1969 engine and transmission in Florida to go in it.

-

JDM Headlight cover difference.

Kats could easily open a parts museum.