Everything posted by inline6

-

Restoration of BringaTrailer 240z - HLS30-35883

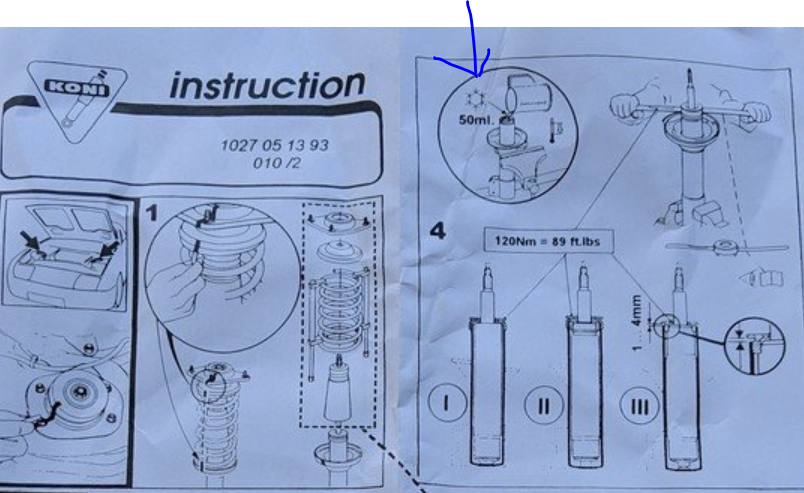

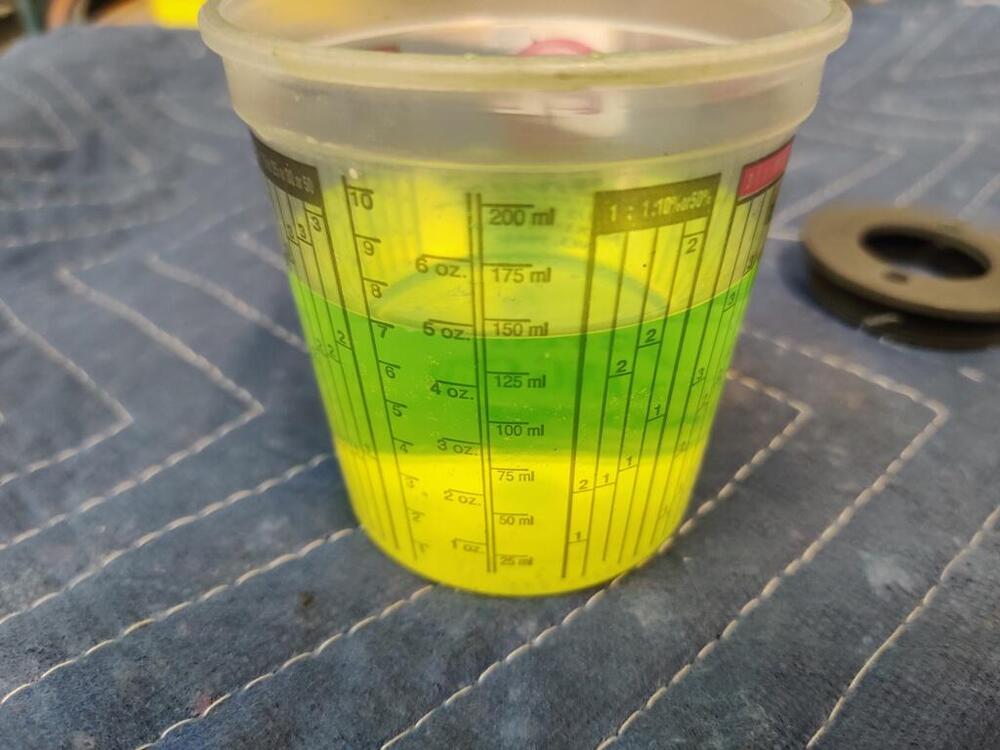

Ok, I will switch to oil. That is easily done at this stage. What types are typically used? The instructions show a picture... with a snowflake, and "50 ml" and a pitcher. Only thing that came to mind looking at the snow flake was anti-freeze. I assumed that heat transfer would be better with coolant, and that rust would not be an issue because of corrosion inhibitors in coolant.

-

Restoration of BringaTrailer 240z - HLS30-35883

I have not. Thanks for the suggestion. I will see what I can find out from places that are nearby.

-

Restoration of BringaTrailer 240z - HLS30-35883

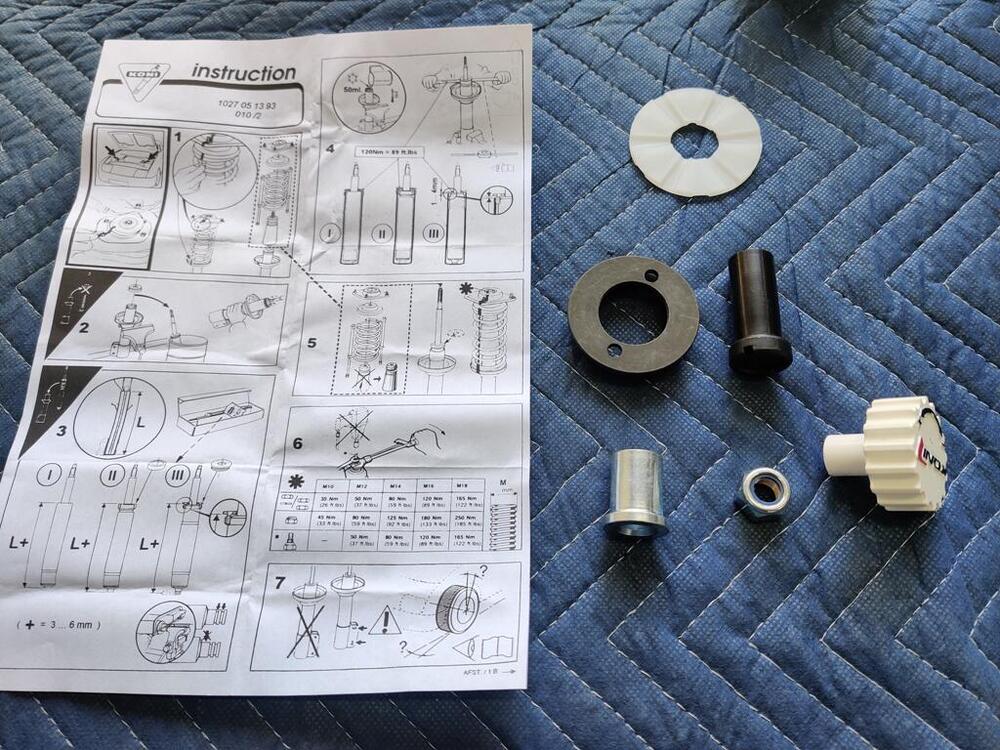

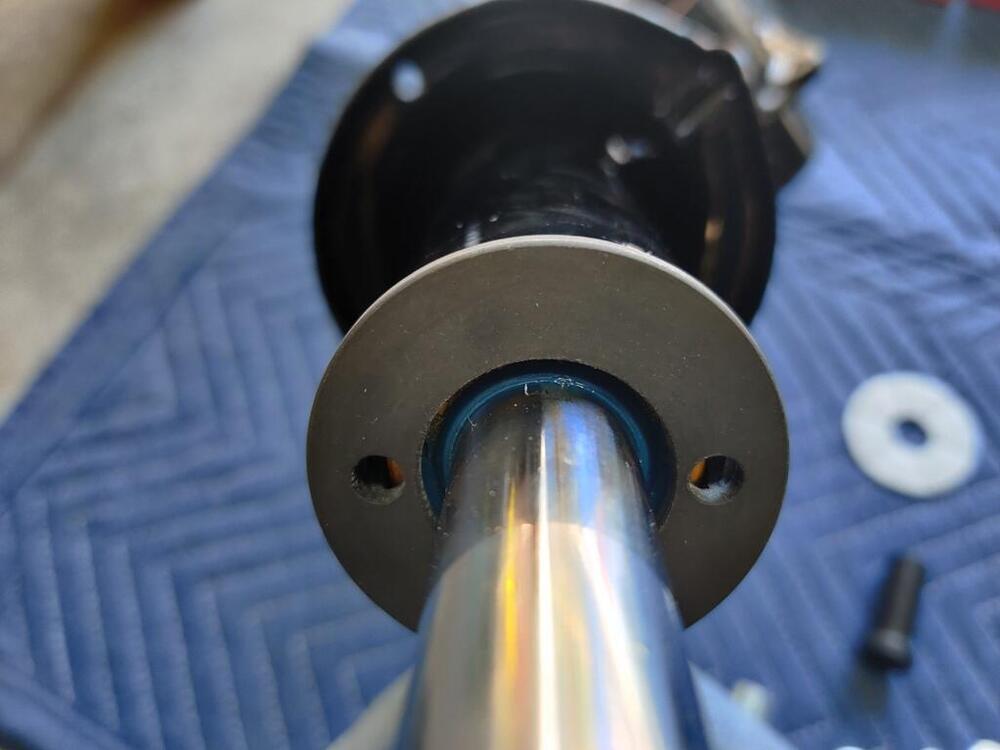

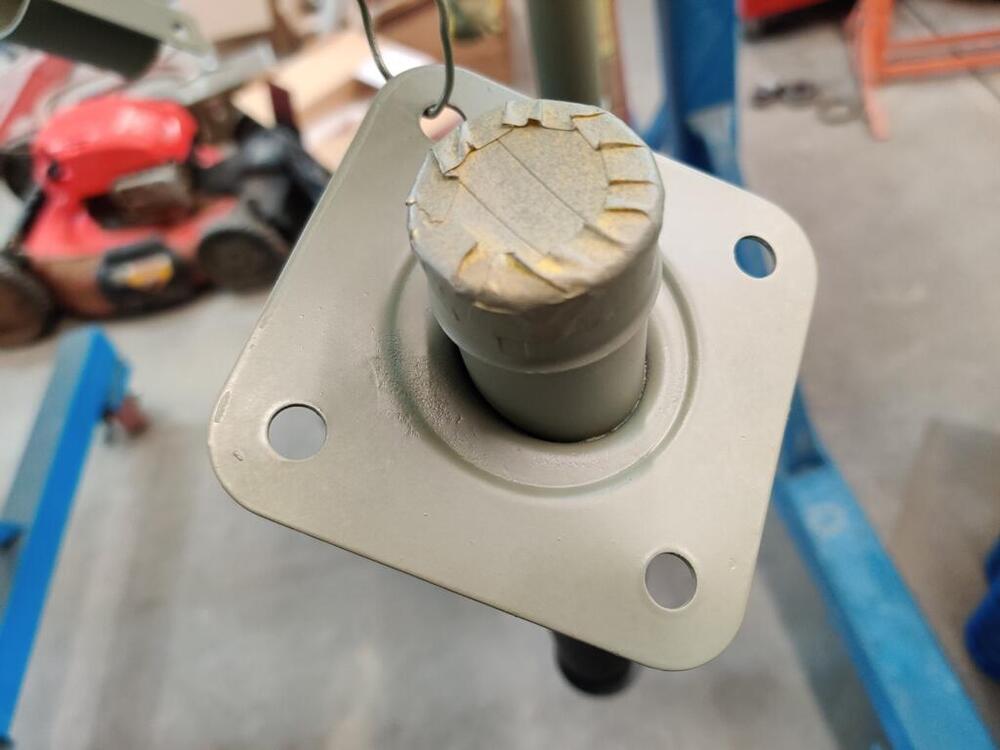

I ran into another issue with getting the engine and transmission in the car last week. None of the clutch throw out bearing collars in my possession were the one I need for this 240z clutch kit. So, I ordered a new one and I am waiting for that to arrive. So, yesterday, I switched over to suspension assembly. I bought the new Yellow Koni's for this car (see the linked thread below). The instructions... do not have any words. Manufacturers save on writing and translating when they do this, but I don't like it. It is not clear to me, in some pictures, what they are communicating. I was surprised to see that the "gland" nuts supplied with the Koni's do not have flats on the sides - they only have two holes in them. I have never encountered gland nuts like this before. I wasn't considering this, and got stuck with having to spend a good bit of time making a tool to deal with these. Essentially, I had to take a thick washer, drill corresponding holes in it, run bolts through the holes, weld those in place and then attach 1 x 1 bar to opposite sides of the washer. I started with the rear struts. Each one calls for 50 ml of non-freezing liquid. I used a 50/50 mix of distilled water and antifreeze. I think this helps with heat transfer from the Koni insert to the outer strut tube. I used two layers of masking tape around the shaft as a precaution to keep from scratching the strut shaft with the tool. After installation of the gland nut, the distance between the top of the strut and bottom edge of gland nut were just under the 1-4 mm specification. Switching over to the front struts, I ran into the issue that others have in the following thread. The insides of my front struts are clean and show no signs of any rust. However the gland nuts would only engage for essentially one turn of thread engagement. In the links below, you can get more context if you wish. I have contacted Motorsport Auto by email and asked about receiving modified gland nuts to fix my issue, as they did for Jim Arnett - @jfa.series1: So, a spacer/shim I think will be needed to assemble the differential is on national backorder with no ETA. No progress can be made on the differential. I am waiting for a throw out bearing collar to arrive. No progress can be made with putting the engine and transmission in the car. I am waiting to see if Motorsport auto can send me modified gland nuts. No progress can be made with assembly of the front struts, but I can continue with the rear struts. Today, I will pivot to the steering rack. Perhaps I can make progress there, and with further assembly of the rear struts.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

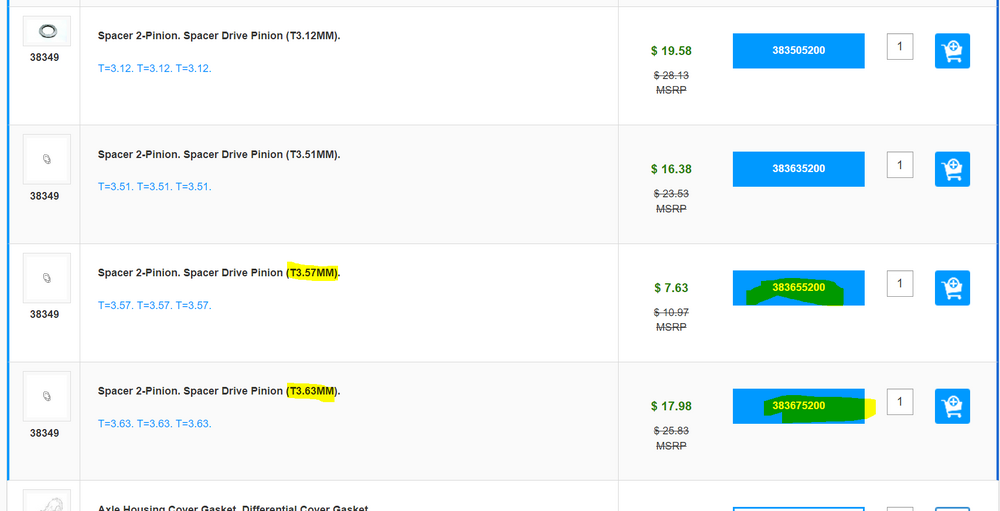

I have waited until I was in the right mood to pick up this project of fixing my back lash issue, and tonight, I was able to take this on. I removed the side flanges, then the one ring gear bolt, so the carrier would come out of the case, and then pressed out the pinion shaft. Rather than removing this bearing (the one in the pic) from the pinion shaft to get access to the washer/spacer (blue arrow) which is sandwiched between the bearing and the gear, I was able to user vernier calipers to measure the washer/spacer thickness. My measurement was about 0.141", (between 140 and 141 thousandths, really). Converting to mm, 0.141" is 3.5814 mm. Looking at what is available on a Subaru website, I found these part numbers: Since my measurement is nearly the same as the 383655200 spacer, it would appear that I only have one spacer which is thicker as an option available. 3.57 mm is equal to 0.1405". 3.63 mm is equal to 0.1429". So, order that one, swap it out, reassemble, and recheck gear lash?

-

Restoration of BringaTrailer 240z - HLS30-35883

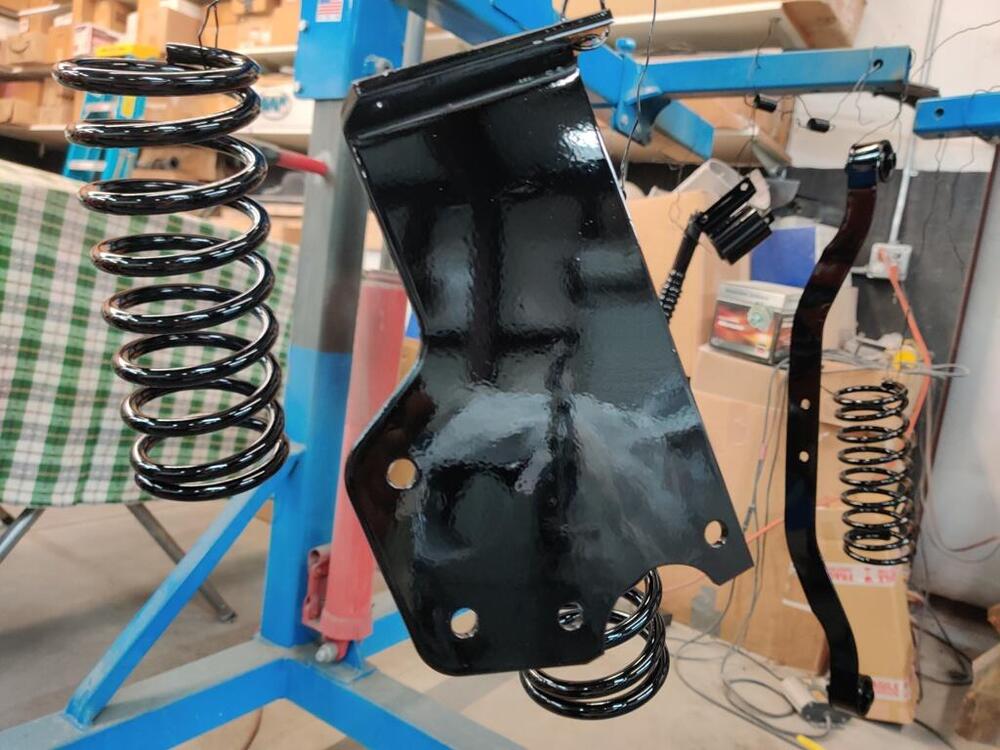

Another batch of parts are now gloss black: The difference between one and two coats is substantial. One coat just isn't sufficient. I didn't quite mix enough paint, so I had a couple of thin areas on a couple parts. I let them dry for an hour or so while I ate dinner and then mixed up some more and reshot the steering rack, transmission mount and the hand brake handle assembly. These Suspension Techniques springs come in a blue powder coat. I scuffed them with red and then green Scotch Brite pads before shooting them with black. Also, while I painted the original suspension "vertical hangers" black already, they will not be installed. Instead, I will be using these which came with the Suspension Techniques rear anti-roll bar kit. These were black powder coated, and I did the same scuffing before painting them with this gloss black. I continue to use 10% (by weight) of flattening agent with each batch of black that I mix up. I will let these dry overnight and tomorrow, hope to get the engine and transmission together and installed in the car.

-

Restoration of BringaTrailer 240z - HLS30-35883

-

Restoration of BringaTrailer 240z - HLS30-35883

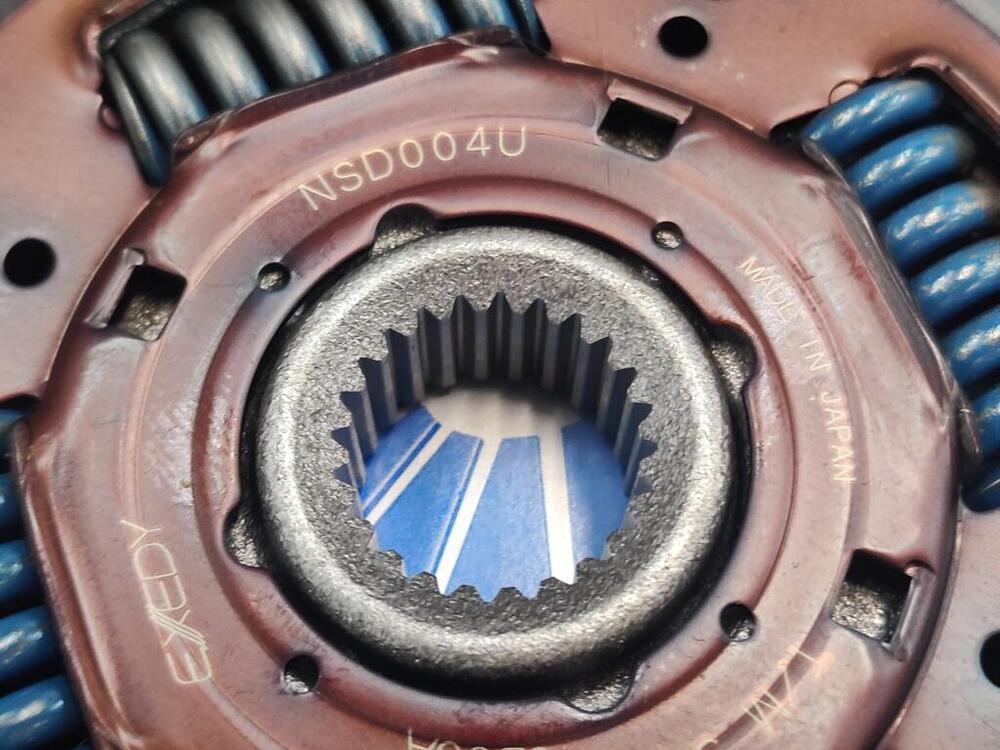

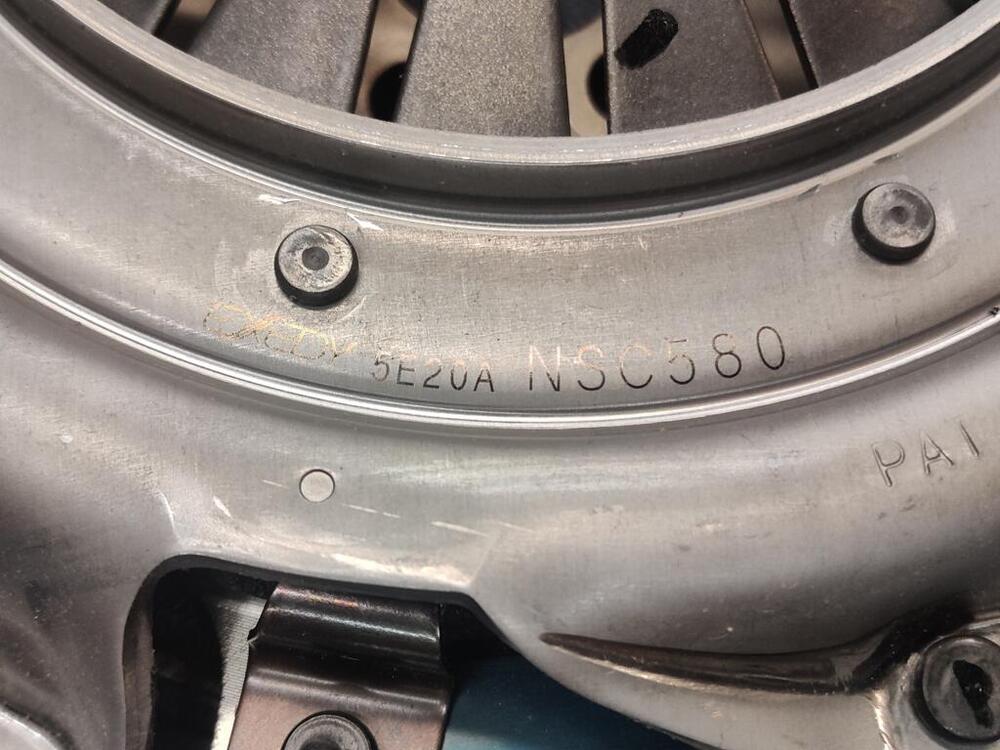

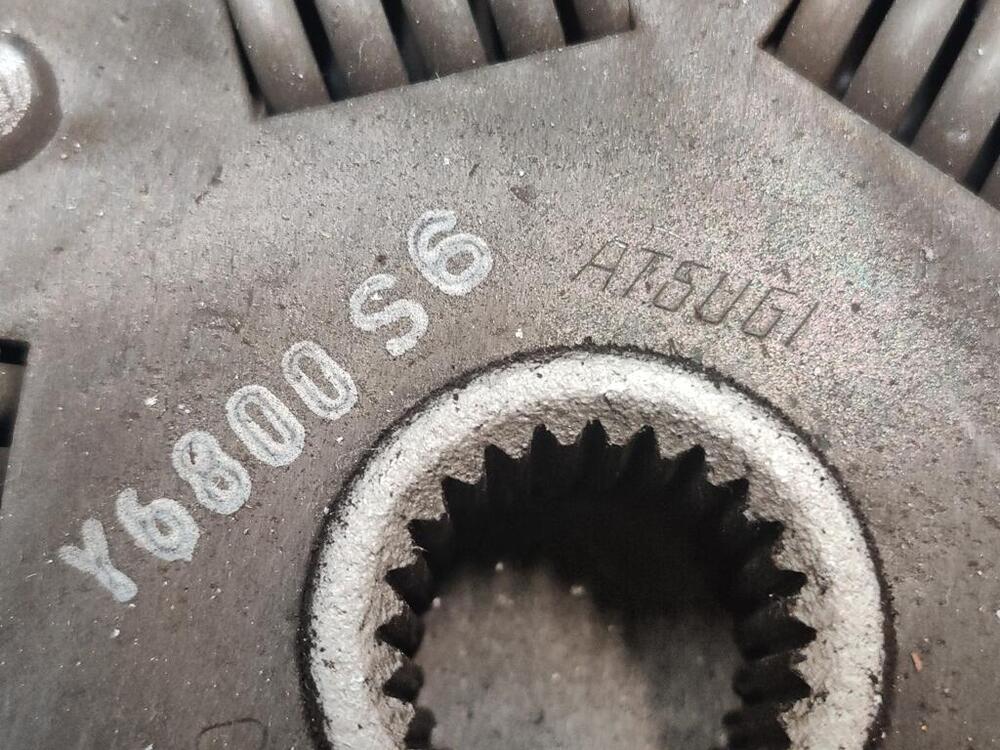

I got delayed with painting the next batch of parts black because I forgot that the gas tank needed a bit of filler work. Where I left off with the tank, I had used the pin welder to pull low spots. When done with that, I blasted the exterior of the tank with black diamond (lightly) to remove the black paint the radiator repair shop had refinished the tank with. Then I glass bead blasted the exterior of the tank to smooth finish. I epoxy primed the tank a few days ago, and planned to paint black about 8 hours later, but again, forgot about needing to do the filler work. I was held up from connecting the engine to the transmission because the flywheel needed resurfacing and while removing the pressure plate alignment dowels, they got destroyed. So, I had to order new ones. I was able to get the machining done this past week (along with having the rear drums turned). Some very shallow rust pits remain, but taking it down further doesn't look to be called for to me. I chose to go with an Exedy clutch kit. PP and clutch that I am replacing were manufactured by "Atsugi": I should be able to install the engine and transmission this weekend.

-

Chrome plater recommendations

It's time to ship off my chrome parts to someone - it is time to make a decision. So, I am revisiting this topic and wondering if anyone else has received re-plated bumpers from a place other than those mentioned that they would highly recommend? My consideration list currently includes: https://www.tricityplating.com TN https://www.redspartsattic.com TX https://speedsportchrome.com TX https://www.ogdenchrome.com UT Reds Parts Attic is a place I found looking on my own online. I got a nice email from the owner of redspartsattic back in July of 2022 - thought I would share: Thank you for contacting us for our chrome plating services. I appreciate the opportunity to earn your business. Our crew has well over 100 years combined experience. I know they will do a great job for you! Your parts will be plated using Copper, Nickel and Chrome. (TRIPLE CHROME PLATING) We go through multiple steps and procedures to achieve a mirror, chrome finish that will last. Not all chrome shops are the same, or complete the work the same way. We will treat your parts as if they were our own and not cut any corners. On our website you can view samples of our work under photo and video gallery. Please take a moment to read our previous customer testimonials. We take pride in customer service and chrome quality. We stand behind every order we do! Chrome Estimate: Bumpers with 2 guards - $1000 each Pricing will vary depending on your parts starting condition. Price includes minor straightening and dent repairs. We are currently running a 6 – 8 week turnaround time. Texas residence will be charged sales taxes. Price does not include shipping costs. I can provide you with a quote based on your zip code. We use FedEx and receive a discounted rate. I can provide you with a pre-paid shipping label. Please ask and I can help with instructions. You may package and ship parts using your own method. Please securely package and include all your contact information inside the box. Please email me your tracking information and I will personally keep a look out for your parts. Once parts are received I will contact you to discuss your order. Please let me know if any questions. I’m your main point of contact from start to finish. Customer service and communication are very important to me. I check and respond to my messages daily. Thank you for the opportunity to earn your business. Best regards, Joe DelVecchio Owner Phone: 713-299-1555 Call any time Email: joe@redspartsattic.com Website: www.redspartsattic.com Testimonials: Customer Reviews Photos: Photo Gallery

-

Restoration of BringaTrailer 240z - HLS30-35883

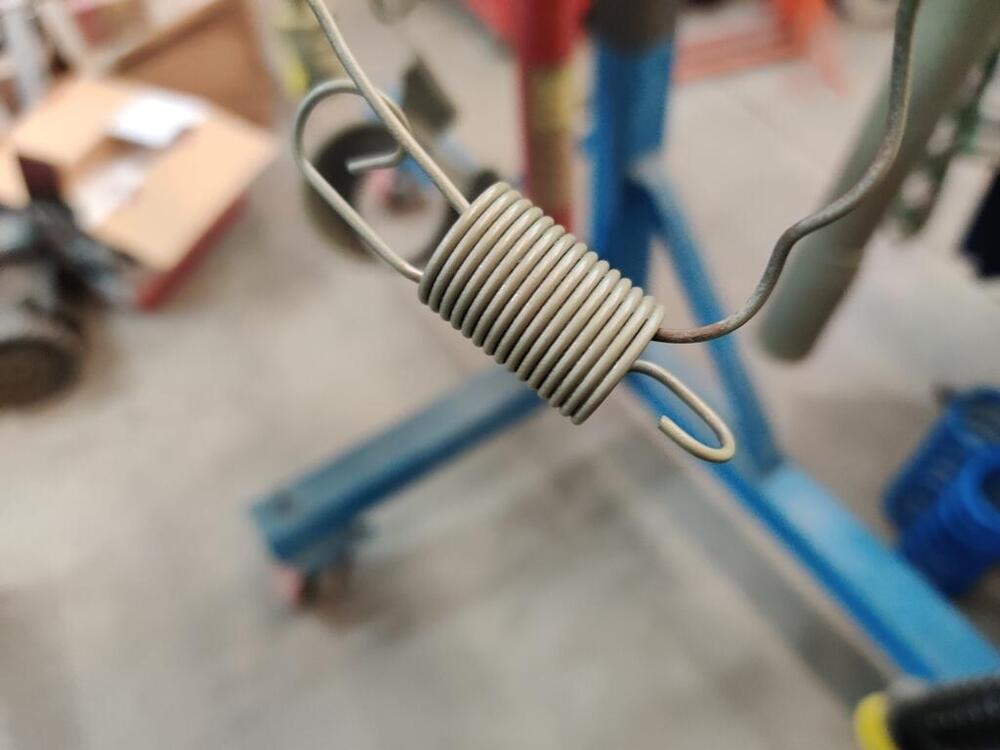

One of the last parts I needed to disassemble, clean, strip and repaint was the steering column. Taping up so I can glass bead blast without getting beads inside: Odd white (I think) paint blotch. I removed the plastic bushings, which were glued into place on the steering column bracket: Springs are for the handbrake cables. Epoxy priming session here is nearly everything that is left that I have yet to paint black: Gas tank - sand blasted - glass bead blasted and epoxy primed. Tomorrow, I will paint these and some other parts black.

-

Restoration of BringaTrailer 240z - HLS30-35883

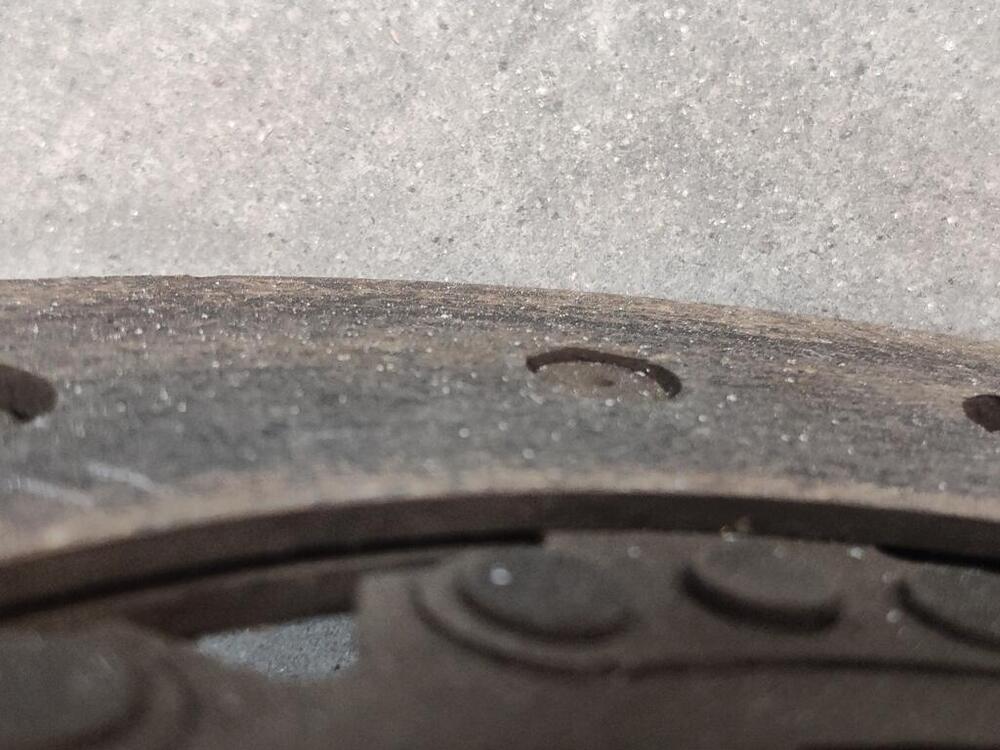

In addition to the black out, I had the drums "turned" and then I glass bead blasted them: Unfortunately, I previous owner banged pretty hard on them with a hammer around the outer circumference. But, that is not seen when the wheels are mounted.

-

Restoration of BringaTrailer 240z - HLS30-35883

Thanks guys! I had some fun this week end with some Krylon flat black paint. I sprayed it into a small cup and then used a paint brush to attempt a similar look with the "black out": Whoops on the runs and drips - ha ha ha 😆 Here are my original reference pictures: It was fun attempting to replicate the original "black out"

-

Restoration of BringaTrailer 240z - HLS30-35883

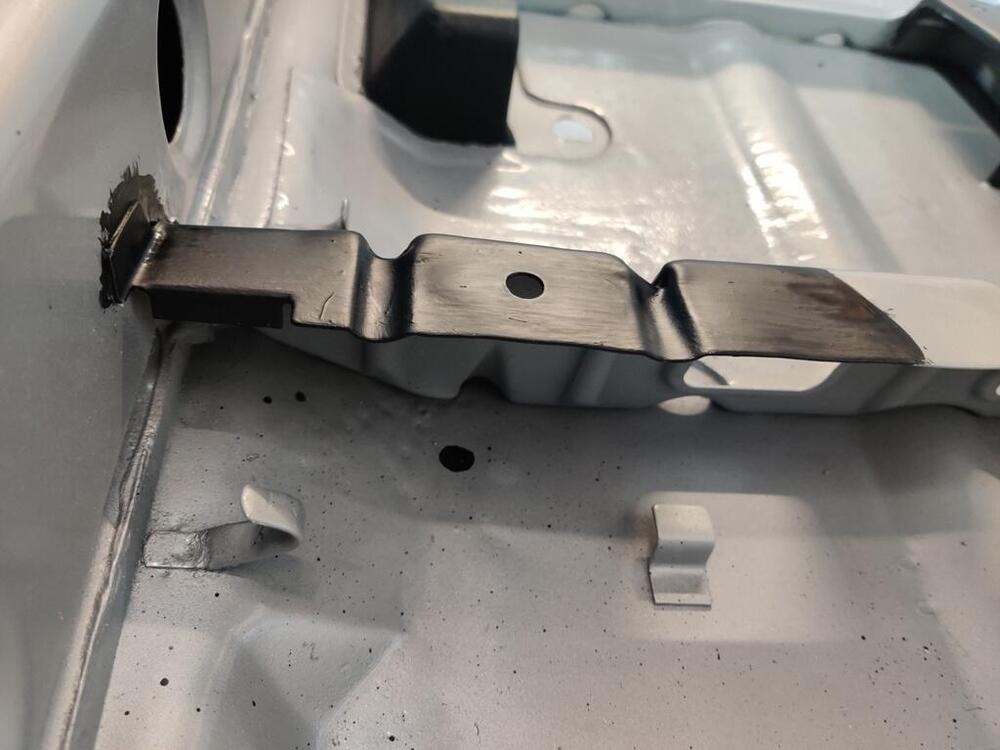

Thanks Steve. I will check those out. Tonight, I put the differential strap in. I reused the original differential arrestor strap. It is in decent shape - it even has original yellow paint dabs on it. One of the things that really excited me about this car was that it spent all of its time prior to my ownership in AZ/CO. The restored hardware is so nice - not pitted from rusting. As these parts go back on the car, some pictures capture the resulting "art":

-

Quaife LSD Installation in R180 - With Questions About Installation Also

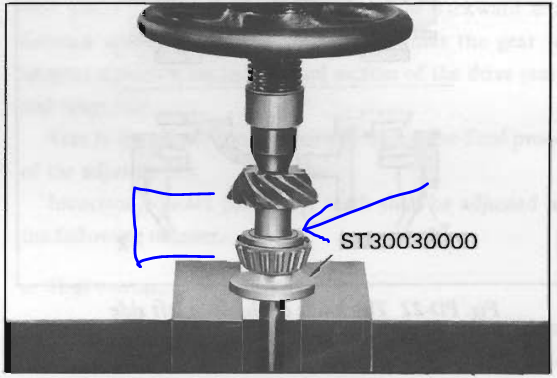

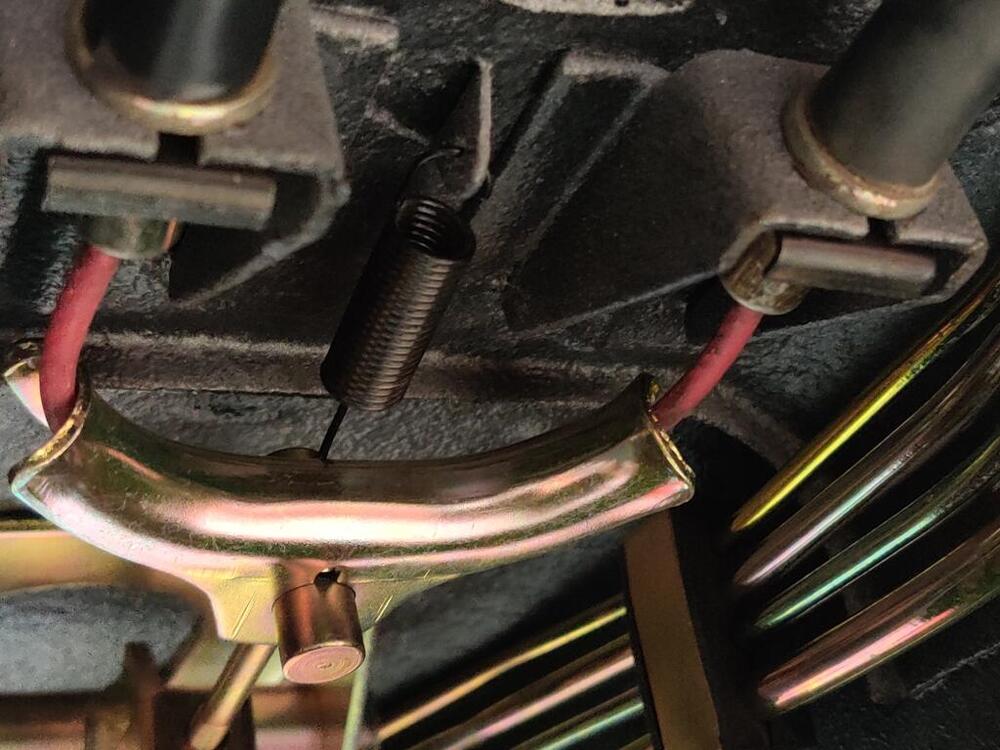

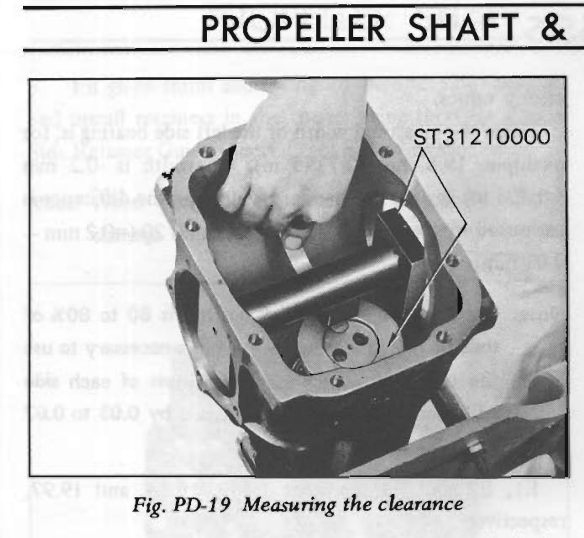

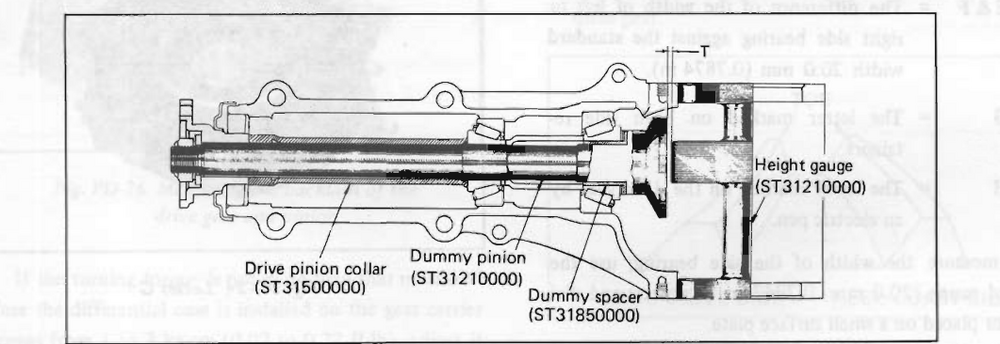

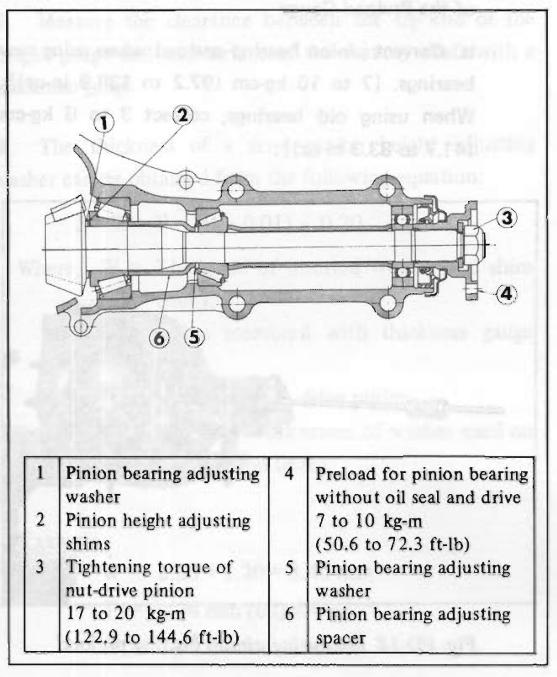

Picture 1 and 2 is using the standard method. Pictures 3 and 4 is just my idea to see if it is any more clear to see the contact areas. The pattern can be hard to see clearly. For what it is worth... here are pictures of the tools for setting pinion gear (height): There is a fake pinion shaft and a bar with square ends. The plan at this point includes removing pretty much everything and pulling the bearings off of the pinion to get to the washer that is #1 in this picture: There were no shims (#2 in the above picture) on this differential. There was only a washer. I need to measure the thickness of this and then either, add a shim (#2) of the correct thickness, or replace the washer (#1) with a thicker one. On Subaru websites, I see only spacers (#1) available: https://www.subarupartwholesale.com/a/Subaru__STI/49247923__6023356/DIFFERENTIAL-INDIVIDUAL/G11-195-03.html Nissan websites show both the spacers and shims as discontinued.

-

Restoration of BringaTrailer 240z - HLS30-35883

Nice collection. Those are the crush washers of course. The o-rings I am wondering about are inside the switch.

-

Restoration of BringaTrailer 240z - HLS30-35883

Ha! Good to know... as I reused the original aluminum crush washers too. I am less worried about those leaking now, given your experience with that. Thanks for sharing. Wonder if there is a way to determine suitable replacements for the o-rings...

-

Quaife LSD Installation in R180 - With Questions About Installation Also

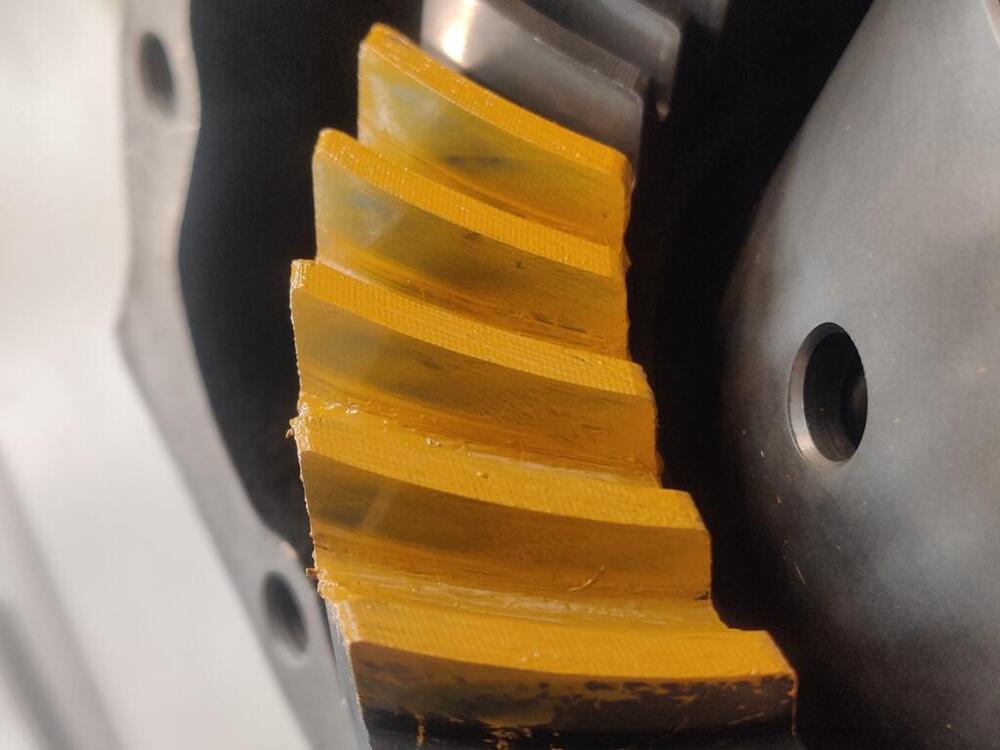

Tonight I backed the pinion nut off and reset torque to the low end of the specification. While I had done 135 ft lbs before, I did 124 point something this time, just a couple of ft-lbs above the 122.9 minimum spec. Interestingly, the inch-lbs of turning torque dropped from 14 to 10, which is much closer to the upper end of the turning torque specification. Keep in mind that I measured this with the pinion seal in place, which is not how the factory manual calls for that to be done. You are supposed to check the turning torque without the pinion seal installed in place, and then remove the nut, install the seal and torque the nut again. I think that is kind of ridiculous. So, I am willing to gamble that the 10 inch-lbs I am seeing with the seal installed is just fine. After doing that, I reinstalled the carrier and side retainers, and check the gear wipe pattern: front side of ring gear (first pic), back side of ring gear (second pic): The first pair of pics shows where I applied the yellow paint directly to the ring gear. I went back and forth through that with the pinion gear to get the first set of impressions. After that, I kept rotating the pinion gear around until the paint that transferred from the ring gear to the pinion gear made another set of marks on "clean" teeth on the ring gear. The transfer of paint from the pinion to the clean teeth on the ring gear is captured in the second pair of pics. What I see is "toe" contact on the coast side of the ring gear (first pic). And I see heel contact on the drive side of the ring gear (second pic). According to the shop manual, I will need to "increase the thickness of the drive pinion adjusting shim and washer so that the drive pinion is moved to the drive gear". As I see it currently, I'm going to have to remove the carrier from the case (which requires removing one of the ring gear bolts in order for it to clear the case), and to remove the pinion gear, and bearings so that I can add a shim of unknown thickness to shift the pinion gear towards the ring gear. If I guess wrong on the shim I install, then I won't know until I assemble everything again. If wrong, it all has to come apart again. I guess again... rinse repeat... I think I see hours of time and frustration for this little project in my future. Anyone have factory tools for me to use to get this thing set up properly without a bunch of hassle? Or ideas for how to save that time and hassle?

-

Restoration of BringaTrailer 240z - HLS30-35883

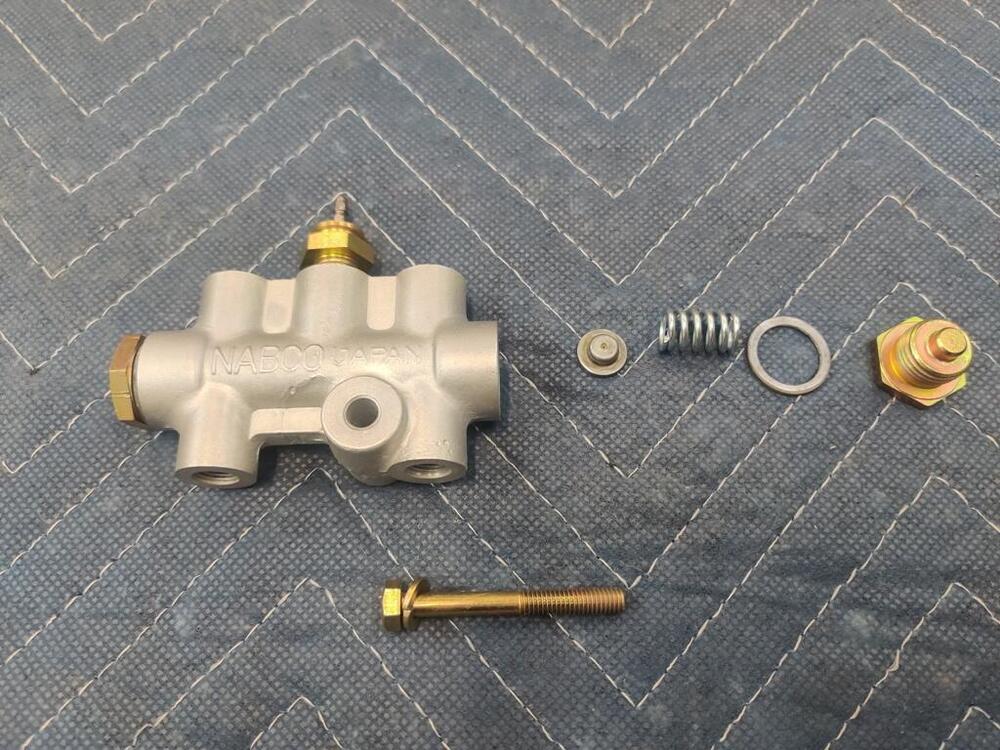

I think you are right - it is a brake light switch (not proportioning valve). That is the one that came with my car. I disassembled it, sent off a few internal and external parts to get them plated, and glass bead blasted the body. I glass beaded it at 90 psi to clean... and then another pass at about 50 psi to give it a smoother finish. Interesting. Maybe I will do the same for a measure of safety. Having brake fluid squirt all over the engine compartment and the damage that would cause... 🥶 I feel a little uneasy about reusing the original o-rings, but that is what I did. I don't know how to source suitable replacements that would meet the performance criteria?

-

Restoration of BringaTrailer 240z - HLS30-35883

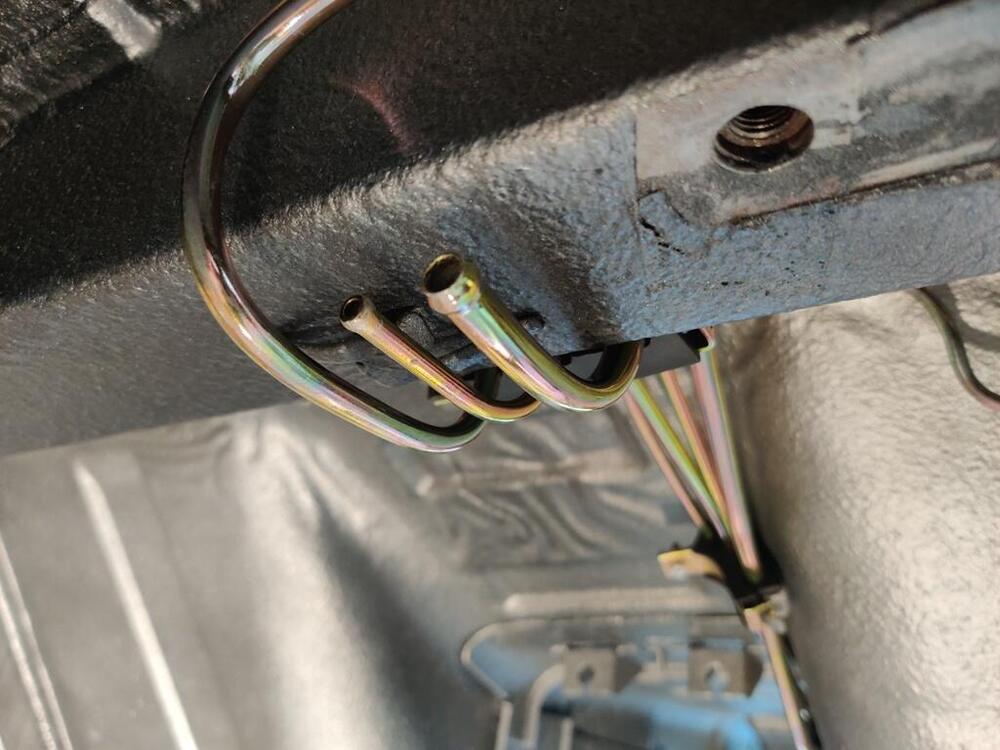

Thanks for the comments everyone. I have decided to use the new ones. I will think about how to check driveshaft alignment, and maybe I can report back what I find when I get to that part of assembly. Over the past two weekends, and for a few hours during the last week, I put my attention to the hard lines. I think it was @motorman7 that I got the tip from for bending the lines for shipping and plating. I used a welding gas cylinder as a "form" and bent the longest lines around it. The 180 degree (or so) bends in these are the result. Unfortunately, either during shipping back to me, or during the plating process, several of the lines got rather "jacked". The vapor tank vent line was especially messed up. I think I have about 10 hours in just straightening and getting the lines refitted, assembly of the brake proportioning valve, etc. I sourced all new rubber insulators for the hard lines from www.240zrubberparts.com. proportioning valve was disassembled, glass bead blasted, internal and external parts plated, etc. I am unsure if there is supposed to be a crush washer under the fitting with the electrical post. There is a rubber o-ring on the shaft of the plastic around the post, so I think that is the only thing that seals this "port". Crush washers are used with the front and rear yellow chromated fittings. As you can see, the vapor line is reaching for the sky at this point (above right). Left front brake line (first two pics) and right front brake line (third pic): Right front brake line from another angle, vapor line orientation corrected, and rear inlets of fuel lines (third pic): Beginning of vapor vent line, rear brake line, and "y block" and rear brake "delay" valve: I have several different things holding up parts of the assembly. I still have to resolve the differential carrier backlash issue. The flywheel needs to be resurfaced. I need to paint the steering rack case before I can assemble the steering rack. I have assembled a long list of reassembly items, specifically in the order I think is best. It is quite long. To share, I will put it into a Google sheet.

-

Restoration of BringaTrailer 240z - HLS30-35883

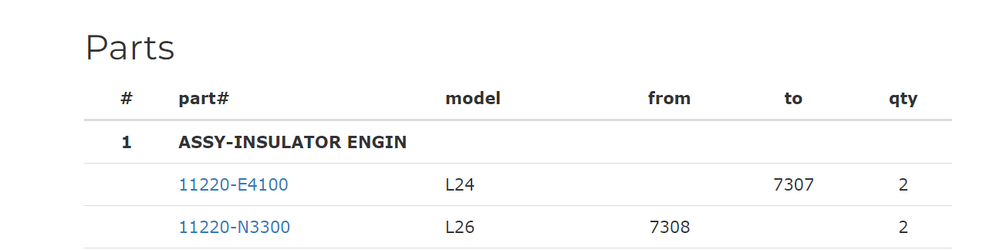

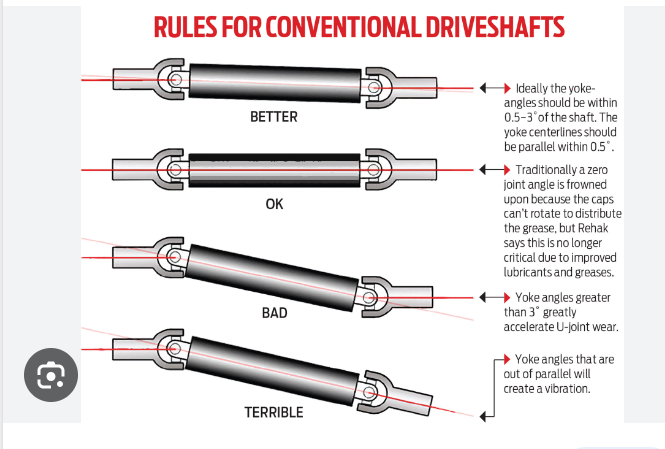

I did some searching for differences in the two OEM motor mounts: I found some discussions about aftermarket motor mounts and problems with them, but I couldn't find information from anyone who compared the two OEM variants. I have a hard time believing that the original rubber mounts have shrunk as much as the difference I measure here. It is certainly easier for me to use the new ones, as I don't have to prep the old ones. I do have one question though. When you raise or lower the engine, that in turn will change the angle of the transmission output shaft. How much will that matter? In theory, it would only change the angle of the splined front section of the driveshaft. I have seen pics where the angle of the front and rear sections of the driveshaft have to be like in the top of this picture: Worth considering?

-

Restoration of BringaTrailer 240z - HLS30-35883

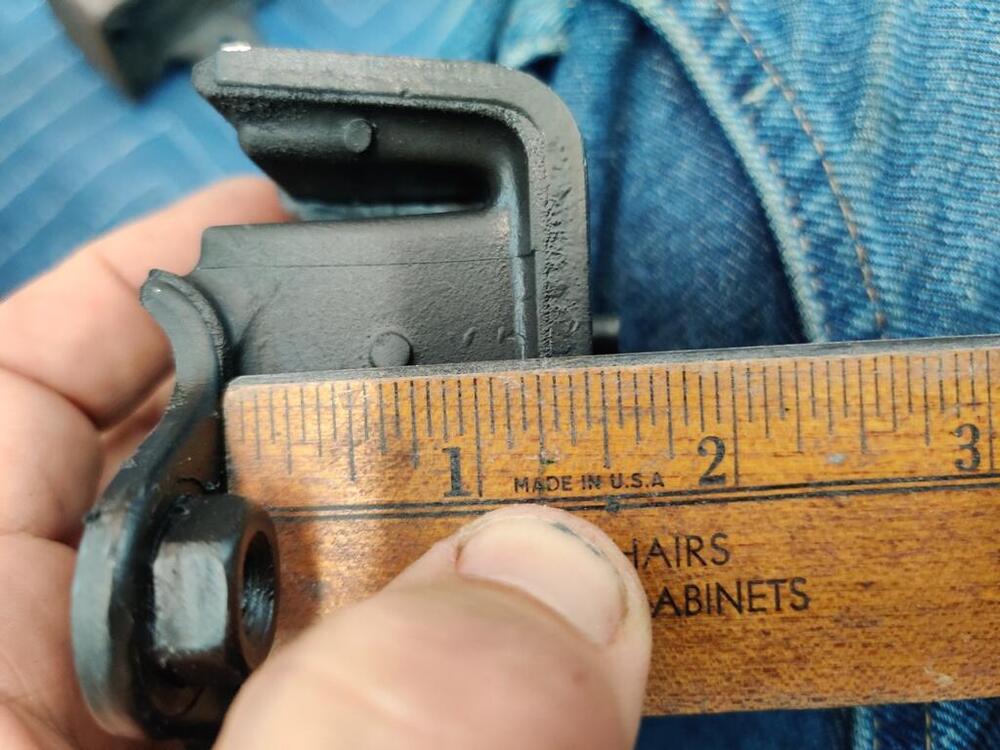

In looking at the new motor mounts I bought and comparing them to the originals, I see some differences. While I would have liked to use brand new parts here, unfortunately, they are about 1/4" taller than the original mounts. My originals appear to be in very good condition, so I will probably glass bead blast and paint them, and re-use them. New: Original:

-

Restoration of BringaTrailer 240z - HLS30-35883

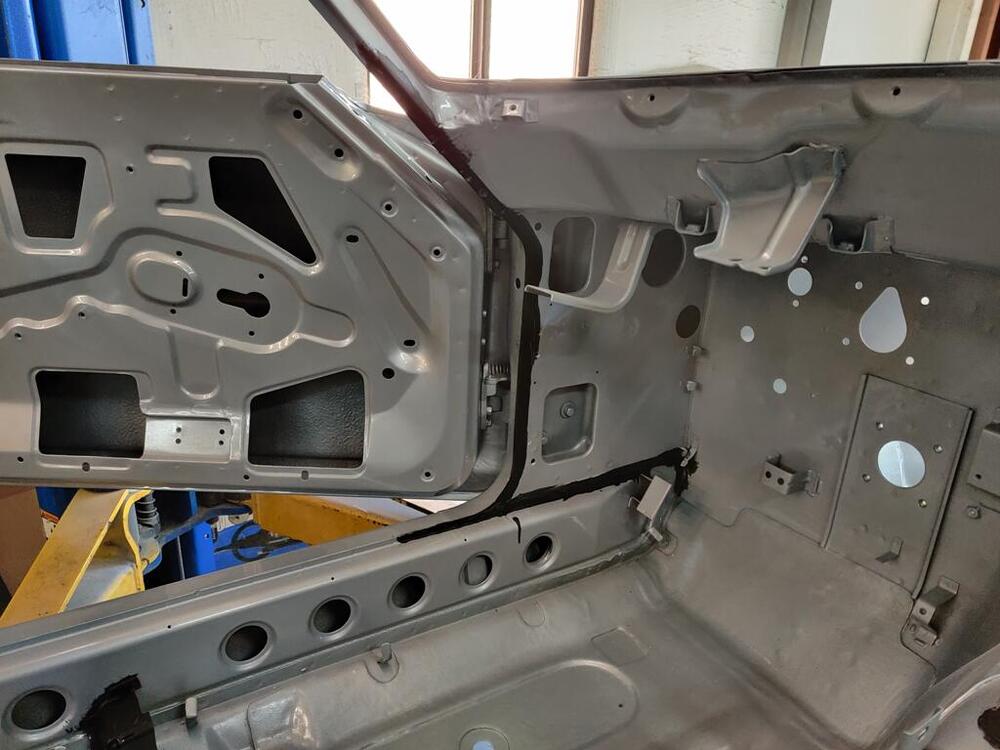

In my 21 pages of instructions to the painter (yeah, I know... it is silly - that's why I keep referencing it!), I provided a bunch of pictures of the original paint on the undersides and in the wheel wells. My thought was that while they were spraying the car, they could attempt to replicate the factory overspray. They did not, but provided me with a pint of mixed and pre-reduced paint so I could do so. Here is the before with pics taken a few hours ago. Note that most of the underside of the car is black. Along with one more pic of before, here are all of the after pictures. I replicated what I found on my car with regard to silver color - wheel wells and spare tire well mostly painted, inner part of the floors and transmission tunnel - not so much. Car dolly wasn't removed for color and clear application by the painter. So, I did remove the front dolly and touched up the bottom of the frame rail where that was bolted to the chassis.

-

Restoration of BringaTrailer 240z - HLS30-35883

Over the weekend, I worked on the engine a bit more. The oil pickup tube gasket was missing, so I wasn't able to put on the oil pan until that arrived Saturday. All of the oil pan bolts are original. I torqued them to 42 inch lbs - a little under 4 ft-lbs. I used a Nissan competition rubber oil pan gasket. These are better than the cork ones that are typically available. The header is some kind of sexy with the engine flipped over:

-

Restoration of BringaTrailer 240z - HLS30-35883

I posted in a separate thread, but will include this in the build thread here also, along with a couple of nice pics:

-

Caliper date codes

I have the same question.

-

The car is back from the body shop with new paint!

Three on the exterior and two on the jambs and back sides.

Subscriber

Subscriber