Everything posted by EuroDat

-

Hello from across the pond! Searching for a 240z

I was also wondering why the L26. I don't think it would be for the valves though. The L26 is the same bore, but different stroke, 79mm like the L28. Its is already notched for the bigger 35mm exhaust valve. Seems a lot of trouble not to notch a bore. Something must have went bad with the L24. That would push me to change a matching number engine to L26.

-

Thinking about installing an BMW M6 engine in my Z

Chris, A piece of advice. It's nice to talk about all these problems with us datsun guys, but in reality we are not the experts. Approximate knowledge is about the best you will get from us. There might be a couple that play with bmw's, but chances they know a lot about motronic 1.0?? You need to get on the Bimmerforums or the Firstfives. They can help you a lot with this, and from what I have seen both forums are friendly. You might get some culture shock when you tell them what you are doing.

-

Thinking about installing an BMW M6 engine in my Z

Chris. I would not spend any money on it until I was certain it was needed. Diagnosing that way can get really expensive. You shouldn't short change yourself either. A lot of us 280Z guys have been were you are now. The fsm could just as well be egyptian hieroglyphs, bug the efi bibble is not called the bibble for nothing. You need the BMW version of this bibble. Knowing bosch, it will be out there somewhere. I quickly googled bmw 1987 troubleshooting and found this http://wedophones.com/BMWManualsLead.htm Not quite thd same, but close. You can download the troubleshooting manual "1987 BMW L6 -M6 troubleshooting manual" Its 188 pages, but the important stuff for you is in the first 30 pages. Read the how to section up to page 8. Take the time to understand the method used for testing. The manual is based on you following this method. I would go straight to page 0670-12 & 0670-13 and test the grounds. The ground tests after page 13 don't seem to have any relation to the motronic. After the grounds, I would go to the front of that section and start testing the power supply (fused power distribution). Basically the only sensor that will stop the motronic is the reference sensor. The rest including the speed sensor should send it to limp mode. You have nothing, so its a ground, power supply or dead ecu causing your problem.

-

Thinking about installing an BMW M6 engine in my Z

You could just run a separate ground for the time being. The ground circuit is complicated by a safety system for if you cash and the engine stops. Its easy to figure out later, but for now you want to get it running and iron out all the small problems as you go. You can solve this with a second oil switch and an extra relay.

-

Thinking about installing an BMW M6 engine in my Z

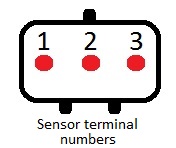

You are getting power at terminal 30 and 86 with the ignition key on, so thats good. The relay should work fine. If you jump the 86 to the 87, you are supplying the fuel pump with power directly from the ECU. Bad idea. The ECU can't handle the for long. What you are basically doing is bypassing the relay function. If the realy is not activating and you have replaced it, then it must be the ground wire on terminal 85. Check it with a volt meter to the battery positive. You should read exactly battery voltage. Its that or the relay is busted. The biggest problem with these systems is ground failure. Some simple checks to do: 1. Check all grounds are clean of corrosion and tight. 2. Speed sensors. These can cause problems. The two sensors are located on the drivers side of the bellhousing: Top is the speed sensor with black plug and bottom is the reference sensor with grey plug. Mix them up and you can confuse the ECU. Its expecting the speed to see movement first. If they are backwards the ECU with interperate that as very slow and think the engine in not running. If speed sensor fails, it will go into limp mode. You should be able to start it If reference sensor fails, it will stop all together. 3. Testing the speed and reference sensors. Check the resistance in the sensors by measuring the resistance across the following terminals: 1 & 2: 850 - 1050 ohms 1 & 3: > 100,000 Ohms 2 & 3: > 100,000 Ohms When looking at the sensor and one locating tab is up and the side with two is down. Left is 1 and 3 is right. See jpeg.

-

Thinking about installing an BMW M6 engine in my Z

I can't remember all the conditions for "pump run", but looking at the diagram I would check the speed sensor. It looks like the motronic 1.0 uses it to give a go signal to the pump. You might need to search the BMW forums like the "firstfives" and see if you can find something about fuelpump controle. I have a couple of wiring diagrams for BMW's, but I think they are for 1.1. Ill check tonight.

-

Stirring the pot - Popular Contributors

I have been getting injector adds, but a spent a couple of days looking for compatible units so that would make sense. I even click on one, because I never heard of that supplier.

-

Thinking about installing an BMW M6 engine in my Z

Looking good Chris. I wouldn't trim any wires atm. Wait until its in the car. You could tidy it up a bit. Messy wiring adds to the confussion. Do you have a wiring diagram you can post. The plug configuration diagram doesn't say a lot. Btw Changing to carbs will be a big job to. You need ignition because it was controlled by the motronic to. Its the Motronic v1.1 it I remember the year 87 correctly which should be a little easier to figure out than a motronic v1.3

-

Help with re-sealing 5spd transmission control shaft

If you try it, warm the striking guide with a hair dryer. Not to hot to touch, just warm. I would try to get it over the top selector pivot section first and then pull it over the back of the striking rod. It's a big ask, but they might stretch enough and they only cost a couple of dollars. It could stop the oil leak without pulling the tranny out. Try it on the spare tranny first to practice what works best. You could also try a softer compound. The softer compounds, like shore 60, generally stretch a little further. The nissan o-rings are shore 70. The o-ring size is 24 x 2.5mm (ID x CS) in NBR or FPM (viton). You could try fluorosilicone (fvmq) They stretch more than the nbr or viton compounds, but are not so easy to find, mostly special order. Fvmq can be found in shore 50 are stretches well. The softer compounds will loose their sealing quality over time at a faster rate, but it should last 4 to 5 years. Don't use silicone, it will react with oil and leak in no time. Its not the same as fluorosilicone.

-

Help with re-sealing 5spd transmission control shaft

You could order a couple extra o-rings and try to stretch the O-ring over the selector end of the striking guide. Depends on how long the "ears" on the selector are. Put the o-ring in a cup of hot water first and use a Ty-rape or piece of insulated electriacl wire thought the o-ring to help pull it over. Don't use screwdrivers or such to pry it over, they only damage the o-ring. The chances it will work without breaking the O-ring are not great, but they don't cost much, and if it succeeded, if would save a lot of time. The NBR compound won't give you that much stretch before breaking. EPDM would stretch more, but it is only suitable for brake fluid.

-

Finally found the wrench I've been looking for!

Over here in NL, they call them Bacho's. That is the name of the swedish company that made them. Years ago, when someone first asked me to give him a bacho, I thought he was talking about the drink. I said; jeess man if the job is getting to you, do something else for a while and come back later. He just looked at me and said; stop smoking what ever it is. Its messing with your head. In Australia they call them a shifting spanner or shifter for slang. Google it and you will find plenty. Its officially called an adjustable wrench. https://en.m.wikipedia.org/wiki/Adjustable_spanner I have a nissan wrench that came in an old Nissan potrol toolkit. Nice addition to my Datsun toolkit.

-

Help with re-sealing 5spd transmission control shaft

Hi takayuki, You will need to remove the transmission. You won't be able to replace the O-ring until you remove the "striking guide" and to do that, the "striking rod" needs to come out. That is the bad news, because the striking rod won't come out without removing the rear extension to get to the striking lever. It could be possible to do it in the car by lowering the back of the transmission and removing the rear extension. I have not done it, never had a reason to just remove the rear extension. My jobs generally turn into "while Im at it, may as well do ....." If you do go forward and remove the striking guide, replace the lip seal for the striking rod. Its probably not much beter. The part number is 32858-U6702 in the attachment. Tranny_Rebuild_FEB2012.pdf

-

Advice lining up MSA exhaust on a 240?

Do you mean its not lining up with the hump spacing in the diff crossmember? I have heard most people need to "tweak" the system to get it to line up right. I can find the thread or remember who it was, but someone here shortened his MSA system about 2" to get it to fit through the rear suspension properly. Can you post some photo's.

-

Speedometer cable grommet (@ trans)

Good move Cliff, If I had that choice I would do the same. Can't turn back time.

-

280z dash repair

Read this thread. The original poster "Bruce" did the job in 2006 an another member has the car now. The repairs are holding up well when I ask 2 years back. Although the car is now looked after really well and protectd rrom the elements. Patience and dedication to quality are the keys to success.

-

Speedometer cable grommet (@ trans)

I am trying to figure out what he stopped leaking with teflon tape on the thread. Maybe his cable was still full of oil and slowly leaking back out. The tape stopped that from leaking. He probably didn't clean the cable, while he was doing the seals. A little bit of trivia: When I ordered the o-rings they quoted two parts numbers for the speedo and striking rod, but when I measured them on a o-ring cone, I came up with the same size. There is a photo of them in the "Leaky transmission" link. My rubber hat washer is long gone. I think the PO left it out when he installed the close ratio. I cut a ring out of 2mm NBR sheet with some hole punches. Its main purpose is to keep dust, grime and water from getting in. It probably would stop oil leaking if the outer cable was in good condition, but that is not its intended purpose. And like chickman said, only available with a new "genuine" inner cable and the better aftermarket units.

-

L-jetronic

That is a good article on checking the L-Jetronic. The instruction works on all the L-Jetronic cars, lk BMW 5 series, Mercedes, Volvo, Citroen, Peugeot, Alfa Romeo and Datsun. For some reason Datsun was very late the include a O2 sensor. I was thinking of going with a BMW 5 series ECU to get the O2 sensor. They are a little easier to find parts for, over here. He did have another one where he suggested adjusting the afm spring for "performance" which is not really true. Adjusting the afm only compensates for other problems.

-

Proportioning valve question

It's a safety device. You should leave it as original. It will warn you of pending brake failure. The proprtioning valve was down the back just before the tee. After July 72 it move to the engine bay. You would do better buying one in the link grannyknot supplied. You will need to fine tune it to get the right balance. The OEM won't do that and probably won't even be close to the balance you need. I cleaned mine up a couple of years back.

- 1976 280Z Restoration Project

- Has Anyone use Lizard Sound Control as Tar Replacement?

-

1977 280z needs help.

Welcome to the club (first post). If you have a color wiring diagram, here is a link to waynes thread (wal280Z) on the color wiring diagram for the 1977 280Z. It's helped me a lot. Its a bit hard to tell what is going on if you don't have a meter to check voltage. A fully charged battery should have around 13.5 volts. Are you sure you have a fully charged battery? It could be an ignition switch problem? A multi meter would help Can you crank the engine with an extra wire from the battery positive to the spade terminal on the starter? See if it will turn over. I don't think that is your problem because you don't tail lights, turn signals and brake light don't If you look in the middle section of the wiring diagram the C9 conector could be causing your problem. You could check it.

-

Windshield wiper motor bag got painted in white

Here are the before and after shots of the wiper motor cover. BTW mine was blue under the red, so it was moet probably painted in the factory. Your paint shop gave it the "factory look" so to speak.

-

Windshield wiper motor bag got painted in white

I used rust-oleum paint stripper to clean mine. The green nr.1 is not so aggressive. Ill post some before and after shot when I get home. http://www.rust-oleum.eu/paintstripper

-

Removed Gauges Successfully

I found the thread on the clocks. It was written by @monkeyman on this forum in this thread. He doesn't post much, but I found his tech artikle very informative. And here is a thread from zclocks on oiling your clock.

-

Removed Gauges Successfully

Great write up. I have the same problem with a dash cap. Wondering what I will find under it. Moelk sent me a km display for the speedo that I would like the change. I think Ill be refering to this thread a lot while doing the swap. One thing I noticed about the clock. A member on this forum @zclocks. He repairs them and has a website, but he also memtioned in another thread not to use oil. It might get them going, but it attracks dirt and that will stop them shortly after. I also have a write up on replacing the resistors and such on the 280Z clock. I can try to find that thread again and link it. I'm thinking of trying this procedure and if it doen't work, ill buy one of zclock's rebuild versions.