Everything posted by EuroDat

-

Found metal at the bottom of my 5-speed. What next?

Just read through this thread. The pieces you found are from a bearing cage. Its probably from the centre bearing on the main shaft. I have seen a couple go there. If the transmission was running good, I would defenatly cosider rebuilding it. Buying one from ebay is a bit like buying a raffle ticket. You don't really know what you have until you put it in the car and drive it. You could pull yours out and flog it on ebay and no one would know. Pulling the drain plug wouldn't tell them anything. Not saying you should do that, but people do. You have to except that risk on ebay unless its a reputable dealer and then it will cost more. Rebuilding it is not all that hard. Like Mark said, you can find lots of info on you tube. I can post a list of all the parts you need to rebuild it. The bearings are easy to find and the seals and gaskets aee still available at Nissan. You will need a bearing puller set, a good set of circlip pliers and metric spanners. A bench vice is enough to hold the adapter plate. You can also identify which version of the 5 spped you have by looking at the rear extension housing. The bolt holding the speedo adapter above is 280Z and under the adapter is 280ZX. The two "Ears" for 280Z and one "Ear" for the 280ZX at the end of the extension housing will also tell you enough to know if its a wide ratio or close ratio (ZX) transamission. See the pdf for details. Im just back from holidays, so I will post the list later if you want. Good luck FS5W71B 280Z and 280ZX transmissions.pdf

-

Need some advice on selling

Good luck selling. Sad to see her go after all the work you put into it. Chris, you might not know it, but you have John's last word of advice on this site. Post#31.

-

1981 280zx 5 speed

What do you mean by fork and sleeve? If you meant clutch fork and throw out bearing collar than its no issue. Use the one in the car, it wiil fit. You only get problems when you start mixing pressure plates with different collars. The bearings and the fork are all the same, only the series I has an extra tab for a return spring.

-

Collapsing Shocks To Push Bumpers Closer To Body

Would that be a problem. If the bumper is moved close to the body, you wouldn't need the finisher to cover the gap. It gap should be just like the 240z bumper. I don't know how far the bumpers shocks will compress or if you would have to make custom brackets to get the gap right. Darn, I think I might have just talked you out of buying my brackets Jokes aside, if you like the look of compressed 280Z bumpers, then removing the finisher should not be the problem. More like what to do with the accordion ends. The next big issue is the accordion ends. I think this is by far the biggest challenge. You could cut them down and glue them, test fit and use them to make a silicone mould. With the mould you can make PU rubber copies. Rossiz is on the right track, but making them out of silicone (even peroxided cured) will bleech out over time and quickly age in sunlight. Cutting and gluing could also be an option. It would be the easiest way to do it. Which glue to use and how long would it last is the issue.

-

Not bad 280Z engine in Portland, OR

L28 with N42 head. Nice price indeed and no egr on the inlet manifold. Manifold is no good for socal, but over here people like them.

-

No power to ECU.

If I read your first sentence. My first place to look would be the AFM switch. You have an early 77 with the fuel pump activation in the AFM where as from Aug 77 it used the oil switch. Then you mention you don't have power to the ECU. Zed Head is right about the fusable link looking good, but really blown under the silicone insulation. It can be very misleading. Easy way to check is with a test light. The fusable link has a spade terminal between it and the red wire going to the ecu. Disconnect it and see if the test light works. 18Watt bulb would work good to load the fusable link. You could also check voltage drop over the fusable link while testing with the bulb.

-

Thinking about installing an BMW M6 engine in my Z

Thats a very nice wipe pattern Chris. It should be a nice diff when its in.

-

Fitting 240Z bumpers and Valences to a 280Z

I pickled the welds today and tried the brackets on my car. Here are the brackets all cleaned up and on the car. I have fibreglas bumpers so its not a 100% guarantee, but with all the measurements I have from people I'm confident they will fit the original bumpers. All the critical distances are within 1 or 2mm and with the slotted holes there is a tolerance of about 15mm.

-

Fitting 240Z bumpers and Valences to a 280Z

This evening we finished the first set of brackets. Still need to pickle the welds and test fit everything to make sure everything fits as it should. Here is a photo of the brackets. Still waiting for bolts and nuts I ordered a week ago. M10 with a 1.25 pitch doesn't seem to be that common. Especially in grade 10.9. I ended up ordering 8.8. Tomorrow Ill fit the brackets and make step by step photo's. For now I'm just going to crash on the lounge and have a beer.

-

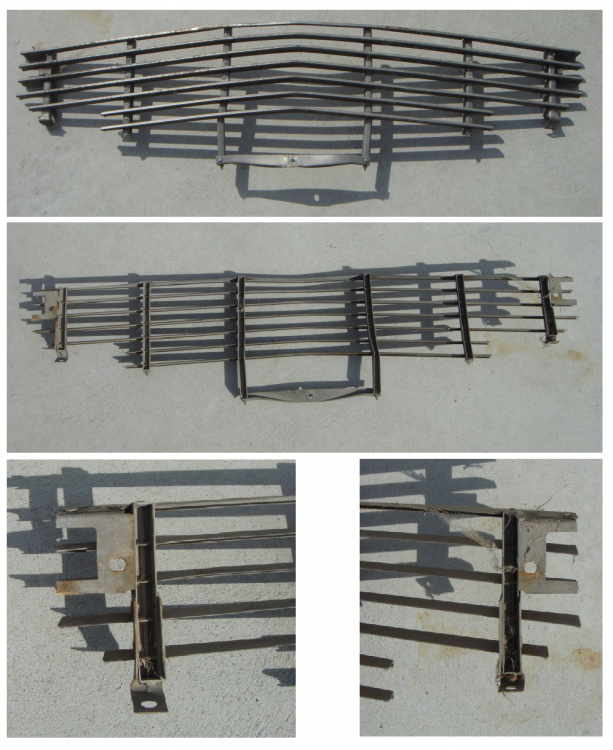

Grille tabs on body

To give an idea of the time line. The grille changed after 4/73. If you have a 5/73 chances are it will have the model with the two short lower bars. The change coincides with the bumper and the heavy bumper brackets. That grille was also used in the US 260Z, but it may have had some small alterations again to get around the 260Z bumper shocks. I gained all that knowledge when I bought the later one for my 280Z bumper project Here are photo's of the two styles of bumper bracket.

-

Grille tabs on body

You basically have two types for the 240Z. Type 1: The series I & II and the Euro model. See first set of photo's The Euro model has 3 long, 1 very short and 3 short horizontal bars. You can see it in the photo I posted and in the photo here below. Type 2: The 240Z Series III (73 model) is a lot different because of the differant bumpers mounts used on that US model. You can tell them apart easily by the two short bottom bars and two extra vertical bars. See second set of photo's Do you have a photo of what you have? See photo's. Note in the 240Z grille US series1 photo a 280Z grille in laying on top. Its basically the same as the Euro except the fourth bar is the same as the bottom 3.

-

Grille tabs on body

What happened to thebrackets? Were they removed to fit an after market grille or something like that. I make brackets for the 280Z to fit the 240Z grille. They use the front two bolts on the hood mounts. No welding, only fitting. You could try something like that.

-

1981 280zx 5 speed

The hole should face downwards. It there to prevent the selector detent from hydraulic locking or slow the spring action down when the spring cavity fills with oil. You could try shimming the spring with flat washers to regain the tension. Now its out of the car its easy to play with different thickness washers and check the effect they have on it.

-

1981 280zx 5 speed

I just tried it at Courtesy nissan and they list it as Discontinued parts, no longer available. If they don't have it, thats bad news. If the selector feels weak and slow to return to centre position, its generally the springs that cause it. Changing all those selector springs makes the selector movement a lot better. My 71C option is looking better and better.

-

1981 280zx 5 speed

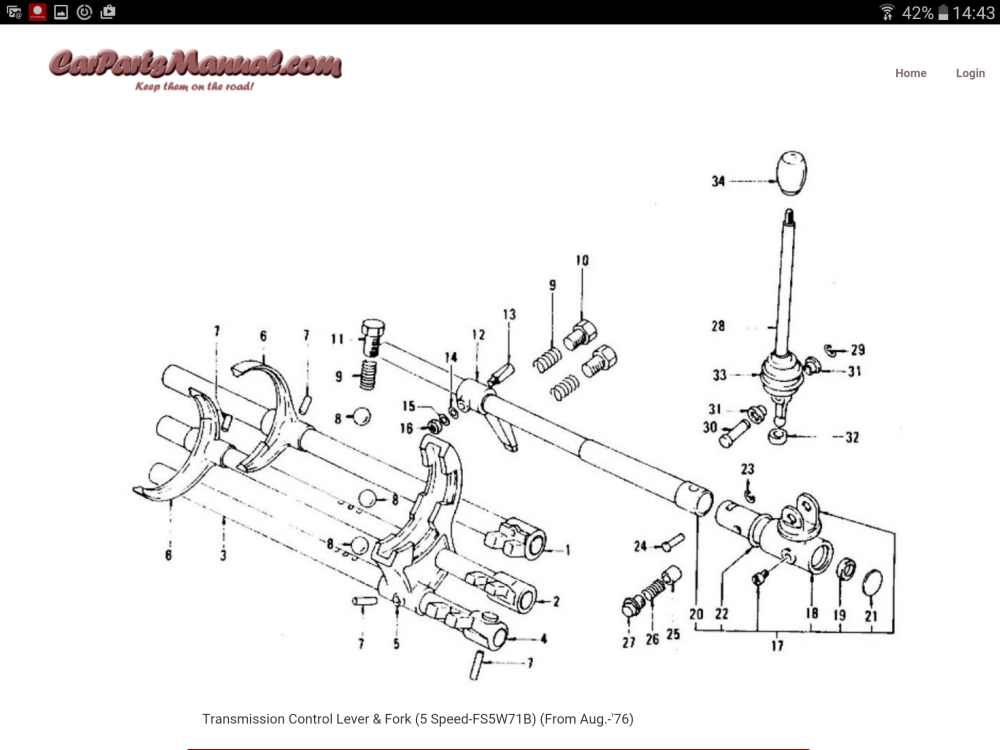

Do you mean part 26 in the selector diagram (see screen shot) part nr. 32852-24901 from carpartsmanual.I have an old one somewhere, but I don't think that will tell you much. I would buy a new one. I mentioned it in post 5. Changing all the detent springs and selector bushings will improve shifting and at a cost of about $10 worth every penny. Its easy now the tranny is out of the car. They are all listed in the file I posted under the section Transmission selector control. The spring you want will cost about $1.35. http://www.nissanpartsdeal.com/parts/nissan-spring-return~32852-24901.html?Make=Nissan&Model=280ZX&Year=1982&Submodel=&Filter=()

-

1981 280zx 5 speed

I used a old screwdriver to pry the tab out a bit. Had to grind the sides of the flat down to the same width as the groove, otherwise you could damage the thread along the shouder.

-

Looking for SU carbs for sale for a 1972 240 z

I know little about the SU, but I believe they changed from 4 screw to 3 screw in mid (june/july) 1971. I think the 4 screws only had an E46 manifold without the water heating circuit to the carb body. The 3 screw took over until july 72. They had water heating and the E88 manifold. The flat tops started around August 72. The dates are not hard facts. There seems to be oddities that go against the rule when it comes to the evolution of these cars.

-

sweatys rebuild

Could be some sort of spring perch rubber insulator? They didn't come in the kits 4 years ago. How many came in the kit?

-

1981 280zx 5 speed

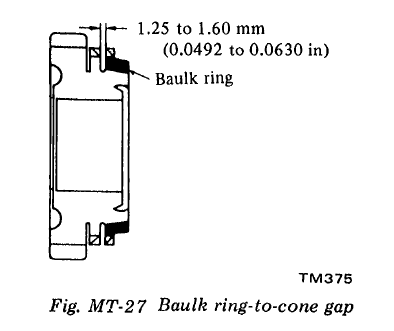

1.3mm is getting close to minimum. The ones in the photo's measured 1.4mm and 3rd was touchy getting into gear. You can't see it in the photo's, but the inside has very fine grooves. The nissan rings were razor sharp. I found that out the hard way. I don't think you will have to worry about selector wear. Measure all the gear end play clearance. If that is within specs then your selectors should be ok.

-

1981 280zx 5 speed

Sorry, My bad. I mis read your post earlier. You can measure the baukring clearance without dismantling the gears. It would give you and idea of wear. Here are some photos of my old ones. They look good, but the new Nissan synchros are so much better. Third is a screen shot from manual with Baulk ring gap meassurement. Forthly, I had a basic bearing puller so I made this one to do the job. To help remove the bearings you can keep the transmission as cool (don't leave it in the sun) as possible and warm the bearings or gears. Don't heat them with a gas torch, but a heat gun or something similar will help. You want about 60 Deg C temp difference to help ease it off. C3 bearings don't like bearing heated too much, but you will most probably replace them if the transmission turns out servicable. Chas

-

1981 280zx 5 speed

Third is easy to get to. You will have to pull the front counter shaft gear off to get the input shaft off. Pay attention to which direction it is mounted on the shaft. It fits on both ways, but one way it will be a little out of alignment and could cause whining noise later. Looking at the reverse gear, looks like a PO has been driving it with a worn out clutch master cylinder or slave cylinder. Not enough clutch travel to fully disengage and he has been grinding it into gear. The oversized tolerance on the baulk ring is a sign it could have aftermarket baulk rings. That means its been played with in the past. Baulk rings can be touchy and cause problems even though they look good. Its not the outside teeth thats most important. The fine ribs on the inside make all the difference.

-

1981 280zx 5 speed

I googled the Omega bush to see if I could find it. They still make them. http://sales.omegamachine.com/Nissan_FS5W71C_Extension_Housing_Bushing_p/71411.htm

-

1981 280zx 5 speed

Hi Dave, If you want to replace the seals, buy genuine nissan. They are not expensive and the quality is good where as aftermarket can be just as good, but there is also the chance it isn't. The seal Pos #19 cost me about €2,50 at my nissan dealer in 2012 and in the states it's cheaper. If you want to replace the rear extension bushing. Google "Omega Machine & Tool P/N: 71411". It fits and the quality is excellent. Nissan never sold them as a replacable part, only complete extension housings. I would replace the selector plastic bushings and the detent springs while you are at it. Makes gear changing feel much tighter and smoother. The springs and bushes will cost you less than $10,00. I attached a list I made when I rebuilt my tranny. I wanted to by a reconditioned one, but when I saw what the parts cost, I decided to do it myself because I wanted genuine parts including the nissan synchros. Most recons are just a bearing kit and some seals. Chas Tranny_Rebuild_FEB2012.pdf

-

EFI System for sale

I can't believe no one snapped it up already. Very reasonable. Try to buy a afm, ecu and injectors and see what it will set you back.

-

Did I screw up?

The one on my 280Z and the spare I have are two piece units. Didn't know they made so many different styles