Everything posted by grannyknot

-

Thinking about installing an BMW M6 engine in my Z

So that's what they are called, being an aftermarket bolt on product, using the door hinges make sense but on a Z the door hinges are so close together there wouldn't be much of a base to the triangle. Finished off the rest of the triangle today, once everything is welded in place I will make patches to seal around that upper brace, total weight for all the bracing will be just under 19lbs. Now is all this really necessary... probably not but I'm still not sure how far I'm going to go with the power output or how much time will be spent on the track. Easier to do now with no regrets later on. Adapted the stock shifter boot to fit the new stick shift,

-

Nissan 2400 OHC value cover

You have one customer here

-

Thinking about installing an BMW M6 engine in my Z

The steering wheel shaft would be poking out my spine before those braces hit me. Here are some pics of the under fender stiffening I'm thinking about, the notched stiffening plate where the crossmember bolts on had to be rebuilt anyway so stealing ideas from disepyon and wheee I rebuilt them and extended the 12ga plate right up to the top of the shock tower so there is a one piece connection. Nothing is welded in yet, still lots of fitting, These next two braces I have seen on a few track cars and appear to connect the rockers to the front quite well, the diagonal brace will be welded to 5 different sections. Found when I put the wheel on that I'm pretty close to the limit on certain things,Also had to remove and rebuild the bumper supports so I could repair the rust behind them.

-

Another Shock Question

Rear end squat as I understand it has more to do with the spring rate than the shock, a stiffer shock like the Tokico Illumina on setting 5, the stiffest, will slow down the rate of the squat but the rear end will still end up at the same height of squat or close to it because it is the spring that is holding the car up not the shock. (If I have that wrong someone please correct me) The Illuminas on setting 1, the softest, will probably give you a stiffer ride than what you have now but a different shock shouldn't effect your height. Your original springs are 46 yrs old now so are probably a little tired, new springs of the same rate as the originals would help your situation, but there are many threads in the archives where guys mention that installing stiffer springs did not adversely effect the ride comfort. For the kind of driving you say you are doing a new set of 4 KYB's would work well for you, they are a great shock for the price and a good all a round shock.

-

Thinking about installing an BMW M6 engine in my Z

Yeah, not my favorite tool but sometimes they are a godsend. Because this engine is so tall and close to the hood I don't have room to install a shock tower brace bar, so I am going to weld in some bracing that will be hidden under the fender that will help keep any flex to minimum. I'll have some pics of that in a couple of days but here are the only visible part of the stiffening.

-

Long time 240 owner, forum newbie wondering about a triple carb setup.

Bingo

-

69 Shell, assorted shells found

^ By Ontario standards those cars are rust free.

-

Hauling a Z on a trailer

Don't put a car cover on if it is going on an open trailer, the front of the cover will be pinned against the car and the rest will repeatedly flap against the paint. When you take the cover off there will be splotches all over the car where the shine has been sanded off.

-

69 Shell, assorted shells found

Modesto ?

-

Thinking about installing an BMW M6 engine in my Z

Came across an interference today between the stock washer fluid bottle and the Tilton 3/4" Clutch Master so had to remove the hanger for the washer bottle and shorten it a bit so there is enough room for the clutch line fitting. Every air chisel I have ever seen or used has a double bevel on the chisel, both sides are ground toward the center. Now maybe it is physics or maybe Murrphy's law but when parting two pieces of metal that are spot welded it is always the metal that you want to keep that gets torn up by the chisel, every time. The flange for the washer bottle was tight in there and I couldn't get the spot weld drill in so used the air chisel and of course the good side tore, then I started thinking about wood chisels that you can 'steer' so you don't have to gouge too deep. One side is ground flat and the other is beveled to the flat side. I grabbed an old chewed up air chisel and re ground it just like a wood chisel and damed if it didn't work like a charm, I had complete control. Now maybe this is something that everyone else knows about but it was new to me. You can see the top spot weld was cut with the double beveled chisel and tore a piece off of the side I wanted to keep, the lower spot weld was cut using the modified wood chisel shape. I manged to remove all the rust from the sugar scoops but some of the metal was so thin you could push it in with your finger, got lucky though, my daily check through craigslist and kijiji paid off with a pair of perfect metal scoops with out a single dent, $75 for the pair

-

69 Shell, assorted shells found

I'm counting 10 Z's in that compound, that would be fun.

-

Front injector bank not firing (1976 280Z)

But if you can't afford an old collector car, then you can't afford an old collector car. I just recently I tried to get the ECU for my 1987 bmw M6 repaired by Programa, as far as I know they are the only game in town for to repair that particular ECU, they wouldn't look at it for less than $500, they wouldn't accept my core and send a rebuilt unit for less than $500, they wouldn't even test it for less than ... Although I didn't care for Programa's price and instead went with megasquirt, I can see why they need to charge so much, in order to stay in business you can't have a bunch money tied up in units sitting on the shelf waiting for someone to buy them or maybe not buy them. Now that the rest of the car collector industry has turned their attention to our Z cars I think the days of inexpensive Z ownership are almost over. Not really arguing with you ZH although I know you enjoy a good debate more then most just saying I understand why they are asking so much for a core, it ensures there is always a unit ready to rebuilt for the next guy.

-

Thinking about installing an BMW M6 engine in my Z

It was running, it will again maybe 8-9 months from now if all goes to plan then I can find out if the exhaust is going to be way too loud. Right now I'm trying to salvage my fenders and sugar scoops, bloody rust.

-

Drive Tribe for zcars

Still don't see the point, you can go to the gallery and look at others cars and not discuss anything.

- 1976 280Z Restoration Project

-

Looking for advice on replacing all the hard brake lines

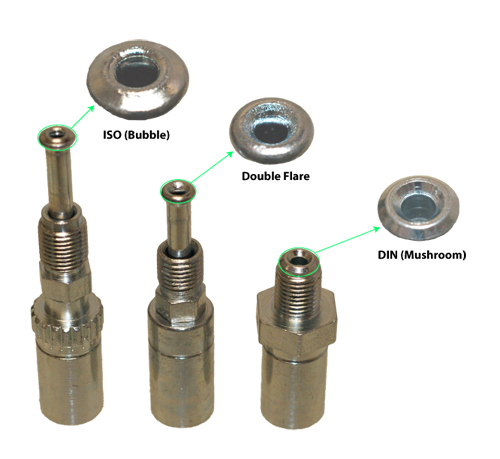

Thanks guys I'll go ahead and order Double flare M10x1 John, that link really lays it out clearly, I missed that when I was on the Fedhill site. Cheers

-

Looking for advice on replacing all the hard brake lines

That is what I have always thought too but my pics of the stock fittings sure look a lot more like DIN flares than double flares.

-

Complete L28 w/ 5 speed, $400 - seem"ED" like a deal. Washington state

The ad says $700 when I just clicked on it.

-

Looking for advice on replacing all the hard brake lines

Got the package from Fedhill today, everything looks good, just a couple of strokes with some 0000 steel wool and you get a mirror finish on it. 240Z 1972, are the brake hose fittings double flare or DIN flare (mushroom)? I'm having some SS braided brake hoses made up and now I'm not so sure, sure looks like DIN to me.

-

another broken bolt 280z

Before using the mig I would try heating up the bolt with a Propane torch, get it nice and hot and cool immediately with WD40, repeat that 4-5 times then try the visegrips again but only try to get the bolt to wiggle a bit back and forth. You may have to go through the heating/cooling process again, funnily enough the WD40 wont ignite when sprayed on the hot bolt, you will only get a small flame when you put the torch back on it and it burns off quickly. You have to break the corrosion between the steel bolt and the aluminum head so clamp the visegrips on very tightly and only try to get the bolt to wiggle a bit in both directions. Welding a nut on can work too and wont harm the aluminum head but if you haven't used a mig before this bolt isn't the place to learn.

- 1976 280Z Restoration Project

-

Kicked the tires and went on a drive

Out of the mouths of babes...

-

Thinking about installing an BMW M6 engine in my Z

Not thee Wick Humble? Of 'How to Restore Your Datsun Z Car' if so, I owe you a big thank you sir, I have been through my copy of your book so much I had to buy another one and have the binding Shurlock so it wouldn't fall apart again. I have most of your book memorized by now but go back to it often even so. Nice job on the fender/sugar scoop, very clean. I'm thinking about doing that on this Z I'm working on but if it is not done perfectly it can look terrible. I'm sure that seamless look is the way the Nissan designers wanted it to be but the bean counters said 2 pieces where cheaper to make then one complicated piece.

-

1976 280Z Restoration Project

Wheee, I'm going to steal your method when I make my frame rail/ X member strengthening plates if that is okay. Have you noticed that the rusty area just above that plate you built and just below the shock tower is only 20ga sheet metal? I know the stresses on that inner fender coming from the X member and the shock tower above it are spread through out the connecting structure but it has always seemed strange that they left those 2-3" of 20ga inner fender without joining that X member plate to the shock tower. Maybe the shock towers wouldn't flex so much if they had.

-

Nice 73 in NW Washington State.

The car is not listed any longer.