Everything posted by grannyknot

-

L24 compression question

A cold engine compression check is not going to give you accurate numbers, a hot compression test will still show a problem with #4 but the other cylinders could be very different. Regardless it looks like your engine is in need of a rebuild but people have driven engines in worst condition for many more miles. But driving an engine that doesn't have balanced compression is a good way to wear it out much faster. Did the cam oiler break off or just crack?

-

[2017] What Did You Do To/with Your Z Today?

Are you rocking a bare metal Z? Very brave.

-

Thinking about installing an BMW M6 engine in my Z

Thank you, but not from my brain, I only steal ideas

- Duffy's 1/71 Series 1 240z build

-

Any install a Stahl header?

Good to hear, always nice to find the easy fix. Stahl headers are getting hard to find.

-

Thinking about installing an BMW M6 engine in my Z

I decided not to make the LCA adjustable for camber but the crossmember instead, there isn't a lot of room to slot on the XM so had to flatten the existing metal and add extra support. Changing camber is done by loosening the LCA pivot bolt nut and adjusting. This is the stock positionLots of camber, not sure what this new position will work out to in degrees but I'm sure it will be plenty.

-

My 240z project

Beautiful, great colour, you work fast.

-

How To: Use Dry Ice to Remove Tar Insulation

Have you done this? I would love to see that technique, I only found it got stickier and harder to remove with heat.

-

Thinking about installing an BMW M6 engine in my Z

That was my first plan but with a turnbuckle you have 3 moving parts and 2 jamb nuts, this way there is 2 moving parts and 1 jamb nut. Just thought that less complicated = less chance of failure. I guess these rods are forged, the metal is pretty grainy, could also just be my lousy technique

-

Thinking about installing an BMW M6 engine in my Z

Sorry, that 2nd picture is confusing because I hadn't threaded that side yet, the curved end side has 2 in" of threads, the bushing end has 5/8" of threads, is screwed into the coupling nut then welded. The curved side is male, the bushing side female.

-

Thinking about installing an BMW M6 engine in my Z

While I'm waiting on the engine I have started a little project to modify the stock lower control arms and the T/C rods to allow me to adjust camber and caster but with out loosing the stock rubber bushings that dampen out so much road noise and vibration. I got the T/C rods finished today, the dia. of the T/C rods are about 10/1000ths" too big for a 5/8"x 18 die so had to skim a bit off first on the lathe. The rods look true but they are not, had to fiddle with them in the chuck to minimize the wobble, probably could have done it with a double cut file. In their fully closed position now they are the stock length and there is about an 1.25" of usable adjustment, should be plenty.

- 1977 280Z

-

Deja Vu: 1971 Restoration

My 70 Z never had a gap either but the 72 does, I can push the panel from inside the car and close the gap up easily so maybe it is just the sun.

-

Thinking about installing an BMW M6 engine in my Z

I did the rock test on all the valves, almost all of them felt new with virtually no wiggle, 2 exhaust valves had a weeny bit more wiggle than the rest, one was on cylinder #3 the other was on #5. Pointing to the rings at the moment.

-

Thinking about installing an BMW M6 engine in my Z

No word yet from the engine builder on when he thinks he'll be finished, he is going to go with a good used crank instead of repairing the original. All of the connecting rods are still good and usable. I finished rebuilding the head, everything is clean and flat, fresh valve seals and lapped the valve seats while I was at it, ready to go.

-

Relay Mounting Locations - Firewall? under dashboard

-

Relay Mounting Locations - Firewall? under dashboard

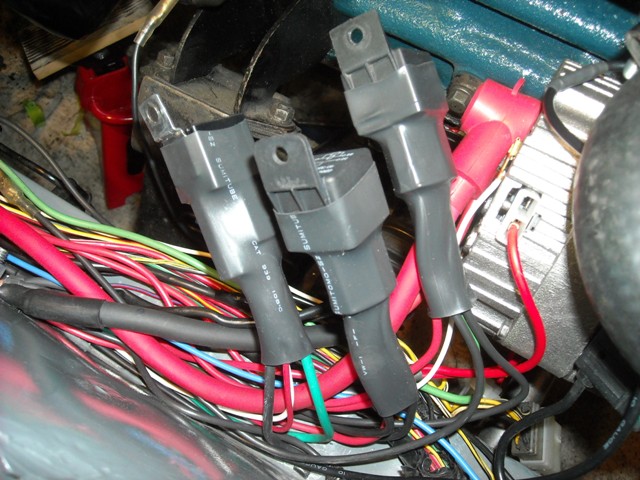

I have some better pics but can't locate them at the moment, the relays were mounted in a line right where the old external voltage regulator was,

- 1977 280Z

-

How to shoot flame from tailpipe

Might not be too hard to rig up a dedicated fuel injector mounted near the end of the exhaust pipe with an electric open/close switch and a simple piezo ignitor down stream. Oh look what I found on the shelf, this could be a fun little project.

- 1976 280Z Restoration Project

-

changing camber using the strut insulator

I could slot the stock mounting holes but then I would also have to modify or rebuild my strut tower braces, not sure I want to do that just yet. As much as I would like a bit more camber and I'll get it one way or another, more caster is what the car needs the most. I was going to order TTT's T/C rods, but as you say I'll lose all of the vibration dampening. Maybe I should look at adding a welded in turn buckle to the stock T/C rods.

-

changing camber using the strut insulator

The inner cup does float completely but there is also an air gap that was molded into the the assembly to allow for movement, I had never noticed it before until I started destroying it. It is a very well engineered piece, also the rubber lip that is used to hold the inner cup in also wraps snuggly around the the horizontal bearing and limits water and grit from getting in. I did contact Steve at 240z Rubberparts.com and he very kindly splashed the cold water of reality on me, here's what he had to say, Chris, you will need a urethane rubber with a high Tensile Strength and a shore hardness between 70-90A. 90A being the hardest and most ridged. you will need to degas the rubber in a vacuum chamber before pouring into the cup. Then it will have to put into a pressure chamber to cure. Then cured in a oven for 8-10 hrs. If you dont degas and cure in pressure chambers, then you will get tiny bubbles and it will be very weak. The rubber would also need something to bite into( iE a void or grooves), so it will not come out. If you just pour it into a metal cup it will come out freely. I do not make any type of parts, if they fail they could cause any problems. This seems to be a trial and error type of project. Steve Owner www.240zrubberparts.com www.Datsun240zrubber.com Well, I'm not prepared to go that far but just as I was about to plow ahead anyway I noticed this, the red pencil is pointing at the upper spring cap, in it's new position it will hit the inner wall of the shock tower sheet metal. So that has stopped me in my tracks for the moment, if I can't find a way to sort that out then I will have to leave the upper mount alone and get the camber from the lower control arm. Now although there are lots of different aftermarket LCA's to choose from all of them have also done away with the vibration control bushings. Got to think about this a bit. There has to be away to have the comfort of a stock setup but the performance of an aftermarket setup.

-

Hardway's Red Rocket 1972 240z Build Thread

What a score, lots to work with, congrats!

-

changing camber using the strut insulator

Excellent idea, will do. Burn baby burn, So I think I would be looking at a repositioning the inner cup so it looked something like this,

-

1973 240z

It looks pretty solid, in southern Ontario that would go for $8-9,000 but in your area there seems to be a lot of selection of older Z's. You get as much as you can for it because no matter what, you are going to kick yourself for selling it Good Luck

- 6 replies

-

- 240z

- extraparts

- fullinterior

- selling

-

+3 more

Tagged with: