Everything posted by Captain Obvious

-

1971 HLS30-14938 "Lily" build

Yeah, but my point is that even if you would get out of the driver's seat and walk around the back of the car you STILL can't see underneath the taillight panels and licence plate backing plate!! The rest of the car better be just as good!

-

I'm a Boy Scout covered with patches, again.

Perfect!!

-

Butthurt Emissions delete....

OK... I think I understand now. I originally thought this thread was started for the purpose of discussing removing emissions equipment, but, in fact that's not at all why this thread was started. This thread was started simply as a complaint. You're complaining about other people because you don't like their reaction to discussions about removing emissions equipment. You're unhappy with other people's input and you thought it would be a good idea to start a thread to complain about it. So I think I got that much, but I still don't know what year service manual to refer to... What year is your butthurt?

-

I'm a Boy Scout covered with patches, again.

Now you see... I don't understand how it can be a secret if they post a video about it. It's like... How can you claim something has a secret location if there's a big sign on the interstate showing you how to get there. Not sure if I posted this before, but this was on the way to ZCON Atlanta:

-

Butthurt Emissions delete....

And actually, I've been confused since the start. You started this thread with the title "Butthurt Emissions delete...." and I'm not sure what you mean. Are you butthurt by your emissions? Are your emissions butthurt by you? Are you trying to delete your emissions BECAUSE they are butthurt? Sorry, but I'm completely lost.

-

Butthurt Emissions delete....

Agreed. I can pretty much guarantee that site wasn't trying to demoralize anybody. Not that kind of guy. Here's my take on what site said: "I don't understand your point with the above. If you want to delete your EGR, then go ahead. It's not that difficult. Heck... With enough reading, even I was able to figure out how to do it. And you, being an engineer, are probably much more capable than I am." That's my read.

-

I'm a Boy Scout covered with patches, again.

Haha!!

-

1971 HLS30-14938 "Lily" build

So if you're spending that much time on the parts of the car you CAN'T see (once it's put back together), I can just imagine how the parts you CAN see are going to turn out!

-

I'm a Boy Scout covered with patches, again.

Nope. That's all I got. Close, but no cigar. I do, however, have a couple of pics that are simply loaded with GRAND MASTERS. Here's a couple of my favorites:

-

I'm a Boy Scout covered with patches, again.

-

I'm a Boy Scout covered with patches, again.

I'm wearing my Back Forty shirt right now. I think of you every time I see it.

-

I'm a Boy Scout covered with patches, again.

I don't know how many badges there are available... All I know is that we're all chasing Cliff! So he's got eleven and you've only got ten. The one that he has that you don't is "Well Followed". You need to have 10 people following you to get that badge and you've only got nine. So you need to lobby JUST ONE MORE PERSON to follow you and you'll have as many badges as Cliff. I'm two badges behind, and the one I'm chasing now is "Dedicated" (which you and Cliff both already have). It requires you to log in for seven days straight. With my hit-and-miss on-line presence, I've apparently never achieved that. I'm trying now though, starting yesterday. Haha!! Of course, if @Mike catches wind of any of this gaming of the system, it's all over. LOL. There are threads on the interwebs about this new badge system and turning it into a video game. It's designed to encourage participation and site traffic. Most people seem to like it.

-

I'm a Boy Scout covered with patches, again.

Actually I'm just here to pad my stats so I get another badge.

-

I'm a Boy Scout covered with patches, again.

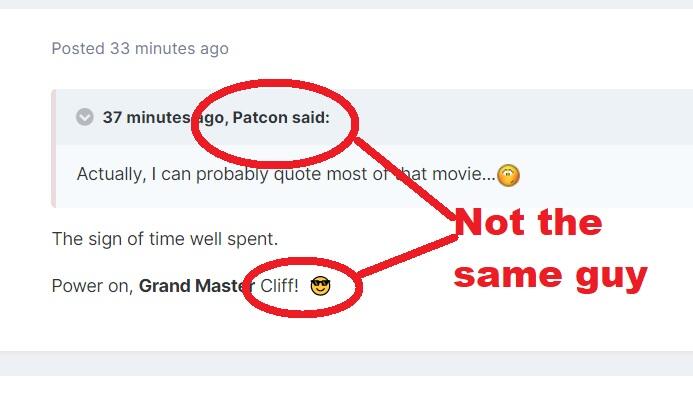

Of course you can! You're Grand Master Patcon!

-

I'm a Boy Scout covered with patches, again.

-

I'm a Boy Scout covered with patches, again.

Well played!! To paraphrase Count DeMonet, "Your Majesty, this is a very serious problem. The peasants feel you have no regard for them."

-

I'm a Boy Scout covered with patches, again.

Haha!! How quick some people are to forget where they came from!

-

I'm a Boy Scout covered with patches, again.

LOL!!! I'm honored to be a 1%er. I'll never forget the little people. Jingle. Jingle.

-

Z Proto: The next z reveal

Actually (in the real world) what probably limits the ability to accelerate your Z is the ability to get that power to the road. Nice equations. I'm hot.

-

Putting in a replacement L-28

i'd have to hear it in person to decide if it's valve noise or just normal injector noise. In any event, the car looks great. I'm so happy you're getting some time behind the wheel!

-

Restoration of HLS30-12070

Haha! I totally get it! Wasn't sure which side of that fence you would fall on, but thought I would mention I had it.

-

Just Another Damned Z Car Project Thread

Yeah, that block vent tube is not stock. Was that fitting screwed into the block when you got it, or did you put that in?

-

Restoration of HLS30-12070

Beautiful. I've got (what I was told was) an NOS original four speed shift knob. Would sure look great in that car.

-

To shim or not to shim?

Site and Ferg, The valve timing position hole on the upper cam gear has no effect on chain tightness. It's a "relative rotation" change only, not a "distance between two gears" change. In other words, moving which cam timing hole you're using will not change the chain tightener position at all. If your cam tightener is sticking out too far, moving to a different timing hole won't do anything at all to change that.

-

78 Z - Water Temperature Switch - Blue Wire - Help!

Well I'm not ready to come to any conclusions yet, but I did take another look at the documentation, and I really can't find any reference to that kind of temperature switch for 78. And for the years that DO have a device like that, it's used to change the ignition timing from "advanced" (when the engine is cold) to "retarded" (once the engine warms up). However, you have a single pickup distributor, which does not support switching ignition timing based on temperatures. I don't know why that temperature switch is there, and what it could do for you, even if it were connected. 76 uses a device like that, and the connection from the harness out to the switch is a red wire, but swapping a 76 harness into a 78 would be a big job and have a whole bunch of pitfall issues. What do you know about the history of the car?