Everything posted by Captain Obvious

-

1st start with rebuilt turbo

Well I know very little about turbos and what's considered "normal", but I really don't like the stiffness of that turbo. Maybe it'll loosen up after the seals run-in, but I have no idea. Maybe some of the turbo guys can chime in and provide some guidance.

-

Headlight switch problem- 1978 280z

Well I'm no ME, but I have concerns about using two dissimilar parts for that assembly. It's really not a big deal and I'm not going to throw my body in front of anyone who wants to try it, but I've just got concerns. Things like this: If you make the tip out of some slippy plastic and press it into a tube... How deep of an engagement do you get? The whole thing is 5mm long. With the spring seat being maybe 3mm deep? So you get .078 inches of some slippy plastic into the end of a brass tube? You make the press fit mild and there's less force to hold it together. You make the press fit aggressive and that slippy plastic squeezes itself out of the hole just sitting static on the desk like toothpaste extruding out of the tube. Change the temperature and who knows what's gonna happen. And then you put that assy into an un-damped spring snapping application? When that thing changes position, what's the frequency of the bounce? That brass isn't going to change direction instantaneously. Newton's laws and all that say there will be forces trying to pull that thing apart. Like I said, not a big deal... A lot of discussion and analysis of such a small simple part.

-

Float level madness

Glad to (try to) help. I'm actually planning to be messing with floats later today. Call me.

-

Float level madness

The struggle is real: https://www.classiczcars.com/forums/topic/55190-float-level-advice-please/?&page=5#comments

-

Float level madness

So those carbs are the 72 three screw versions. They are supposed to have different needle valves in front and rear. Do you know what Ztherapy put in them?

-

Headlight switch problem- 1978 280z

Yeah, the original part was injection molded. That's what you do when your making hundreds of thousands of them. Or you're @SteveJ And I'm not sure what you meant about a brass tube with a plastic knob inserted... Are you suggesting the possibility of making the finished item out of two parts pressed together? If that's the case, I'd be wary of that. Remember, the bottom of the hole is the spring seat. And it's pressing in a direction to separate the two parts. Yes, in theory, all the force would be on the spring seat (and not on the thin wall tube around it), but there's the transition positions when the spring extends and all that inertia. I don't know how many G's that part sees when it snaps from one position to another, but I bet it's not trivial. Remember the same lubricity the plastic provides to the tip (to let it slide smooth across the switch contacts) will be allowing the two parts to come apart.

-

Brake Booster Recommendations for 240Z with Wilwood Disc Brakes

I'm no brake expert, but I would want a "stock-like" booster, not the tandem.

-

1st start with rebuilt turbo

Could you put the stock intake snout back on and run the engine like that? In other words... Run the intake tract in NA mode and pull the turbo intake stuff off, but leave the turbo installed. I'm thinking that with the turbo in place you could look inside it while the engine is running to see if the impeller is spinning at all? I'm no turbo expert, but your description of how much force is required to spin it has me concerned.

-

‘77 280z signal fuse keeps blowing up

And remember to take pics in 93 and 94 miles!

-

Headlight switch problem- 1978 280z

I would not consider either ABS or acrylic to be a good choice in the long term. Certainly usable for proof of concept and testing a procedure. Careful with the acrylic as it can be brittle and shatter if you push it too hard. Don't hurt yourself and wear eye protection! This could be done in a drill press, but it's really not the tool for the job. For the spring hole, you want the hole in the center and it probably has a flat bottom. The rounded tip is actually the easy part here... Just use a file while the part is spinning. Heck, since I don't consider it to be a high precision job, that's what I would do on the lathe. Use a file and eyeball the radius.

-

Headlight switch problem- 1978 280z

Got your message and sent one back.

-

‘77 280z signal fuse keeps blowing up

Horn broke. Watch for finger.

-

1977 280z Radiator clutch fan engaged too frequent

I don't have any input into your fan issue, but just wanted to ask... Are you driving on the road when you took that pic, or sitting at idle somewhere? Reason I ask is, the oil pressure is low if you're out driving around. It would be OK for idle, but not for higher RPMs. Based on your posture on the road it looks like your RPMs should be higher than idle.

-

Headlight switch problem- 1978 280z

gotham22, If you want to send me a good part to use as a guide, I'll see if I can make a replacement? And no... I'm not going into the replacement headlight nubbin business unless someone presents me with a credible business case.

-

‘77 280z signal fuse keeps blowing up

I'm not totally thrilled without the smoking gun, but let's hope the problem has been resolved and doesn't come back.

-

Headlight switch problem- 1978 280z

LOL!!

-

Headlight switch problem- 1978 280z

Sorry. My bad. Who am I to say something like that! Objection withdrawn!

-

Headlight switch problem- 1978 280z

Casting in brass??? Pardon my French, but you're out of your mind!! LOL!! Unless you're going to make a hundred thousand, just turn it on a lathe! I could make that part in less than ten hours. Nine-and-a-half to figure out how to make it right, and then thirty minutes to make a good one.

-

Headlight switch problem- 1978 280z

I think epoxy or something 3D printed would both be fine for proof of concept, but I don't think they would last. The thing that worries me about epoxy, would be low abrasion resistance and adhesion to the original remaining nub. And the thing that worries me about something 3D printed, is the very thin cross section where the nub captures the end of the spring. Brittle and prone to cracking? And regardless of what material is used, the original part looks like it melted. So the root failure here looks like it got too hot. That needs to be taken care of first. So since I'm in here... Other than friction resistance, is there any reason those nubs must be made out of plastic? Does it have to be non-conductive? Based on the switch pics above, it looks to me like the could be made out of metal? Brass for example?

-

Headlight switch problem- 1978 280z

Nylon 6/6 would be my first choice with Delrin being a close second. Both are easy to machine at that scale, but I think the Nylon is a little stiffer and stronger.

-

Strange intake noise?

Awesome! You guys beat me to it! Glad you figured it out and got the idle down to where it belongs. I think that had been suggested before too. Guess it never happened.

-

Strange intake noise?

chaseincats, This is correct. On the Z throttle bodies*, you have to be careful about how you block off the BCDD. Search around the forum a little and you'll find details. If you can't find them, let me know and I'll see if I can dig them up. * ZX is different.

-

Overheating Only Under Load

Yeah, you'll need to spend some time on that. Glad I helped you make it "better"? LOL! First thing I would do now is pull the wire off the new sender when the gauge is at max and see what happens. It SHOULD drop to low temp. If it doesn't, then there's a problem in the wiring or inside the gauge itself.

-

Cody's Goon

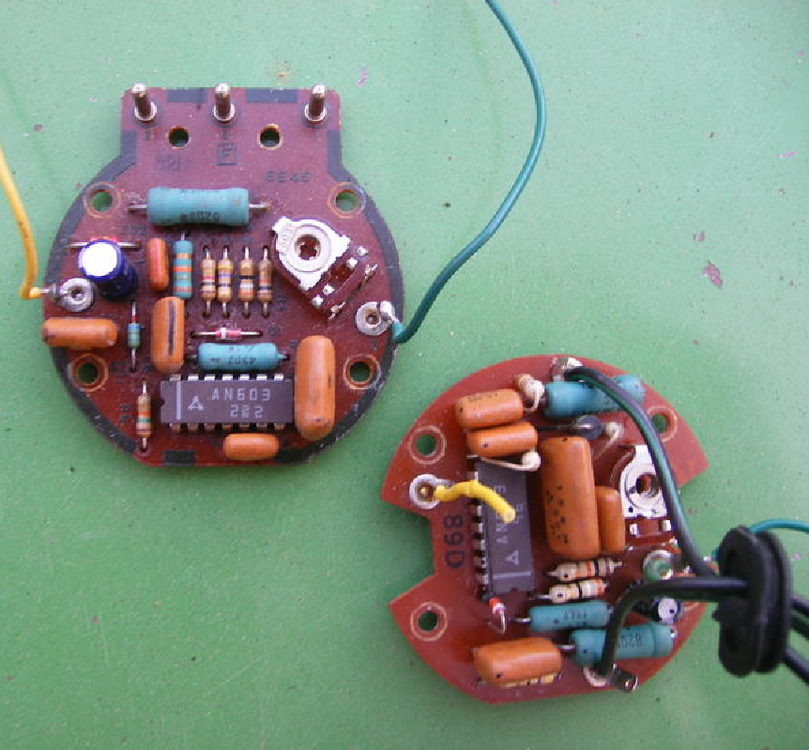

Yeah, that's the article in which I found the pics I was talking about. This is a 200SX on the left and 510 on the right. Oh, and youtube says the current sensing Z tachs don't have any IC's at all. Nothing integrated. Just discrete transistors.

-

Cody's Goon

Who knows... Maybe? Those sites always seem to have stock of any IC you are ever looking for. But do they really? I don't think I'd ever trust them enough to even try