Everything posted by Captain Obvious

-

Dave W 1971/240Z rebuild

OK, so it wasn't simply a valve lash issue. Not surprising, but too bad. And those valves look a whole lot worse on the stem side than the cylinder side. Definitely enough carbon chunkies to cause the leakdown you saw. Smoking gun there. So as for cleaning up the valves.... Two words. "Wire. Wheel":

-

Dave W 1971/240Z rebuild

Haha!! I know it's a longshot, but the insides of the cylinders really don't look that bad. In order to leak that much past the exhaust valves, I would have expected everything to look worse. Longshot, but here's hoping it's something simple like a valve lash issue!

-

Dave W 1971/240Z rebuild

Are you sure the exhaust valves in cylinders 1 and 2 were not being held open by too little (less than zero) valve lash? The whole thing doesn't look caked with exhaust carbon that would cause such poor leakdown results. I know... I know... I just have to ask.

-

75 280 Rear Suspension Work & Disc Brake Conversion (MilkFab)

I'm not sure I would trust loctite there, even the red stuff. If that nut comes loose, you could lose a wheel. Highly unlikely, but just not sure I would trust a loctite bond and ONLY a loctite bond. So I've done rear wheel bearings a couple times and I've switched over to the newer style of deformed thread nuts they used on the 280ZX cars. I'm not sure how the thickness of the newer ones compares to the older ones, but if it's thin enough and the deformed threads are down far enough, they could be a simple solution. The newer nut looks like this. Photo credit @ Blue:

-

75 280 Rear Suspension Work & Disc Brake Conversion (MilkFab)

I've never messed around with converting to the CV axles, so I'm all kinds of confused. With that in mind... You cut length off the end of the stub axle. And now (with just the washer and nut) on the threaded portion of the stub, the end of the axle is below the surface of the nut? How does it look with everything assembled in-situ? The reason I ask is that when installed "as used" the nut will not thread on as far as you have in your pics and you will have even less thread engagement. I'm not really worried that you'll have enough threads, but I am a little concerned that there won't be any place to put your anti-vibration peen. In other words... When you put everything together, it's the bearings and spacer tube (distance piece) that establish where that nut will get tight. Not where the washer bottoms out on the splines like you have in your photo. The nut will become tight before it's as far on as you have it in your pics. Another question is how do the new CV adapter flanges attach to the original rectangular flanges? I've never messed with them, so I have no idea. Do you drill holes for bolts, or do you weld them on or what? And lastly. it should be a relatively simple matter of machining the original wheel mounting flange to accommodate some sort of hub-centric ring. I haven't done it, but seems like you could turn down the original center hub to a smaller diameter and fit a special made centering ring over it. Press it on with no welding required? What is the diameter of the original hub ring, and what diameter are you trying to achieve?

-

A couple of SU questions

They fit just fine. Fuel profile is different (no surprise), but mechanically they mount identically.

-

A couple of SU questions

It's a 3-screw round top. 1972 only.

-

A couple of SU questions

Well if you've been working with new ITB's, they probably have ball bearings and viton vacuum seals on the shafts. They probably are a lot smoother and tighter than the old SU stuff. If you aren't worn through the chrome, then I'd assume you're fine. As for the needles, my notes say that the N-54's were the factory needle for the 72 year. Manual trans I believe. They should be OK for what you're doing. My assumption is over the years, they leaned things out a little bit for emissions. So the 72 needles are a little leaner than the previous years. I've got a pair of brand new aftermarket "N-54s" here that are complete trash. The profile is so far off that it's not suitable for any Z. I think it was a screw-up by the company that sold the rebuild kit (or their supplier). The numbers for yours look much better than what I have here.

-

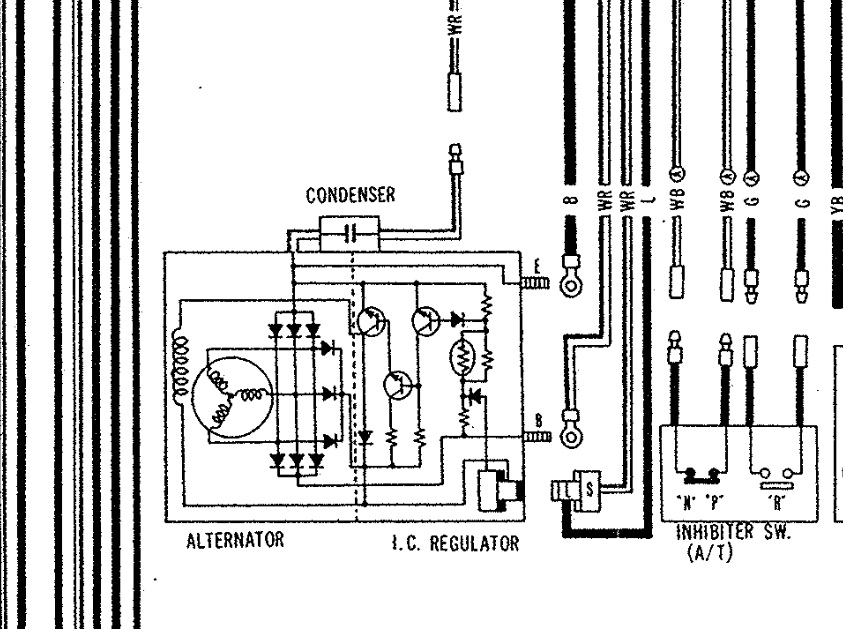

Alternator overcharging

I meant stick a short piece of wire between the two shorting them together. They are already supposed to be connected hard together inside the wiring harness. One of the working theories is that connection inside the harness has become questionable. If you're not comfortable just trusting some guy on the internet who says "Naaah. It'll be fine. Just short that junk together." I totally get it. Next time the problem comes up, just start by taking the voltage measurements from each of those wires to the alternator case. We'll go from there. Actually, the first thing you should do the next time the problem starts is to wiggle that "T" connector around on the back of the alternator and see if wiggling does anything. Then take the two voltage readings of the two W/R to case.

-

Alternator overcharging

Thanks for the post haircut pic. Much better. So as for the test... Yes, the "T" connector is involved. When the problem is occurring and the alternator voltage is too high, try sticking a wire in the back of the "T" connector at the W/R wire and connect the other end of that wire to the other W/R at the BATT connection. Here's a pic of the back of my alternator. Jumepr the two W/R red wires together like this:

-

A couple of SU questions

I'm pretty much positive the needles that come in the generic rebuild kits are the wrong profile. According to some of the documentation, they claim to be suitable for the 72 carbs, but I think that's incorrect as well. The needles that are supposed to be in the 4-screw SU's are N-27's. I can see the "N" in one of your pics, but can't read the rest of it. Can you read it? Many people change over to "SM" needles, but I'm not a fan. If you want original profile needles and can't find them commercially, let me know. As for sealing up the shafts, yes... One side is pretty simple. Just cap over the whole thing. Other side where the linkage connects is a little more complicated, but putting an O-ring in there would certainly help. How sloppy are they? Is the shaft worn through the chrome plating into the brass?

-

Heater Core Alternative - Escort Core into 260/280

Great work on the heater core stuff. Excellent camera work. I like the AN bulkhead feedhrough.

- 75 280Z Front Suspension Work, Brake Upgrade and 15x7" Konig Rewinds

-

Alternator overcharging

Oh, and it looks like your PO was into the harness. Always suspect when that happens. The W/R that goes into the twp position connector... What direction does that wire head? Does it turn the curve and head into the harness? Can't tell on the pic because the tape flap is in the way.

-

Alternator overcharging

Good. Those colors match the 78 wiring diagram I'm working from. That page EE-15 from the 78 manual is all kinds of messed up. Bottom line is you should have the same voltage on both the W/R wires at all times. So if you're taking voltage readings, it would be good to get one with the car off, and another one when the problem is occurring. One lead to the alternator body, and other lead to the W/R wires. And the idea that Zedhead suggested would be a good test... When the problem is occurring, if you jumper between the two W/R wires, does the problem go away? You don't have to run a fresh wire all the way from the battery to run the test, just run a wire between the two W/R right on the back of the alternator and see what happens.

-

Show is vendor "THE UNOBTAINIUM"

I agree. There are no mis-statements anywhere, but kinda deception through omission. There were a couple feedbacks that highlighted that situation. Some people were surprised and disappointed that the parts they got were 3-D printed. The seller is very responsive to problems and does his best to make it right, but I think some of those misunderstandings could have been prevented at the get-go if it was more clear what the parts are.

-

Show is vendor "THE UNOBTAINIUM"

Yeah, I'm no ebay jockey and was wondering about that. So it sounds like ebay asks you if the part is new or not and as soon as you say your part is "new", they fill all that in for you. I did browse through some of the feedback and it's clear that the guy is credible and trying to make things work. I just think it should be called out specifically somewhere that the parts are 3D printed repros.

-

A couple of SU questions

I doubt the needles in the replacement kit were the correct profile.

-

Alternator overcharging

Uh-Oh. Now I'm worried that we're getting caught up with potential mistakes in the documentation and discrepancies in wire colors. When I was saying there are two W/R going to the back of the alternator, I was operating from this: And that's clearly different than the pic from the 78 manual posted above. So @chaseincats, what color wires do you have going to the two position spade connector on the back of your alternator? Here's a pic showing the connection layout:

-

Alternator overcharging

I would think the highest amount of info would come from two readings... 1) With the engine off, and 2) While the problem is occurring and the engine is running. And just to be able to keep the analysis simple... I'd measure it to the alternator body (ground on the body itself).

-

Show is vendor "THE UNOBTAINIUM"

My thoughts on the matter are in the form of a complaint... I don't like the condition description of the parts. I find it deceptive. There is no mention that the part is 3D-printed, and in fact, I find it easily misconstrued as an original part. For example: "New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details." Of course it's new. Of course it's in it's original packaging (because since he made it, "original packaging" would be whatever packaging this guy puts it in). And of course it's the same as what's found in a retail store unless it isn't. Maybe it's just me, but I find it deceptive. I think the condition should be "New aftermarket 3D printed reproduction part.".

-

A couple of SU questions

First Q - Depends on your definition of "needed". I've seen junk in those filters, so I consider them cheap insurance as a "last chance" filter. Would catch anything that comes off the inside of your fuel pump or the rubber hoses between the main filter and the bowl. As mentioned above, they are still available (for the round tops) and they're not that expensive. I'd run 'em. Second Q - No. And I doubt the real issue is the bushing. I bet the problem is more the shaft than the bushing. Once you wear through the hard chrome into the soft brass underbelly, it wears pretty easily. You comfortable with precision stuff on your lathe yet? Third Q - My (non-expert) method is to use a thin layer of rubber sheet (1 mm thick rubber gasket sheeting) on the jaws of your bench vice. The rubber provides a little stickier surface to grip the needle along with some cushion and compliance to spread the force. Grip up high, slight twist and pull. Don't chew your needles up with pliers.

-

1977 280z Dash Harness Connectors

Yeah, I probably should have prefaced my post with "In my limited, ancient experience...." Haha! So hope the parts work out and whether they are good enough or not, I find the fact that the people here are willing to jump up and try to help out by making parts i fantastic. One of the reasons this is the best forum!

-

FS5W71B Transmission Failure. How and Why

Exactly. That will take care of it. Failures like this are really intriguing. When the "impossible" happens. I will have to look at the gear train and flow of power, but I wouldn't have thought that portion of the gear train was even under stress when that failure happened. He was in 1st gear, right? And the wheels locked up and skidded to a stop after the "bang"?

-

Replacing All Large Opening Seals & Hatch Small Seals

Starting in 77 they included a groove along the top of the stainless window trim to accept a piece of rubber stripping. I don't have any pics handy, but can snap one if you want to see it. Just another reason that the 77s are better.