Everything posted by Captain Obvious

-

Resurrecting my horn (the sans Viagra thread)

I'm really confused... You said "I love this method of de-rusting: gets into all the places I can’t with a brush!" But then you found all that rust inside!! I though it got into all the places??? Sorry, but I'm lost.

-

FPR project - cheaper, more available (for a while anyway)

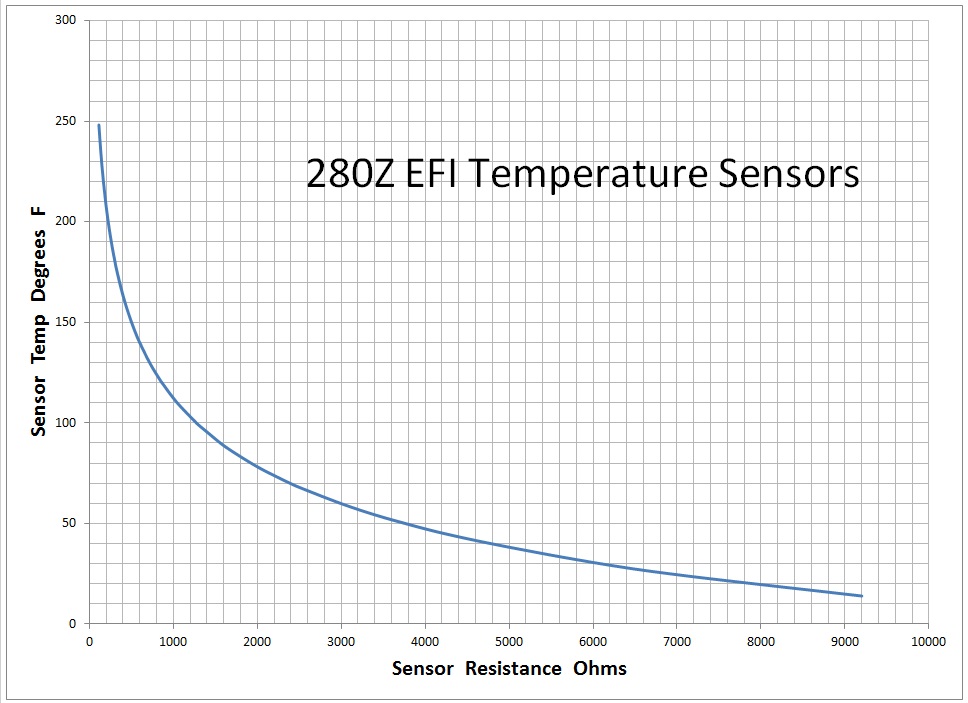

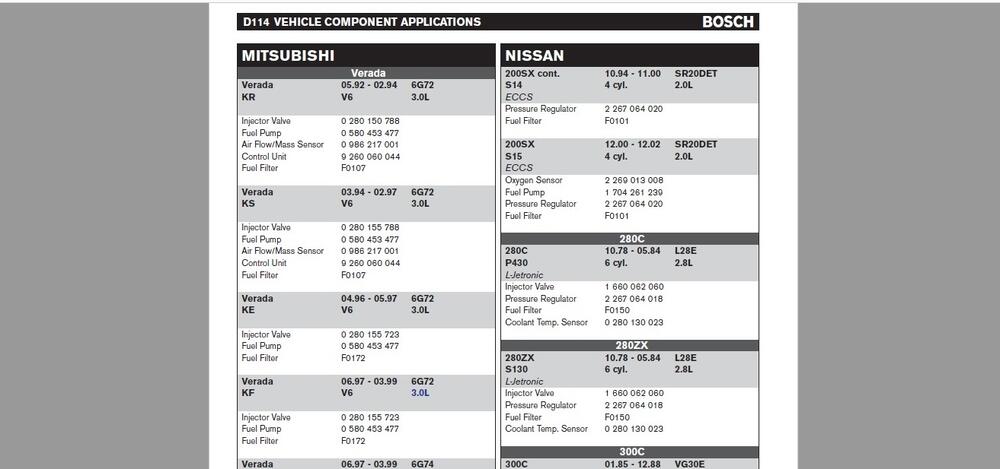

Here's an excerpt from an old Bosch catalog that indicates that the 280ZX (which is the same as the 280Z) uses the 0 280 130 023: And here's a chart I derived from the resistance points found in the Z service manuals:

-

Window crank extension available?

I took a quick look at a window regulator yesterday and making a whole new part to replace the original shaft would be a large undertaking. Not only would you have to deal with the gear on the other end of the device, but the whole thing is riveted together originally and you would have to figure out a way to put it back together. I think there is enough length there to cut off the original and put in an extendo collar. The other things to look into would be "Is there enough room in the system to allow for the increase in diameter an extendo collar would cause?" In other words... Is there enough room to increase that diameter or will it hit the door frame or door panel or something? If there is clearance, I would try an extendo tube device of some sort. Make it a precision fit onto the old shaft diameter and use setscrews to hold it in place?

-

Camshaft Oil Spray Bar Redesign and Rebuild

Haha! Nice fountain! You could do the same test again with the head installed but without the spray bar. See how much oil comes out sideways from the cam towers where the bar attaches. Should be a substantial amount just like your fountain.

-

Camshaft Oil Spray Bar Redesign and Rebuild

And as for the mechanical gauge, I think you could put a couple wraps of teflon tape around the 1/8th-27NPT gauge and be OK enough for a test. It might seep a little at the joint, but not enough to affect the pressure reading. Just don't crank it down so much that you deform any metal on the threads. I would test fit one of your gauges and see if you get a couple good turns on the gauge before it starts to tighten up. If you get a couple turns, I think it will be fine for a temporary test.

-

Camshaft Oil Spray Bar Redesign and Rebuild

I don't remember the difference offhand, but here's a pic showing the difference between the regular and the high flow:

-

Window crank extension available?

Yes, because of the very small extension amount you're looking to achieve, it's inherently impossible to do that with an extension. The problem is the splined portion of the extendo one and the splined portion of the original shaft must share the same space, and that is impossible. So you're looking at a different solution. I'm not real keen on making a whole new shaft. I don't remember what is on the other end, but it might not be simple. I think I would try to "extending the existing shaft." Is there enough room to put in a short coupling collar? Or if not, a short piece of rod stock and weld the three parts back together. Or cut the original splined portion off completely and then make a new splined piece (like what you've already made) and slip it over the (now blunt) stub of the original shaft? Wouldn't stick out as far because you've cut some length off. Something like that.

-

Camshaft Oil Spray Bar Redesign and Rebuild

Yeah, I wouldn't open up those oil restricter orifices at all. If everything is working as intended, there should be plenty of oil delivered to the cam lobes. Did you put a mechanical oil pressure gauge in the block and see what kind of oil pressure you're getting?

-

75 280Z Clock Repair?

You got to be a little more enthusiastic with the success. You're hiding that little note under all the pics! How about this: "Woo Hoo!!! MY CLOCK WORKS!!!" That's what I would do.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

You need something else to be aware of? That sender unit threads into a passageway inside the block. That passageway is not very deep and you run the risk that something you tap into the broken off stud bottoms out on the far side of that passageway. In other words... If you try to use an extractor in the hole in the middle, it's going to need to be sized carefully so that you don't bottom out the tip of the extractor inside the block before the teeth of said extractor bite in. I know... You really needed just one more complication in this whole ordeal.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

The consensus, based on the comments above, is that the stub of material remaining in the block will come out easily if you could just get a hold of it, either on the inside or the outside. I, however, disagree with that consensus. That things is tapered threads and it's in there tight enough to snap itself off when you twisted the oil pressure sensor with a pair of vice-grips. It's not gonna come out without a fight. That thing was threaded in there tight enough to seal the pipe threads and snap off the sender unit. I don't think it's going to turn easy. It's certainly worth a try to use an extractor into the center hole, but I'm not confident that will work. Just don't snap off the extractor inside the remaining stub. Unfortunate.

-

Triple Webers setup

To simply get the engine to run, the absolute positioning of the distributor driveshaft really doesn't matter. All you need to do is assure that the timing is correct. I would pull the plugs, put a timing light on it, and use the starter to spin the engine over. It should spin fast enough just like that to get a good reading off the timing light. If the ignition timing is correct, it doesn't really matter if the distributor shaft is a tooth off or not. You have accounted for it with the rotation of the distributor body. Of course, since it's been almost a day since you were looking into this, I assume you've already solved this issue, put new brakes on the rear, and powder coated the front control arms.

-

75 280Z Clock Repair?

Actually the way you measured the zener voltage, you are almost spot on. You are at 4.94 V across the zener. So it won't start by itself, but what does it do if you give it a push start? Will it stay running, or does it come back to a stop? And if it does come to a stop (which I assume it will), does it stop in about the same amount of time as if there's no power applied at all? In other words.... Does it take longer to come to a stop when you give it a push with the power applied, or does it stop in the same amount of time whether there is power applied or not? Nice photography. But I'm thinking we shouldn't be surprised.

-

75 280Z Clock Repair?

Cool. With your stash, you're already well on your way! So is that tantalum cap polarized? I don't see a polarity marking on it, but the tantalum caps I've worked with were. And if it is polarized, make sure you get the polarization correct. Tantalum caps really don't like to see reverse polarity, especially at temperature. I'm wondering (thinking?) that might be a ceramic cap and not tantalum. And who doesn't have a bag of 5.1V Zeners laying around?

-

Window crank extension available?

Bummer. So going back to the beginning... Why won't the available aftermarket adapters fit? Number of splines wrong? What? Did you ever purchase any of those aftermarket adapters?

-

75 280Z Clock Repair?

Sounds like a plan. Root problem might not be one of the caps, but it's certainly a good place to start without really digging into it. If that doesn't take care of it, we can go from there.

-

75 280Z Clock Repair?

Well we could work into this in a couple of ways. First option would be to start by shotgun replacing the electrolytic caps (as DaveWM mentioned) and see what happens. Electrolytic caps are known to not last forever. They contain chemicals inside that eventually dry out, or leak out, or sometimes they fail short. In any event, they're a known source of long term issues and may or may not be what's causing the problem with your clock. So I'm certainly not poo-pooing the shotgun approach in this case, it's a valid approach. If that shotgun approach isn't doing it for you, we can get into some specific measurements you can take that might help narrow down the problem. And speaking of which....... When you say you have continuity across the circuit, where are you taking that measurement? If you're taking that measurement across the blue and black wires, then there's a problem. You should not be seeing significant "continuity" across those two wires. So talk some more about that.

-

75 280Z Clock Repair?

I've been inside that clock version in the past (surprised? ). Not an expert, but might be able to help. What's yours doing or not doing? Completely stone dead?

-

Changing an Amp gauge for a Volt gauge

And about your fuel lamp, yes... In 75 that lamp was located in the small square location below the radio. In later years, they moved it up to above the center vent outlets in the HVAC panel, but your car (especially since it's a California spec) has those locations above the HVAC populated with other items. And honestly, it probably doesn't work anymore. Your thermistor in your gas tank probably burned open years ago.

-

Changing an Amp gauge for a Volt gauge

Best way I could describe the connector mating: 1) Hold your two hands out in front of you, palms facing up. 2) Then bring your two palms together. That's how the connectors on the wiring diagrams mate. And as for which side is which... In general, things are laid out on the wiring diagrams like they are laid out in the car. So for the Cn connectors the half on the left is the engine bay side, and the half on the right is the passenger compartment side. Does any of that help at all? As an additional aid on this C-2, the "X" is an unused cavity in the connector shell. That should help show how the two sides go together "mirror like". For example, the G/L on the far left connects to the G/L on the far right. While the "X" on the left connects to the "X" on the right side.

-

Changing an Amp gauge for a Volt gauge

Actually, taking a closer look at your pics, it looks like the white two position connector includes a red/GREEN, not red/blue. And if that's the case, then the wiring diagram indicates it was for the fog lamp switch. Optional for other countries, I think.

-

Changing an Amp gauge for a Volt gauge

Yup, that color pair of red/blue and green/white are used pretty much universally throughout the dash and console as illumination lamp power. The red/blue becomes hot when the headlight switch is turned to the first position, and the green/white is pulled to ground through the brightness control knob pot. The wires you found there could be for the A/T gear lever position illumination and/or for the ash try illumination bulb. Don't remember offhand if they had that yet in 75. In any event, they are dash/console illumination.

-

Changing an Amp gauge for a Volt gauge

If everything else is accounted for, then I would also assume that 6-position connector is for the radio. There are five wires leading to the original radio: The red/blue and green/white are for the illumination lamp inside the radio. The white and white/black go to the speaker, and The blue wire is hot when in ACC and ON. Note that power wire goes dead during cranking, so when your voltmeter shuts off while you are running the starter, that's why. Also note that same blue wire also supplies power to the rear defogger switch and the antenna switch. So you could verify you've got the right connection by confirming that it's tied to those other two items. And....... One last thing to talk about. You mentioned earlier about a wide band? That meter system may draw significant power (because of the sensor heater?) and you might not want to pull power for that meter off the same place you put your voltmeter unless you are sure you've got a rock solid clean connection all the way back to the source. I'm thinking the current draw for the sensor may affect the voltage reading. Your voltmeter draw will be negligible, but your wide band may not be.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Oh... And maybe slow down a little. Focus on one thing at a time. Pick one problem and get that item working and then move on to the next one. It's easy to become overwhelmed and then overwhelm your help.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

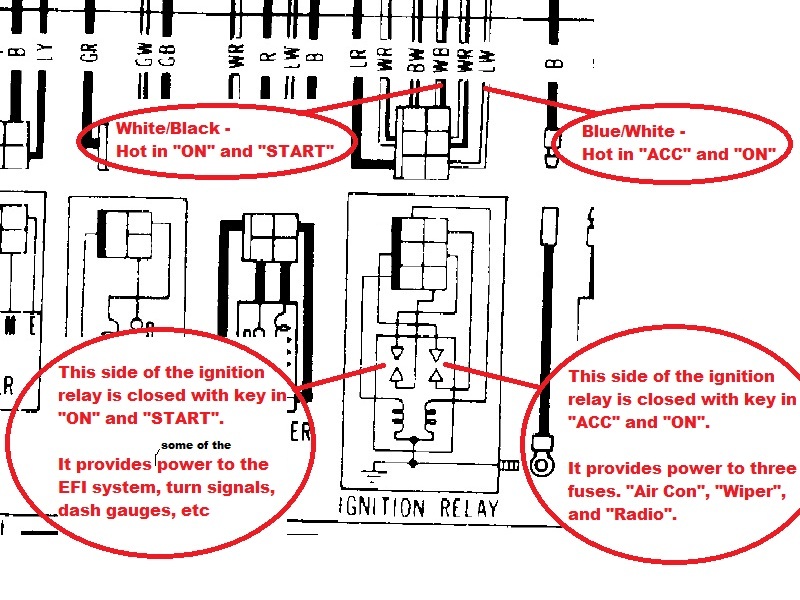

Here's a sketch I whipped up a while ago showing the functions of the ignition relay. Might help augment what SteveJ already posted.