Everything posted by Captain Obvious

-

Vapor Tank Question

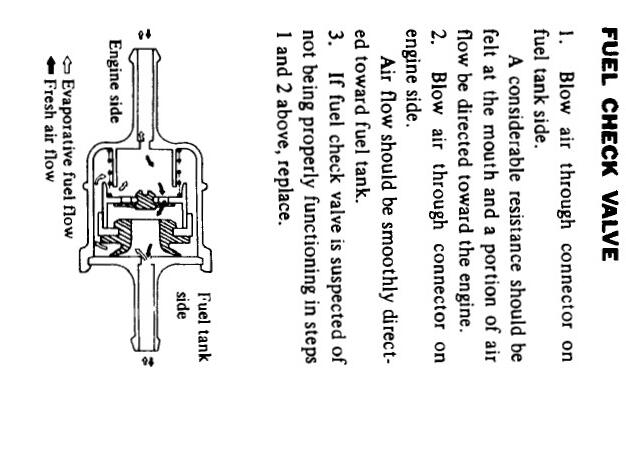

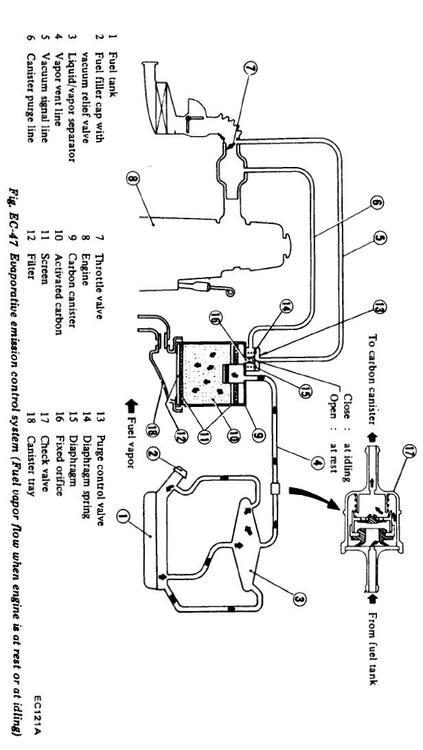

The "check valve" isn't a traditional check valve. The way it operates is that it passes flow both directions (unlike a "real" check valve), but the trick is that it passes flow much EASIER in one direction than the other. Here's some pics that help explain operation and location: Not sure why my pics are showing up sideways, but that's what I got.

-

A couple of SU questions

Haha! I'll get right on that!

-

A couple of SU questions

@grannyknot I added a step in the alignment procedure above. You should test to make sure the nozzle didn't squirm around as you tightened the lock nut.

-

Wiring harness A-pillar buzzing?

The fresh air openings for the 77 and 78 bodies is under the cowl area. Previous years they piped air through the frame rails behind the headlights, but with the extensive metal redesign in 77 they moved the intake holes to under the cowl panel. Couple years ago I had my cowl panel off to work on my windshield wiper assemblies, and while it was off, I stuck my camera down there and took a couple pics. This should explain things:

-

A few parts I haven't found a home for

The large washer looks like a generic electrical box knockout reducer bushing. Any chance you got some home electrical parts mixed in? The other washer with the four holes in it... It's so unique it should be an easy ID, but I'm not getting it. And except for the fact there are no captive washers on those bolts, they could go anywhere. The fact that they don't have any captive washers (lock or flat) makes them a little unusual. I don't think they are for carb bowl drains. Head is too thick, and I don't think you're working on that year anyway.

-

Wiring harness A-pillar buzzing?

Haha! He needs to roll the windows up when he parks that thing!

-

A few parts I haven't found a home for

Haha! I did the same thing. I just took a look for pics and all the good pics of the undersides have that stopper removed already. Here's the best I have. Pic is intended to show side detail, but you can see the stopper underneath: And this one is intended to show detail of the nozzle, but you can see that limit stopper in the background:

-

A few parts I haven't found a home for

I believe those two disk parts are limit stops for the carb nozzle adjustment knob. Thread a nut onto them first and then thread that pair into the underside of the round tops after the nozzle has been installed? Prevents the accidental complete unscrewing of the adjustment knob. I think I have pics around here somewhere.

-

A couple of SU questions

Most of the methods I've seen tossed about can get the nozzle "close", but aren't great. It's really difficult to discern when the needle is rubbing against the nozzle. I made a special tool (surprised?) to re-establish the alignment nub positioning on the 3-screw roundtops as well as the flat-tops, but it also works great for nozzle positioning on the 4-screw round tops. That said, since you have a lathe, I think you could get close enough with something simpler. Make yourself a short "alignment needle". Should really have a picture, but I'll try to use just words: Chuck up a piece of 4mm dia (or larger) brass in your lathe and turn a 20mm length down to .125" diameter. Make it so it just barely fits into the suction piston hole like the needle does. Close tolerance fit, but not a press fit. Then continue to turn down a 10mm length down to .100" so it just barely fits into the nozzle hole. Make sure you do both of those operations without taking the piece out of the chuck. That will ensure that the two different diameters are concentric. Then.... cut it off and debur any kicked up areas if necessary. You should have a 20mm long piece of brass that is .125" at one end and .100" at the other end. This is your stubby alignment needle. Install the alignment needle into the suction piston. Loosen (really loose) the nozzle alignment nut. Put the suction piston (with alignment stub installed) into the carb body making sure the stub goes correctly into the nozzle hole. Install the round top cover and tighten the screws. Tighten the nozzle nut. The nozzle should now be aligned with the center of the suction piston, but you can verify the alignment by lifting the suction piston and letting it back down gently. If the needle is properly aligned, it will re-enter the hole in the nozzle smoothly without catching on the side of the hole. If the stub needle doesn't enter smoothly, it's because the nozzle position shifted a little bit when you tightened the lock nut. Repeat the loosening and re-tightening of the nozzle lock nut as necessary until the stub needle enters the hole properly without catching on the side of the hole. * Take the cover off and pull out the piston. Remove the alignment stub and install the real needle in it's place. When you put everything back together, the nozzle should be aligned with the center of the suction piston. Does that make sense? * And this is one of the reasons the typical methods of aligning the nozzle using a normal needle fails. The tapered lead in of the normal needle will always enter the hole even if the nozzle is misaligned. It may rub against the needle near the hilt, but you may never notice a small amount of interference.

-

Z's on BAT and other places collection

Haha!! No, not yet. But that doesn't necessarily keep me from doing something stupid, would it?

-

Am I looking at a monster vacuum leak here?

I made two. One for proof of concept, and a second one since the first turned out so well. Short story... I've got one available for sale if you're interested.

-

Am I looking at a monster vacuum leak here?

Those plugs cover over a passageway between the EGR passageway and into the individual runners. That "sand" you poured out is probably just years of decomposed aluminum and combustion byproducts and debris. If you removed one of the threaded plugs, you "should" see the hole up into the cylinder runner. And again, if you don't it's because it's all plugged with crap. It's there. How do I know all this? Because I did an EGR delete on a ZX intake manifold. It was not a simple job. Went like this: Step one was getting the plugs out. First one came out with no significant drama. Kinda like yours. Lulled me into a false sense of security. Just like yours. Next couple required torch heat and an impact to get them out: Next couple stripped out the hex (just like yours) and required emergency measures: But if you manage to get all the plugs out, you should be able to look down inside the holes and see the passageway into the runners. Here's an example. Note that I've labeled the hole as 8mm, but be aware that they changed that later in the run and made the holes further from the EGR larger, presumably to even out the amount of recirculated gasses between the cylinders: I drilled and tapped the holes and loctited a blug bolt into each of the holes. Then I sawed off the EGR section, milled it flat, and made a block off plate: Quite a bit of work, but turned out great, and since the sealing into the runners is done with bolts, that plate doesn't even really need to seal.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

Yeah, I wouldn't have even suggested it since it's such overkill (and not "small and simple"), but it's just so cheap. So I'm assuming there are a bunch of different varieties, but the one I had here did one shot with variable pulse width. If yours has that mode, you should be good.

-

75 Datsun 280Z Headlamp Covers

Really? All those pics, and not one obligatory shot with the headlights on? C'mon.

-

I need everyones input on this one (Combo and T/S switches)

Does that female contact say "AMP" on it? That would be a raging clue.

-

Restoration of BringaTrailer 240z - HLS30-35883

That's my read. I'm not sure I understand the concept either, but it seems to work. In ancient times, wheel bearing grease had strands of fabric or fiberglass included in the mix. Made it stringy with the intention of those strands would get caught up in the balls and pull grease into the bearings as they spun. As grease was expelled from the bearings, it would be pulled back in with the tangle of strands. However, newer wheel bearing greases that I've bought (newer being in the last ten years?) do not seem to have those strands included. Seems to be a smooth paste. Couple theories, ideas, possibilities? Maybe the grease melts into a liquid during use (when hot) and flows in and out of the bearing balls with ease? Maybe the grease just stays put where you originally smeared it? I don't really think either of those last two really happen, but just tossing out ideas.

-

Replacing All Large Opening Seals & Hatch Small Seals

Not great pics because it's in the dark garage, but hopefully these will help. If not, let me know and I can take some out in the sun next time. Sorry for the dark. This is the front leading edge. Rear trailing edge trying to show the channel that the weatherstrip fits into. My corner is torn off:

-

Replacing All Large Opening Seals & Hatch Small Seals

I finally had the opportunity to snap a couple pics of my later version window trim (sash?) mounting points. Certainly too late to help much now, but here's what I got. This last shot is a wide headed Phillips screw behind the door panel up at the door lock corner of the panel.

-

Restoration of BringaTrailer 240z - HLS30-35883

I thought I was really smart when I did my wheel bearings and I came up with this elaborate plan to fill the entire housing cavity with grease. Even involved injecting grease with a large syringe: Well after I completely packed the entire cavity with grease and put the whole assembly together, it was really hard to spin the stub axle. Way way too stiff. I had to take it apart again and pull some (most?) of the grease back out. So short story? I would not do that. I would pack the balls of the bearings and put a little extra in there and call it a day. I would not fill up the whole thing. Sounds like a good idea, but it's not.

-

75 280Z - Starter Motor intermittently clicks when restarting after car has been driven for several miles/in town driving

Man how I hate rebuilds. Glad you got it cranking reliably.

-

Tail Light Panel Paint Question

That was one of my most enjoyable and memorable days of my life, my friend!

-

Tail Light Panel Paint Question

Yes I did. I changed on the previous page of this thread, but it's too late for me to go back and edit that old post. Don't know why I didn't fix it back then, but I don't have rights anymore to change it now. And as for the flat top comment, it's simply to point out that I've been known to buck the mainstream consensus on some controversial topics and hence may have questionable judgement. I've heard some even say that I "might not be all there."

-

Restoration of BringaTrailer 240z - HLS30-35883

OK, well then those washers clearly do not go onto the pinion gear to adjust end play. Without having a 240 rack here for analysis, I'm not a lot of help. Hope you figure it out!

-

Restoration of BringaTrailer 240z - HLS30-35883

I've never been inside a 240 rack but I would assume those washers are not for the bronze preload shoe, but are in fact used to adjust the pinion gear end play. On the 280 rack, the spring DOES push directly against the bronze show, and since there is no relative motion between the two in-use, I think that's OK. So without having any of the parts in my hands, I would guess that those washers would go onto the small end of the pinion gear shaft before the pinion gear goes into the housing. I'm thinking that with those washers not installed, you're likely to have a lot of end play "in-and-out" of the housing. And unfortunately you would most easily check and measure that end play with no other parts installed into the housing. If you take the bronze preload shoe out (which is easy) and grab the splined end of the pinion gear shaft, can you feel any play when you push it into and pull it away from the housing? There should be no movement of that splined shaft. I'm not sure you would be able to really check for that end play with the rack installed, but taking the rack back out is a lot more work than just pulling the preload shoe.

-

Tail Light Panel Paint Question

The best paint option I've found is different than what the general consensus uses. Bottom line? Rust-Oleum 261413 Metallic Carbon Mist. Top coat with Krylon Colormax 53530 Flat Clear. Bunch of detail here: https://www.classiczcars.com/forums/topic/67836-rear-tail-light-panels/#comment-645395 I know I'm swimming upstream against the other recommendations for the BFM0360 Ford Dark Shadow Gray, but if you're willing to entertain other options, I recommend the Metallic Carbon Mist. I also like the flat top carbs.