Everything posted by Captain Obvious

-

Rear bushings

Excellent! Did you pickup a cheap hydraulic press? So how does it feel compared to before? Feel better? Also, did you normalize all the rubber bushings with the suspension loaded?

-

What's the Catch? Free Photoshoot for Your Datsun Z, 510, Skyline, GTR, etc

So.... Is that Lorena?

-

PCV Flow Direction - Can I Reverse?

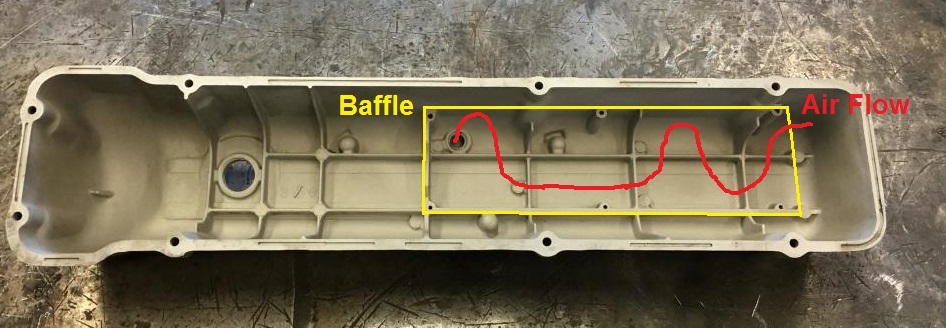

Using your pics, I whipped up a (very) crude sketch of how I think the baffle works. How does this look to you?

- Valve cover breather thread

-

PCV Flow Direction - Can I Reverse?

Excellent! Thanks for the pics!! So with the original baffle, the air travels into (or out of) the rear of the baffle, up and over the two humps in the baffle and finds it's way to the original tube connection about midway in the valve cover. The bumps in the baffle and cast ribs are the labyrinth that is supposed to separate liquid from vapor. And the general consensus is that the original factory baffle does a pretty good job of doing just that?

-

Brian Schou AKA "Olzed"

Sorry to hear about this. RIP.

- Valve cover breather thread

-

Something's wrong, headlight switch controls my fan etc

Or both!!

-

FI Connector Electrical

bjreed1119, Dave is correct in that there are no permanent magnets involved, just a steel plunger that is pulled by the electromagnetic coil. With that in mind, the polarity doesn't matter. Only thing that I might wonder academically about is that there may be some small amount of residual magnetism retained in the injectors after being used in one direction for some time. Not sure how much of an effect that might have, or how long it might last until the fields have been readjusted. When I redid my harness, I found most (but not all) of the injectors were wired the same polarity. So when I rebuilt things, I wired them all the same, using the predominant polarity. I think I kept four the same and switched the remaining two to match the other four.

-

Something's wrong, headlight switch controls my fan etc

Wow! Damn you're good!!

-

Valve cover breather thread

Thanks!! If you want to, you can put that pic both here and in the thread where I was talking about changing the PCV direction. I'm still thinking about changing the PCV scheme, and that's why I wanted a peek at the baffle design(s). http://www.classiczcars.com/topic/57136-pcv-flow-direction-can-i-reverse/

-

Thinking about installing an BMW M6 engine in my Z

Haha! I don't know if the other owners with those kinds of cars like the association or not. I guess it would depend on the association. On a related note, I went to a show a couple weeks ago and there were maybe thirty DeLoreans there. And almost all had some sort of reference to the Back To The Future movies. Looking very hard, I think I found three of the thirty on which I could find no reference to the movies.

-

ZX alternator upgrade

Cool! So it was just a bum rebuilt alternator? Man how I hate rebuilds...

- Valve cover breather thread

-

16 Year Olds RB25 240z

Welcome to the club, but wow....... That thing has been hacked, jacked, and molested!! You either better be really really good with electrical troubleshooting yourself, or you better find someone else who is. I suspect that thing is going to take a lot of effort to get into a running safe state of reliability. I think you should be happy that it wouldn't start. I'd be worried about simply connecting the battery up without something catching fire. Buy a decent meter and learn how to use it!! And you're going to love the car once you get stuff sorted out!

-

Thinking about installing an BMW M6 engine in my Z

I'm thinking Pursuit Interceptor:

-

BBQ

I am so hungry right now!!!

-

Heater Core Alternative - Escort Core into 260/280

I don't think you would be able to convince anyone that what I did was a Datsun factory-recommended replacement. Sounds like you either need to find the "correct" drop in parts, or find a shop that's interested in doing custom work. My old stock fitting heater core leaked a little, but I'm sure it's easily fixable by someone trained in the art. Would that help you out at all?

-

Proper Wiper Blade and Arm Color?

Yup. That's what my blade holders look like. Thanks for the pic. I gave my arms a good lookover and found small residue areas of black paint on the underside in the corners. So my suspicion is that they used to be black, and somewhere sometime along the way, that changed. Either it wore off over the years, or my PO bead blasted it off and missed some small spots on the back. In any event, the mystery is over, and my arms "should" be black. Thanks again everyone for the input!

-

Proper Wiper Blade and Arm Color?

That was what I was figuring. I could either paint my arms black, or I could strip my blade holders to silver. It's not like my car is a purist stock 77 to the year. It's already got lots of things that aren't quite year correct. Wrong color wipers wouldn't be the worst of it. Would certainly look better if they were all just the same color whichever color that may be!

-

New member here from the island of Guam.

Oh, and welcome aboard!! Beautiful set of cars you've got there!

-

New member here from the island of Guam.

I think that final generation of RX-7's are one of the most beautiful looking cars ever produced. I would probably own one if it weren't for the unusual rotary underpinnings. I just don't want the hassle. Too bad it wasn't available with an aluminum block V-8.

-

Proper Wiper Blade and Arm Color?

Thanks guys! So for 77, everything should be black, but prior to that, everything should be silver. For me moving forward, it sounds like it really doesn't matter which color I go with, as long as everything is the same color. Makes me wonder why I've got a mix-match... Either my PO put earlier arms on, or the black finish came off over the years. I'll take a pic or two of what I've got as soon as I've got a stable picture host set-up.

-

Proper Wiper Blade and Arm Color?

The wiper arms on my 77 are unpainted silver (stainless?), but the blade holders are black. I believe the blade holders are original (the two metal bar torsion spring style). They are metal, but painted or anodized black. Anyone know what the 77 wiper arms and blade holders should look like? Should everything be black? Should everything be silver? Or is correct to have silver arms and black blade holders?

-

Photobucket Rant - They SUCK

Derek, I feel your pain. Here's to hoping PB changes their mind and re-allows 3rd party posting. Not likely, but I guess it could happen!