Patcon

Subscriber

Subscriber

-

Joined

-

Last visited

-

Currently

Viewing Topic: Is anyone there?

Everything posted by Patcon

-

Zx 5 speed rebuild

Perfect Chas! Yes the scribbles are very helpful 🙂

-

Zx 5 speed rebuild

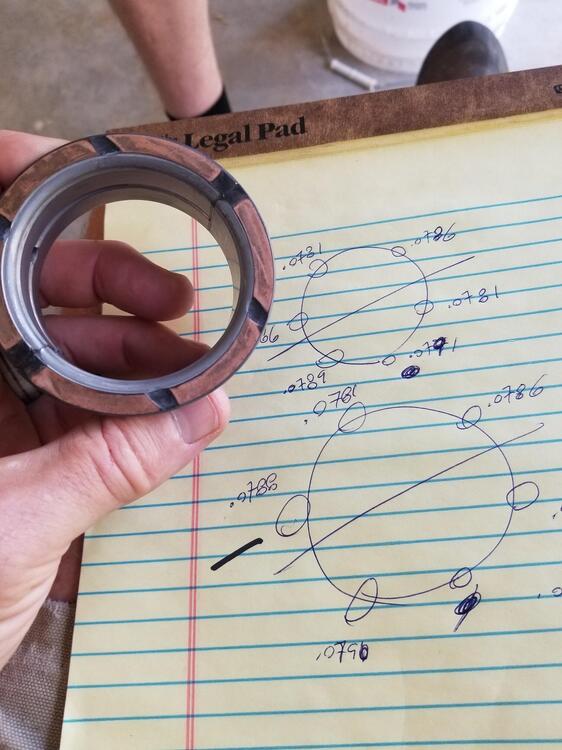

So I ordered some brass shim stock from amazon (0.001,2,3,5 & 0.010") We used the 0.010" sheet. The really thin stuff is like tin foil thin. Traced the outside of the needle bearing for OD and used a socket that was about the right ID Various methods to cut the ID. Little die grinder, a dremel tool, etc. I eventually got a hole that worked Then I cut the OD with scissors. All torqued back down and just inside the low spec number. Waiting on a new oil gutter and a new front case seal to check that and then hopefully we will be all good

-

My Detailer Buffed Through My Paint! Has this ever happened to you? What next?

I don't believe you will be able to touch it up if it's single stage paint. I agree you should go to a reputable body shop for advise. If it's BC / CC then a good painter can match it and melt in the clear coat but it's difficult to do it well. I am afraid the detailer may have really done you a major disservice!!

-

Zx 5 speed rebuild

@EuroDat Thanks for that reply. The manual shows a spec on page MT-11 in the 280zx manual for 3rd gear. (0.13 - 0.37 mm) Edit: Although we only have about 0.002" of clearance and it doesn't seem like it would matter because all of those pieces appear to rotate as a unit...

-

Zx 5 speed rebuild

The large bearing at the front input shaft that has the snap ring on it. In post #102 it has space on both sides of it. It has some on the rear side but not enough. There is more on the front side between the bearing and the snap ring. Do we need to pull that bearing forward to move the gap to between the gear and the bearing or will the helical cut gears do it on their own?

-

Oil pressure gauge says no oil pressure.

You will see some leakage from the oil galley but it should be limited

-

Brake Booster Recommendations for 240Z with Wilwood Disc Brakes

Unless I am missing something, I would expect the vacuum to go down when touching the brakes. That's where the boost effect comes from... What am I missing?

-

[2022] What Did You Do To/with Your Z Today?

18 years is a long time to sit in the grass...

-

Zx 5 speed rebuild

Thanks Chas! That's perfect. Do we need to shift this bearing forward?

-

Is the Zcar Depot dead?

Ernest, Steve makes the parts that are out of stock when you order them. He is a one man show

-

Zx 5 speed rebuild

I don't totally understand the technique for checking the front bearing shim. Can you clarify that for me? Also how do you adjust the rear clearance. You torque the nut to spec but then I don't have enough clearance. Do you then back it off? Are the other locations the proper places to check? Do we need to move the large bearing forward to get the clearance on the backside?

-

Zx 5 speed rebuild

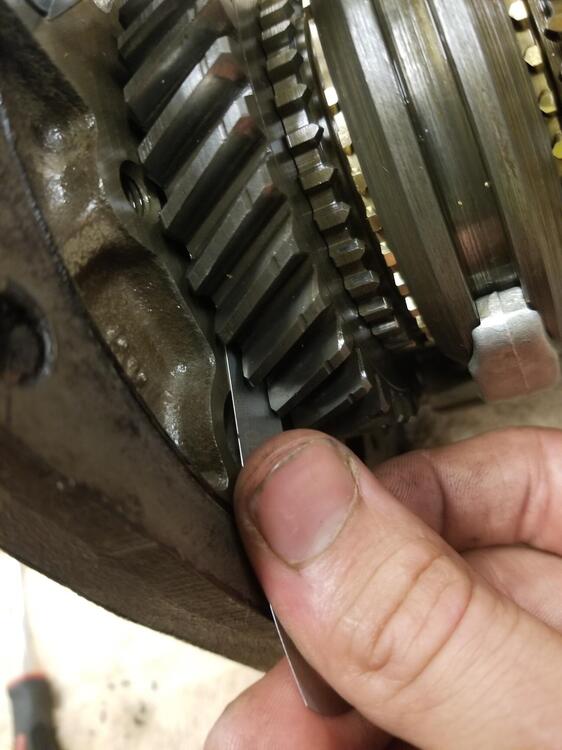

So can somebody confirm that I am checking these in the correct spots? 1st gear 2nd gear 3rd gear We don't have enough clearance on this side of the gear but there is extra on the front side between the bearing and clip Reverse 5th gear We do not have enough clearance at this location. We only have 0.0025" versus min .0122"

-

Zx 5 speed rebuild

So the countershaft front bearing shim, If I don't do this test (MT-7 to 8), what is the downside risk? I believe we reused the existing shim that was in the transmission

- Cody's Goon

-

My parts hauler

Looks great! Paint makes such a difference!

-

Strange intake noise?

Take a legth of hose and use it like a stethoscope, move it around and see if you can pin point the noise. You may here it good at the intake opening but see if you can here it somewhere else. Like around the manifold or injectors

-

Cody's Goon

Is there something in the tach that would reduce the current by 90%? Too much resistance on the loop or a bad component on the board?

-

Cody's Goon

Also, were you splitting current between two tachs or just the 510?

-

Cody's Goon

Does the 240 current sensing tach only have one loop out the back of the tach? Edit: It does so that is not the issue. I was wondering if a loop had been removed because of the hacked wiring, but that's not the case. I sent an email off to Hamp's

-

Cody's Goon

I thought a shop like that might be the next logical step. Our guest house is empty again, so we're gonna get that cleaned up. Maybe you and SWMBO could come up for a visit when we get to that point...

-

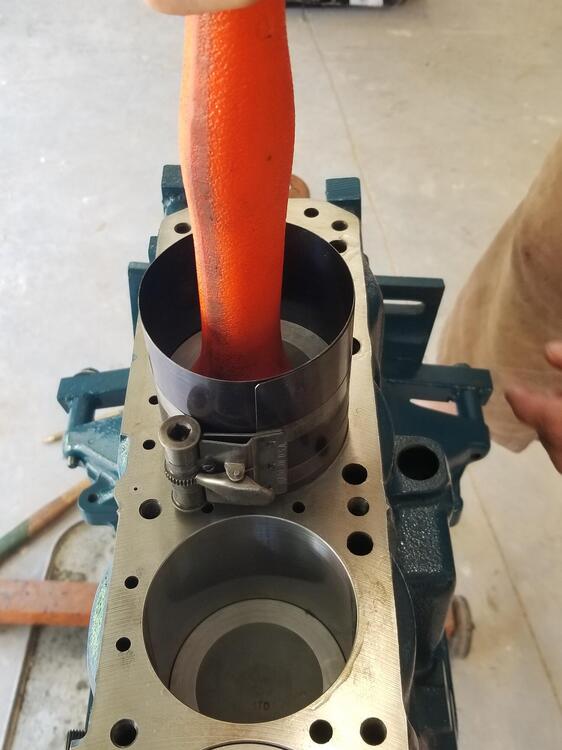

L20b Cody's Goon

So we worked on the motor some more today. We started by checking end play float. We could force 2 thousandths of play be we really had more like 1-1 1/2. So we pulled the crank back out and we checked the thrust bearing thicknesses. I logged all of those down. Then we did some calculating and decided we wanted to add 1 1/2 thousands. So we removed half of that from each side of the bearing plus a little. Tom Monroe calls for using 320 grit paper but I used 600 wet. 320 seemed way too course. You need to be able to keep track of which side is which. I made a sharpie mark on one side and the oil hole gives a reference point to work from. Each pad is treated as a measured location. We set the shells against each other and wrapped with a couple of turns of electrical tape. We used the granite counter as a flattening plate but a piece of glass would work good too. I made circular motions when sanding and counted revolutions. I did 10 to the side and then mic'd. Then 10 more. It took about 30 to the side to take off 0.00075". After we reassembled we had 2 thousands that would indicate with no pressure applied. We could force it up near 3 thousands. While we had the crank out we heated the timing gear in the oven and installed it on the crank. Then we put rings on the pistons and installed them. The pistons are 7 thousands proud at TDC. Off my rough calculations we will be about 10.35:1 compression. So we may have to keep the timing down until we upgrade the head and cam. Now we need to get the timing cover cleaned and then work on the rest of it. I couldn't really turn the crank by hand before without the pistons, just the crank. I can now turn the whole assembly, pistons and all by hand. It's tough but doable

- Cody's Goon

-

Cody's Goon

That would have been my thought too. When I tried it on the car a couple of years ago, I couldn't get it to respond at all. I was attempting to run it off a ZX type module dizzy. It is of course possible, I had it wired improperly

-

Zx 5 speed rebuild

@heyitsrama thanks for that. I was thinking of the gear end play. I suspect there is nothing for me to check with the baulk ring to gear clearance because they are all new. Don't know on the front counter shaft

-

Zx 5 speed rebuild

We need to double check the internal clearance in the 5 speed. Can someone clarify exactly where we need to measure?