Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

That was funny!!! Yeah a little body massage just like that It's surprising how much I have gotten used to just moving panels around with my hands

-

Cody's Goon

I had two inductive loop Z tachs. They both measured .04 Amps too! So does that mean that the tach should work or could the circuitry still be bad?

-

1971 HLS30-14938 "Lily" build

Good to see you too Guy. Cody's is still growing hope he doesn't get much above 6'-7" Getting shorter every day. That's funny. I was trying not to fall down

-

1971 HLS30-14938 "Lily" build

Someone PM'd me with this: "Hi Charles: A while back you mentioned that you had, on occasion, resorted to twisting a door as part of your panel alignment strategy. I can see an element of usefulness to this, because it seems like it would permit moving the bottom (or top) of the door inboard or outboard at the rear without disturbing the front edge quite as much. On the other hand, using shims at the hinge-to-post mounting point looks like it would move both the front and the rear edge outboard by the same amount, meaning that the door-to-front fender alignment would be affected. Also, shims will only move the door outboard. Can you tell me a little bit about: Why you decided to try twisting the door. How you did it. How you think it worked (i.e Did the door's box structure twist, or did the front wall of the door distort where the hinges mount?) How much movement you accomplished at the bottom (or top) of the rear of the door. Any cautions that need to be observed?" So this was my reply, it occurred to me it might beneficial to others so I copied it over to here: Why I decided? There are actually body tools available to do this. They fasten into the door latch so you can twist a door. I could get three corners of the door right but never the fourth. How you did it? So I set the front two corners of the door properly. If I need to shim the hinges, I do that. Then you have one of the rear two corners that line up. So If depending on which way you have to twist it you brace your leg against the door and pull with your hands. I am sure if you got too rowdy you could crimp the door somewhere. This door is a 280z door, so it is stouter than the 240z door. The drivers door was 3/8" or more proud of the rocker panel when it was flush at the top. After a couple of tries at twisting, it lines up really nice. I haven't seen any unintended consequences of this technique. I suspect you could twist a door 1/2" or more if necessary but that door would be pretty far out. I tape some shims in what ever location is flush so it makes it easy to repeatedly check when the door lines up on all 4 corners. Does that make sense?

-

Cody's Goon

Never had a tach I might could did up an early 240z tach and check it. We'll see what I get.

-

Cody's Goon

I got like .04 amps when I tried it today. That seems awful low. Does that seem right?

-

Where to go with this rusthole

The real issue with using the compressor for an air supply is compressor oil. The air needs to be filtered and run through an oil remover to make it suitable for breathing. The other thing is the compressor intake needs to be pulling air from a safe area. Not near any exhaust ports or pulling fumes into it. It's the filtration on these systems that make them expensive. I have a fresh air mask but usually use the respirator as it's so much easier and I don't have 2 hoses to keep out of the paint. When I do a big spray I use the fresh air mask. It is much nicer because there is no inhaling effort compared to pulling through a cartridge and the air is cool in the hood so it helps reduce sweating in the booth and dripping in your fresh paint The ones that feed the gun and mask off one line are really nice systems although the air will only be as cool as the compressor supplying it.

-

Where to go with this rusthole

I don't now. It's a good question. Like lead in paint. The lead made it work better but was hazardous, so no more lead.

-

Where to go with this rusthole

Be careful spraying epoxy! Good respirator! You don't want any isocyanate exposure.

-

Just what the Doctor ordered. 1977 280z

Will it come off with lacquer thinner? If it does, it's single stage. If it doesn't it's probably a 2k primer. I wouldn't expect epoxy. What type I don't know, but from my experience it seems to stick pretty good.

-

78 280z Rear ended...need parts

I have concerns about reinforcement around the fuel tank. I just see a piece of steel failing to yield and breaking instead, to end up punching the fuel tank it's meant to protect. I would think reinforcement would have to be very well thought out. I think a more interesting idea would be coming up with a puncture resistant liner like fuel cells have.

-

You got Trump, May, Macron, et al... we have Trudeau

Yes, I would agree with that

-

78 280z Rear ended...need parts

There is very little room between the rear valance and the tank. It would be difficult to make anything substantial enough for reinforcement to the rear and still be able to get the tank in and out.

-

Takata TK-656 seat belt buckle disassembly

I have not. It would be interesting to know how in order to refresh hem. Provided it could be done without compromising them

-

78 280z Rear ended...need parts

I don't think I have what you need but I have found that is a difficult place to put back right. There is a lot of really solid metal right there. My car took a similar shot but less and I have had a hard time making it right. You will want to pull the tank or have the shop do it to have a good shot at getting it back the way it needs to be Look on "Car-part.com" and find yards with the right year cars. Then call them and tell them what you want. I wouldn't search for the rear valance. I would search for rear quarters. If they have good quarters they most likely will have a good rear pan. Might take some leg work but you should be able to find one

-

Z Car store vs motorsport rear disc kit

That's actually not a bad idea. Many people get the cart before the horse when they get the extra horsepower before they get the extra braking. Much wiser to improve the braking then improve the "Go"

-

1971 HLS30-14938 "Lily" build

Thank you from one who would know!

-

Where to go with this rusthole

I think I agree. It's much harder to make a crooked hood straight. If the rust is bad enough I might actually weld in a patch, but you would have to be really careful and keep the heat low.

-

You got Trump, May, Macron, et al... we have Trudeau

Why would any good sane individual run for public office and step up for the abuse of you and your family to run for a job that pays $150k to 400k. There are a lot of easier ways to make money. If you're honest and don't intend to abuse the system there's no money in it! Why would you step up for that and have people accost your wife or kids in public. Drag people up out of your past that may or may not be telling the truth. The system is built to protect itself now. It's a leviathon that wants to be fed. Don't get in the way or you might look like a meal! Rich kids have the connections to keep a lot of this off of themselves. When was the last time you saw a newspaper run a crushing ad on a car dealership. They don't because that is one of their main sources of ad revenue.

-

Cody's Goon

I ordered an oil gutter for the 5 speed. I will have more info when it gets here. We plan to clean the 5 speed, reassemble and run it to see how it does. On another note Cody has decided he hates body work and wants to find a shop to finish his car. That's fine with me because it will free me up and he will pay most of it. It also gets his car finished sooner. We found a guy by talking to a couple of shops and he works out of his own garage at home, but the finished work appears to be good. We'll see... On a related note, I need to source an antenna for his car. The one mounted to the windshield pillar. Does anyone have one? @zKars Even if I have to make it from a couple of different ones. The one on his car now is after market and doesn't use the proper holes. I need to source one before we can get his car in to do paint, so that we don't paint the car and then have to fix extra holes.

-

Where to go with this rusthole

You will be dealing with a great guy, BTW

-

1971 HLS30-14938 "Lily" build

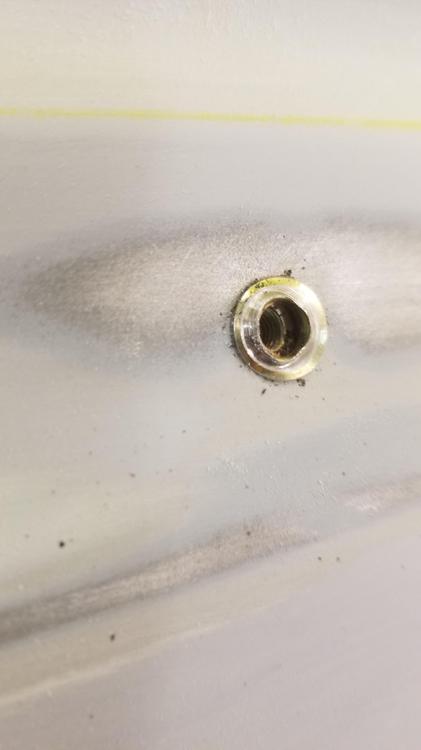

So I did some more blocking tonight. Also worked on getting the new mirrors mounted. I bought a kit with an assortment of metric rivnuts. I also ordered some oval head 5mm SS screws from Ebay. Matched up the rivnut diameter to a step drill and enlarged the holes in the door. Then made an attempt with a self made tool, and the result The nut I had on the bottom was a different diameter and pulled some of the threads up. So I drilled that one out and redid it. I used a small washer with a larger one on top to make it easier to tighten down the 5mm nut. So I ended up with this, by using a ratcheting wrench and a socket You need to apply a good bit of downward force to keep the rivnut from spinning in the door. Once it starts to expand it gets easier. A new door mirror mounted up I like these mirrors. I sourced them off Ebay a number of years ago, but what I like about them is the passenger mirror is a wide view mirror and the drivers side is normal. I haven't seen them again

-

Z31 N/A RB project

I think pictures would be excellent. I would love to learn the how's and why's...

-

Rust Advice 78 280z

Excellent. I don't remember what I ate yesterday...

-

Rust Advice 78 280z

My apologies if we covered this somewhere else, but I don't like to hang the car with all the suspension on it. It nearly doubles the weight of the car and adds a lot more stress on the attachment points. My 2 cents

Subscriber

Subscriber