Everything posted by Zed Head

-

Piston and Rings

There's nothing wrong with putting the name out here, especially if you've done the homework and taken the proper measurements. We need to know who the good and bad suppliers are. The "How To Rebuild..." book )pg. 76) says the skirt should be at least 0.0005" (.013 mm) bigger at the skirt than at the wrist pin area. No upper limit mentioned though. .75 mm (the middle) seems off, about 60 times bigger than minimum. Even your smallest measurement seems big. The question though is what are the ITM specs.? It will be interesting to see what the Silv-O-Lite pistons measure at. What does "did not fit correctly" mean on the HG? Looks like fun.

-

Was running great, but then on the way home it just died

Actually, this is exactly, to the T, how the engine dies when the fuel pump runs dry om a corner because of poor baffling. I should mention that it will also happen on a right hand turn, but it starts sooner (with more fuel in the tank) on the lefties. I have a certain corner that I accelerate through, from a stop light, and it will happen every time if the tank is getting low. Only adding for clarity. The repeatability will tell the story on that possibility.

-

Was running great, but then on the way home it just died

On the pickup tube blockage - I think that engines tend to rev higher as they go lean, like when they're running out of fuel. Especailly if they're running rich beforehand. So that might explain the rev to 3000. The difference between the two potential causes is that the left turn baffle problem is reproducible. So, if you can get the engine to die on a left turn, repeatably, that would lean towards the low fuel/poor baffles theory. If it's random, clogged pickup.

-

Was running great, but then on the way home it just died

It may be that the two things aren't related. SteveJ seems on target. Were you taking a left turn the first time, at a fair pace,with a tank less than 1/3 full? The 280Z's fuel tank baffling is known to be deficient at low fuel levels. The fuel pump runs dry on left hand turns. I've had it happen but it starts right back up once it straightens up. Is your car a manual or automatic? An automatic might just die and not restart. I have a manual transmission so the engine keeps turning when it happens.

-

280Z Difficulty starting

There's a fairly large vacuum hose directly from the intake manifold plenum to the cap of the emission's carbon canister, in the vicinity of the fuel filter. You might check that. I've used the carb cleaner trick. Since it's only a squirt, if there was a spark you'd just get a flash. But you do need to be careful. The other thing about it though is that it will dissolve some paints, and the glue on tapes. It's potent stuff. I wouldn't use it on a good-looking engine. Stater fluid is a potent solvent also but more flashy/vaporous. If you decide to try one, experiment on a known (self-created) leak to see how little it takes so you don't dissolve things by accident. The tiny vacuum bottle hose on the top of the plenum is a good practice spot.

-

Starting Issues (injectors?)

I think that ground wire is an extra ground path. The mounting screws should allow the same path. The plug hangs below the AFM. Gravity might have pulled it loose. First place to check.

- 280Z Difficulty starting

-

280Z Difficulty starting

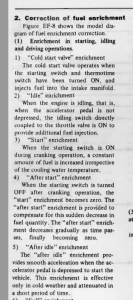

Kind of funny - I misinterpreted the chart again. It actually shows CSV enrichment as separate from Start enrichment. So Start enrichment is probably always there hot or cold, maybe to varying levels depending on temperature. Since the system is designed to be started with the throttle closed, idle switch actuated, I wouldn't be surprised if your idle switch is dirty or maladjusted and part of the problem. Also wouldn't be surprised if ti was fine and not your problem.

-

280Z Difficulty starting

Since you're above CSV activation temperature, but the engine does try to start, you might look at the other enrichments. I've studied the chart and the descriptions and sometimes misinterpret what they're saying, and can't always tell when exactly things happen, but they're still worth a ponder. "Start enrichment" is the CSV contribution I believe. In the past I thought that it might be more time on the injection pulse but probably not. "After start" enrichment is an interesting one. Seems to fit your time frame but it's not clear what parameters put it in to action. Maybe the "idle" switch along with the Start signal? Maybe just the Start signal? Who knows? "Idle enrichment" seems easy enough. If the idle switch is actuated the ECU adds time to the injection pulse for more fuel. So there's two things that might affect behavior right after starting, both connected to the idle switch. Were it my car, I'd check the throttle position valve [TPV (aka TPS)]. They have contacts inside, not well protected from the elements. They get dirty. Maybe you're missing your idle enrichment. Check at the ECU connector first, where the signal gets used. Here's another link to a useful book, which hsows how to check everything at the ECU connector, maybe easier to work through than the FSM. Use the 280Z/ZX Electronic Fuel Injection Guide. Third one down. http://www.xenonzcar.com/s30/otherguides.html

-

Restoring a 1977 280z! (My first z car)

Here's a specific tip -assume that the distributor breaker plate is rusted together. Take the distributor out and take the breaker plate off and examine it before trying to start the engine. It might save you some money if you can refurbish it before you break the plastic ball bearing holder.

-

Restoring a 1977 280z! (My first z car)

Nice find. Good body and a nice paint job. Assume that many small parts will need replacing, like the brake master cylinder (no caps means moisture ingress), and try to save money on the new parts. The nickels and dimes will add up quickly and you'll need to replace more parts than you think. RockAuto.com is a place to spend time on. Here are some links to browse. A lot. http://www.xenonzcar.com/ http://www.nicoclub.com/FSM/280z/

-

Clutch Choices

I would get specs. on the clutches and specs. on the engine and see if anything gets eliminated. Then I'd consider how I plan to use the car. If you'll have big tires and want to break the tires loose, use the strongest clutch. If you'll be tooling around the city, only using roll-on power, consider pedal pressure, for driveablity. Some of the high-perf. clutches have a pretty heavy pedal. Also consider that the puck-type clutches generally chatter if your technique is off and can be a pain to drive. I'm thinking Center Force unless you want to drag-race, and forget both of them if you want a comfortable clutch. Maybe a 240 mm stock setup. The Center Force has a heavy pedal, I think.

-

280Z Difficulty starting

This is good. You're on the right forum and you picked the right car. I've often thought that the 280Z EFI system is an excellent starting point for learning about cars and EFI. Very basic and fundamental, with excellent documentation in the FSM's. If I was an auto shop teacher, I'd use the 280Z as a teaching aid. Looking back, you might be making a bigger deal out of the starting issue than it really is. This technology is primitive, compared to today's cars. The occasional stuttering start is fairly normal, and as I mentioned, could well be a tank of fuel that the system has trouble with. But, if you want to forge ahead - consider the cold start valve (CSV) as CO mentioned in #42. But look at it both ways, working too well and not working well enough. It's function is to squirt a load of extra fuel in to the intake manifold, to give a fast start. Many of us have removed our CSV's because we're okay with an extra second or two of cranking. But there are times when I realize I could use its benefits (cold day after sitting in the garage for a week or two). By the way, Captain Obvious and SteveJ are the two electrical/electronics gurus on the forum (no offense to any unknown gurus,sorry for the pressure Steve and CO). Consider their electrical words most carefully.

-

280Z Difficulty starting

You're kind of at the "think" portion of the typical learning process. Usually starts with Do. Do-think-do-think-do...etc. You have the tools and you're taking measurements but some of them are done using incorrect methods. Working on old EFI can be tough if you haven't had some lessons in basic electrical concepts but it's possible to learn on the job. The two things you're looking at now are voltage and resistance. Voltage is typically measured from a component's electrical contacts to a ground point, which is any metal body or engine part. The battery's negative post is connected to the body and engine, so you're actually measuring the supply of voltage from the battery by this method. Resistance can be measured between any two points and is used to determine either how good the path to the component or to ground is, or to see if a component has the proper resistance for its function (the coil, for example). Sorry to get all teachy, but your methods show some lack. No offense. The more times you run through the do-think cycle the more comfortable you'll be with the troubleshooting process. Even the pros have to stop and think occasionally.

-

280Z Difficulty starting

The FSM says that you should see battery voltage at the coil with the key On. You're seeing zero, although it's not clear how you're measuring. There's a diagram in the FSM. You should measure from coil negative to ground. Actually, coil positive to ground would work also. The around 12 volts while cranking is a good number though. You could evaluate spark strength, and fuel injection. Put some of FastWoman's Christmas tree lights on the injectors for injection evaluation. Also described in the FSM. Make sure they're flashing. And check that the spark produced is thick and blue, not thin and weak. There are many other basic meter measurements you can take, coil resistance, for example. These things are all described in the Engine Fuel chapter, and Engine Electrical chapter, in detail. Just saying, if you want to get ahead of the thread. You might have a weak coil, or a weak pickup coil, or just a loose connection, or a dying ignition module. You'll know what's right, what's wrong, and what's marginal.

- 280Z Difficulty starting

-

280Z Difficulty starting

I also recently had a battery go bad and do the same. It would turn the engine over for a while, not starting, then slowly lose energy. I put a meter on the battery and found that it was dropping to about 9 (if I remember right) during cranking, then 6 before it was done. I think a reasonable reading during cranking is ~11 or better. If you get a low voltage then there are a many things to look at for that problem.

-

280Z Difficulty starting

I'd measure voltage drop at the coil during starting. Both the ECU and the ignition system don't like low voltage. The ECU won't work right, and the ignition system will put out a weak spark. I had a problem with an engine that would only start with starting fluid. The spark was too weak to start the engine, with the voltage drop of the starter motor, but was fine once it started and the ignition system was at full voltage. You've gone full-circle and are repeating things, with the removal of the FPR hose in the video. Electrical is next. It's not as hard as it seems, once you get in and start measuring you'll wonder why you waited so long.

-

280Z Difficulty starting

That's for you, not me. Your wiring is not normal. You should understand what's not normal. One screwed up thing can lead to other screwed up things. It could be that your fuel pump actually loses power at Start, because of some unknown wiring or relay problem, and is starting on the residual pressure from when you primed it. I mentioned also, the possibility of a voltage drop when starting causing a weak spark. This is a real thing, and is why car makers have a specific wire bypassing the ballast resistor and turning off everything unnecessary to starting when the key is turned to Start. Measure voltage at the coil when starting, and with the key on. That's a simple test and is a common test for all cars with starting problems. A bad battery, for example, can drop voltage during starting but run the car just fine once the engine starts. A multimeter will be very useful. Do those relay tests. Something will show up. Take good notes, with real numbers.

- 280Z Difficulty starting

-

280Z Difficulty starting

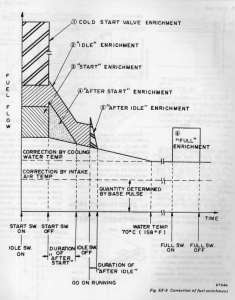

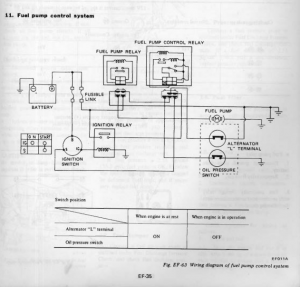

Here's the 1978 fuel pump control scheme. BUT, back to my other point, this scheme does not provide power to the pump by turning the key On/Off as described earlier. In a correct system you should not be able to "prime" the fuel system with the key. So you're studying something that has already been shown to be modified somehow. OR, your oil pressure switch is bad, but this would just give power via two methods, one when the switch is open, and one when the switch is closed. Neither scenario cuts power to the pump. The Start circuit bypasses the control scheme anyway. I see FSM avoidance. It's not as bad as it seems, it's actually very educational and a good read.

-

What's it worth? CLSD diff

Actually, that's not even true. Depends on time-frame. Here's your competition, or what a professional business thinks they're "worth". http://whiteheadperformance.com/product-category/240z-260z-280z-70-78/240z-280z-diff-differential-axles-lsd/

-

I've got no heat.

He's probably looking for the big white bottle. Could be that somebody removed it to "clean up" the engine bay.

-

What's it worth? CLSD diff

Put it on eBay with a really high reserve. "Worth" discussions always spin off in to philosophy and personal opinion. And usually end with everybody dissatisfied.

-

I've got no heat.

Probably. There's a supply hose from the intake manifold over to the big white bottle on the passenger side fender well area. I've had that hose split also. It's a very small port, kind of like the one on the bottom right in site's picture. My 76 has it more to the left of that spot though. With the engine running, pull the hoses from the bottle and see if there's vacuum.